Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing and extruding in one unit and directly affects product quality and production efficiency. Understanding its…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type of equipment can help practitioners select models accurately, improve production efficiency and reduce operational costs.…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key support for numerous production processes. Whether optimizing production workflows, improving product quality, or conducting precise…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for product matching in business expansion. This article will break down the specific types of twin-screw…

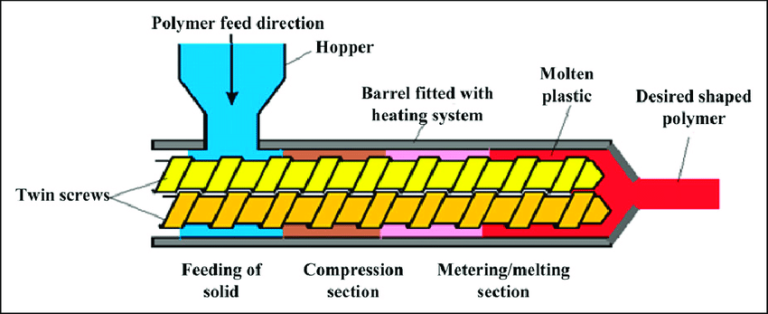

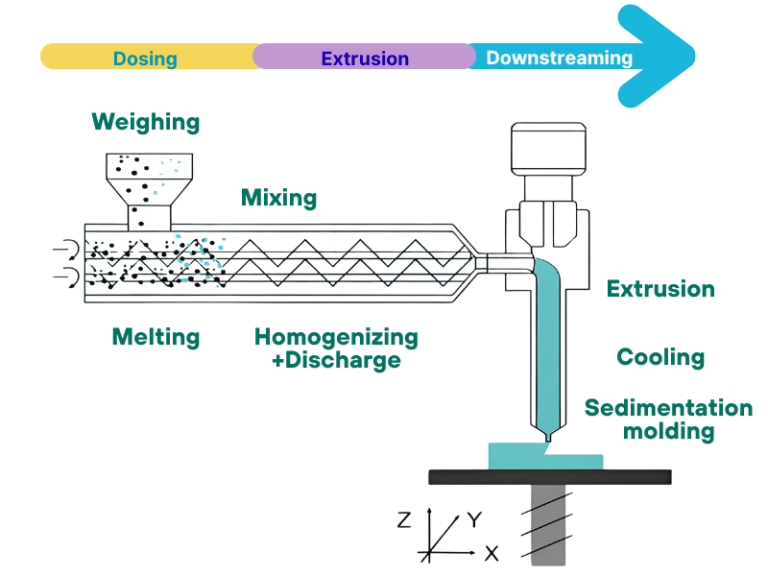

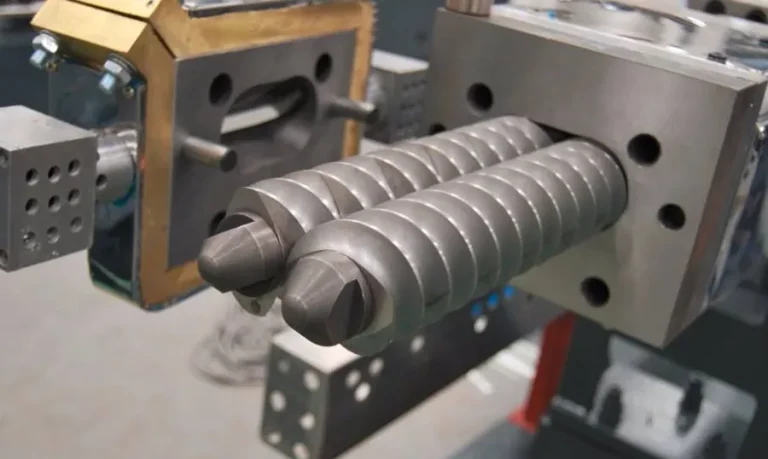

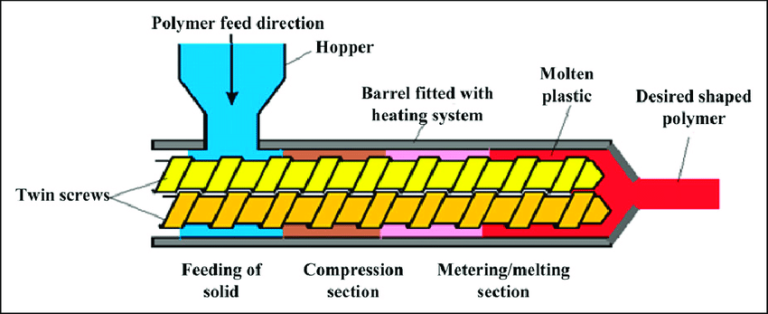

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down their working principles, core components and application scenarios in detail, and compare the differences between…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down the application value and core benefits of Single Screw Extruders across three key industries. Additionally,…

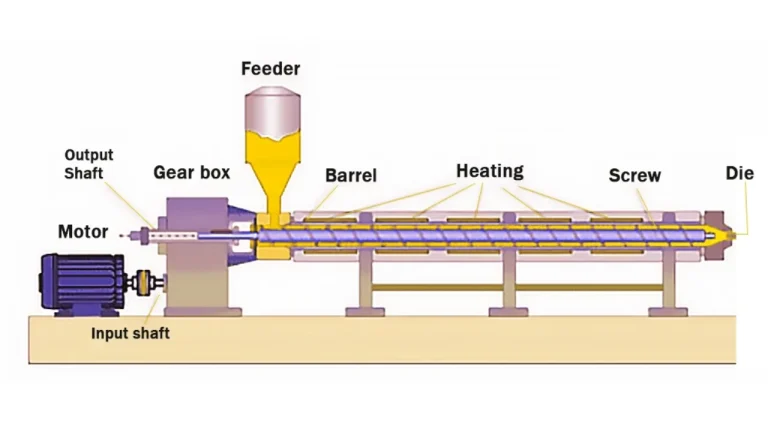

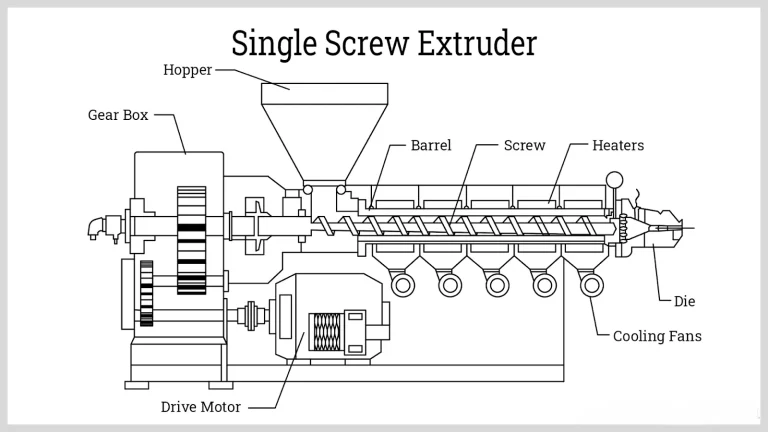

Detailed Single Screw Extruder Design Diagram

For overseas distributors, understanding the design drawings and core structure of single screw extruders enables them to quickly address customer technical inquiries, grasp the equipment’s structural advantages, and enhance their sales messaging. For manufacturing enterprises, a clear understanding of the…

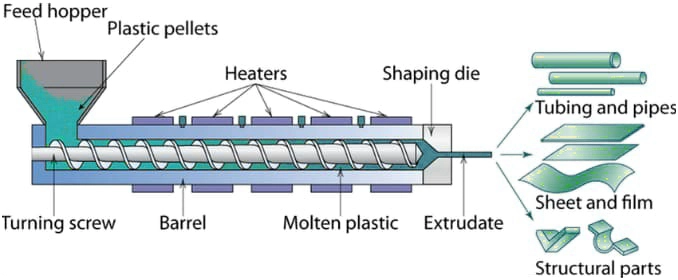

Single Screw Extruder Working Principle

Understanding the working principle of the single-screw extruder is critical information for distributors to promote products accurately and for enterprises to select models correctly and perform operation and maintenance. It can effectively resolve production issues such as poor plasticization and…

Learn About the Applications of Single Screw Extruders

For equipment distributors and end user manufacturers, a thorough understanding of the application scenarios of single screw extruders is a core prerequisite for seizing market opportunities and optimizing production configurations. For distributors, clear knowledge of application scenarios helps determine a…

What Is Single Screw Extruder

The single-screw extruder is the most widely used general-purpose extrusion equipment in the industrial sector, spanning several core industries such as rubber and plastic, food, and chemical engineering. This article will systematically explain its basic definition, core components, working principle,…