Exporting countries

Global Users

Extruders Delivered

Number of Employees

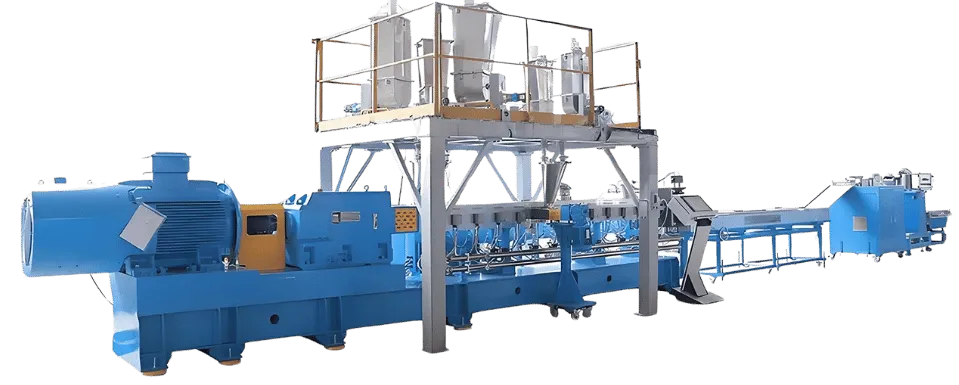

Learn About UET Machine’s Extruders

Are you looking for reliable extrusion molding equipment? Explore our full line of efficient and stable extruders to immediately enhance your production processes and efficiency.

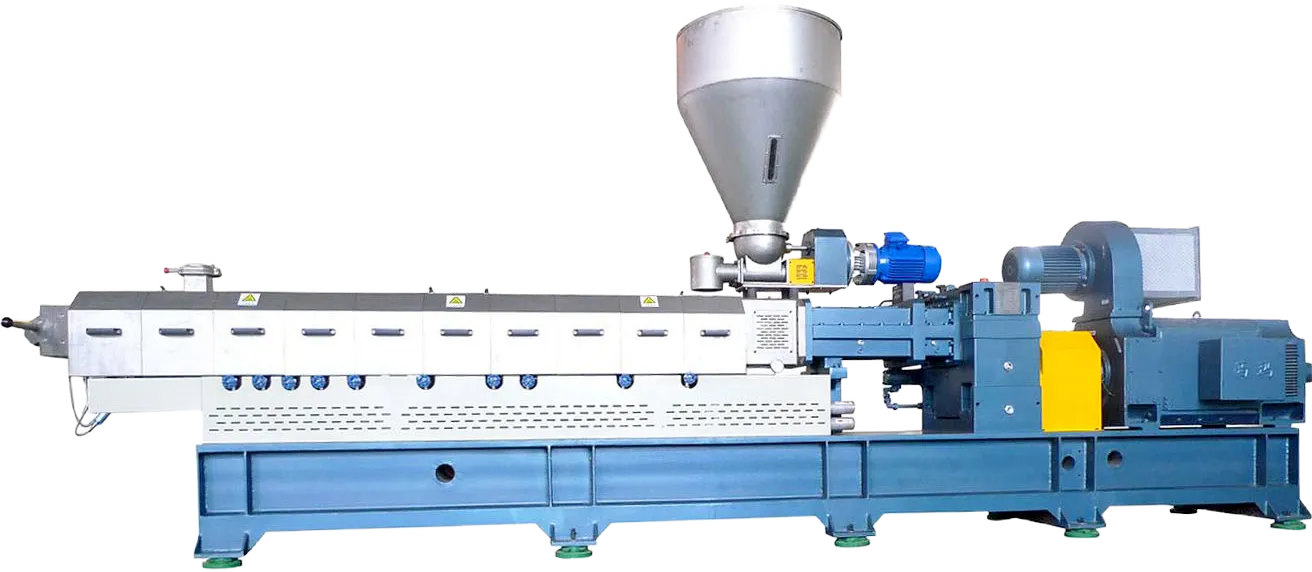

Single Screw Extruder

UET Machine Single Screw Extruder specializes in plastic melting and molding. It is compatible with main general purpose materials such as PE, PP, PVC and used for producing pipes, sheets, profiles and films. With a compact structure, easy operation and maintenance, stable performance and high cost effectiveness, it is a highly reliable efficient and practical choice for general plastic processing.

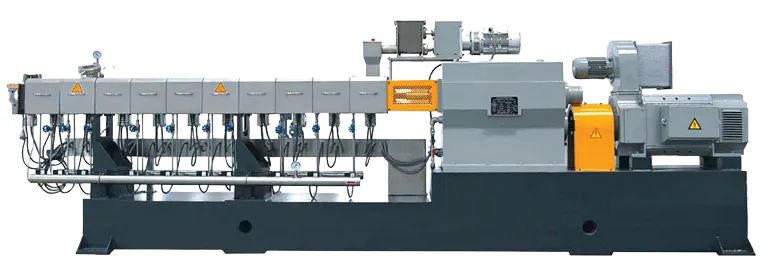

Twin Screw Extruder

Adopting a co rotating screw design it achieves precise shearing and uniform compounding. Custom built for the production of modified plastics color masterbatches and new energy materials its high torque density design reduces energy consumption by 15% and the modular structure cuts changeover time by 30% meeting the strict requirements for efficiency and product consistency in high end customized processing.

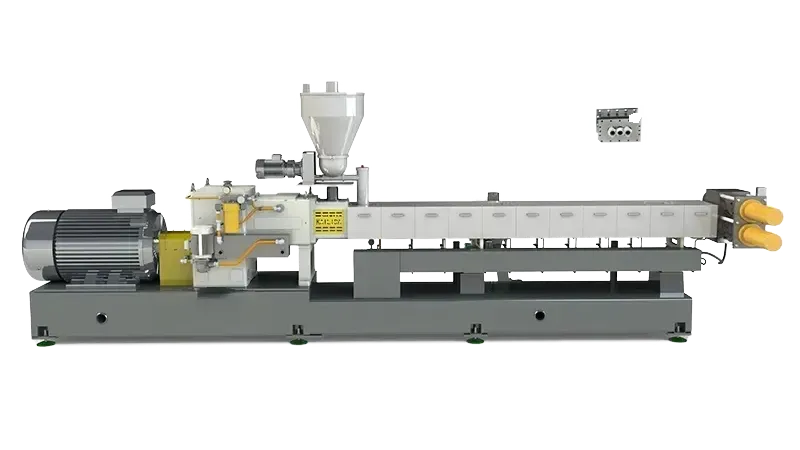

Triple Screw Extruder

The innovative screw structure significantly enhances precision compounding and nano dispersion performance. Suitable for high end materials like biodegradable plastics and medical grade polymers it features a temperature control accuracy of ±1.5℃ effectively reducing material degradation risks and ensuring excellent product stability providing solid technical support for high value added material processing.

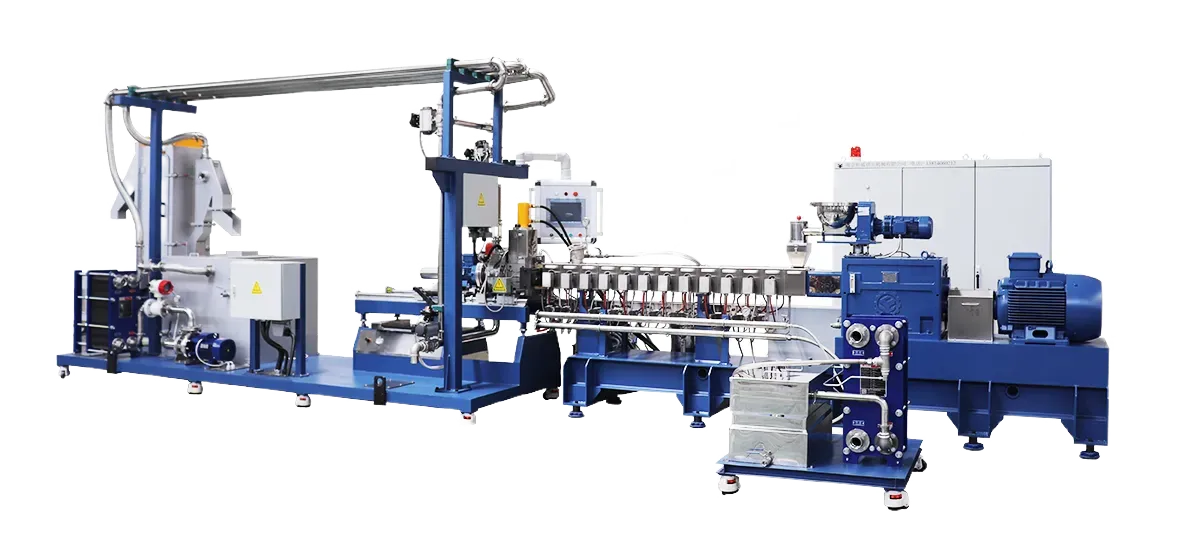

Underwater Pelletizing

Integrating integrated functions of extrusion pelletizing cooling and drying it is suitable for processing engineering plastics modified materials and recycled materials. The pellets offer high sphericity low dust and excellent fluidity. The automatic control system ensures product stability with high efficiency energy saving and space saving modular design making it suitable for large scale production scenarios.

Compounding Extruder

Equipped with a high strength mixing device and zoned temperature control system it is compatible with various plastics and biodegradable materials for modification color masterbatch production and recycling. It delivers high mixing uniformity ensuring full integration of additives and base materials with flexible operation and easy maintenance aligning with green production and circular economy concepts.

Rubber Extruder

Optimized for rubber characteristics it offers efficient plasticization and stable extrusion with wear resistant core. Compatible with natural and synthetic rubber it is used for producing pipes, seals and tire components. Featuring stable extrusion pressure, temperature resistance and continuous long term operation it meets strict service requirements of the automotive and construction materials industries.

Not finding the right extrusion equipment for your needs?

Beyond the above extruder types, UET Machine also offers other extruder models and can deliver custom extrusion solutions based on your actual production requirements.

Filler Masterbatch

UET extruders excel at filler masterbatch processing. They stably and uniformly blend and melt high-load fillers with base materials, no excessive shearing. The finished masterbatch offers excellent processability and high rigidity, enabling high-volume production of high-quality filler masterbatch for packaging and construction materials.

Color Masterbatch

UET extruders process color masterbatch: precise temperature control and stable extrusion let high-concentration pigments uniformly coat resins. Equipment allows easy changeover and supports small-batch multi-color switching. Finished product has consistent color strength, suitable for coloring items like packaging and toys.

Additive Masterbatch

UET extruders produce additive masterbatch. Matched temperature control and kneading rhythm allow functional additives like antioxidants to uniformly blend with carrier resins. The masterbatch has stable composition, ensuring uniform additive release during processing, suitable for plastic modification applications.

Engineering Plastics

UET extruders can process engineering plastics such as ABS. They stably plasticize medium and low melting point substrates, ensuring the mechanical strength of finished products. The produced material can be used to manufacture common engineering products like appliance housings and small mechanical parts.

Biodegradable Plastic

UET extruders process biodegradable plastics. Precision zoned temperature control preserves resins’ bioactivity and enables uniform blending with modifiers. The finished product meets specs, suitable for eco-friendly items like fully biodegradable packaging bags and disposable containers.

Thermoplastic Elastomers

UET extruders process thermoplastic elastomers. They retain the original elasticity of substrates while uniformly melting with modified materials. The finished product has controllable hardness and wear resistance, suitable for mass production of items like seals and soft rubber daily necessities accessories.

Cable Compounding

UET extruders process cable composite materials. Stable material conveying enables uniform blending of insulating substrates and fillers, while precise temperature control ensures insulation performance. The finished product can be used for insulation layer coating of small cables and low-voltage wires.

PVC Compounding

UET extruders reliably and efficiently handle PVC compounding. They enable uniform blending and melting of PVC resins with plasticizers, stabilizers and other key additives. The process is stable, producing customized PVC compounds suitable for manufacturing products like pipes, films, and cables.

Why Choose UET Machine

Rooted in product quality and cost-effectiveness, UET Machine is committed to delivering exceptional value to our clients. We have established in-depth partnerships with customers across multiple countries worldwide. Our extruders are distributed to more than 80 nations spanning Southeast Asia, Africa, South America and other regions, having earned widespread recognition in the global market through reliable quality and professional services.

Provide Customized Solutions

Per your product types (pipes, color masterbatches, etc.), materials, and capacity needs, we customize core equipment setups and process parameters. They align perfectly with real production needs, enhancing line adaptability and accuracy.

Comprehensive Customer Support

Our support covers pre-sales consultation, equipment installation/commissioning, operational training, and after-sales maintenance. End-to-end technical support responds in real time, resolving issues promptly to ensure stable production.

Wide Material Compatibility Range

Our equipment stably processes a wide range of materials, including PE, PVC, biodegradables, and modified polymer materials. No frequent adjustments needed during processing, ensuring consistent product quality across materials.

Competitive Price Plans

While ensuring equipment processing accuracy, operational stability, and end-to-end service quality, we offer market-competitive pricing. This helps you effectively control investment costs and increase your production investment return rate.

What Our Clients Say

Below are genuine feedback from select users after using UET Extruders. We are honored to help users resolve key challenges in their production processes.

We’ve relied on the UET Single Screw Extruder for 16 months—its stability is outstanding. It processes PE, PVC, and PP flawlessly, producing extruded products with consistent thickness and smooth finishes. Easy to operate, low maintenance, and responsive after-sales make it a factory workhorse.

Sophia Hale

The UET Single Screw Extruder exceeded our expectations! Workers mastered it in 3 days, and it handles high-volume orders effortlessly. Extruded pipes have uniform walls, zero defects, and daily upkeep is a breeze. Prompt after-sales support adds to its reliability—highly recommend.

Ryan Carter

For 14 months, the UET Single Screw Extruder has delivered precise results. It processes rigid and flexible materials with tight tolerances, and the intuitive interface saves training time. Low maintenance and prompt technical support give us complete confidence in daily production.

Derek Morgan

Frequently Asked Questions (FAQs)

A: UET Machine specializes in a range of plastic extrusion molding equipment including single screw, twin screw and triple screw extruders. We also provide customized configurations based on customers’ production capacity requirements and product types such as pipes, films and cables. Our mature and reliable technology can meet production needs in different scenarios.

A: Our extruders have excellent compatibility, capable of processing general purpose plastics like PE, PP and PVC, engineering plastics such as PA, PC and ABS, as well as special materials including modified plastics, recycled plastics and biodegradable plastics. Whether for basic pipe extrusion or high precision cable coating and film production, the equipment can adapt stably and switch production quickly without frequent parameter adjustments.

A: Our extruders have excellent compatibility, capable of processing general purpose plastics like PE, PP and PVC, engineering plastics such as PA, PC and ABS, as well as special materials including modified plastics, recycled plastics and biodegradable plastics. Whether for basic pipe extrusion or high precision cable coating and film production, the equipment can adapt stably and switch production quickly without frequent parameter adjustments.

A: You can contact us by filling out the form on the Contact Us page or via email at [email protected]. Please provide information such as the required machine model production capacity requirements processing materials and target products. We will provide you with an accurate quote within 2 hours. The quote includes equipment configuration technical specifications estimated shipping costs and payment terms with full transparency and no hidden fees. We can also offer an optimized configuration plan based on your budget.

A: Of course we can! We have a professional R&D team that can provide end to end customized services from machine design and parameter debugging to auxiliary equipment matching based on customers’ production scenarios, capacity goals, processing materials and product specifications. Whether for special process requirements, capacity upgrade needs or site adaptation adjustments, we will respond promptly and tailor exclusive solutions that fit actual production.

A: The delivery time for standard models is only 1-2 weeks, while customized models take 4-6 weeks. We have a large scale production base and a complete supply chain system to efficiently ensure production progress. We also offer expedited production services to meet customers’ urgent commissioning needs. Strict equipment debugging and quality inspection will be conducted before delivery to ensure stable production immediately upon arrival.

A: All extruder products come with a 1 year 整机 warranty, and the warranty for core components such as screws and barrels is extended to 24 months. During the warranty period, we provide free maintenance services and replacement of faulty parts, as well as lifelong technical support and maintenance consulting. We have service outlets in many countries around the world, enabling timely response to maintenance needs and minimizing downtime losses.

A: Our customers are located all over the world. Typical customer cases include: a pipe manufacturer in the United States purchasing single screw extruders for water supply and drainage pipe production, a modified material manufacturer in Germany selecting twin screw models for engineering plastic processing, a cable company in India customizing exclusive equipment for wire coating, and a packaging enterprise in Brazil using our equipment to produce PE heat shrinkable film. These cases fully demonstrate the international adaptability and operational stability of our equipment.

A: Our extruders adopt high wear resistant accessories and optimized structural design, with maintenance costs more than 30% lower than the industry average. Routine maintenance mainly involves replacing vulnerable parts such as filters and seals. The accessories have transparent prices and sufficient supply, and are easy to replace without the need for professional technicians. At the same time, the equipment has a low operation threshold, which can reduce failures caused by improper operation and further lower maintenance burdens.

A: We support a variety of payment methods that comply with international trade practices, including Letter of Credit (L/C), Telegraphic Transfer (T/T) and Western Union. We can flexibly choose according to your region and cooperation needs. For long term cooperative customers, we can also provide more favorable payment terms. The transaction process is standardized and fund security is guaranteed to ensure smooth cooperation between both parties.