What is an extruder? Learn more

Within the global industrial production chain, extruders serve as core forming equipment, widely used across high-demand sectors such as plastics, building materials, food, and rubber. This article will provide an in-depth overview of extruders by exploring key aspects: basic definition, operating principles, core components, type classifications, and application scenarios.

What is an Extruder?

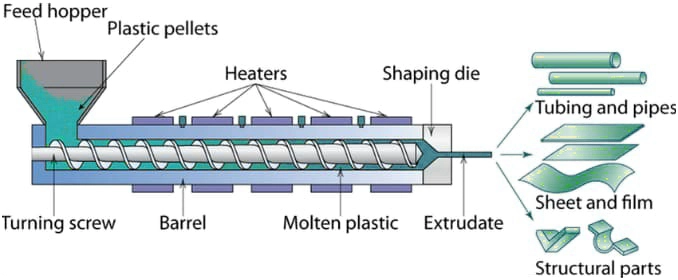

An extruder is an industrial equipment that heats and pressurizes materials (such as plastic pellets, rubber raw materials, food powders, etc.) to plasticize and melt them, then continuously extrudes and shapes them into products with specific cross-sectional profiles. Its core value lies in the “continuous, standardized, and efficient” material forming capability—it can convert loose raw materials into various end products such as pipes, sheets, films, and profiles, serving as a critical production link connecting raw materials to finished goods.

The extruder’s key advantage lies in its wide industry applicability and stable market demand: whether it’s pipe extruders needed by plastic product manufacturers, profile extruders essential for building materials enterprises, or extrusion puffing machines in the food processing sector, all fall under the category of equipment with rigid demand from end customers. This means the extruder distribution business boasts sustained profit potential.

How Extruders Work

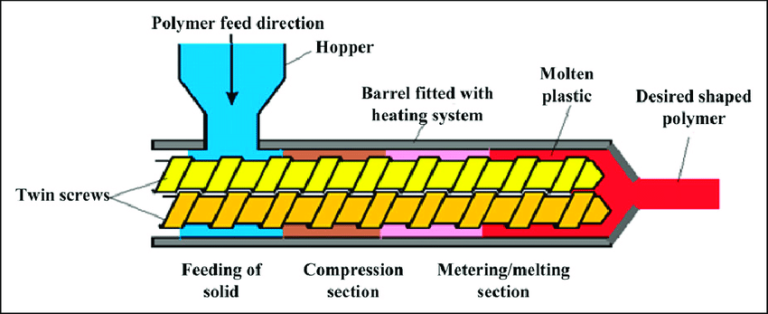

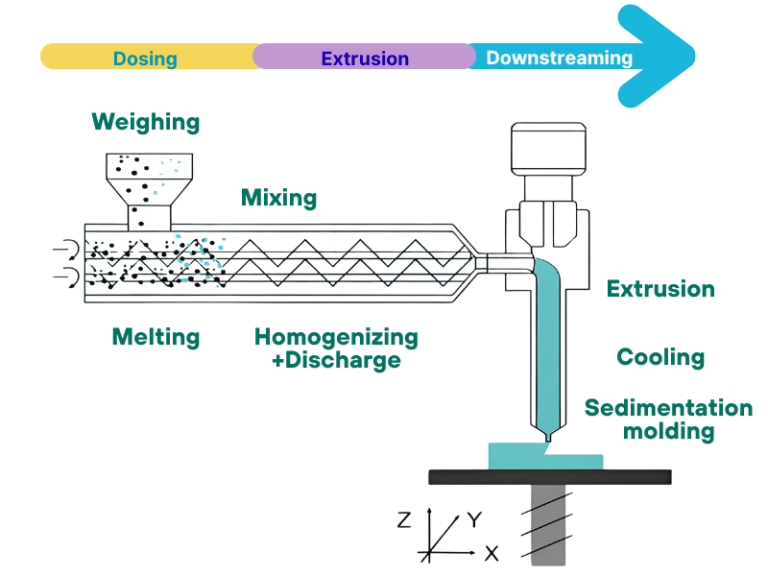

The working process of an extruder can be summarized into four core stages: “Raw Material Pretreatment → Plasticization & Melting → Extrusion Molding → Cooling & Shaping.” Each stage is interconnected to ensure molding quality and efficiency, with detailed breakdowns as follows:

1.Raw Material Pretreatment and Feeding

First, raw materials undergo pretreatment (e.g., plastic pellets need drying to remove moisture, preventing bubbles in finished products). Subsequently, the raw materials are uniformly fed into the extruder barrel through a hopper. The stability of the feeding stage directly affects subsequent molding quality, so high-quality extruders are usually equipped with precise feeding control devices.

2.Conveying and Compression

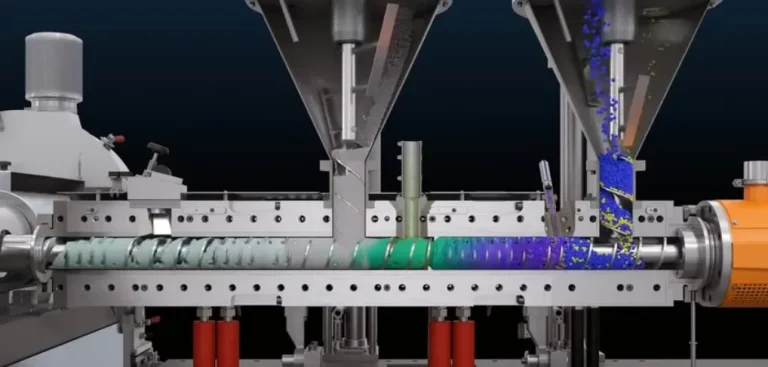

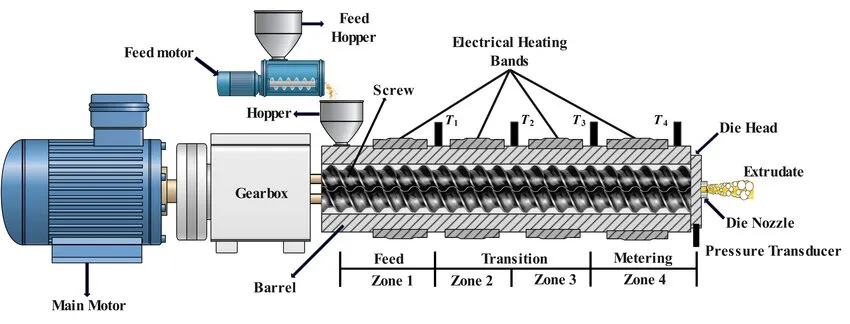

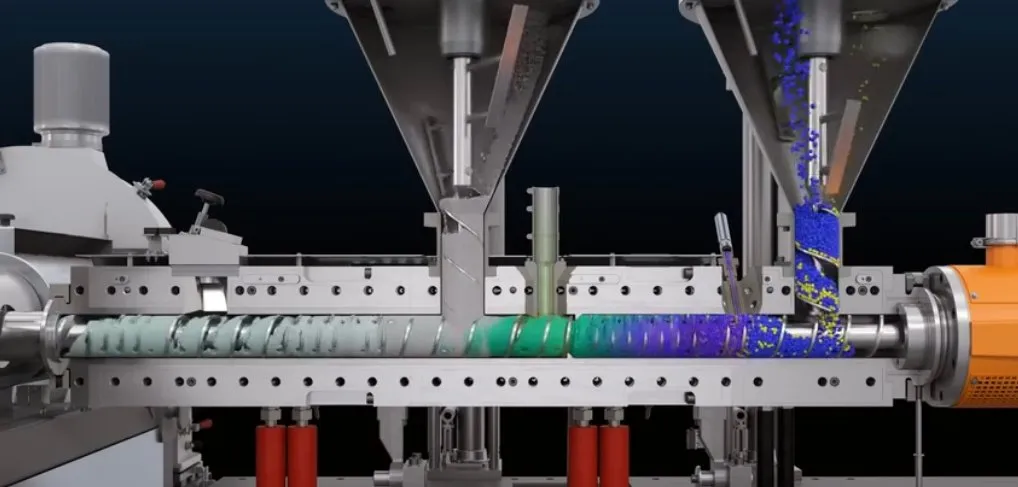

The screw inside the barrel rotates at high speed, conveying raw materials forward via the thrust of spiral blades. Meanwhile, the screw’s pitch gradually decreases, exerting compression on the raw materials to expel air and achieve preliminary compaction, laying the foundation for subsequent melting.

3.Plasticization and Melting

Heating devices (such as electric heating coils, hot oil jackets) are installed outside the barrel. Combined with the shear heat generated by screw rotation, the raw materials are gradually heated to a molten state under dual action. The key to this stage is “uniform plasticization”—ensuring complete melting of materials and stable temperature to avoid local overheating or unmelted particles affecting finished product quality.

4.Extrusion Molding and Cooling & Shaping

Molten materials are extruded through a custom-shaped die in the machine head under the thrust of the screw, forming continuous profiles with specific cross-sections. They are then rapidly cooled by cooling equipment (such as water tanks, air cooling systems) to solidify and shape. Finally, the profiles are pulled by a tractor and cut by a cutter to obtain finished products that meet specifications.

Key Components of an Extruder

An extruder’s performance core depends on the quality and compatibility of its key components. Below are the main core components and their functions:

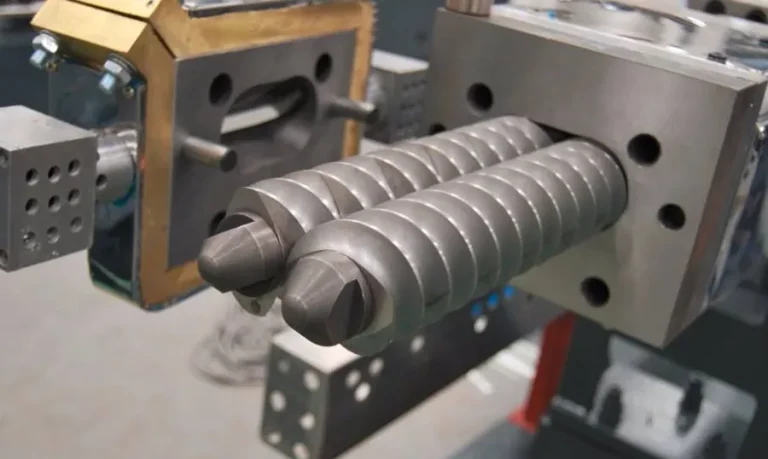

1.Screw:Known as the “heart” of the extruder, it is responsible for material conveying, compression, plasticization, and melting. Based on processing materials and product requirements, screws are classified into gradual compression, abrupt compression, barrier, and other types. High-quality screws are made of wear-resistant alloy materials to ensure service life and plasticization efficiency.

2.Barrel:A cylindrical component that works with the screw, featuring minimal clearance between its inner wall and the screw to provide a closed space for material compression and plasticization. Barrels are typically manufactured from high-strength, high-temperature-resistant, and wear-resistant alloy steel, with heating and cooling devices attached externally to achieve precise temperature control.

3.Hopper:A storage and feeding device usually installed at the top of the extruder. Some models are equipped with an agitator and level sensor to ensure uniform, stable feeding of raw materials, avoiding equipment load fluctuations caused by material interruption or overfeeding.

4.Head and Die:The head is a transition component connecting the barrel and die, responsible for smoothly guiding molten materials into the die. The die determines the final product’s cross-sectional shape (e.g., pipe die, sheet die, profile die) and can be customized to meet customer needs, serving as a core component for extruders to adapt to different products.

5.Drive System:A power supply unit for screw rotation, mainly composed of a motor, reducer, and coupling. The stability of the drive system directly affects the uniformity of screw speed, which in turn impacts product dimensional accuracy and molding quality. High-quality extruders are usually equipped with a variable frequency speed control motor to achieve precise speed regulation.

6.Temperature Control System:Consisting of heating devices, cooling units, and temperature sensors, this system is responsible for maintaining the temperature of the barrel, machine head, and die within preset ranges. Different materials require specific plasticization temperatures, so the precision of the temperature control system is critical to ensuring uniform material plasticization and preventing product defects.

What Are the Types of Extruders?

Extruders can be categorized into various types based on different criteria. For distributors, the most critical classifications to prioritize are by “number of screws” and “application scenarios,” as they facilitate catering to the needs of clients across industries. Details are as follows:

Classified by Number of Screws

This is the most common classification method, with significant differences in application scenarios among extruders with varying screw counts:

- Single-screw extruders: Featuring a simple structure, easy operation, and low cost, they are suitable for processing commodity plastics such as polyethylene (PE) and polypropylene (PP). Primarily used in producing pipes, films, wire coating, and other products, they are the highest-demand entry-level models and core products for distributors entering the market.

- Twin-screw extruders: Divided into parallel twin-screw and conical twin-screw types, they offer high plasticization efficiency and excellent mixing uniformity. Ideal for processing complex materials like PVC, modified plastics, and filled plastics, they can produce high-value-added specialty profiles and composite pipes, targeting mid-to-high-end processing enterprises.

- Multi-screw extruders (triple-screw, quadruple-screw, etc.): Characterized by complex structures and high costs, they are mainly used for processing high-end specialty materials (e.g., biodegradable plastics, high-performance engineering plastics). While market demand is relatively small, they boast higher profit margins, making them suitable for serving clients in niche high-end markets.

Classified by Application Scenarios

Customized to meet end-industry needs with strong targeting, this classification is an important basis for distributors to accurately connect with clients:

- Plastic extruders: The most widely used type, with specialized models including pipe extruders, sheet extruders, film extruders, profile extruders, and pelletizing extruders, covering the entire plastic processing industry chain.

- Rubber extruders: Specifically designed for rubber material molding, such as tire treads, rubber pipes, and sealing strips, catering to the needs of rubber product manufacturers.

- Food extruders: Used in the food processing sector for products like puffed snacks, breakfast cereals, and pet food. Constructed with food-grade stainless steel, they comply with food safety standards.

- Other specialty extruders: Examples include 3D printing filament extruders, biomass material extruders, and extruders dedicated to the pharmaceutical industry, adapting to the needs of niche market segments.

Applications of Extruders

Extruders find applications across multiple core sectors of the national economy, with fragmented yet stable market demand. Specific industry applications and corresponding products are as follows:

1.Plastic Processing Industry (Core Application Sector)

As the primary application field, extruders adapt to various plastic molding products:

- Construction Plastics: PVC water supply and drainage pipes/fittings, plastic door and window profiles, ceiling panels, geotextiles, waterproof membranes;

- Packaging Plastics: BOPP biaxially oriented film, PE heat-shrinkable film, food vacuum packaging film, plastic woven bag flat yarn, express bag base film;

- Daily-Use Plastics: PET preforms, HDPE plastic hoses, plastic parts for home appliance casings, toy structural components, plastic accessories for daily necessities;

- Industrial Plastics: Engineering plastic (PA, PC) pipes, automotive wire harness coating materials, insulation coatings for electronic components, industrial plastic profiles.

2.Building Materials Industry

Meeting the molding needs of new building materials, specific products include:

- Thermal Insulation Materials: XPS extruded polystyrene boards, EPS expanded polystyrene boards, polyurethane insulation profiles;

- New Wall Materials: Fiber-reinforced gypsum boards, ceramsite concrete extruded profiles, lightweight partition boards.

3.Food Processing Industry

Adapting to food and pet food processing, specific products include:

- Snack Foods: Puffed potato chips, popcorn, filled rice cakes, cereal crisps;

- Nutritional Foods: Breakfast cereal loops, infant nutritional rice noodles, high-protein meal replacement bars, elderly nutritional paste;

- Pet Foods: Puffed dog food, granular cat food, pet snack meat strips (extruded from mixed raw materials).

4.Rubber and Chemical Industry

- Rubber Products: Tire tread rubber, nitrile rubber pipes, automotive sealing strips, industrial conveyor belt bases, silicone seals;

- Chemical Materials: Special functional coating substrates, high-performance adhesive carriers, carbon fiber precursor fibers, nanomaterial composite profiles.

5.Other Emerging Fields

Catering to material molding needs in emerging industries, specific products include:

- 3D Printing Materials: PLA/ABS/TPU 3D printing filaments, resin-based composite printing consumables;

- Biomass Energy: Straw solidified fuel, wood chip pellet fuel, biomass charcoal molding rods;

- Medical Industry: Medical PVC infusion tubes, PP urinary catheters, pharmaceutical sustained-release microsphere carriers, plastic accessories for medical consumables.