Underwater Pelletizing System

Reliable Underwater Pelletizer Manufacturer in China

UET Machine’s underwater pelletizer is designed for high precision clean plastic particle pelletization, ideal for granulating polyethylene polypropylene and engineering plastics. It delivers consistent uniform particles with smooth surfaces, featuring an intelligent cooling and temp control system and low operation threshold—easy for new operators to learn. Vs traditional pelletizers it keeps particle size deviation ±0.1mm, cuts production dust by 80%, energy use by 15%, and maintenance downtime by 35%, meeting high end plastic particle mass production needs.

98%+

Pellet Sphericity Rate

99.2%

Operation Stability Rate

≤0.1%

Pellet Moisture Content

85% Less

Dust Emissions

UET Machine Underwater Granulation System Solutions

Whether you’re engaged in precision plastic pellet processing, new energy cable compound granulation, or biodegradable material production, UET Machine’s underwater granulation system delivers high precision clean custom solutions—aligned with your process requirements and tailored to your production needs.

For high-end materials’ strict requirements for particle uniformity and surface finish, our equipment can well control particle precision within ±0.1mm. This addresses the pain points of large particle errors and frequent surface defects in traditional granulation, making it suitable for high-end scenarios like medical and precision packaging.

For hard-to-process materials such as high-viscosity cable materials and biodegradable PLA, we have optimized the die head and cooling system. This resolves issues like material blockage and poor forming, and the equipment is compatible with various special modified materials, covering needs in niche fields like new energy and environmental protection materials.

For the pain points of excessive residue and time-consuming purging during material changes, we adopt quick-release die head and material path modules. Purging time is reduced by 60%, and cross-material contamination is avoided, making it suitable for small-batch, multi-category production scenarios.

For the pain points of production capacity fluctuations and frequent shutdowns of traditional equipment after long-term operation, we have enhanced the power and cooling systems. The equipment supports 24/7 continuous full-load operation, with a production capacity fluctuation rate ≤ 5%, ensuring stable order delivery.

For the pain points of slow after-sales response and spare parts shortages in cross-border production, we have equipment parts warehouses in key regions. We provide technical support response within 72 hours, and spare parts are delivered within 15 working days, resolving operational challenges for overseas equipment.

For the pain points of energy consumption and emissions under new industry environmental regulations, our equipment’s energy consumption is 15% lower than the industry average. There is no waste gas emission during granulation, and it complies with CE and RoHS standards, helping enterprises meet environmental compliance requirements.

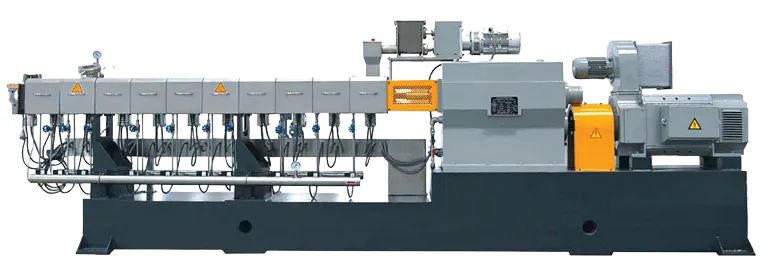

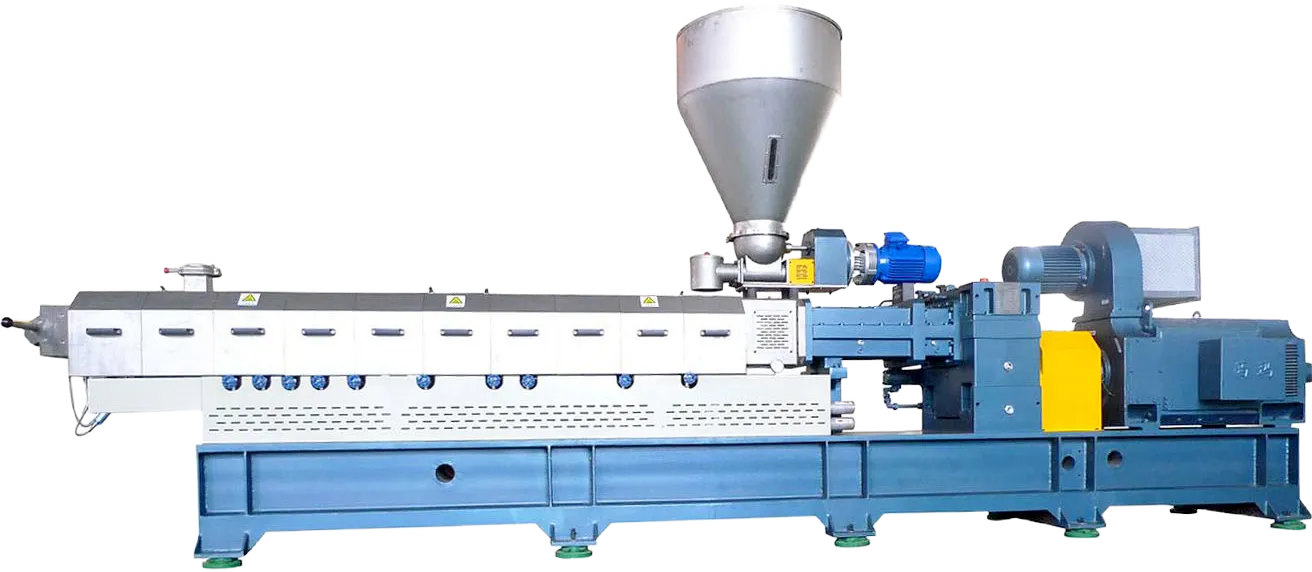

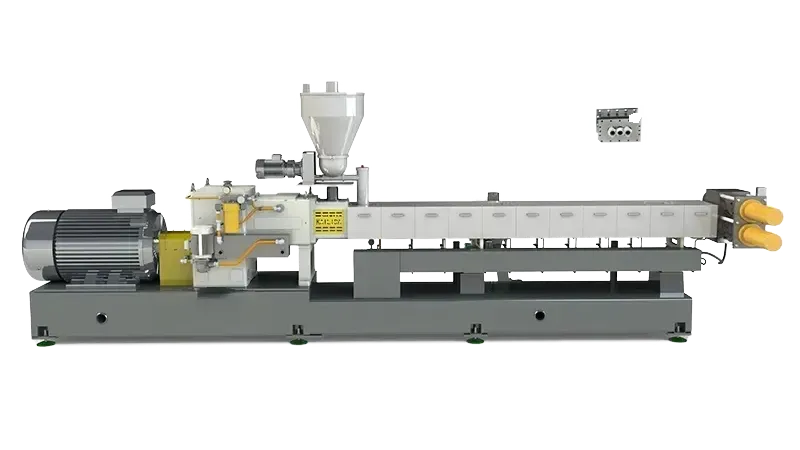

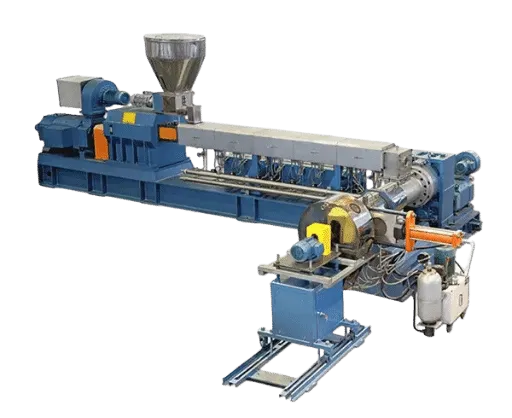

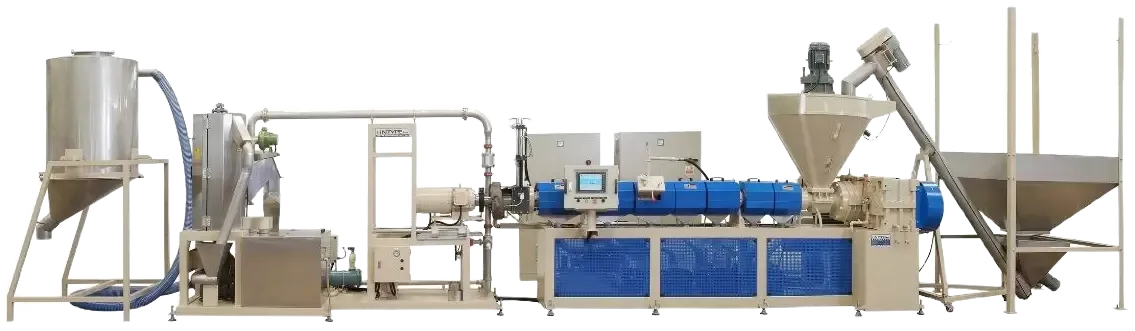

Underwater Pelletizing Systems for Sale

UET Machine’s underwater granulation system accommodates processing multiple materials including engineering plastics and new energy materials. It delivers high-precision particles with smooth surfaces, consistently meeting the rigorous production requirements of sectors like medical and automotive. Additionally, we offer custom equipment configurations tailored to your specific needs.

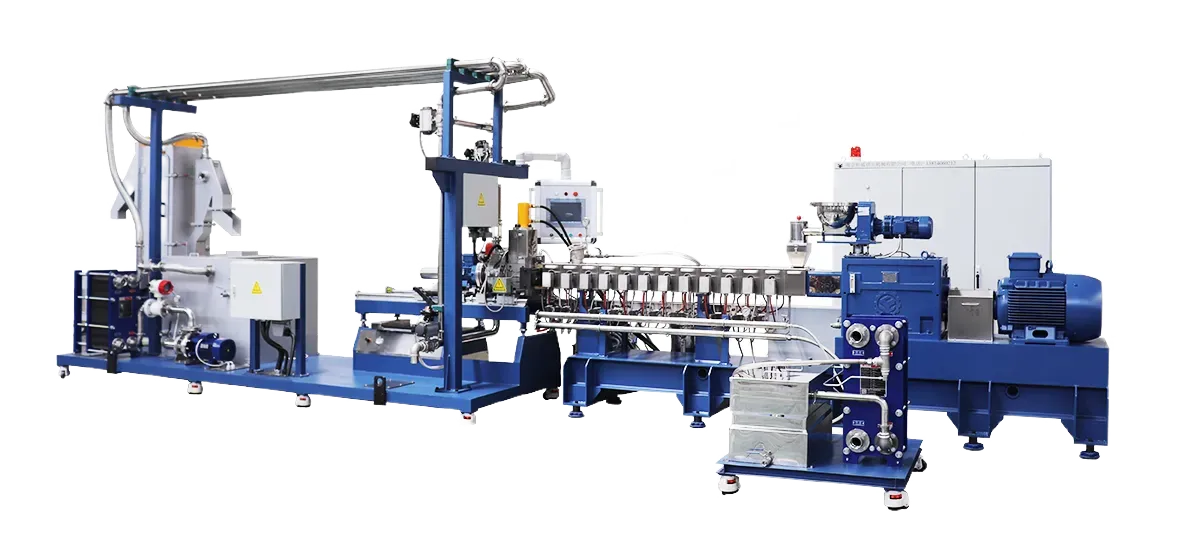

High Precision Underwater Granulation System

Ideal for precision granulation of high-end engineering plastics and specialty resins. Particle size deviation is tightly and strictly controlled within ±0.1mm, with smooth, flawless, and highly uniform finished products that meet the rigorous production standards for plastic particles used in medical supplies and automotive core components.

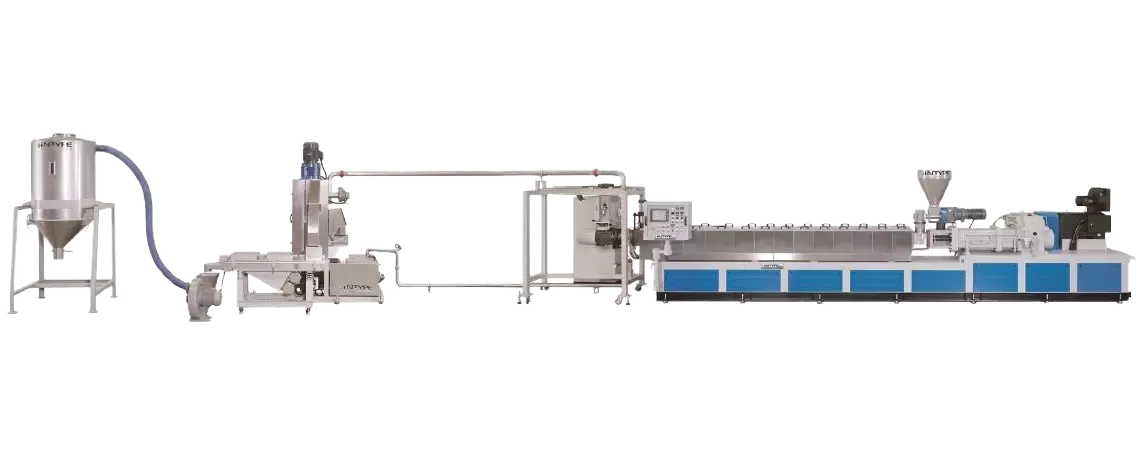

New Energy Spec Underwater Granulation System

Custom-designed for high-viscosity new energy cable compounds, equipped with an intelligent thermostatic control module. It achieves low dust emissions and 15% lower energy use in granulation, with stable and consistent particle insulation performance, ideal for large-scale continuous production of cable compounds in the photovoltaic and energy storage sectors.

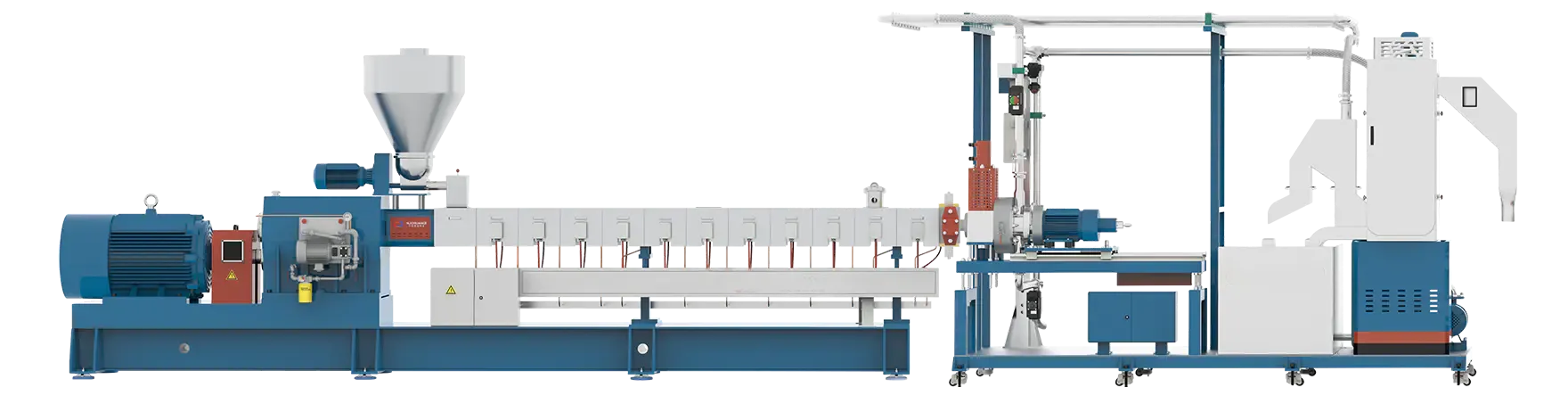

Biodegradable Submerged Granulation System

Precisely adapted for gentle granulation of bio-based biodegradable materials. Adopting low shear core technology to avoid material performance loss, it ensures a stable product qualification rate of over 99% with regular, non-adherent particles, suitable for processing biodegradable packaging and daily necessities with PLA, PBAT, and other materials.

UET Underwater Granulation System Technical Specifications

UET Machine offers three series of twin screw extruders. In addition, we provide customized equipment and deliver tailored twin screw extruder solutions to meet your specific production needs.

| Model | Diverter Hole No. | Knife No. | Knife Movement System | Water System | Output Capacity |

|---|---|---|---|---|---|

| UET250 | D25 | 6-9 | Manual | W250 | 30-250 kg/h |

| UET450 | D35 | 15-25 | Electric | W450 | 150-600 kg/h |

| UET800 | D45 | 30-50 | Electric | W800 | 1.5 ton/h |

| UET1500 | D55 | 80-120 | Hydraulic | W1500 | 2-5 ton/h |

| UET3000 | D65 | 150-200 | Hydraulic | W3000 | 4-7 ton/h |

| UET6000 | D75 | 250-350 | Hydraulic | PCW600 | 8-18 ton/h |

| UET12000 | D85 | 350-450 | Hydraulic | PCW1200 | 18-32 ton/h |

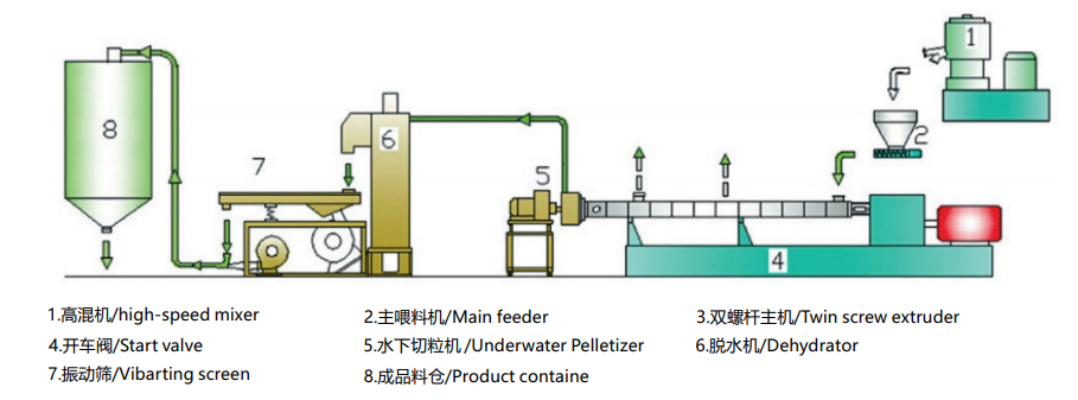

Flowchart of the Underwater Pelletizing System

Flowchart of the Underwater Pelletizing System

UET Underwater Granulation System Manufacturing Facility

Welcome to the UET Underwater Granulation System Manufacturing Facility. Our facility is equipped with top-tier core component processing equipment in the industry and a full-process intelligent quality inspection system. We ensure the stability, reliability and long-term high-efficiency operation of each piece of equipment.

UET Underwater Granulation System Customer Reviews

Explore genuine customer reviews of UET’s Underwater Pelletizing Systems. These reviews come from our clients across diverse industries.

The particle precision of UET’s underwater granulation system far exceeds expectations, and its surface finish fully meets packaging material standards. The equipment has now been in operation for 10 months without any malfunctions, its production capacity remains consistently up to standard, and it has greatly improved production efficiency.

Mike

We specialize in PLA material production, and UET’s equipment is perfectly suited for the granulation needs of such biodegradable materials. Cooling and cutting are completed simultaneously, the particles have high uniformity, energy consumption is 15% lower than our old equipment, and the cost control effect is significant.

Lisa

After we purchased the UET12000 model, the production capacity of modified plastic particles doubled immediately. The equipment’s hydraulic system responds quickly, the cutter precision is stable, it is highly compatible with our existing production line, and it operated at full capacity just one week after commissioning.

David

Granulating high-viscosity cable materials has always been a challenge for us. The die design of UET’s system is very reasonable, the strand formation is smooth, the cooling efficiency is high, the melt index fluctuation of the particles is small, and it fully meets performance requirements.

Chris

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs) about UET Twin Screw Extruders cover core information including product compatibility, performance specifications, installation, operation and maintenance, and after-sales support.

A:UET’s underwater granulation system is compatible with engineering plastics (e.g., PC, PA), new energy cable materials, biodegradable materials (PLA/PBAT), various thermoplastics, and modified materials. It supports high-viscosity and functional materials, meeting the processing needs of overseas industries such as automotive, medical, and packaging.

A:UET offers professional on-site installation services. We dispatch experienced technical teams to debug equipment, optimize process parameters, and provide installation and acceptance standard documents as well as operational guidance, ensuring overseas users can put the equipment into production quickly and achieve optimal operating performance.

A:UET fully supports customization on demand. Based on overseas users’ production capacity goals, particle precision (within ±0.1mm), material characteristics, and existing production line layouts, we exclusively design equipment parameters and configurations to provide one-stop customized granulation solutions.

A:The delivery cycle is 4-8 weeks. Standard models are shipped within 2-4 weeks after completing production and quality inspection, while customized equipment takes 4-8 weeks (including scheme design, production debugging, and sea freight preparation). We provide full process logistics tracking services to ensure overseas users receive goods on time.

A:UET offers comprehensive training services, including bilingual Chinese English operation manuals and online video tutorials. Overseas users can apply for on-site hands-on training (1-3 days) covering equipment operation, maintenance, and troubleshooting of common issues, ensuring operators can master the skills quickly.

A:We can arrange on-site demonstrations or sample trial production free of charge. Overseas users are invited to visit UET’s factories or nearby cooperative customer cases. Trial production is conducted using materials provided by users, and test reports on particle precision, production capacity, etc., are issued simultaneously for decision-making reference.

A:The entire machine comes with a 1 year free warranty, and core components (such as motors and hydraulic systems) have an extended 24 month warranty. Overseas users can feedback issues through an exclusive after-sales channel, and we will respond with solutions within 72 hours to ensure the stable operation of the equipment.

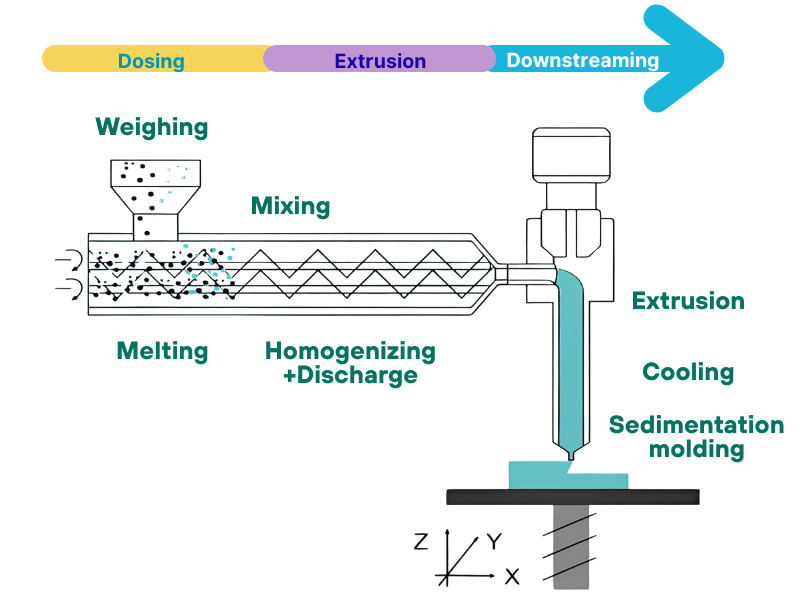

A:An underwater granulation system is an efficient plastic processing equipment that integrates extrusion, rapid underwater cooling, and synchronous cutting of molten plastic through a die head to form uniform particles. It has advantages such as high particle precision, smooth surface, and low energy consumption, and is widely used in automotive, medical, packaging, new energy and other industries.

A:The working principle of an underwater granulation system is as follows: molten plastic is first extruded through a die head to form strands, which then enter circulating water for rapid cooling and solidification. Next, a high speed cutter operating synchronously with the die head cuts the strands into uniform particles. Finally, after dehydration and drying process, high quality plastic particles ready for direct use are obtained.