What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for product matching in business expansion. This article will break down the specific types of twin-screw extruders from two core dimensions: structure and application scenarios, and provide targeted model selection suggestions to help quickly identify the suitable equipment.

Types of Twin-Screw Extruders by Structure

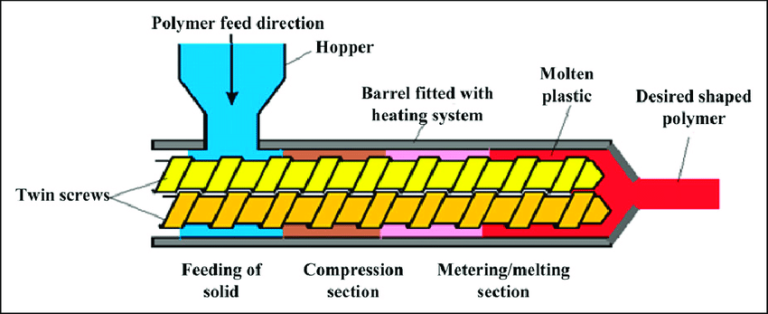

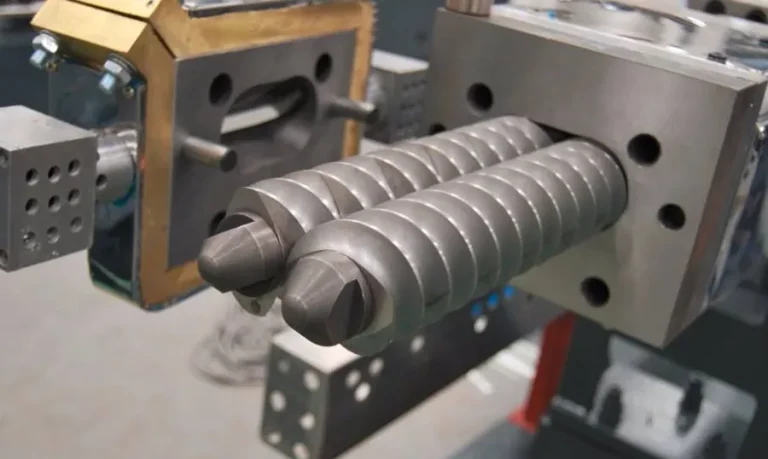

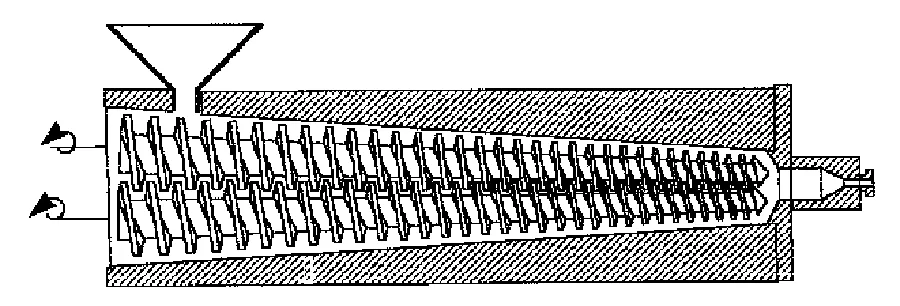

Structure is the core factor determining the performance, material compatibility, and processing efficiency of twin screw extruders. Classified by structural differences, twin screw extruders can be divided into mainstream types such as co rotating twin screw extruders, counter rotating twin screw extruders, parallel twin screw extruders, and tapered twin screw extruders. Each type has significant differences in meshing method, screw arrangement, and other aspects, with focused applicability for different scenarios.

Co Rotating Twin Screw Extruders: Features, Advantages and Typical Applications

1.Features of Co Rotating Twin Screw Extruders

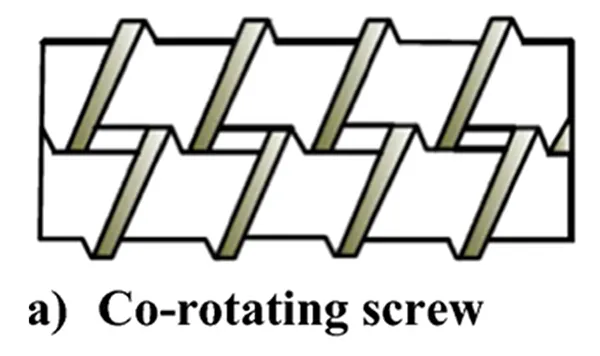

The core feature of co rotating twin screw extruders is that the two screws rotate in the same direction, and they generally adopt a fully intermeshing design. This intermeshing structure enables the formation of stable material conveying channels between the screws, effectively preventing material slippage while ensuring subsequent uniform mixing and kneading. It is suitable for high precision processing scenarios.

2.Advantages of Co Rotating Twin Screw Extruders

Benefiting from the co rotating and fully intermeshing design, its advantages are mainly reflected in two aspects: first, it has strong material conveying stability and outstanding mixing uniformity, which can easily meet high filling and high shear processing requirements, allowing full integration of additives and base materials; second, it has an excellent balance between production efficiency and energy consumption, which can reduce energy consumption per unit product and improve production efficiency in batch processing.

3.Applications of Co Rotating Twin Screw Extruders

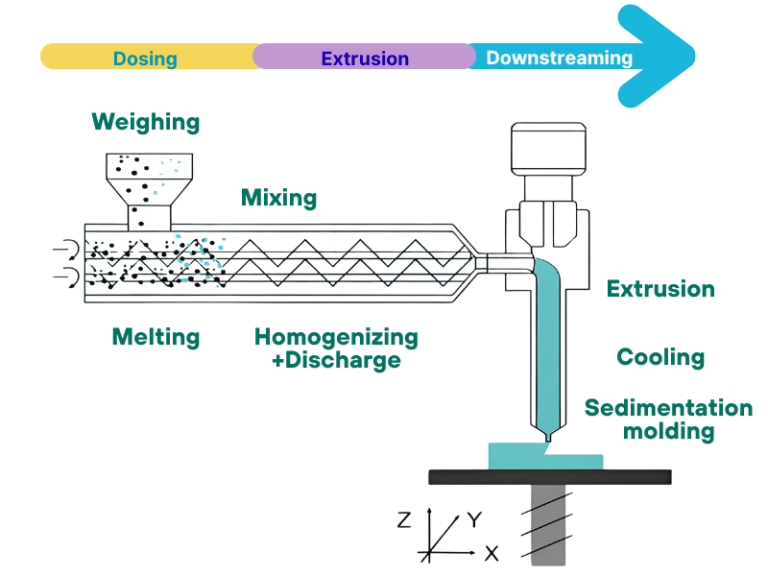

It is mainly suitable for processing scenarios requiring high material mixing precision. For example, in modified plastic processing, it is used in processes such as glass fiber reinforcement and flame retardant modification, which can ensure uniform and stable modification effects; it is also applicable to masterbatch production, ensuring full integration of color powder and base materials; in the mixing and kneading of biodegradable materials, it can prevent material degradation while achieving uniform mixing.

Counter Rotating Twin Screw Extruders: Characteristics, Advantages and Applicable Scenarios

1.Core Characteristics of Counter Rotating Twin Screw Extruders

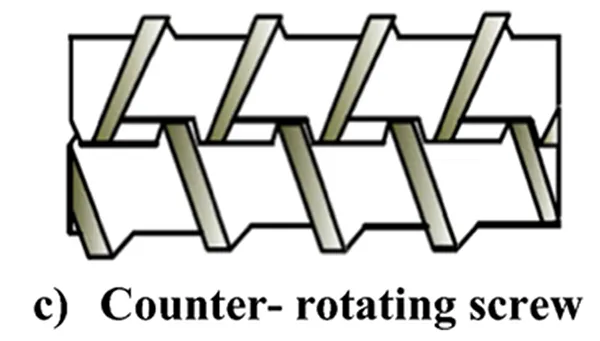

The core characteristic of counter rotating twin screw extruders is that the two screws rotate in opposite directions. They can be divided into two categories based on the degree of meshing: intermeshing type and non intermeshing type. Among them, the intermeshing type is more widely used because it can achieve more precise material conveying and control, while the non intermeshing type is mostly used for extensive processing of specific high viscosity materials and has a relatively narrow scope of application.

2.Core Advantages of Counter Rotating Twin Screw Extruders

The core advantages focus on pressure conveying and material adaptability: first, it has high material conveying pressure, which can meet the extrusion needs of high viscosity materials and avoid stagnation during conveying; second, it has excellent self cleaning function, as the counter rotating screws can scrape each other, reducing material residue and cleaning costs; in addition, it has stronger adaptability to heat sensitive materials.

Applicable Scenarios of Counter Rotating Twin Screw Extruders

Due to its stable pressure conveying performance, it is widely used in the extrusion molding of PVC pipes, profiles and other products, ensuring uniform wall thickness and stable dimensions of the products; it is also applicable to rubber product processing, enabling continuous plasticization of rubber materials; in the preparation of high viscosity coatings, it can uniformly extrude materials through stable pressure, improving product quality.

Parallel Twin Screw Extruders vs Tapered Twin Screw Extruders: Core Differences

Structure and Performance Advantages of Parallel Twin Screw Extruders

The core structural feature of parallel twin screw extruders is that the axes of the two screws remain parallel, and the screw diameter is consistent throughout. This structure ensures extremely high processing stability and balanced material mixing efficiency, preventing uneven material handling caused by structural changes. Additionally, maintenance is convenient, with low difficulty in replacing and maintaining vulnerable parts such as screws and barrels, making it suitable for large scale continuous production.

Typical Application Scenarios of Parallel Twin Screw Extruders

With stable mixing and production performance, it is mainly used in plastic modification processing, such as high end scenarios like glass fiber reinforced plastics and flame retardant modified plastics, ensuring uniform modification effects. It is also suitable for mass production of masterbatches, enabling full integration of color powder and base materials. It also performs excellently in plastic alloy processing, serving as the core equipment for mass production of high end plastic products.

Structure and Performance Advantages of Tapered Twin Screw Extruders

The screws of tapered twin screw extruders adopt a tapered gradual structure, with a certain angle between the axes of the two screws. This structure provides a larger capacity in the feeding section, accommodating material feeding of different particle sizes and avoiding feeding blockages. It has a high material compression ratio, enabling full plasticization of materials, especially suitable for processing heat sensitive materials, as it can reduce the risk of material degradation due to high temperatures.

Application Scenarios of Tapered Twin Screw Extruders

Due to its good adaptability to heat sensitive materials, it is widely used in the extrusion molding of PVC pipes, profiles, sheets and other products, ensuring stable performance of PVC materials during processing. It is also applicable to the molding processing of some low melting point plastics, offering higher flexibility in small and medium batch production. It can meet the processing needs of multiple product types, making it suitable for small and medium sized manufacturing enterprises.

Core Differences Between Parallel and Tapered Twin Screw Extruders

The core differences between the two are mainly reflected in three dimensions: first, structural adaptability—parallel models are suitable for standardized mass production, while tapered models are suitable for materials with multiple particle sizes and heat sensitive properties; second, material processing range—parallel models focus on high uniformity mixing, while tapered models emphasize high compression ratio plasticization; third, processing stability—parallel models have stronger stability in continuous production, while tapered models offer better flexibility in small and medium batch production.

Classification by Application Scenarios: Types of Twin Screw Extruders Commonly Used in Key Industries

Significant differences exist in processing requirements (such as material characteristics, product specifications, and production capacity demands) across various industries, leading to distinct focuses on the corresponding types of twin screw extruders. The following section will specifically introduce suitable twin screw extruders, including co rotating parallel, counter rotating tapered, and counter rotating intermeshing types, focusing on three core fields: plastic processing, rubber and elastomer production, and biodegradable material processing.

Types of Twin Screw Extruders for Plastic Processing Industry

The plastic processing industry is the core application field of twin screw extruders. Based on different processed products, co rotating parallel twin screw extruders and counter rotating tapered twin screw extruders are mainly selected. Among them, co rotating parallel twin screw extruders are mostly used in high end processing scenarios such as modified plastics, masterbatches, and plastic alloys. Counter rotating tapered twin screw extruders focus on the molding processing of products like PVC pipes, profiles, and sheets, capable of adapting to the viscosity and molding requirements of different materials in plastic processing.

Types of Twin Screw Extruders for Rubber and Elastomer Production

Rubber and elastomer production have high requirements for equipment wear resistance and temperature control precision. Counter rotating intermeshing twin screw extruders and special co rotating twin screw extruders are mainly adopted. Counter rotating intermeshing twin screw extruders can achieve continuous mixing and plasticization of rubber materials, improving material uniformity. Special co rotating twin screw extruders are suitable for the modification and composite processing of elastomers, meeting the requirements for strength, elasticity, and other properties of rubber products. They are commonly used in production links such as seals, rubber pipes, and automotive rubber parts.

Types of Twin Screw Extruders for Biodegradable Material Processing

The processing of biodegradable materials (such as PLA and PBAT) has strict requirements for equipment mixing precision, temperature control, and environmental friendliness. Co rotating parallel twin screw extruders are mainly selected. This type of equipment can achieve uniform mixing of biodegradable materials and additives, precisely control processing temperature to avoid material degradation, and simultaneously possess high production efficiency. It is suitable for the production of products such as biodegradable films, tableware, and packaging materials, complying with the industry trend of green processing.

How to Choose the Right Type of Twin Screw Extruder for Different Industrial Needs

1.Clarify Processing Material Characteristics: Material characteristics are the core of model selection. Focus on viscosity, heat sensitivity, and filling level. For heat sensitive materials such as PVC, prioritize counter rotating tapered models or co rotating models with precise temperature control to shorten high temperature residence time and prevent degradation. For high filling materials such as high glass fiber modified plastics, select co rotating fully intermeshing models to ensure uniform mixing. For high viscosity materials such as rubber, counter rotating intermeshing models are recommended to guarantee stable high pressure conveying.

2.Product Type Determines the Extruder Model: For plastic modification such as glass fiber reinforcement and plastic alloy production, choose co rotating parallel models to ensure precise modification. For PVC pipe profile extrusion molding, select counter rotating tapered models to maintain stable product dimensions. For the processing of biodegradable materials such as PLA and PBAT, specialized co rotating models are ideal as they balance uniform mixing and degradation prevention.

3.Match Extruder Specifications Based on Production Capacity: For large scale continuous production such as mass masterbatch manufacturing, parallel models are preferred for their high stability and compatibility with automation. For small and medium batch multi product production such as multi specification pipes, tapered models offer flexible feeding and low switching costs.

4.Consider Long Term Usage Value: Prioritize models where energy consumption matches production capacity. Parallel models feature easier maintenance, making them suitable for long term large scale production. Choose models with modular design to facilitate subsequent upgrades of temperature control and mixing components, aligning with long term development needs.