Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing and extruding in one unit and directly affects product quality and production efficiency. Understanding its core information such as definition structure and working principle can help enterprises select models accurately and optimize production processes. This article will comprehensively analyze the twin screw mixing extruder from the aspects of basic definition key components and working principle core advantages and cross industry application scenarios.

What is a twin screw mixing extruder

A twin screw mixing extruder is an industrial equipment that takes two intermeshing or non intermeshing screws as its core working components. It pushes materials forward through the rotation of the screws and completes mixing, plasticizing, shearing, melting and extrusion molding of the materials during the conveying process. Compared with single screw extruders, it has more advantages in mixing uniformity, processing stability and adaptability to complex materials. Its core function is to carry out efficient mixing and modification treatment on various materials with different properties such as resins, fillers and additives, and finally extrude them into products or semi finished products of specific shapes. It is a key equipment for material modification and molding in the field of material processing.

Main Components of Twin Screw Mixing Extruder

The core components of a twin screw mixing extruder work in coordination to ensure the stable operation and processing efficiency of the equipment, mainly including the following categories:

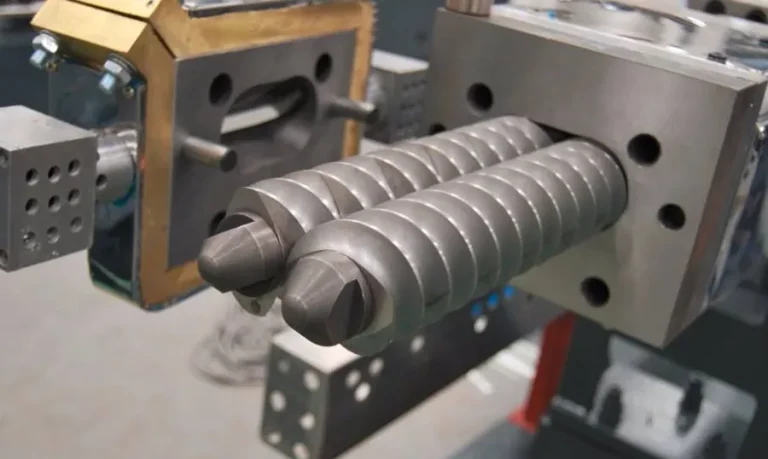

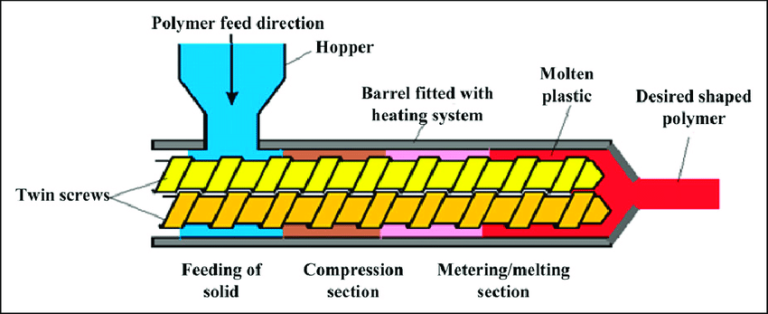

1.Screws: As the core working components of the equipment, screws are usually divided into four sections: feeding section, compression section, mixing section and extrusion section. Each section features distinct flight structure and pitch, undertaking the functions of material conveying, compression melting, shearing mixing and pressurized extrusion respectively. Based on the meshing method, screws can be classified into intermeshing type (co rotating or counter rotating) and nonintermeshing type. Among them, intermeshing screws offer better mixing effect and more stable material conveying performance.

2.Barrel: The barrel forms a closed processing chamber in conjunction with the screws, providing the processing space for materials while realizing the heating and plasticizing of materials through external heating devices. The inner wall of the barrel is generally made of wear resistant and corrosion resistant alloy materials to extend the service life of the equipment. Some barrels are also equipped with exhaust ports to discharge the gas generated during material processing, thereby improving product quality.

3.Feeding Device: Composed mainly of a feed hopper and a feeding screw, the feeding device is responsible for uniformly and stably conveying the materials to be processed into the barrel. The feeding speed of the device can be adjusted according to production requirements, ensuring that the material supply matches the processing rhythm of the screws. This prevents problems such as barrel blockage caused by excessive feeding or reduced processing efficiency due to insufficient feeding.

4.Transmission System: Consisting of components such as motor, reducer and coupling, the transmission system provides power for the rotation of the screws. It also enables precise control of screw speed by adjusting the motor speed. The stability of the transmission system directly affects the uniformity of screw speed, which in turn impacts the processing quality of materials.

5.Heating and Cooling System: The heating system usually adopts electric heating or oil heating methods to provide precise temperature control for different sections of the barrel, meeting the temperature requirements of materials in different processing stages. The cooling system is used to control the temperature of the screws and barrel, preventing material degradation caused by excessive temperature while ensuring the safe operation of the equipment.

6.Head and Die: The head connects the barrel and the die, playing the role of transition and pressurization. The die is designed according to the shape and specification of the product. After passing through the die, the materials are extruded into products with specific cross sectional shapes, such as pipes, plates and profiles.

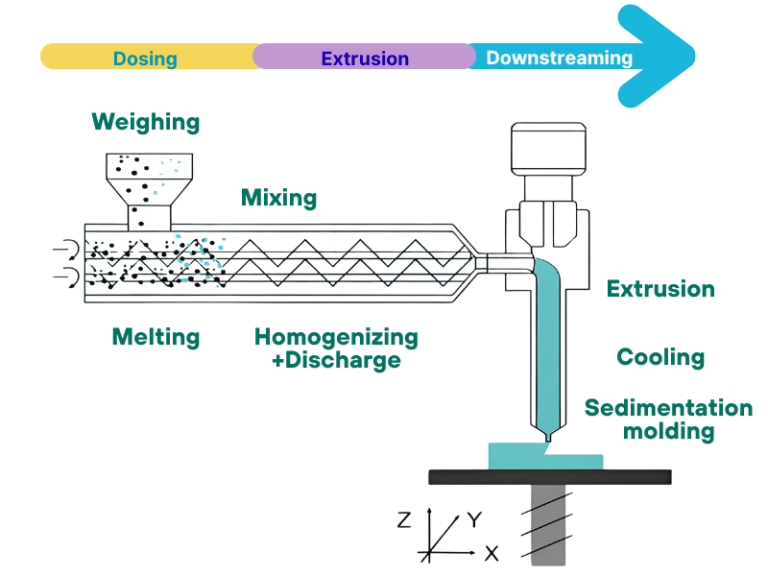

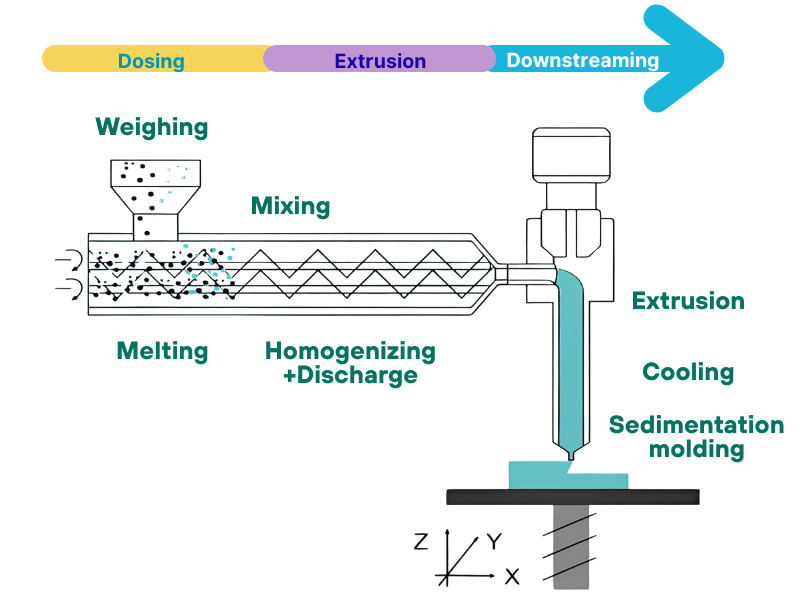

Working Principle of Twin Screw Mixing Extruder

The working process of a twin screw mixing extruder can be divided into four core stages: feeding, conveying and compression, mixing and melting, as well as extrusion molding. All these stages are closely connected with one another:

1.Feeding Stage: Solid materials to be processed such as granular or powdered resins and various additives enter the barrel through the feeding device. Driven by the transmission system, the two screws rotate synchronously and push the materials forward by virtue of the friction between the screw flights and the materials.

2.Conveying and Compression Stage: The materials are pushed into the compression section by the screws. As the screw pitch in this section gradually decreases or the depth of the screw channel becomes shallower, the volume of the materials is compressed. Meanwhile, under the effect of the barrel heating device, the materials start to soften gradually. During this process, air in the materials is squeezed out and part of the materials begins to melt preliminarily.

3.Mixing and Melting Stage: When the materials enter the mixing section, special mixing elements on the screws such as kneading blocks and toothed discs exert intense shearing, extruding and stirring forces on the materials, which enables the full and uniform mixing of materials with different components. At the same time, under the combined action of shear heat and barrel heating, the materials are completely melted to form a homogeneous melt.

4.Extrusion Molding Stage: The molten materials are pushed into the extrusion section by the continuous rotation of the screws. The screws pressurize the melt, forcing it to pass through the head and enter the die. The melt is formed into products consistent with the shape of the die cavity inside the die. After subsequent processes such as cooling and shaping, the final products are obtained.

What Are the Advantages of Twin Screw Mixing Extruders

With its unique structural design and working principle, the twin screw mixing extruder has many remarkable advantages in industrial production, which can effectively meet the efficient processing needs of enterprises:

1.High Mixing Uniformity and Excellent Material Modification

EffectCompared with single screw extruders, twin screws generate intense shearing and stirring effects on materials through the mutual meshing and rotation of the two screws. Especially when equipped with special mixing elements, they can achieve full mixing of materials with different components, including highly filled and high viscosity materials. Whether it is the mixing of resins and additives or the blending modification of different materials, the uniform distribution of all material components can be guaranteed, which greatly improves the quality stability of the final products.

2.High Processing Efficiency and Stable Production CapacityTwin

screws have stronger material conveying capacity and stable conveying process, which are not prone to material accumulation or conveying interruption. At the same time, their mixing and melting efficiency is higher, which can complete material processing in a shorter time and effectively improve the production capacity per unit time. In addition, the equipment has strong operational stability and small production capacity fluctuation, which can ensure the smooth progress of continuous production and reduce losses caused by production interruption.

3.Wide Material Adaptability and Strong Applicability

Twin screw mixing extruders can process a wide variety of materials, including various thermoplastic resins, thermosetting resins, elastomers, powder materials, highly filled materials with filling capacity up to more than 80 percent and fiber reinforced materials. Whether it is low viscosity or high viscosity materials, granular or powder materials, efficient processing can be achieved by reasonably adjusting the screw structure and processing parameters, which is suitable for a variety of different processing scenarios and product requirements.

4.Strong Controllability of the Processing Process and Stable Product Quality

The equipment is equipped with a precise temperature control system, speed regulation system and feeding regulation system, which can accurately control the key parameters in the processing process such as the temperature of each barrel section, screw speed and feeding speed. By optimizing these parameters, problems such as material degradation and excessive shearing can be effectively avoided, which ensures that the physical properties, appearance quality and other indicators of the products meet the standards stably and reduces the rate of defective products.

5.Relatively Low Energy Consumption and Good Production Economy

Although the initial investment of a twin screw mixing extruder is relatively high, its energy saving advantages gradually emerge during long term use. Due to its high mixing and melting efficiency, it consumes less energy while achieving the same processing effect. Meanwhile, the equipment has a long service life and low maintenance cost. Coupled with its high production capacity, it can effectively reduce the production cost per unit product and improve the production economy of enterprises.

Wide Cross Industry Application Scenarios of Twin Screw Mixing Extruders

With its excellent processing performance and wide material adaptability, the twin screw mixing extruder has been widely applied in multiple industrial fields, and has become one of the core equipment for material processing and product production in various industries:

1.Plastic Processing Industry

This is the most core application field of twin screw mixing extruders, covering the modification and molding of general purpose plastics, engineering plastics and specialty plastics. For example, in the reinforcement, toughening and flame retardant modification of general purpose plastics such as polypropylene and polyethylene, modified plastics with better performance are obtained after processing by twin screw mixing extruders with the addition of materials such as glass fiber, elastomers and flame retardants. In the alloying processing of engineering plastics such as polyamide, polycarbonate and polybutylene terephthalate, it can realize the blending of different engineering plastics and improve the comprehensive performance of the materials. In addition, it can also be used for the extrusion molding of plastic products such as films, pipes, profiles and plates.

2.Rubber Industry

It is used for the mixing, plasticizing and extrusion molding of rubber, such as the mixing of natural rubber and synthetic rubber, as well as the production of products such as rubber seals, rubber pipes and tire tread rubber. The twin screw mixing extruder can realize the uniform mixing of rubber with additives such as carbon black, vulcanizing agents and accelerators, improve the mechanical properties and service life of rubber products, and at the same time enhance the automation level and production efficiency of rubber processing.

3.Food Processing Industry

In food processing, it is mainly used for grain processing, modification of food raw materials and production of functional foods. For example, it can extrude and puff grains such as corn and rice to produce puffed food; it can modify starch to improve its stability, emulsibility and other properties for the production of food additives; it can also be used for the composite processing of functional ingredients such as protein and dietary fiber to produce fortified food.

4.Building Materials Industry

It is used for the production of new building materials, such as plastic door and window profiles, plastic pipes, thermal insulation materials and waterproof materials. The modification and molding of building materials raw materials by twin screw mixing extruders can improve the weather resistance, compressive strength, thermal insulation performance and other properties of building materials products, meeting the demand of the construction industry for high quality building materials. In addition, it can also be used for the composite processing of inorganic materials such as gypsum and cement to produce new composite building materials.

5.Chemical Industry

It is used for the processing and modification of chemical raw materials, such as the dispersion processing of pigments and dyes, the production of plastic color masterbatches, and the composite molding of various chemical additives. The twin screw mixing extruder can realize the uniform dispersion of pigments and dyes with carrier resins, improving the tinting strength and dispersibility of color masterbatches. In the processing of chemical additives, it can compound multiple additives to produce multi functional composite additives, meeting the application needs of different industries.

6.New Energy and New Materials Industry

It plays an important role in the production of new energy materials such as lithium battery cathode materials, anode materials and separator materials, as well as new functional materials such as conductive materials, thermal conductive materials and biodegradable materials. For example, in the processing of lithium battery cathode materials, the twin screw mixing extruder can realize the uniform mixing of cathode materials with binders and conductive agents, improving the conductivity and charge discharge performance of electrodes. In the processing of biodegradable materials such as polylactic acid and polybutylene adipate terephthalate, it can realize the modification and molding of materials, promoting the application of environmentally friendly materials.