Single Screw Extruder Working Principle

Understanding the working principle of the single-screw extruder is critical information for distributors to promote products accurately and for enterprises to select models correctly and perform operation and maintenance. It can effectively resolve production issues such as poor plasticization and low efficiency. This article will break down practical knowledge points from four aspects: overview of the working principle, impact on material plasticization, industry applications, and production process optimization, to facilitate the efficient application of the equipment.

Overview of the Working Principle of Single-Screw Extruders

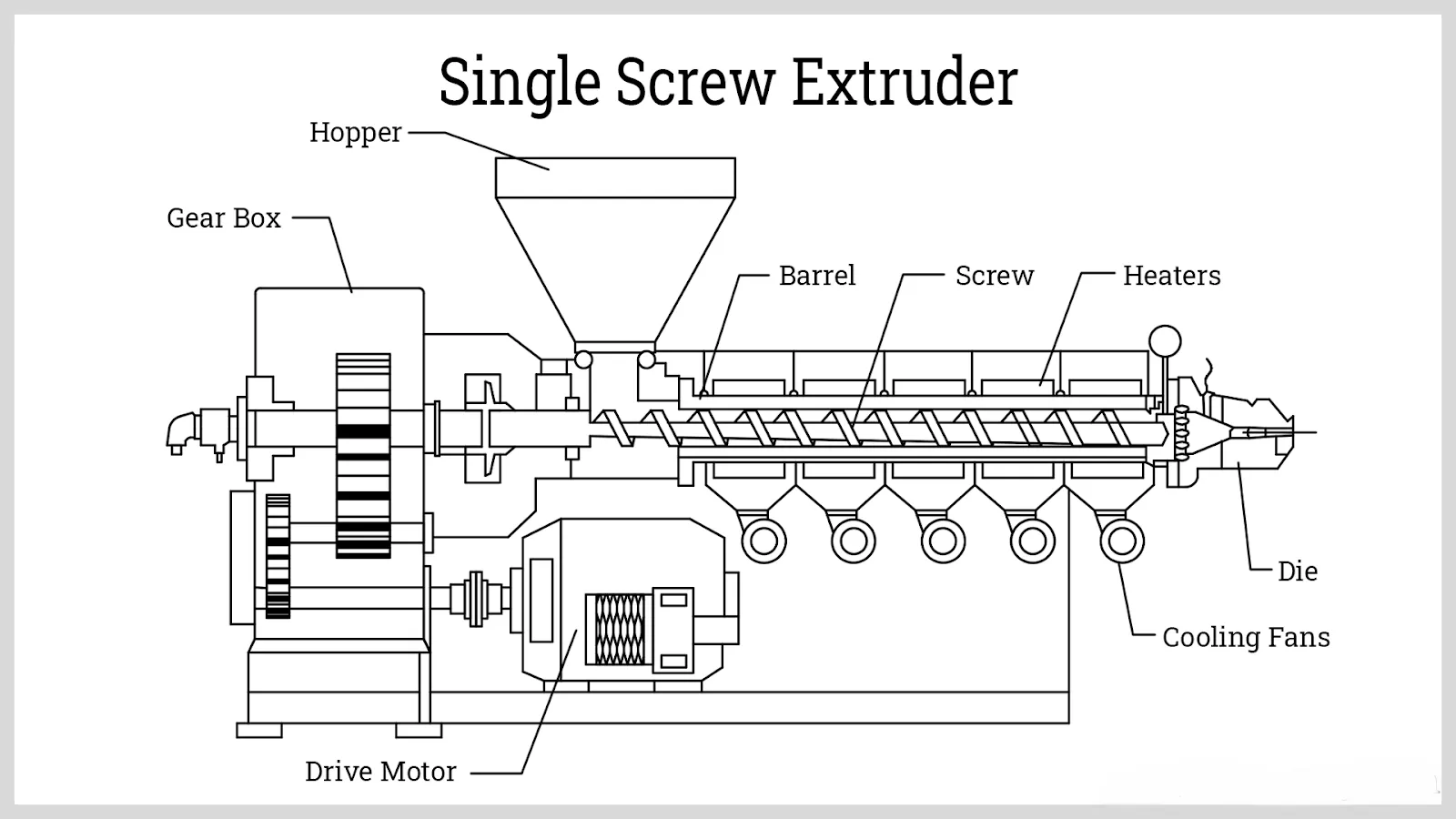

Core Components and Their Functions

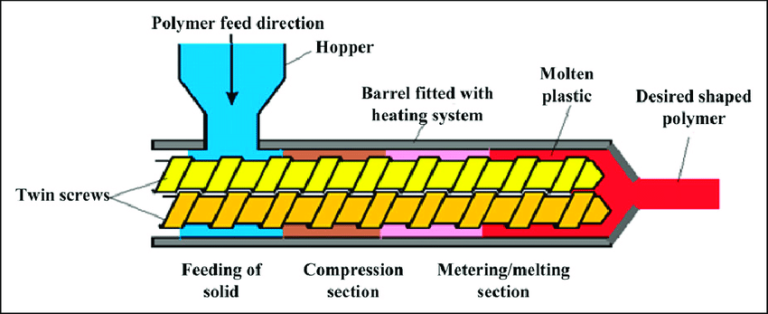

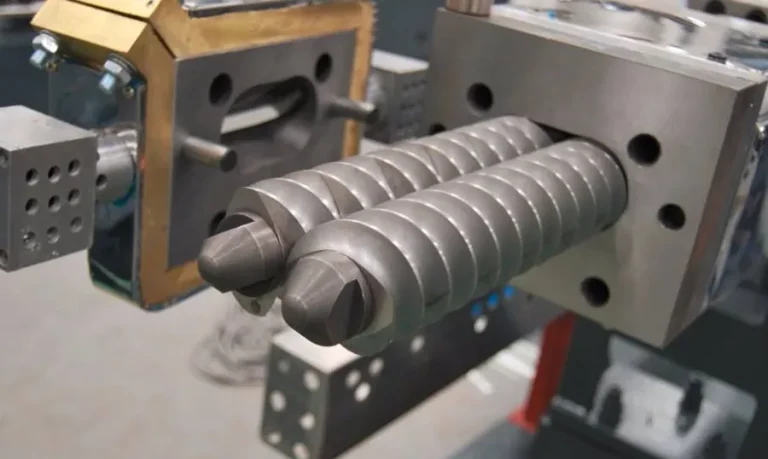

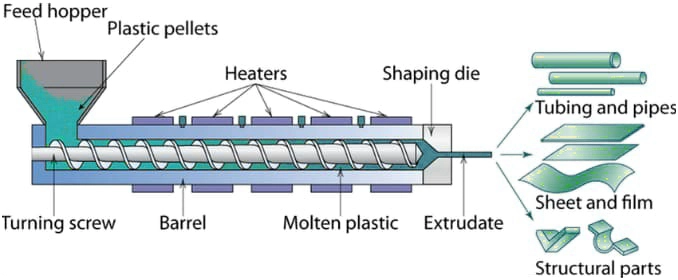

- Screw: The core moving component, functionally divided into the feed section, compression section, and metering section. It generates thrust through rotation and works in tandem with the barrel to transport, pressurize, and plasticize materials. Its pitch and length-to-diameter ratio directly influence operational efficiency.

- Barrel: Precisely mated with the screw to form a sealed working chamber. Heaters are attached to its outer surface to provide a stable temperature-controlled environment for materials. It also minimizes material leakage during transportation to ensure optimal plasticization results.

- Die Head: Also referred to as the extrusion die. Designed with a specific cross-sectional shape based on product requirements, it accurately controls the extrusion profile of the melt. It is a critical component that determines product specifications and dimensional accuracy.

- Heater: Typically features a zoned heating design, enabling precise temperature regulation across different barrel sections. This meets the gradual heating requirement for materials transitioning from a solid state to a molten state, preventing local overheating or insufficient heating.

- Drive Unit: Provides the power for screw rotation and allows for speed adjustment, which in turn controls material transport speed and residence time. It is a core control component adapted to the processing requirements of different materials.

A single-screw extruder consists primarily of a screw, barrel, die head, heater, and drive unit. As the core moving component, the screw propels materials forward through rotation. The barrel, in conjunction with the heater, delivers a temperature-controlled environment to ensure the phase transition of materials. The die head determines the cross-sectional shape of the final extruded product. All components work collaboratively to execute the extruder’s core working principle.

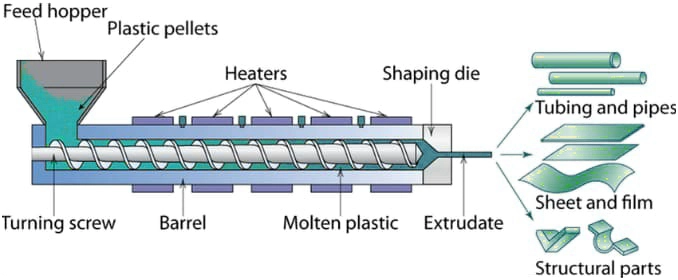

Core Working Process

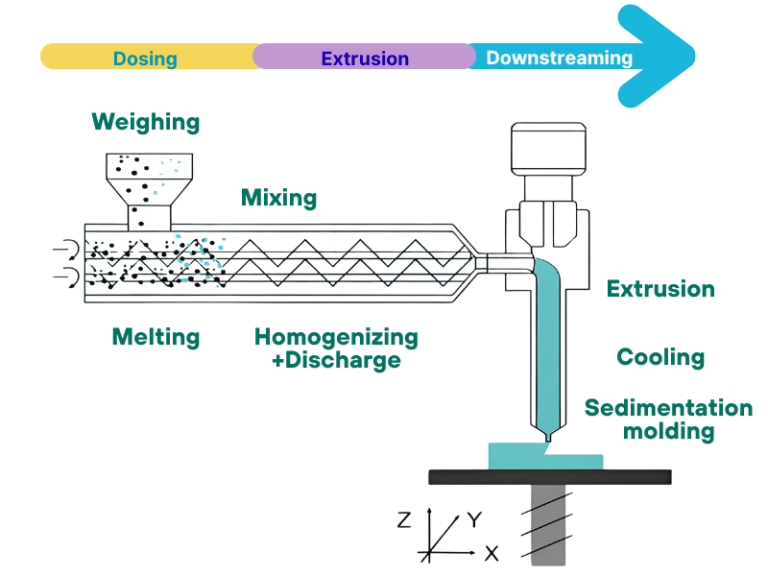

- Feeding and Conveying: After entering the barrel from the hopper, materials move forward under the rotational thrust of the screw’s feed section. Simultaneously, they undergo preliminary preheating to prepare for subsequent plasticization.

- Heating and Pressurization: As materials enter the compression section, the reduced screw pitch creates a gradually narrowing space. Combined with heat from the barrel heaters, materials are subjected to both compression and heating, initiating softening and melting.

- Melting and Plasticization: Upon reaching the metering section, materials are fully melted in a stable temperature and pressure environment, forming a homogeneous, impurity-free melt. The screw further homogenizes the melt to ensure consistent flow properties.

- Extrusion and Shaping: The homogeneous melt is pushed through the die head by the screw, extruding into the preset shape. It then passes through a cooling system to solidify, ultimately forming finished products that meet specifications and completing the entire processing cycle.

During operation, materials enter the barrel from the hopper and are conveyed forward by the screw’s rotational thrust. Throughout the process, heaters gradually raise the material temperature, while the screw’s compression section applies pressure. This causes materials to transition from a solid state to a fully molten and plasticized homogeneous melt. Finally, the melt is pushed through the die head by the screw and solidifies after cooling, resulting in products that meet specifications. This completes the full “conveying-plasticization-extrusion-shaping” process.

Impact of Single Screw Extruder Working Principles on Material Plasticization

The quality of material plasticization directly determines the qualification rate of extruded products, and the operational logic of the single screw extruder is the core factor influencing plasticization performance. Screw speed dictates the material residence time inside the barrel. Excessively high speed results in insufficient heating and pressurization of materials, leading to uneven plasticization and common product defects such as delamination and air bubbles. Conversely, excessively low speed reduces production efficiency and increases energy consumption.

At the same time, the compatibility between barrel temperature control and screw compression ratio requires precise regulation based on core working principles. A mismatch between heating temperature and screw conveying pressure can cause either over-plasticization and carbonization or insufficient plasticization of materials, both of which negatively impact key product metrics such as mechanical strength and surface finish. By properly controlling the synergistic relationship between temperature control, speed and pressure as outlined in the working principles, manufacturers can achieve simultaneous improvements in both the uniformity and stability of material plasticization.

Applications of Single Screw Extruder Working Principles in the Plastics, Packaging, and Building Materials Industries

1.Applications in the Plastics Industry

In the field of plastics processing, the single screw extruder’s principle of gradual plasticization and continuous extrusion enables the production of basic products such as plastic pipes, profiles, and films. For example, during the production of PVC pipes, adjusting the screw speed and temperature control ensures full plasticization of PVC resin. Meanwhile, the forming characteristics of the die head are utilized to guarantee uniform wall thickness and a smooth surface for the pipes, meeting the requirements for subsequent applications.

2.Applications in the Packaging Industry

Within the packaging industry, the working principle of this equipment is primarily used to manufacture packaging films, strapping bands, and preforms for plastic containers. Taking packaging film production as an example, the screw’s ability to uniformly plasticize materials is combined with specialized die heads to achieve film extrusion. Subsequent stretching and cooling processes then impart excellent flexibility and sealing performance to the films, making them suitable for packaging food products and industrial goods.

3.Applications in the Building Materials Industry

In the building materials sector, the extruder’s principle of high pressure extrusion and stable shaping is widely employed to produce products such as plastic drain pipes, underfloor heating pipes, and decorative trim. To meet the strength and weather resistance requirements of building materials, optimizing the screw compression ratio and temperature control parameters ensures more thorough material plasticization. This enhances the products’ compressive strength and anti aging properties, making them adaptable to the complex environments of construction projects.