Learn About the Applications of Single Screw Extruders

For equipment distributors and end user manufacturers, a thorough understanding of the application scenarios of single screw extruders is a core prerequisite for seizing market opportunities and optimizing production configurations. For distributors, clear knowledge of application scenarios helps determine a product’s market coverage and profit potential, enabling precise alignment with the needs of local end users. For end user manufacturers, clarifying the equipment’s application scope and suitable scenarios can effectively reduce selection costs and improve production line efficiency. This article will systematically break down the core application fields of single screw extruders, their scenario specific advantages compared to twin screw extruders, and the adaptation logic for different materials, providing readers with a comprehensive guide that is both practical and referential.

Applications of Single Screw Extruders

With core advantages of strong versatility, easy operation and high cost performance, single screw extruders have become fundamental processing equipment across multiple industrial sectors. Their application scenarios cover both basic raw material processing and end product manufacturing, with the key areas as follows:

1.Rubber and Plastic Processing Industry

This is the most core application area for single screw extruders, which are compatible with a variety of rubber and plastic raw materials such as polyethylene, polypropylene, PVC and ABS. They can produce end products including plastic pipes, profiles, films and cable sheaths, and also complete rubber extrusion molding and pre vulcanization treatment. They are essential equipment for rubber and plastic processing enterprises to build basic production lines.

2.Food Processing Industry

Single screw extruders that meet food grade material standards are widely used in the production of products such as grain puffed food, pet food, noodles and vegetarian products. The extrusion process achieves cooking, sterilization, molding and puffing of materials. Some models support automated continuous production, which can effectively improve the production efficiency of food processing enterprises.

3.Chemical Production Industry

They are suitable for the mixing, stirring and extrusion of viscous materials such as coatings, adhesives and sealants, and can also complete the granulation, molding and modification treatment of chemical raw materials. Their characteristic of being compatible with high viscosity and low corrosiveness chemical materials helps chemical enterprises efficiently complete intermediate material processing or end product manufacturing.

4.Building Materials Manufacturing Industry

They can produce construction products such as plastic door and window profiles, water supply and drainage pipes, thermal insulation materials and waterproof membranes. The equipment must meet the building materials industry’s requirements for product specification accuracy, durability and environmental friendliness, helping construction projects achieve energy saving and efficient construction.

Single Screw Extruders vs. Twin Screw Extruders in Applications: Advantages in Specific Scenarios

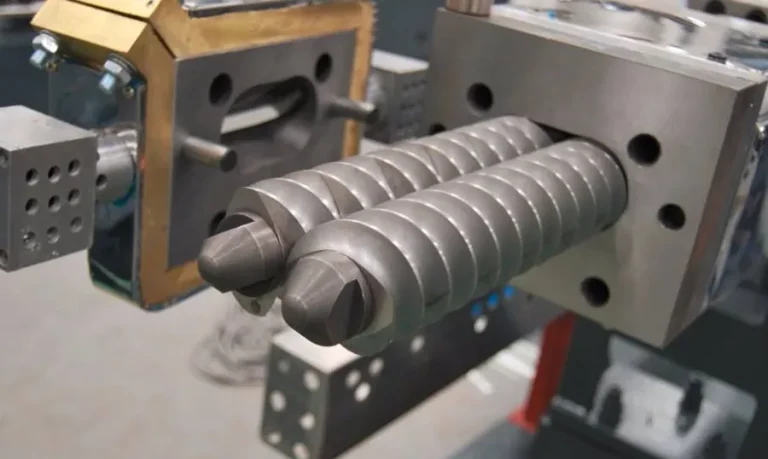

Single screw extruders and twin screw extruders are not substitutes for each other but complementary options tailored to different application scenarios. In specific use cases, single screw extruders offer irreplaceable advantages, which are detailed as follows:

1.Small and Medium Scale Production Scenarios

Single screw extruders feature a simple structure and lower manufacturing and maintenance costs, making them ideal for small and medium sized production enterprises or startup factories. Unlike twin screw extruders, they do not require high equipment investment or specialized maintenance teams. They can meet basic processing needs with high cost performance, which is also a core selling point for distributors when expanding the small and medium sized customer market.

2.General Purpose Multi Product Processing Scenarios

By replacing the screw and die and adjusting process parameters, single screw extruders can quickly adapt to a variety of materials and product types without the need for separate dedicated equipment. This high versatility gives them a distinct advantage in multi product, small batch processing scenarios. They are particularly suitable for end user enterprises with diverse product lines or distributors looking to serve customers across multiple sectors.

3.Cost Sensitive Project Scenarios

For projects with strict cost control requirements, the high cost performance advantage of single screw extruders is particularly prominent. Their equipment procurement costs, energy consumption costs and long term maintenance costs are all lower than those of twin screw extruders. On the premise of meeting basic product quality requirements, they can effectively help end user enterprises reduce production costs and enhance the market competitiveness of their products.

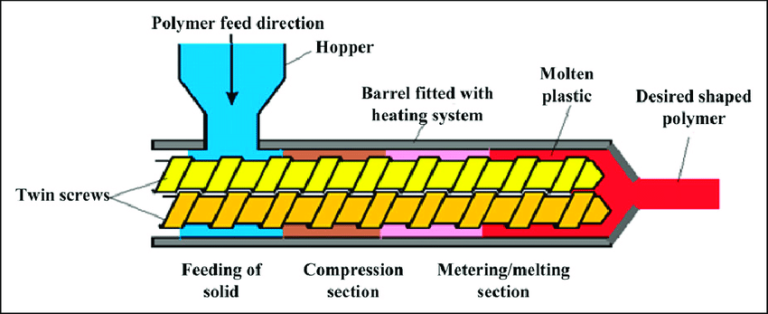

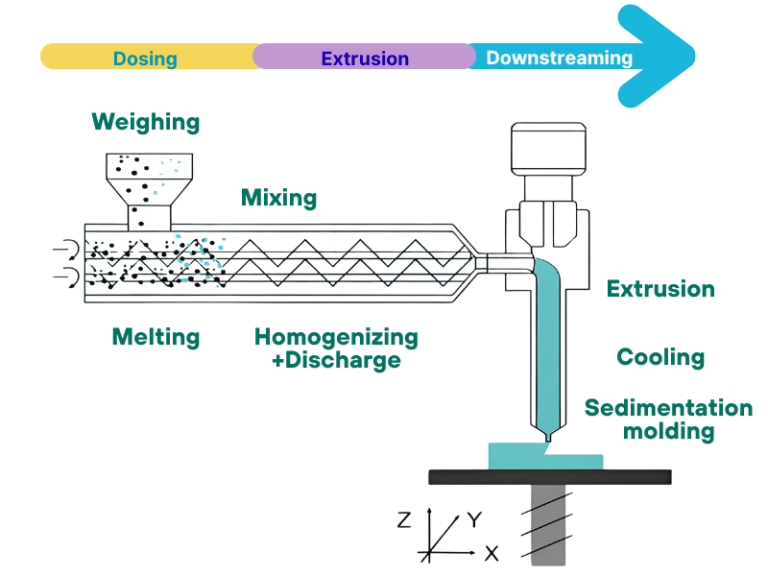

Material Compatibility in the Application of Single Screw Extruders

The application performance of a single screw extruder is directly related to its compatibility with material properties. Materials with different viscosity, heat sensitivity and hardness require matching screw types and equipment configurations to ensure uniform plasticization and stable extrusion. The core compatibility principles are as follows:

1.Compatibility with Standard Materials

For standard low viscosity non heat sensitive materials such as polyethylene and polypropylene, a general purpose single screw extruder is sufficient to meet the requirements. Such equipment adopts standard screw and barrel configurations, features easy operation and does not require complex process adjustments. It can efficiently complete basic extrusion molding tasks and is the most widely used model in the market.

2.Compatibility with Heat Sensitive Materials

Heat sensitive materials such as PVC and certain engineering plastics are prone to decomposition and discoloration due to excessive local temperature. For these materials, gradual change type screws and models with segmented temperature control should be selected. The gradual change type screw has a gentle variation in screw channel depth, which can avoid local overheating caused by excessive material pressure. The segmented temperature control system can accurately control the temperature of each section of the barrel, ensuring a stable and controllable material plasticization process.

3.Compatibility with High Viscosity Materials

Materials such as rubber and high viscosity resins have poor fluidity and require greater extrusion pressure and shearing force. In such cases, abrupt change type screws and high power drive models should be chosen. The abrupt change type screw has a sharp reduction in screw channel depth over a short distance, which can quickly increase material pressure. The high power drive system provides sufficient power for screw rotation, ensuring smooth plasticization and extrusion of materials.