Energy Save

Yield Rate

Temp Precision

Eco Cert

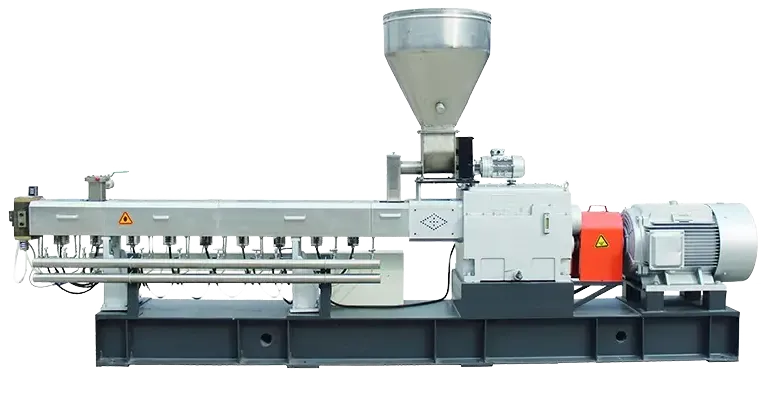

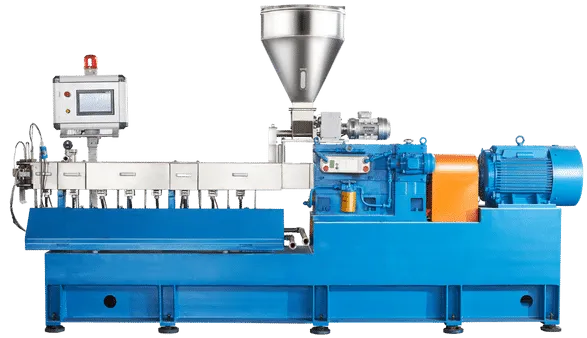

UET Machine Recycled Plastic Extruder Solutions

UET Recycled Plastic Extruder Solutions: streamline your equipment operation process

Tolerates over 30% impurity content in recycled materials, features wear resistant screens to lower clogging risks, reduces downtime and effectively boosts continuous production efficiency.

Adopts high efficiency variable frequency drive and energy saving temperature control design for optimization, saves 20% more energy than standard models and lowers electricity costs with long term use.

Relies on precise temperature control of ±1℃ and uniform mixing structure, limits performance fluctuation of recycled products within 2% to ensure consistent batch quality meeting downstream processing standards.

Equipment emissions comply with key international RoHS and REACH standards, VOC emissions levels are far below limits, meeting market environmental access requirements and avoiding compliance risks.

Handles over 6 types of common key recycled materials including PP PE ABS and high fill systems, no frequent parameter adjustments needed for material processing scenarios with complex material varieties.

Core components are made of durable wear resistant alloy materials, maintenance intervals extended to over 180 days, easy replacement of consumables reduces downtime for maintenance.

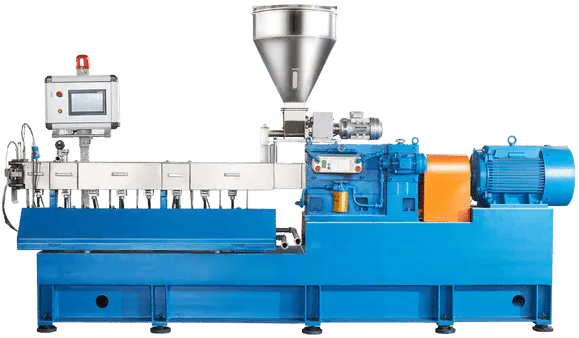

Recycled Plastic Extruders for Sale

UET Machine delivers high-quality recycled plastic extruders that accommodate a wide range of recycled material processing needs, are easy to operate, and maintain consistent operational reliability.

Energy Saving Precision Recycled Plastic Extruder

Features variable frequency drive and ±1℃ precision temperature control, saves 20% energy vs standard models, controls product performance fluctuation within 2%. Intelligent operation easy maintenance eco friendly durable materials solve high energy consumption and unstable quality.

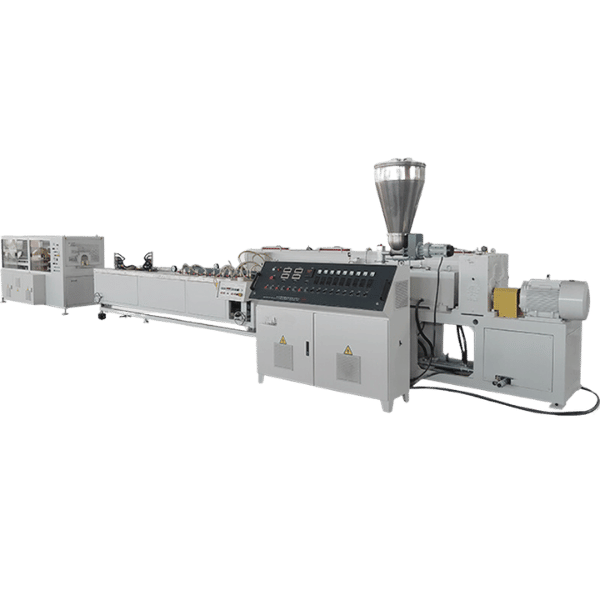

High Capacity Smart Recycled Plastic Extruder

Offers 500 to 2000kg per hour adjustable capacity, smart process preset system enables quick production switching without frequent debugging. Variable frequency energy saving design cuts electricity costs, outstanding batch efficiency solves insufficient capacity and cumbersome debugging.

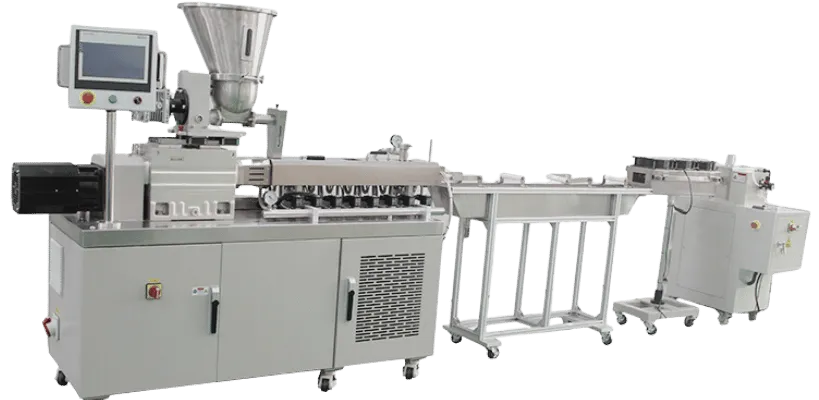

Multi Material Compatible Recycled Plastic Extruder

Supports over 6 key recycled material types including PP PE ABS grades and high fill systems, 10+ preset programs enable easy flexible efficient material switching. Corrosion resistant materials meet environmental standards, solving complex material varieties and poor adaptability.

UET Recycled Plastic Extruder Specifications

| Feature | Specification |

|---|---|

| Recycled Material Compatibility | PP/PE/ABS/PS + High-Fill Recycled Blends |

| Screw Configuration | Twin-Screw (Wear-Resistant Alloy Construction) |

| Automation Level | Full-Automatic (12+ Smart Process Presets) |

| Certification | CE, ISO9001:2015, RoHS |

| Equipment Condition | Brand-New |

| Processing Capacity | 600-2000 Kg/H (Adjustable by Material Type) |

| Material Impurity Tolerance | Up to 35% (For Dry Recycled Materials) |

| Energy Efficiency Rating | Class A (20% Energy Saving vs Standard Models) |

| Electric Component Brands | Siemens/Schneider (ABB as Optional Upgrade) |

| Control System | PLC + 10-inch Touch Screen (Remote Monitoring Opt) |

| Extruder Net Weight | 1200 kg |

| Transport Package | Seaworthy Fumigation-Free Wooden Crate + Pallet |

| Brand | UET |

| Country of Origin | China |

| Annual Production Capacity | 250 sets/Year |

Different Models of UET Recycled Plastic Extruders

| Feature | UET-25 | UET-40 | UET-55 | UET-70 | UET-85 | UET-130 |

|---|---|---|---|---|---|---|

| Screw Diameter (MM) | 25.2 | 40.8 | 55.3 | 70.2 | 85.1 | 130.4 |

| Central Distance (MM) | 20 | 34 | 46 | 58 | 72 | 108 |

| Length Diameter Ratio | 30-55 | 30-55 | 30-55 | 30-55 | 30-55 | 28-52 |

| Main Motor Power (kW) | 5-7.5 | 25-50 | 80-120 | 120-200 | 170-300 | 95-170 |

| Max. Screw Speed (RPM) | 600 | 600 | 600 | 600 | 580 | 550 |

| Output Torque per Shaft (N.m) | 35-48 | 180-370 | 620-900 | 900-1500 | 1300-2300 | 900-1600 |

| Reference Output (KG/HOUR) | 50-80 | 30-100 | 90-220 | 160-380 | 320-650 | 850-1600 |

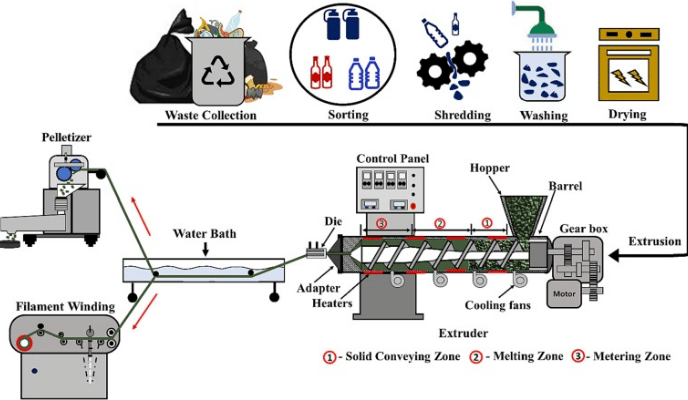

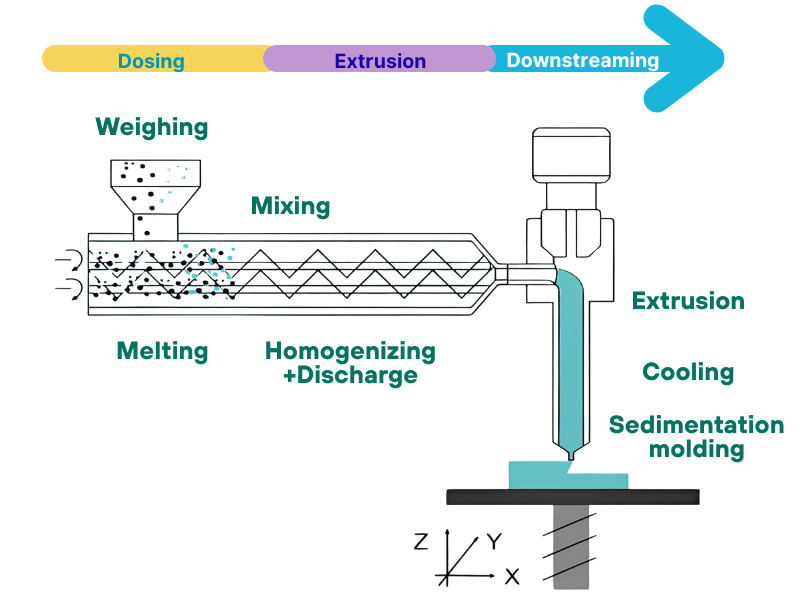

Flowchart of the Plastic Recycling Extruder

Flowchart of the Plastic Recycling Extruder/Image Source:sciencedirect.com

UET Recycled Plastic Extruder Factory

Welcome to the UET Recycled Plastic Extruder Factory. We maintain extremely rigorous standardized quality inspection procedures to ensure our equipment is compatible with a wide range of recycled materials, while maintaining consistent and reliable operational performance.

Customer Reviews for UET Recycled Plastic Extruders

Check out the real customer reviews for UET Recycled Plastic Extruders to learn how UET equipment helps customers meet their mass production needs for recycled materials.

Having used UET equipment nearly a year it has never jammed processing PP recycled materials with mixed impurities. It is more energy efficient than the previous brand daily maintenance is simple basic cleaning no frequent overhauls needed. When a minor part issue arose last time after sales provided a solution the same day reliable and hassle free.

David Carter ,Plastic Recycling

The equipment has run continuously for a reliable eight consecutive months without any faults the intelligent control system is easy to operate even for non technical staff to master quickly. The qualified product rate has increased from 92 percent to 98 percent fully complying with strict global environmental compliance standards.

Emily Rodriguez ,Packaging Materials

For the processing needs of 50 percent calcium carbonate high fill recycled materials the equipment achieves uniform plasticization with extrusion stability far exceeding expectations. It has 25 percent higher capacity than the previous brand with low noise easy cleaning prompt after sales response and professional technical support.

Michael Bennett ,Construction Materials

After replacing old equipment recycled material processing efficiency has increased by 30 percent and production cost per ton has decreased by 12 percent. It is compatible with multiple recycled materials like ABS PS with quick material change commissioning intuitive PLC touch screen operation very well adapting to multi batch small batch production needs.

Sarah Wilson ,Automotive Parts Supply

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:The minimum order quantity for standard model Recycled Plastic Extruders is 1 unit supporting small batch trial orders. For customized models such as those with special screw configurations or capacity adapted designs the minimum order quantity is 3 units. Volume purchases are eligible for volume based pricing discounts. Specific minimum order quantities and quotes can be negotiated and adjusted according to procurement needs to meet the production and budget requirements of different customers.

A:UET Recycled Plastic Extruders come with a 1 year whole machine warranty and the warranty period for core components including screws barrels motors and PLC control systems is extended to 24 months. During the warranty period free fault repair and spare parts replacement services are provided. After the warranty period cost price spare parts supply and technical support are offered for life to ensure the long term stable operation of the equipment.

A:Yes UET provides free remote installation commissioning guidance and operational technical training covering equipment installation processes parameter settings daily operations basic maintenance and other content. If on site services are required engineers can be arranged to visit after negotiation with travel expenses borne by the customer. Detailed Chinese and English technical manuals and video tutorials are also provided.

A:Common international payment methods are supported including Telegraphic Transfer (T/T) Letter of Credit (L/C) and Western Union. An installment payment model of 30% advance payment plus 70% payment before shipment is also accepted. For long term cooperative customers or large value orders more flexible payment terms can be negotiated to ensure the capital safety and smooth cooperation of both parties.

A:UET Recycled Plastic Extruders can adapt to common general purpose plastic recycled materials such as PP PE ABS PS and PVC. They can also process high filled recycled materials with calcium carbonate or talc powder filling ratio up to 50% mixed recycled materials with a small amount of impurities up to 30% and recycled materials of different forms including crushed materials film materials and runner materials. They are widely used in plastic recycling packaging building materials and other industries.

A:Material blocking is mostly caused by excessive impurities in raw materials improper temperature control or screw material accumulation. It is recommended to first perform screening for impurities and drying treatment on recycled materials. Adjust the temperature of each section of the barrel to the range suitable for the raw materials to avoid incomplete plasticization due to low temperature. Regularly clean the screw and barrel check if the filter is blocked and replace it in a timely manner. Reasonably control the feeding speed to ensure uniform extrusion of materials.

A:The replacement cycle of core wear parts such as screws and barrels is 6 to 12 months depending on the impurity content and hardness of the processed raw materials. Regular wear parts such as filters and seals are recommended to be inspected and replaced every 3 to 6 months. Components such as motors and bearings can be used for 3 to 5 years under normal maintenance. Regular maintenance can extend the service life of wearing parts. UET provides the supply of standardized wear parts to ensure convenient replacement.

A:Yes UET Recycled Plastic Extruders have optimized the screw structure and temperature control system for heat sensitive recycled materials such as PVC and PET. They adopt low temperature plasticization design and precise PID temperature control to avoid overheating and degradation of materials. Equipped with a venting device volatile substances can be discharged to improve the quality of finished products. It is recommended to control the barrel temperature at the lower limit of the raw material melting point during processing and appropriately increase the screw speed to shorten the material residence time.