Melt Homogeneity

Temp Control Precision

Energy Efficiency

Cooling Uniformity

UET’s Engineering Plastic Extrusion Line Solutions

UET Engineering Plastic Extrusion Line: adapt to diverse engineering plastic types and maintain consistent product quality standards

To address uneven mixing and component separation of engineering melts optimize screw configuration and temp control enhance melt mixing and ensure uniform structure and stable mechanical properties.

To resolve over tolerances and size variation of engineering plastic parts precisely adjust extrusion parameters and shaping systems improve dimensional control and meet mass production needs of precision components.

To address poor equipment stability in high temperature processing conditions optimize machine structure and sealing design improve heat resistance and ensure continuous production without abnormal stops.

To tackle high raw material loss and cost pressure in engineering plastic processing optimize extrusion processes and material compatibility reduce molding waste and improve utilization rate of high end materials.

To resolve limited compatibility with various engineering plastics optimize screw configuration and process systems support materials like PA PC POM and meet processing needs of diverse products.

To address complex equipment maintenance and high technical thresholds optimize intelligent control systems and wear part design simplify maintenance steps extend maintenance cycles and reduce labor and time costs.

Engineering Plastic Extrusion Lines for Sale

Looking for a reliable Engineering Plastic Extrusion Line? UET Machine has equipment that fully meets your production needs covering the processing requirements of various engineering plastic formulations.

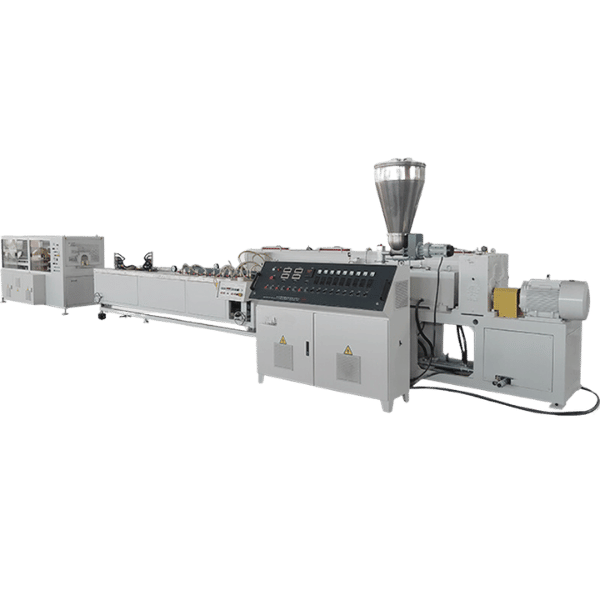

Precision Molding Extrusion Line

Adopts precision temp control and screw optimization size tolerance ≤ ±0.03mm suitable for PA PC POM and other engineering plastics. Supports multilingual operation meets UL standards simplifies maintenance meets high precision needs for auto parts and electronics.

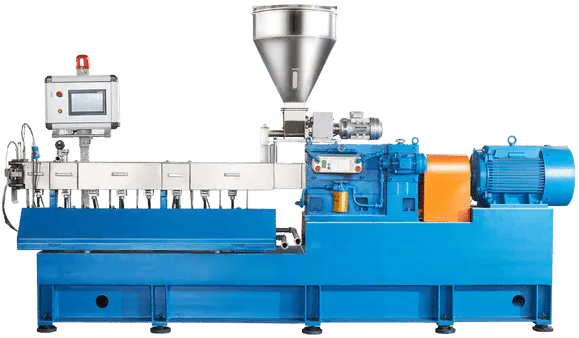

High Efficiency Stable Extrusion Line

Optimizes power system and heating structure energy consumption 18% lower than traditional lines supports 24 hour continuous operation. Mold change ≤15 minutes noise ≤73dB meets CE standards enhances production consistency and cost control.

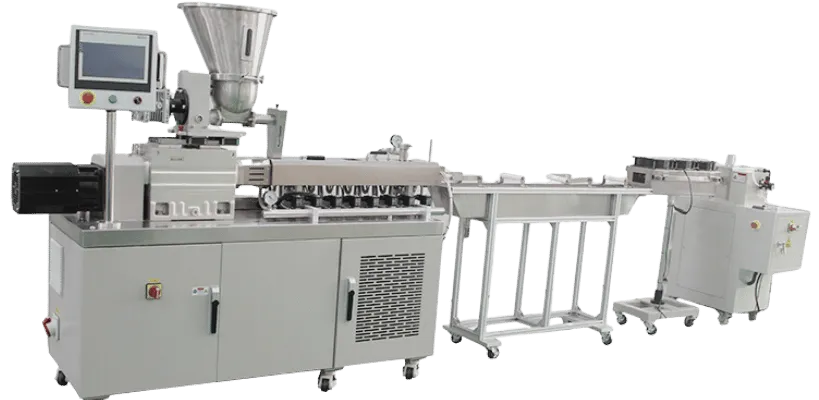

Multi Formula Compatible Extrusion Line

Compatible with 12+ engineering plastic formulas including PBT PET and PPS equipped with intelligent parameter storage for 150+ process schemes. Corrosion resistant body adapts to high temp conditions widely used in industrial parts and medical devices.

UET Engineering Plastic Extrusion Line Specifications

| Feature | Details |

|---|---|

| Trademark | UET |

| Origin | China |

| Production Capacity | 300–1200 kg/h (varies by material type & product specification) |

| Screw Configuration | Twin-screw (co-rotating, high-mixing type; optimized for engineering plastic homogenization) |

| Automation Level | Full-automated integrated line (covers feeding, extrusion, cooling, cutting, and semi-packaging) |

| Certifications | CE, ISO 9001:2015, UL |

| Machine Condition | Brand-new (pre-delivery factory acceptance test included) |

| After-sales Service | 1-year full line warranty; 2-year core component warranty (motor/gearbox); 72-hour technical response for overseas clients |

| Key Electrical Components | Inverter (Siemens/ABB, customizable per regional preference); Contactor (Schneider) |

| Suitable Materials | Engineering plastics (PC, PA6/66, POM, ABS, PBT, modified PP) |

| Finished Product Types | Engineering plastic profiles, structural load-bearing pipes, precision industrial components |

| Product Dimension Range | 20–500 mm (custom die heads available for special-shaped products) |

| Pipe Diameter | 30–400 mm (for structural load-bearing pipe products) |

| Control System | PLC + HMI touchscreen |

| Packaging Type | Export-fumigated wooden crates |

| Core Advantages | High material mixing uniformity (≤3% composition deviation); 10% lower energy consumption than industry average; modular design for quick process reconfiguration |

| Material Homogenization Tolerance | ≤3% |

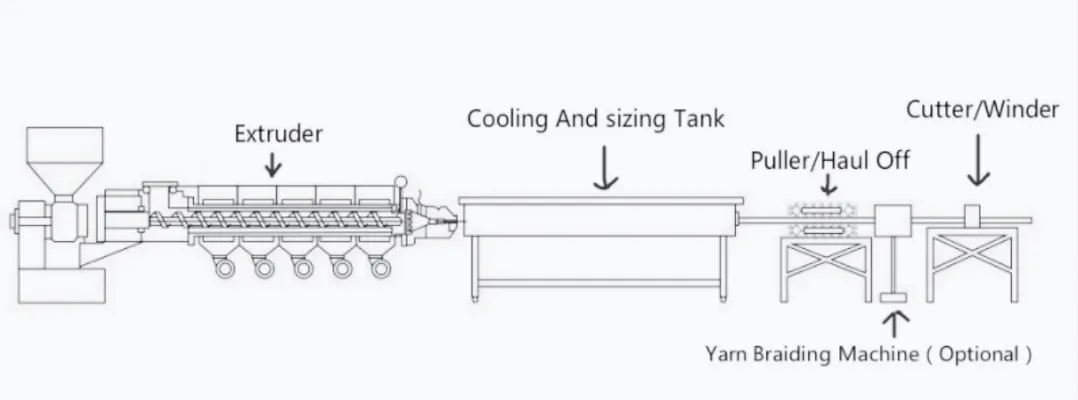

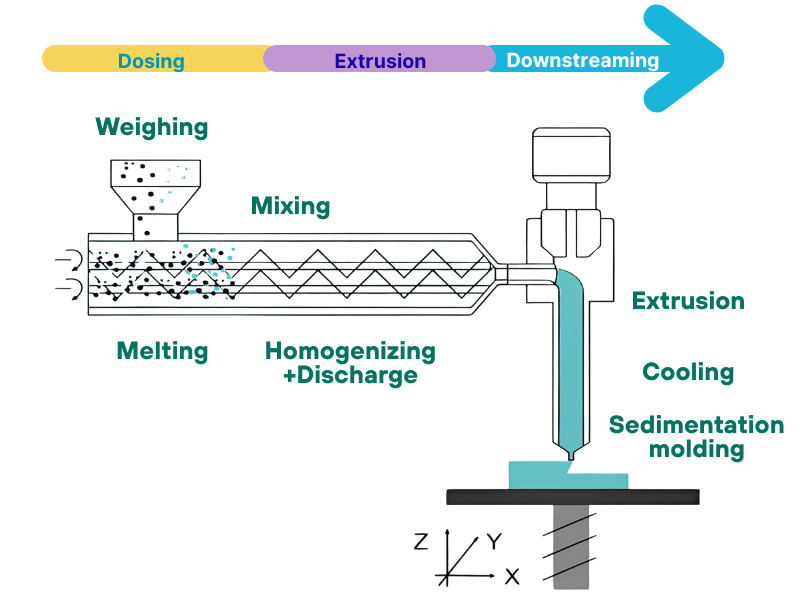

Flowchart of the Engineering Plastic Extrusion Line

Flowchart of the Engineering Plastic Extrusion Line

UET Engineering Plastic Extrusion Line Factory

Welcome to UET Engineering Plastic Extrusion Line Factory. As a leading manufacturer of extrusion molding equipment in China we have many years of experience in extruder manufacturing.

Customer Reviews for UET Engineering Plastic Extrusion Lines

Learn about the authentic reviews from some users who have used UET Engineering Plastic Extrusion Lines and see how we help customers solve their production challenges.

We used the UET engineering plastic extrusion line for six months. It operates stably with no breakdowns and has high extrusion precision. The dimensional deviation of finished products is strictly controlled within 0.02mm. The user friendly interface lets new staff master operations quickly. After sales technical support responds promptly, fully meeting our mass production needs.

Mike Thompson ,Production Manager

The UET equipment has excellent compatibility and can process various engineering plastics like PA, PC and POM. Its precise temperature control system ensures stable mechanical properties of finished products. Post commissioning capacity rose 25 percent, reject rate fell 18 percent. It delivers far better value than similar models and is highly recommended.

Lisa Müller ,Technical Supervisor

We selected the UET engineering plastic extrusion line after comparing multiple suppliers. The equipment has a robust and durable body, with energy consumption 12 percent lower than industry standards and low operation noise. The installation team is professional and efficient, with controllable long term maintenance costs, making it a high value production investment.

Juan García ,Purchasing Director

The UET equipment has been in continuous use for three months, with no major breakdowns reported so far. It features a wide adjustable range of extrusion speed, suitable for producing products of different thicknesses. Pre sales custom solutions are thoughtful, with regular post sales follow up guidance, making it our reliable production partner.

Aisha Patel ,Factory Manager

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:Mainstream models can process general engineering plastics such as PA PC POM PET and PPO. Some high end models are compatible with special engineering plastics like PEEK and PI. Different plastics require matching screw structures temperature control systems and molds. Some materials also need vacuum venting or dedicated feeding devices.

A:Standard production lines can process engineering plastics with low glass fiber content (≤15%). For high glass fiber content (≥20%) it is necessary to replace with wear resistant screws and barrels upgrade the high torque transmission system and optimize the temperature control curve. This prevents glass fiber agglomeration or excessive equipment wear.

A:The core steps include thoroughly cleaning residual materials in the screw barrel and mold after production checking the accuracy of the temperature control system and electrical circuits lubricating transmission components and bearings tightening connection bolts regularly testing screw wear and replacing aging seals and wearing parts.

A:It can be seamlessly integrated with in line diameter measurement thickness testing surface defect detection equipment and automatic cutting and fixed length blanking devices. The PLC control system enables data linkage to adjust extrusion parameters in real time achieving full process automated production and quality control.

A:The core influencing factors include screw diameter and length to diameter ratio material melt fluidity temperature control system stability mold structure rationality and the degree of production line automation. When running stably at full load the production capacity is more likely to meet the design standard and the energy consumption is also more optimal.

A:The warranty period for core components such as screws barrels main motors and gearboxes is usually 12 to 24 months. The electrical control system generally has a 12 month warranty. The specific duration depends on component materials and manufacturer policies. Standard operation and maintenance can extend the actual service life.

A:It is necessary to configure a precise closed loop temperature control system to avoid material overheating and decomposition. Adopt a low shear screw design to ensure uniform dispersion of flame retardants. Some models need to add a vacuum venting device to discharge small molecule gases generated during processing ensuring stable product performance.

A:Small production lines have small screw diameters and low output. They are suitable for laboratory research and development small batch customized production or processing of precision small products. Large production lines have large screw diameters and high output. They are suitable for large scale standardized production of large products or continuous production with high output demand.

A:It is necessary to optimize the screw speed and temperature control curve to ensure uniform material plasticization. Regularly calibrate molds and in line inspection equipment. Adopt an automatic closed loop control system to adjust parameters in real time. Recycle qualified edge materials in a certain proportion and standardize operating procedures to reduce human errors.