Bio Material FDA Compliance

Product Batch Consistency

Low Temp Extrusion Stability

GMP Process Compliance Rate

UET Machine Bio Extruder Solutions

UET Bio Extruder Full Scope Solutions, Bio Material Processing Challenges.

Covers processing needs for bio based materials like biopolymers and biomass. We offer parallel small lab type Bio Extruders for all scenarios from formula R&D to large scale mass production.

Uses low temperature extrusion process and millisecond precision temperature control system. It retains over 90% of bio active ingredients, preserves core functions of bio products, fitting heat sensitive bio materials.

Equips sterile cavity structure and residue proof design, paired with closed feeding system. It achieves class 100 clean processing environment, fitting high hygiene standard bio product production.

Relies on modular screw components and intelligent process parameter library. It completes parameter debugging for new bio material formulas within 8 hours, responding efficiently to personalized needs.

Adopts dedicated screw conveying structure design. It maintains continuous stable operation despite high viscosity and stickiness of bio materials, supporting mass production efficiency of bio products.

Equipment and processes meet strict standards in bio processing field. It comes with complete production process technical documents, ensuring compliance and reliability throughout bio product production.

Bio Extruder for sale

UET Machine delivers high quality Bio Extruders, compatible with a wide range of bio materials, offering stable and reliable performance.

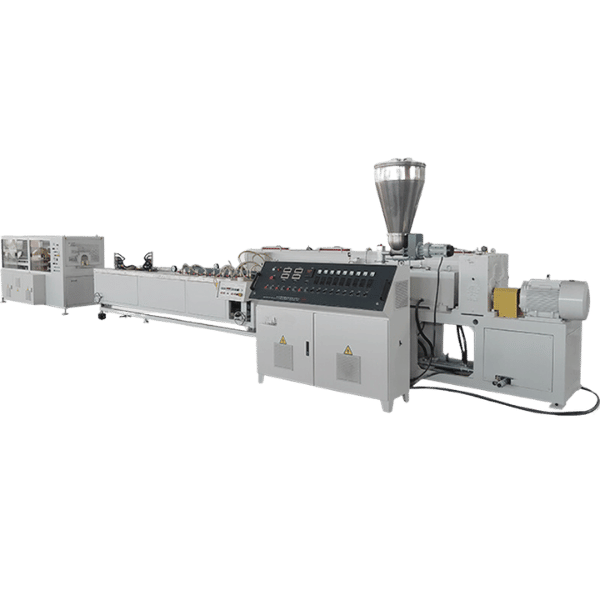

LabScale Bio Extruder

Designed for formula R&D and small batch production, it features precision temperature control system and modular screw components, compatible with biopolymers, biomass and more. Compact and easy to operate, it enables quick process parameter switching to meet core laboratory innovation R&D and small scale sample prep needs.

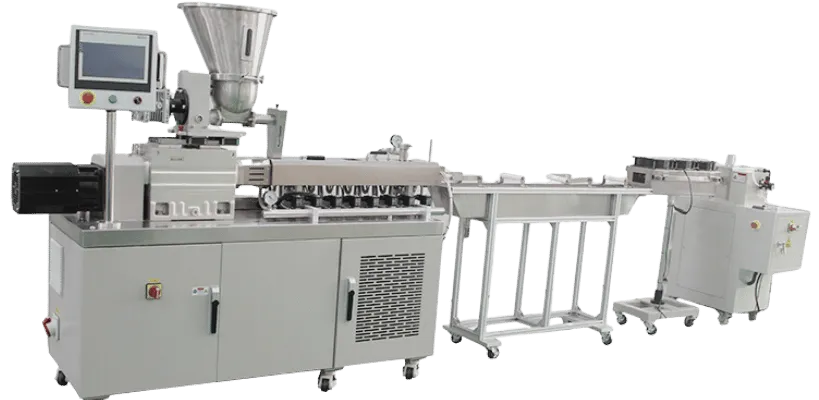

PilotLine Bio Extruder

A pilot scale equipment bridging R&D and mass production, it offers medium capacity and flexible adaptability. Adopting a closed feeding structure and residue proof design, it ensures preservation of bioactive ingredients, supports custom multi specification discharge, and helps users efficiently complete process verification and small batch commercial production.

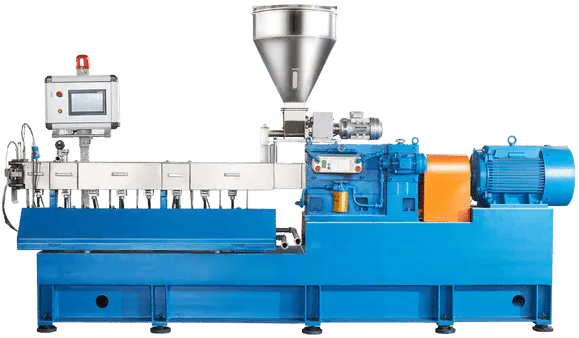

ProSeries Bio Extruder

A highend model for large scale production, it features intelligent control and efficient screw conveyor, stably processing high viscosity biomaterials. Meeting strict industry standards, it boasts large capacity, low energy use and stable operation, complete technical docs included, suitable for mass production of biobased products.

UET Bio Extruder Specifications

| Feature | Specification |

|---|---|

| Screw Design | Double-screw (optimal for bio material processing) |

| Screw Material | 38CrMoAlA (high wear resistance for bio-based materials) |

| Compatible Bio Materials | Biopolymers, biomass composites, biodegradable packaging materials |

| Key Applications | Biobased product manufacturing, biodegradable packaging production, biomass pelletizing |

| Motor Power (kW) | 11 – 220 (model-dependent) |

| Typical Output (kg/hr) | 10 – 1500 (model-dependent) |

| Warranty | 1 Year (covering core components) |

| Lead Time | 45 Days (customizable for bulk orders) |

| Supply Type | Factory Direct |

Different Models of Bio Extruders

| Model | Diameter (mm) | Max. Speed (rpm) | Motor (kW) | L/D | Output (kg/hr) |

|---|---|---|---|---|---|

| UET35 | 35 | 650 | 11 | 32 | 10-30 |

| UET50 | 50 | 600 | 45 | 36 | 150-300 |

| UET75 | 75 | 550 | 110 | 40 | 500-800 |

| UET90 | 90 | 500 | 220 | 44 | 1000-1500 |

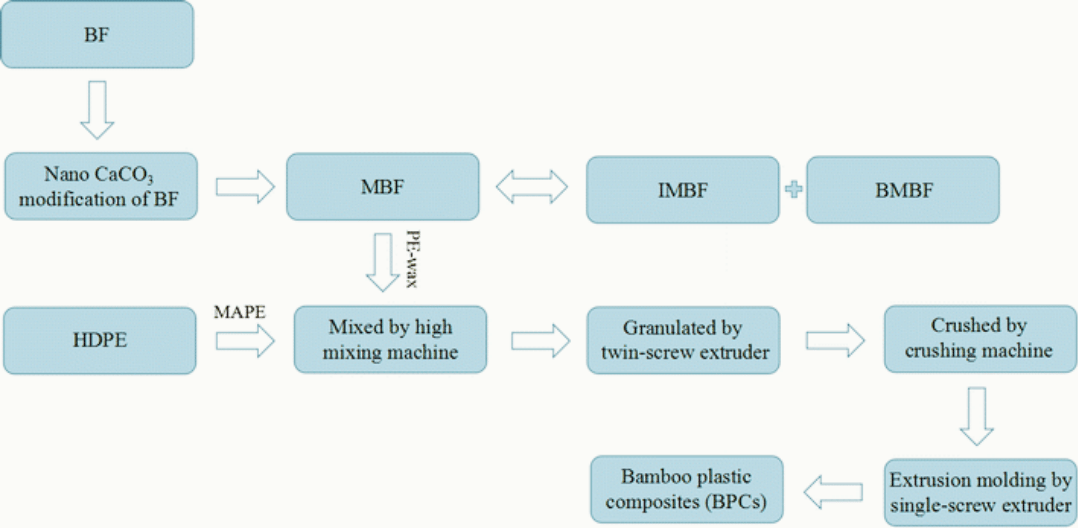

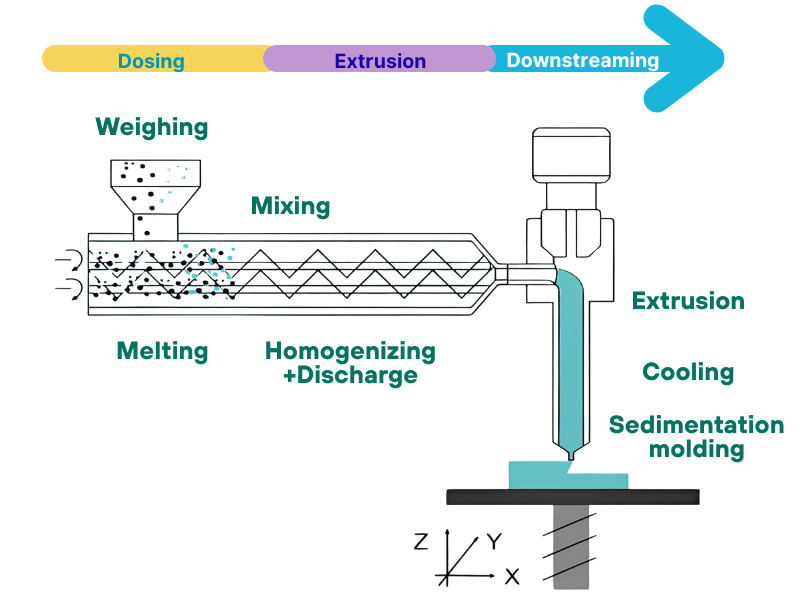

Flowchart of the Bio Extrusion Process

Flowchart of the Bio Extrusion Process

UET Bio Extruder Factory

Welcome to the UET Bio Extruder Factory. We are equipped with customized processing equipment exclusively for bio based materials, and feature standardized quality inspection processes. These ensure our equipment has high compatibility with various bio based materials and superior operational stability.

Customer Reviews for UET Bio Extruders

Check out the real customer reviews for our UET Bio Extruders to learn how UET Machine solves production challenges for its customers.

The UET Bio Extruder resolved the uneven mixing of bio-based materials in our small-batch R&D. Its responsive technical support during commissioning boosted sample quality stability by 30% compared to our previous equipment.

Lila Morgan ,R&D Supervisor

Using the UET Bio Extruder for high-viscosity biomass materials eliminated our past clogging issues. It ran continuously for 72 hours with stable 350kg/hr output, perfectly meeting our mass production requirements.

Kyle Bennett ,Production Manager

The UET Bio Extruder flexibly switches between 5 materials like biopolymers and biomass pellets. Changeover time dropped from 2 hours to 20 minutes, helping us meet EU environmental standards for bio-products.

Soren Jax ,Operations Director

The UET Bio Extruder’s wear resistant screw works exceptionally well. Processing abrasive biomass for 3 months without replacing parts, its remote debugging cut costs on overseas engineers, with 98% output compliance.

Eli Carter ,Technical Engineer

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:The price variation among different UET Bio Extruder models mainly depends on production capacity, screw configuration, and customization requirements. We provide accurate quotes based on your production scale (laboratory, pilot, or mass production) with no hidden fees. Our cost-effective configurations can meet the needs of different budgets, ensuring the optimal input-output ratio.

A:Yes, the UET Bio Extruder supports screw customization tailored to material properties. Our technical team will optimize the screw structure, length-diameter ratio, and material (such as 38CrMoAlA high-wear-resistant steel) based on your biobased material’s viscosity, wear resistance, activity requirements, and other factors. This ensures high compatibility between the equipment and materials, improving processing efficiency and product quality.

A:The UET Bio Extruder comes with a 1-year warranty covering core components (screws, motors, control systems, etc.). During the warranty period, we provide free repair and spare parts replacement services. Additionally, we have established a lifelong technical support system to ensure the long-term stable operation of the equipment and reduce long-term maintenance costs.

A:Yes, professional installation and commissioning services are included with every UET Bio Extruder purchase. Our engineers will conduct on-site guidance for equipment installation, parameter calibration, and trial operation to ensure the equipment quickly meets production standards. They will also answer operational questions on-site to help your team master usage skills efficiently.

A:Yes, the production capacity of the UET Bio Extruder can be flexibly adjusted to meet production requirements. By adjusting screw speed, temperature parameters, and feeding rate, a single unit can cover a production capacity range of 10 to 1500 kg per hour. No additional replacement of core components is needed, making it easy to adapt to small batch sample preparation and large-scale mass production needs.

A:We support a variety of flexible payment methods for UET Bio Extruder purchases, including telegraphic transfer, letter of credit, and installment payment. Customized payment plans can be negotiated based on the cooperation scale and cycle, ensuring the financial security of both parties, simplifying the transaction process, and facilitating efficient cooperation progress.

A:The qualified rate of products processed by the UET Bio Extruder remains stable above 98%. Equipped with a precise temperature control system, efficient mixing structure, and intelligent monitoring module, the equipment effectively avoids issues such as uneven material mixing and temperature fluctuations. This ensures consistent quality across every batch of products and reduces production losses.

A:Bio extruders can process various bio based materials including biopolymers (PLA, PHA), biomass composites (straw or wood chip fillers), biodegradable packaging materials, biomass pellets, bio fertilizer carriers and others. Any bio based material requiring melting mixing and molding can be processed by adjusting equipment parameters according to its characteristics.

A:Twin screw bio extruders are more suitable for bio material processing. Their strong shear force and high mixing efficiency ensure uniform blending of bio materials while effectively controlling processing temperature to reduce loss of bioactive components. They also have better adaptability to high viscosity and easy agglomeration biomass materials, whereas single screw extruders are more suitable for preliminary extrusion of simple materials.

A: Bio extruders are suitable for both laboratory research and development and industrial mass production. Laboratory grade equipment (such as UET35) has an output of 10-30kg/hr, ideal for small batch formula development. Industrial grade equipment (such as UET90) can reach an output of 1000-1500kg/hr, supporting continuous mass production. Some models can flexibly connect R&D, pilot and mass production stages.

A:High quality bio extruders will not easily clog when processing high viscosity biomass materials. Through optimized screw design (such as gradual pitch and special feeding section), precise temperature control system and anti clogging monitoring device, the equipment can effectively improve material conveying efficiency, maintaining stable operation even when processing high viscosity materials and avoiding shutdown for cleaning.

A:The selection of length to diameter ratio for bio extruders depends on material characteristics and processing requirements: 28-32 for laboratory R&D or low viscosity materials; 36-40 for pilot scale production or conventional bio materials; 40-44 for high viscosity materials requiring deep mixing (such as biomass composites). A larger length to diameter ratio provides better mixing effect but requires matching motor power.