What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down the application value and core benefits of Single Screw Extruders across three key industries. Additionally, by comparing them with Twin Screw Extruders, we will help you understand how to select the right equipment and optimize production layout, providing practical references for your equipment procurement and business planning.

Advantages of Single Screw Extruders in the Plastics Rubber and Food Packaging Industries

Plastics Industry

- Stable plasticization performance enables precise control over material melting quality. It is suitable for the continuous production of various products such as pipes sheets and films meeting diverse molding requirements.

- Flexible and convenient commissioning allows for quick switching between different product specifications. It balances small and medium batch production with multi category orders improving production line utilization rates.

Rubber Industry

- Uniform feeding and thorough mastication reduce rubber material waste ensuring product precision and consistency. It is suitable for the production of rubber pipes seals and other products.

- Low vibration and noise during operation allow integration into continuous production processes. It also has strong adaptability to high viscosity rubber raw materials expanding the range of processable materials.

Food Packaging Industry

- Compliant with sanitary grade standards it features excellent body sealing performance to prevent material contamination. It is suitable for the production of food packaging films hoses and other products.

- Precise temperature control prevents material degradation due to high temperatures. The equipment is also easy to clean and maintain meeting the industry’s strict hygiene requirements and reducing compliance costs.

What Are the Advantages of Single Screw Extruders

1.Compact Structure and Easy Maintenance: The core components only include key parts such as the screw and barrel. Not only are the manufacturing costs lower than those of complex models, but there are also fewer failure points and simple maintenance procedures. There is no need for frequent replacement of precision parts, which can significantly reduce initial procurement investment and long term operation and maintenance costs, as well as minimize equipment downtime losses.

2.User Friendly Operation and Labor Savings: There is no need to rely on a highly skilled professional operation and maintenance team. Ordinary operators can proficiently master processes such as startup, commissioning and daily inspections after just one to two weeks of basic training. This effectively shortens the production preparation cycle, while reducing labor recruitment and training costs, and adapts to the staffing needs of production facilities of all scales.

3.Stable Operation and High Efficiency: The rational design of the machine body structure results in low vibration and stable load during operation. It can achieve long term continuous production and is not prone to downtime due to equipment failures. This effectively ensures production line continuity, avoids order delivery delays, and significantly improves productivity and finished product qualification rates per unit time.

4.Wide Material Compatibility: It can be compatible with various raw material forms including pellets, powders and recycled materials. There is no need for additional specialized feeding or pre processing equipment. It can flexibly adapt to the processing requirements of different materials, easily switch production categories, reduce investment in production line transformation, and adapt to multi scenario production layouts.

Comparison Between Single Screw Extruders and Twin Screw Extruders

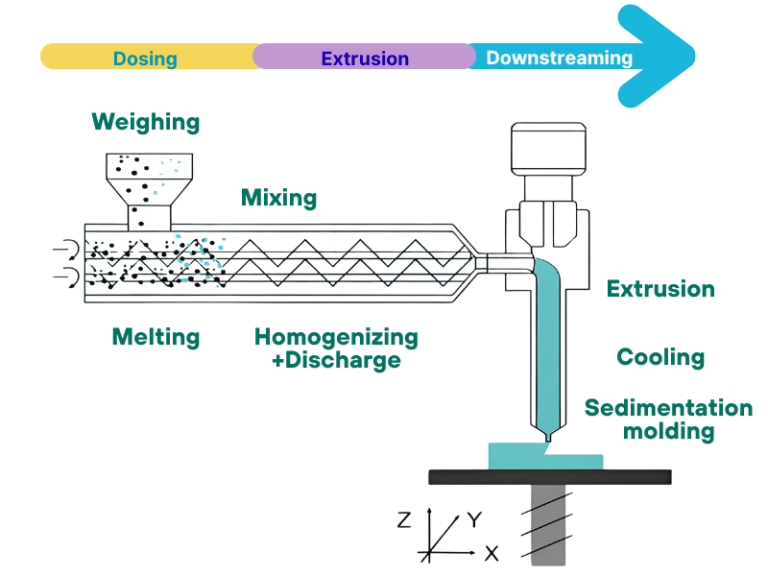

Single screw extruders and twin screw extruders differ significantly in structure, performance and applicable scenarios. Understanding the characteristics of these two machines will help you select the most reliable equipment based on your production needs, material properties and cost budget. Below is our comprehensive multi dimensional comparison of the two machines across key aspects:

Structure and Cost

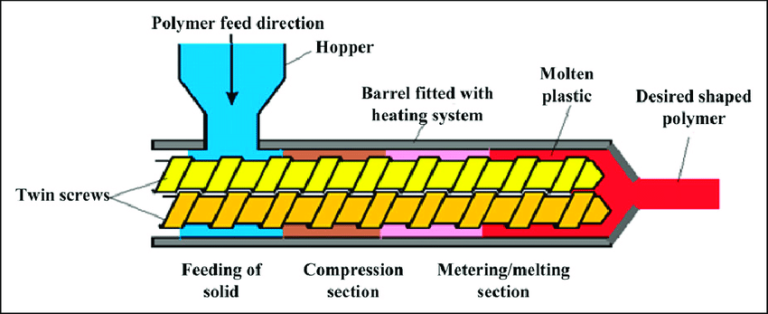

- Single Screw Extruder: Features a simple and compact structure with core components limited to the screw, barrel, drive unit and other key parts. Its components offer high universality and easy procurement. Not only does it have a low initial purchase cost and simple installation process, but it also has fewer failure points in later operation. Maintenance requires no special tools or precision parts, leading to significantly reduced operation and maintenance costs and outstanding cost effectiveness over long term use.

- Twin Screw Extruder: Boasts a complex and precision engineered structure that requires supporting components such as twin screw meshing transmission, high precision sealing and synchronous control systems. Its components pose high processing difficulty. Initial purchase, installation and commissioning costs are relatively high. In addition, later maintenance requires operation by professional personnel and replacement of precision parts comes with high costs. The overall operation and maintenance difficulty and costs are significantly higher than those of single screw models.

Applicable Scenarios

- Single Screw Extruder: Ideal for the molding and processing of general purpose materials such as PE, PP, PVC and other conventional plastics. It excels in small to medium batch production and continuous molding of single type products. Capable of meeting the production needs of basic products such as pipes, films and sheets, it is widely used in regular industrial production scenarios.

- Twin Screw Extruder: Focuses on material compounding, modification, filling and reinforcement processes. Suited for high volume, high precision production scenarios, it can handle high viscosity and multi component composite materials such as modified engineering plastics and special rubber compounding. It is mostly used in high end manufacturing, special material processing and other fields with stringent process requirements.

Operation and Adaptability

- Single Screw Extruder: Features a low operation threshold. Ordinary operators can master its operation after basic training. The commissioning process is simple and switching product specifications only takes one to two hours. It can quickly respond to multi category, small batch order demands with strong production flexibility, making it suitable for scenarios with frequent product changeovers.

- Twin Screw Extruder: Has a complex operation process that requires professional technicians to adjust multiple parameters such as screw speed, meshing clearance and temperature gradient. The commissioning cycle is long, usually taking more than half a day. Switching product specifications incurs high costs and takes a long time. It has extremely high requirements for operator skills, making it more suitable for continuous production of fixed product categories on a large scale. It is not ideal for scenarios with frequent product changeovers.