Twin Screw Extruder

High Quality Twin Screw Extruder Manufacturer from China

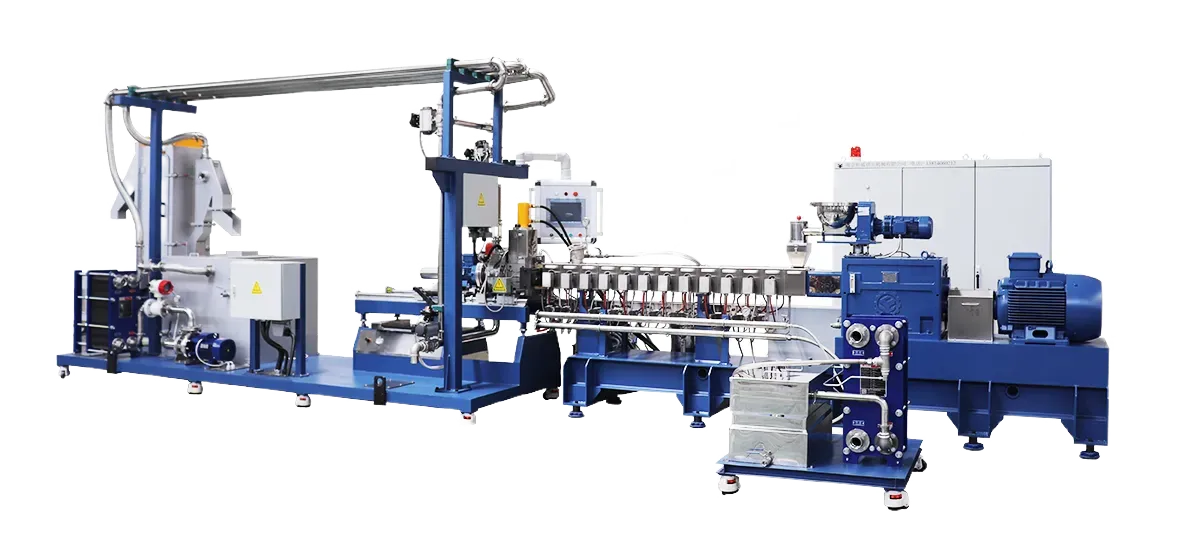

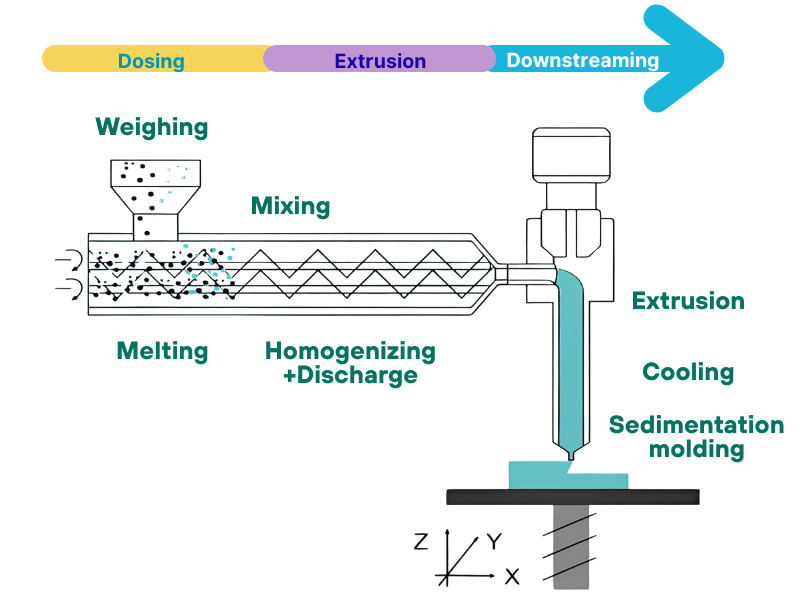

UET Machine’s twin-screw extruders are widely suited for high-performance processing applications across industries including plastics, chemicals, food, and pharmaceuticals. They can be used for various production processes such as extrusion molding, pelletization, and material conveying. If you’re looking for a professional twin-screw extruder manufacturer that delivers high-quality products with efficient lead times, UET Machine is an excellent choice for you.

±0.5%

Extrusion Accuracy

20%↓

Energy Savings

90%+

Process Flexibility

1500+

Units Delivered

UET Machine Twin Screw Extruder Solutions

Whether you operate in plastic processing, building materials manufacturing, or other industries, UET Machine’s twin-screw extruders deliver reliable solutions tailored to your needs.

Offering parallel twin-screw extruders, conical twin-screw extruders, small-scale laboratory extruders, and more, we adapt to diverse production and research scenarios such as mass production processing and formula R&D.

We tailor screw parameters and functional modules according to your production capacity and material characteristics, precisely matching the individualized needs of your actual production conditions.

Covering raw materials including thermoplastics, rubber, and modified compounds, our equipment can process end products such as pipes, profiles, and films—breaking through the material limitations of single-purpose machinery.

With over 20 years of experience in manufacturing twin-screw extrusion equipment, we boast mature technology that ensures stable operation even under harsh environments such as high temperatures and heavy loads.

Featuring a co-rotating twin-screw conveying design, our extruders improve material conveying efficiency by 30% compared to single-screw models. Ideal for continuous mass production, they reduce production lead time.

Our twin-screw extruders hold international certifications including CE and ISO, and comply with EU RoHS environmental protection and industrial safety standards—ensuring compliant, reliable production processes.

Twin Screw Extruders for Sale

UET Machine’s high-quality twin screw extruders meet all your production needs.

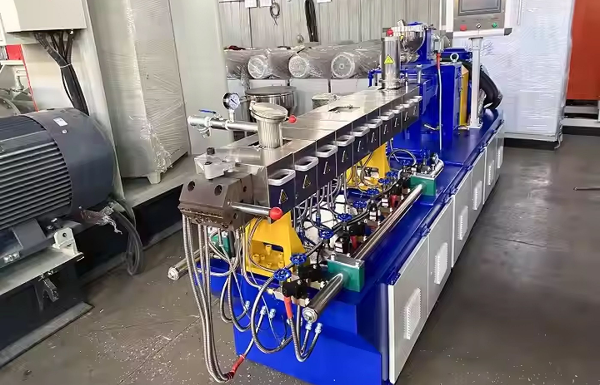

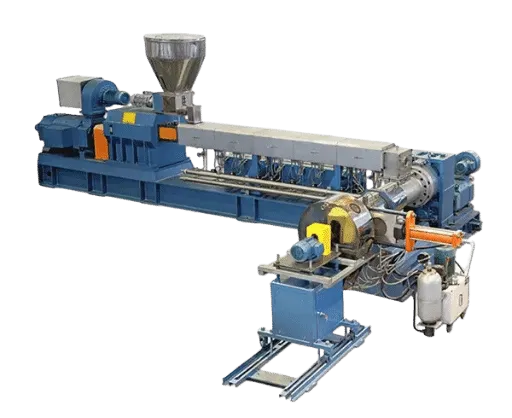

UET-B Series Twin Screw Extruder

Screw diameter ranges from φ25mm to φ80mm. Featuring a compact frame design and an intuitive operation interface, it is ideal for practical small-batch, multi-variety plastic modification and profile extrusion scenarios, with more controllable operation and maintenance costs.

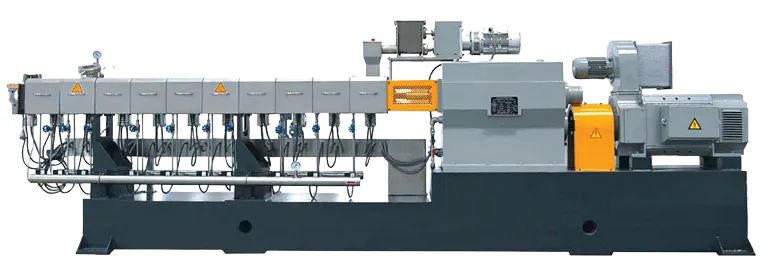

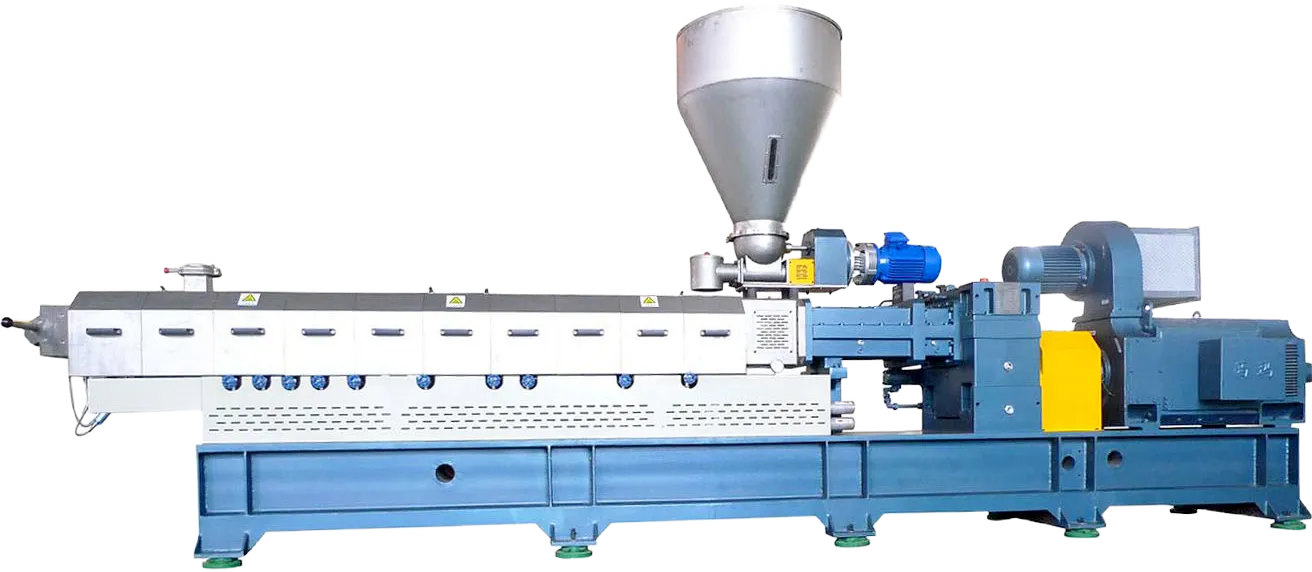

UET-D Series Twin Screw Extruder

Equipped with non-equidistant high-shear intermeshing screws and a precision PID intelligent temperature control system, it improves mixing uniformity by 20%. Perfect for continuous production of high-viscosity materials, it offers outstanding operational stability.

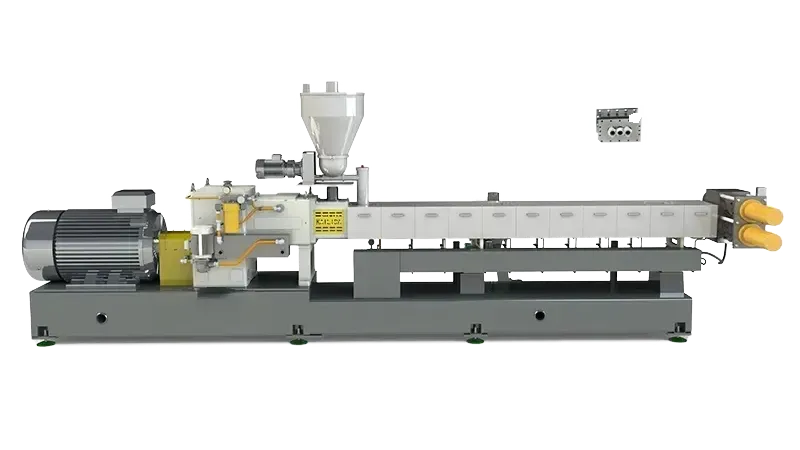

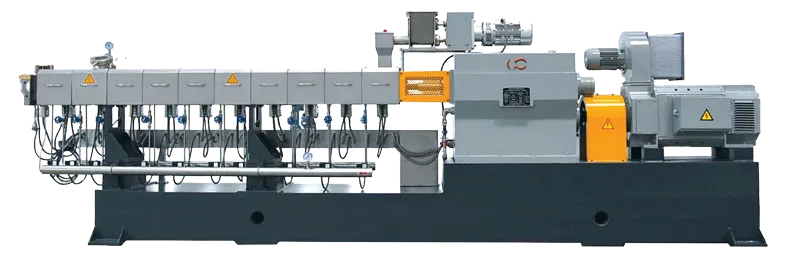

UET-Max Series Twin Screw Extruder

Screw diameter reaches φ90mm to φ180mm, paired with a dual servo drive system. It delivers 50% higher maximum capacity than standard models, making it suitable for industrial-scale mass production of modified materials and composite materials, with superior durability of key components.

Specifications for UET Machine Twin Screw Extruders

UET Machine offers three series of twin screw extruders. In addition, we provide customized equipment and deliver tailored twin screw extruder solutions to meet your specific production needs.

UET-B Series Twin Screw Extruder

| Model | Screw Diameter (mm) | Length-to-Diameter Ratio (L/D) | Speed (rpm) | Power (kW) | Output (kg/h) |

|---|---|---|---|---|---|

| UET30-B | 30 | 28~32 | ~550 | 15~20 | 80~120 |

| UET40-B | 40 | 28~32 | ~550 | 35~40 | 180~220 |

| UET50-B | 50 | 32~36 | ~550 | 50~60 | 280~350 |

| UET60-B | 60 | 32~36 | ~550 | 80~90 | 380~450 |

| UET70-B | 70 | 36~40 | ~550 | 120~130 | 500~600 |

| UET80-B | 80 | 36~40 | ~550 | 200~220 | 750~850 |

| UET90-B | 90 | 36~40 | ~550 | 350~380 | 1200~1500 |

UET-D Series Twin Screw Extruder

| Model | Screw Diameter (mm) | Length-to-Diameter Ratio (L/D) | Speed (rpm) | Power (kW) | Output (kg/h) |

|---|---|---|---|---|---|

| UET35-D | 35 | 30~34 | ~580 | 45~55 | 150~200 |

| UET45-D | 45 | 30~34 | ~580 | 65~75 | 250~300 |

| UET55-D | 55 | 34~38 | ~580 | 100~120 | 350~450 |

| UET65-D | 65 | 34~38 | ~580 | 140~160 | 480~580 |

| UET75-D | 75 | 38~42 | ~580 | 230~260 | 750~850 |

| UET85-D | 85 | 38~42 | ~580 | 300~330 | 950~1100 |

| UET95-D | 95 | 38~42 | ~580 | 460~500 | 1600~1800 |

| UET105-D | 105 | 40~44 | ~580 | 650~700 | 2200~2500 |

UET-Max Series Twin Screw Extruder

| Model | Screw Diameter (mm) | Length-to-Diameter Ratio (L/D) | Speed (rpm) | Power (kW) | Output (kg/h) |

|---|---|---|---|---|---|

| UET40-Max | 38 | 32~36 | ~590 | 80~95 | 200~320 |

| UET50-Max | 48 | 32~36 | ~590 | 140~165 | 420~520 |

| UET68-Max | 60 | 36~40 | ~590 | 230~260 | 720~820 |

| UET78-Max | 72 | 36~40 | ~590 | 270~320 | 850~1050 |

| UET98-Max | 95 | 40~44 | ~590 | 620~680 | 2000~2600 |

| UET115-Max | 112 | 40~44 | ~590 | 850~920 | 2700~3200 |

| UET125-Max | 128 | 42~46 | ~590 | 950~1050 | 3300~3800 |

| UET140-Max | 142 | 42~46 | ~590 | 1300~1400 | 4200~4500 |

Applications of UET Machine Twin Screw Extruders

The solutions offered by UET Machine Twin Screw Extruders are widely utilized across industries including general processing, biodegradable plastics, cable compounding, pharmaceuticals, and chemicals—along with direct screw processing for reactive operations.

Filler Masterbatch

When producing filler masterbatch with the UET twin-screw extruder, its gradient shear screw design ensures full integration of high-load fillers with the base material. The finished product boasts excellent dispersibility, enhancing product rigidity while maintaining processing fluidity.

Color Masterbatch

When processing color masterbatch with UET twin-screw extruders, precision temp control & intermeshing screws enable even encapsulation of high-concentration pigments in resin. The finished masterbatch has strong tinting strength, delivering consistent product color with no variations.

Additive Masterbatch

When preparing additive masterbatch with the UET twin-screw extruder, its multi-stage compounding module ensures full dispersion of functional additives (e.g., antioxidants) with the carrier resin. The finished masterbatch offers consistent dosage and long-lasting effectiveness.

Engineering Plastics

When processing engineering plastics (e.g., PBT) with the UET twin-screw extruder, its high-temperature stable plasticizing system enables full bonding with reinforcing fillers. The finished material has high mechanical strength, making it suitable for manufacturing precision electronic components.

Biodegradable Plastic

When processing biodegradable plastics with the UET twin-screw extruder, a gentle plasticizing process preserves resin activity while fully compounding it with modification additives. The finished product is suitable for producing fully biodegradable packaging items.

Thermoplastic Elastomers

When processing thermoplastic elastomers with the UET twin-screw extruder, its gradient shear screw design enables uniform integration of elastic components with modified materials. The finished product features controllable hardness, a smooth texture, and high durability.

Cable Compounding

When processing cable compounds with UET twin-screw extruders, its dead-zone-free compounding ensures full integration of conductor coatings with functional components. The finished product has excellent insulation, suitable for high-end communication cable production.

PVC Compounding

UET twin screw extruders for PVC: interlocking screws offer high-shear mixing for uniform PVC dispersion with high-load additives (plasticizers stabilizers). Complex formulations blend/melt efficiently for customized PVC materials: precision pipe fittings industrial thick films high-voltage cables.

UET Machine Twin Screw Extruder Factory

Welcome to UET Machine Twin Screw Extruder Factory. Our facility is equipped with industry-leading high-precision processing equipment and a full-process intelligent inspection system. Through multiple rounds of performance testing and durability validation, we ensure the stability and long-term operational efficiency of every piece of equipment.

Customer Reviews of UET Twin Screw Extruders

Explore real customer reviews of UET Twin Screw Extruders. These insights come from our clients across a range of industries—and we’re also proud to support clients across sectors in reaching their production objectives and driving business growth through our reliable equipment solutions.

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs) about UET Twin Screw Extruders cover core information including product compatibility, performance specifications, installation, operation and maintenance, and after-sales support.

A:A twin screw extruder is a core plastic processing equipment that uses two intermeshing (or counter-rotating) screws within the barrel to work synergistically, enabling material conveying, shearing, mixing, plasticization, and extrusion. Its working principle is as follows: after materials enter the barrel through the feeding system, they are gradually compacted, melted, and uniformly mixed under the combined action of the screw’s rotational thrust and barrel heating, ultimately being extruded into shapes or pelletized through a die. It offers advantages such as high mixing uniformity, stable production capacity, and wide adaptability, making it widely used in fields including plastic modification, masterbatch production, biodegradable material processing, and composite material preparation. It can handle various materials ranging from commodity plastics to specialty engineering plastics.

A:UET twin screw extruders are compatible with a wide range of materials, including commodity plastics (PP/PE), engineering plastics (PA/PC/PBT/PEEK), functional masterbatches (color masterbatches, filler masterbatches, additive masterbatches), biodegradable materials (PLA/PHA), thermoplastic elastomers (TPE/TPR), cable compounding materials, 3D printing filaments, and glass fiber/carbon fiber reinforced modified materials. They meet processing needs across industries such as plastic modification, packaging, electronics, automotive, and medical.

A:It has excellent suitability. Equipped with a precision PID intelligent temperature control system, temperature fluctuations are controlled within ±1°C. Combined with a gentle plasticization process and gradient shear screw design, it effectively prevents degradation or performance damage to temperature-sensitive materials (e.g., PLA, medical-grade polymer materials, heat-sensitive additives), ensuring the stability and functionality of processed materials.

A:UET extruders adopt a dual servo drive system and optimized screw structure design, with energy consumption 15-20% lower than comparable products in the industry. Core components are upgraded via lightweight and high-efficiency transmission technology to achieve high output with low power. For example, the UET-D series consumes only 80-100kWh per ton of material produced on average, significantly reducing production costs with long-term use.

A:Core components (screws, barrels) are made of 38CrMoAlA nitrided steel or bimetallic material; 316L stainless steel is available for medical-grade applications. The surface hardness reaches HRC60 or higher, offering excellent wear resistance. Under normal operating conditions (processing conventional plastics), the service life is 8,000-12,000 hours; when processing highly filled or abrasive materials, the service life is approximately 5,000-8,000 hours (adjusted based on material properties and operating specifications).

A:Routine maintenance is required once per month, including cleaning the equipment, inspecting filters and seals, and refilling lubricants. Core components (screws, barrels, servo motors) require comprehensive inspection and precision calibration every 6-12 months. Wear parts (e.g., filters, gearbox oil seals) are recommended to be replaced every 3-6 months. Proper maintenance extends equipment service life and ensures production stability.

A:Operation is easy and quick to master. The equipment is equipped with a color touchscreen that supports Chinese-English interface switching, with clear and intuitive operating logic. Key parameters (temperature, speed, feeding rate) can be set with one click and monitored in real time. New operators can independently complete startup, production, and basic troubleshooting after half a day of basic training. Remote operation guidance and fault diagnosis functions are also provided to lower operation and maintenance barriers.

A:The entire machine comes with a 1-year warranty, while key functional components (screws, barrels, servo motors, temperature control systems, gearboxes) have an extended 2-year warranty. During the warranty period, free repairs, spare part replacements, and technical support are provided for manufacturing defects and natural component wear—this does not cover failures caused by human error, force majeure, or non-compliant use.

A:Common wear parts (filters, seals, sensors, drive belts) are in full stock and can be shipped within 24 hours of order placement, with delivery to North America taking 3-5 business days. Lead time for core spare parts (screw assemblies, temperature control modules, motor accessories) is 7-15 business days, with expedited order processing available. Spare part pre-storage services are also offered to minimize production downtime risks.

A:Complimentary full-set installation and operational support are offered post-purchase: detailed installation manuals and site planning solutions are included, with engineers providing remote assistance for equipment positioning, wiring, and commissioning. Customized combined online and offline training is tailored to your specific business needs—offline training lasts 1-2 days (covering equipment operation, parameter optimization, routine maintenance, and troubleshooting), while permanent retraining access and one-on-one remote guidance are available online. The training caters to both operators and technical staff, ensuring your team quickly masters the core operational skills of the equipment.