PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type of equipment can help practitioners select models accurately, improve production efficiency and reduce operational costs. This article will systematically answer key industry-related questions from the aspects of equipment definition, working principle, core components, application fields and product advantages, helping readers quickly establish a comprehensive understanding.

What is a PVC Twin Screw Extruder?

A PVC Twin Screw Extruder is a continuous plastic processing equipment developed for the material characteristics of polyvinyl chloride (PVC). Its core structure consists of two intermeshing or counter-rotating screws and matching barrels. Its core function is to complete the mixing, plasticization and continuous extrusion molding of PVC resin, additives and fillers through the synergistic effect of mechanical extrusion and thermal energy. Compared with single screw extruders, it has more advantages in PVC processing especially suitable for difficult-to-process materials such as rigid PVC and filled modified PVC. It can achieve more uniform plasticization effect and more stable output, and is a key equipment for large-scale production of PVC products.

Working Principle of PVC Twin Screw Extruder

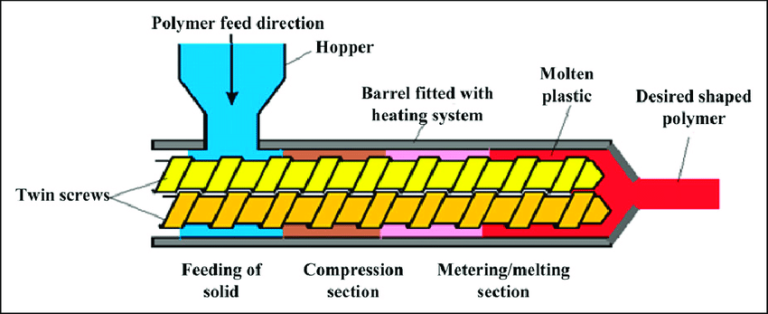

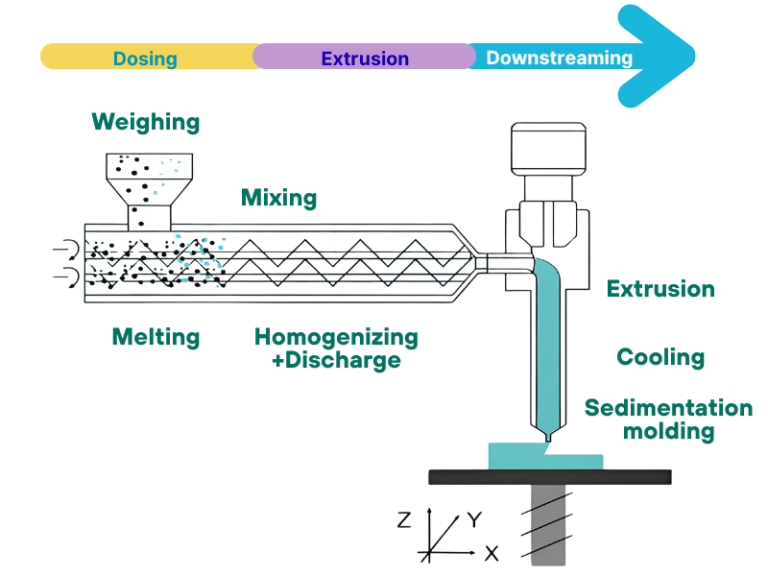

The core of a PVC Twin Screw Extruder lies in a closed loop of continuous material processing. Through the synergistic operation of screws and barrels, it completes the morphological transformation of PVC materials in four key stages:

1.Feeding and Pre-compaction Stage

Mixed PVC materials including resin, stabilizers and fillers enter the barrel through the feeding device. Driven by the pushing force of the screw flights, the two rotating screws steadily move the materials forward along the axial direction of the barrel. This stage also achieves initial compaction of the materials, expelling air trapped in the gaps between material particles. It lays a solid foundation for the subsequent plasticization process and prevents air residues from affecting the quality of final products.

2.Plasticization and Melting Stage

As the materials move into the heating zone of the barrel, they are gradually heated and softened under the combined effect of shear extrusion from the screws and external heating from the barrel, eventually melting completely. Meanwhile, volatile components in the materials such as residual moisture from additives and low molecular weight volatiles are forced out. The core goal of this stage is to achieve uniform plasticization of the materials, eliminating any unmelted particles and ensuring the mechanical properties of the subsequent products.

3.Mixing and Homogenization Stage

The molten PVC melt is subjected to intense shearing and stirring forces as the intermeshing screws rotate. This process fully integrates resin, additives and fillers to form a melt with uniform composition and stable performance. For modified PVC products such as impact modified PVC and flame retardant modified PVC, the mixing effect in this stage directly determines the final performance of the products, making it a key link for improving product quality.

4.Metering and Extrusion Stage

The homogeneous PVC melt is continuously pushed by the screws, passes through the die head runner and enters the customized mold. It is then extruded into continuous profiles such as pipes and sections or billets that match the mold cavity. After undergoing subsequent processes including cooling, traction and cutting, the melt is finally formed into qualified PVC products. The entire process enables continuous and large-scale production.

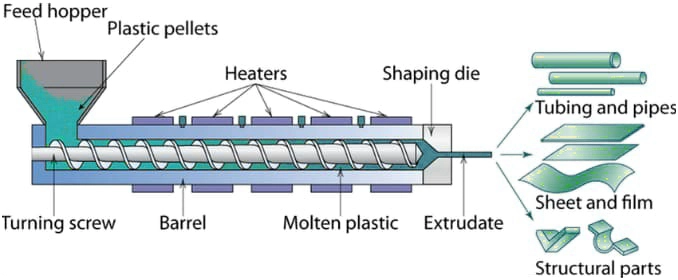

Main Components of PVC Twin Screw Extruder

The core performance of a PVC Twin Screw Extruder directly depends on how well each key component adapts to the processing characteristics of PVC materials. Its main core components and customized designs are as follows:

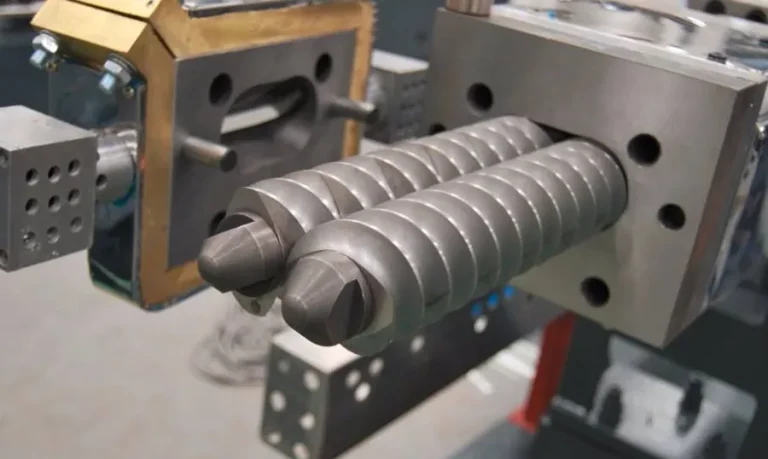

1.Specialized Screws

As the core component of the equipment, specialized screws are made of high strength wear resistant alloy materials suitable for PVC processing. Their surfaces are treated with nitriding or wear resistant coating, which can withstand the abrasive wear caused by PVC materials especially filled modified PVC. The screws adopt a customized segmented structure feeding section, compression section and metering section according to PVC processing requirements: the feeding section features optimized pitch design to ensure smooth feeding of mixed PVC materials; the compression section has enhanced shearing and extrusion capacity to meet the plasticization needs of PVC resin; the metering section precisely controls the melt delivery volume to guarantee extrusion stability. Corresponding screw configuration parameters can be customized for different PVC materials such as flexible PVC, rigid PVC and high filled PVC.

2.Customized Barrels

Customized barrels are precisely matched with specialized screws and adopt an integral or segmented structure. Their inner walls are equipped with wear resistant and corrosion resistant bushings to adapt to the chemical properties and mechanical abrasion of materials during PVC processing. The exterior of the barrels is equipped with a segmented temperature control system, including resistance or electromagnetic heating devices as well as air cooling and water cooling systems. It can accurately control the temperature of each section within the reasonable range required for PVC plasticization, avoiding PVC degradation caused by local overheating or insufficient plasticization due to low temperature.

3.PVC Specific Feeding Devices

PVC specific feeding devices adopt a forced spiral feeding structure, which can precisely adjust the feeding volume to ensure accurate matching with screw speed and extrusion speed, thus preventing fluctuations in product quality caused by feeding instability. The feeding port is equipped with an independent cooling device, which specifically solves the problem of PVC materials being prone to softening and caking when heated. It prevents feeding blockage, ensures smooth feeding and avoids premature plasticization of materials that may affect subsequent processing.

4.High Precision Transmission Systems

High precision transmission systems are composed of variable frequency motors, high precision reducers, couplings and other components, providing stable and adjustable power output for screw rotation. To meet the high requirements for speed stability in PVC extrusion, high precision variable frequency control technology is adopted to realize stepless adjustment of screw speed with minimal speed fluctuation error. The reducers are precisely calibrated to ensure stable power transmission, avoiding problems such as uneven PVC plasticization and fluctuating extrusion output caused by speed fluctuations.

5.Die Heads and Customized Molds

Die heads are transition components adapted to the flow characteristics of PVC melt. Their internal flow channels are optimized to ensure smooth transition and uniform pressure distribution of PVC melt, preventing PVC degradation caused by melt retention. Molds are core components customized for PVC products. They are processed according to the external dimensions and performance requirements of different PVC products such as pipes, profiles and sheets. With high cavity precision, they can ensure the regular shape, dimensional accuracy and surface finish of PVC products.

6.Intelligent Electrical Control and Temperature Control Systems

Intelligent electrical control and temperature control systems are based on PLC control systems, equipped with special control programs adapted to PVC processing technology, as well as high precision temperature sensors, pressure sensors and touch operation interfaces. They can real time monitor and precisely adjust the temperature of each barrel section and die head, while jointly controlling key parameters such as screw speed, feeding volume and traction speed to realize automatic control of the entire PVC extrusion process. In addition, the system has functions such as fault alarm for common PVC processing problems and storage of process parameters, which reduce the difficulty of manual operation and improve production stability.

Core Application Fields of PVC Twin Screw Extruders in the Plastics Industry

With excellent plasticizing and mixing performance as well as stable large scale production capacity, PVC twin screw extruders are widely used in the entire industrial chain of PVC products. Their core application fields include the following:

1.PVC Pipe Production

They are suitable for processing various types of PVC pipes such as water supply pipes, drainage pipes, gas pipes, conduit pipes and corrugated pipes. They are especially good at the stable production of high filled PVC pipes such as calcium filled rigid PVC drainage pipes. The equipment can produce pipes with uniform wall thickness and precise dimensions. The finished products have the advantages of strong corrosion resistance, high compressive strength and long service life, making them the mainstream processing equipment in the pipe industry.

2.PVC Profile and Sheet Production

They are used for processing products such as PVC door and window profiles, decorative profiles, foamed sheets, rigid PVC sheets and corrugated sheets. By changing molds and adjusting process parameters, it is possible to produce products with different cross sectional shapes and thicknesses, meeting the needs of multiple fields such as building decoration, interior decoration and industrial protection. Meanwhile, the equipment can ensure the finished products have smooth surfaces and stable mechanical properties.

3.PVC Cable and Packaging Material Production

They are mainly applied to the extrusion molding of PVC cable sheaths and insulation layers, as well as the processing of products such as PVC heat shrinkable films, packaging films and stretch films. The equipment has high speed extrusion capacity, which can ensure uniform melt plasticization and high dimensional accuracy of products. It meets the high speed and refined requirements of cable production, and simultaneously satisfies the core requirements of packaging materials for transparency and flexibility.

4.PVC Modified Material Processing

They are used for the pelletizing production of modified PVC materials such as filled modified, reinforced modified, flame retardant modified and impact modified materials. Through the strong shearing and mixing effect of the screws, modifiers such as glass fiber, flame retardants and impact modifiers are fully integrated with PVC resin. This significantly improves the mechanical properties, heat resistance, flame retardancy and other indicators of the materials, providing high quality raw materials for high end PVC products such as automotive PVC components and industrial wear resistant PVC products.