What Is Single Screw Extruder

The single-screw extruder is the most widely used general-purpose extrusion equipment in the industrial sector, spanning several core industries such as rubber and plastic, food, and chemical engineering. This article will systematically explain its basic definition, core components, working principle, application scenarios, advantages and disadvantages, as well as selection methods. Whether you are a distributor seeking cost-effective products for agency or an enterprise planning a production line, mastering this knowledge is crucial for making informed product selection and model configuration decisions.

Basic Definition of the Single Screw Extruder

The single screw extruder is a standardized industrial device that uses a single screw as its core driving and processing component. Through the continuous rotational movement of the screw inside the barrel, it sequentially completes the conveying, compressing, melting plasticizing, and extrusion molding of materials. It is the most mature and widely used type of equipment in the field of extrusion molding technology.

Its core characteristics set it apart from double screw and multi screw extruders. It relies on the precise coordination between the single screw and the barrel to achieve full-process material handling. While boasting a simplified structural design, it also offers strong versatility and scenario adaptability, making it capable of meeting the requirements of most basic extrusion processing tasks.

As a general purpose piece of equipment, the single screw extruder can be adapted to different materials and product specifications by replacing core accessories and adjusting process parameters. It strikes a balance between flexibility and practicality, and is widely utilized in small and medium-sized production operations as well as multi category processing scenarios.

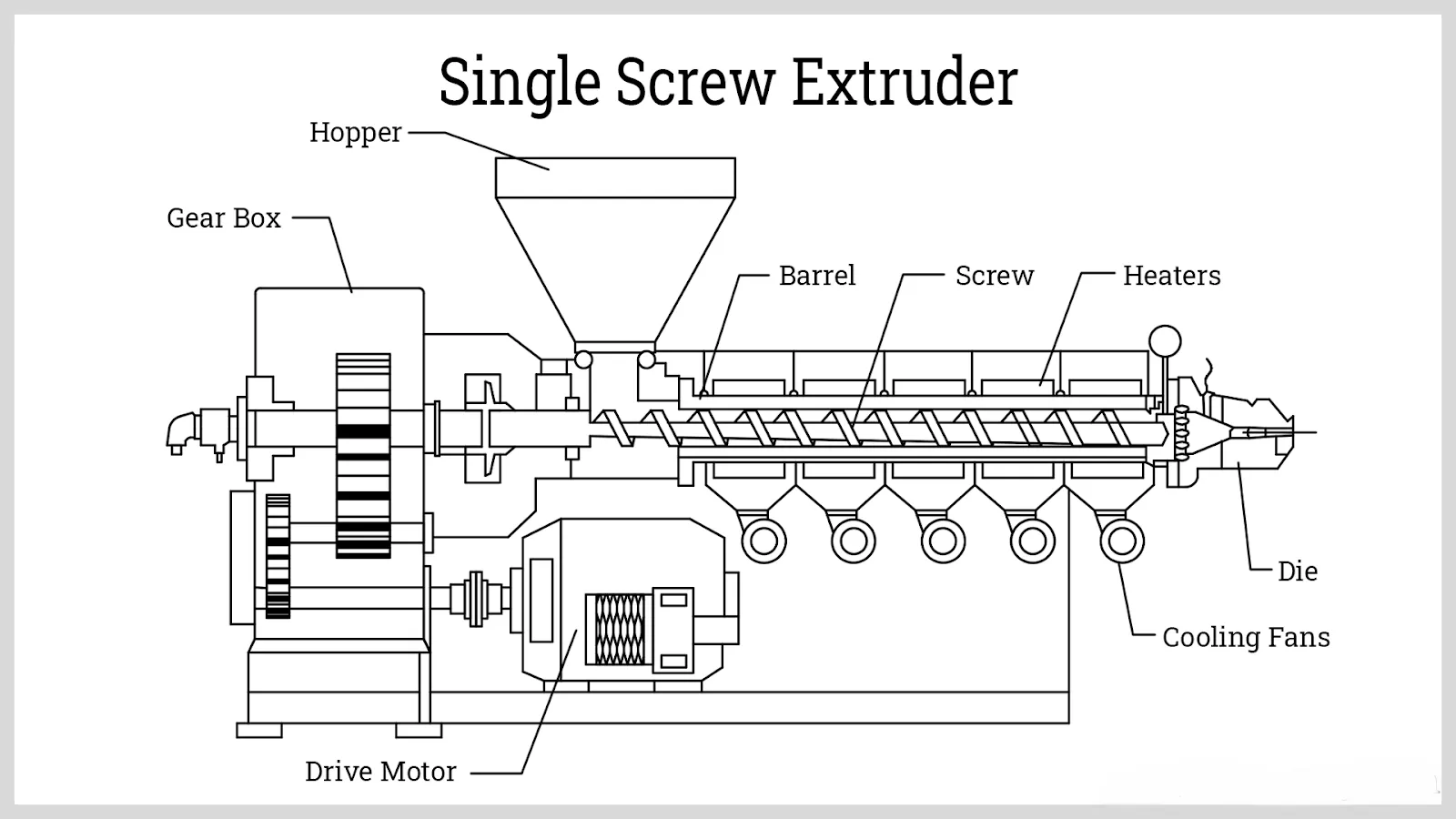

Core Components of the Single Screw Extruder

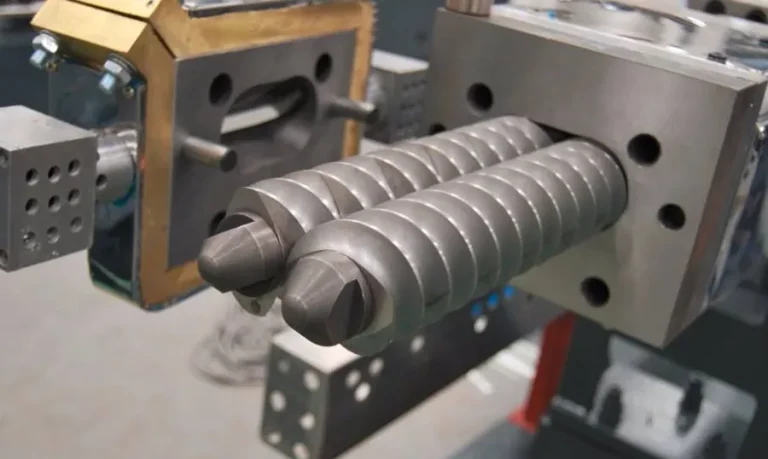

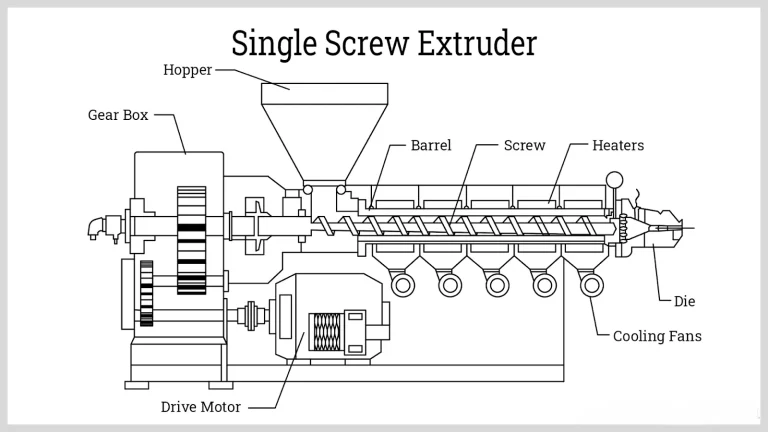

1.Screw: As the core functional component of the equipment, it directly determines the plasticization quality of materials, extrusion efficiency, and finished product precision. Based on design differences in pitch and screw channel depth, screws can be classified into gradual transition type, abrupt transition type, and universal type. The gradual transition type is suitable for heat sensitive materials, the abrupt transition type is designed for high viscosity materials, and the universal type can handle a variety of conventional materials. Most screws are made of high strength alloy steel with wear resistant treatment to extend service life.

2.Barrel: A cylindrical component that fits precisely with the screw. Its inner wall is smooth and features high temperature resistance, wear resistance, and corrosion resistance. Barrels are typically machined from seamless steel pipes, and some high end models undergo inner wall coating treatment. The barrel not only provides a sealed space for material plasticization but also transfers heat through an external heating system. Working in conjunction with the screw’s extrusion force, it melts the materials while ensuring stable extrusion pressure.

3.Hopper: A feeding device located at the top of the equipment, used for storing and uniformly conveying solid raw materials. Its volume must match the equipment’s production capacity to avoid frequent refueling that could disrupt production continuity. Some high end hoppers are equipped with agitation functions, heating and moisture proof devices, or level monitors. These features effectively prevent material caking and moisture absorption, monitor material levels in real time, and ensure uniform and stable feeding.

4.Heating and Cooling System: Distributed on the outer wall of the barrel, this is the core system for controlling material temperature and ensuring optimal plasticization. The heating system mostly adopts a segmented design with electric heating coils, allowing for precise temperature control of each barrel section. The cooling system uses air cooling or water cooling devices to rapidly lower the temperature when material temperatures become too high, preventing overheating and decomposition of materials and ensuring a stable and controllable extrusion process.

5.Drive System: Composed of a motor, reducer, and coupling, it provides stable and adjustable power output for the screw’s rotation. The power output and rotational speed stability of the drive system directly impact the equipment’s extrusion efficiency, production capacity, and operational smoothness. High power models are suitable for high capacity requirements, while speed regulation functionality meets the processing speed needs of different materials.

6.Die Head and Die: Molding components located at the end of the equipment, which work together to shape the final product. The die head uniformly guides the plasticized molten materials to the die, while further increasing material pressure and eliminating air bubbles to ensure material density. The die is custom designed according to the shape of the final product, such as pipes, profiles, and films, and is the key component for achieving precise material molding. Its material must have high temperature resistance and easy demolding properties.

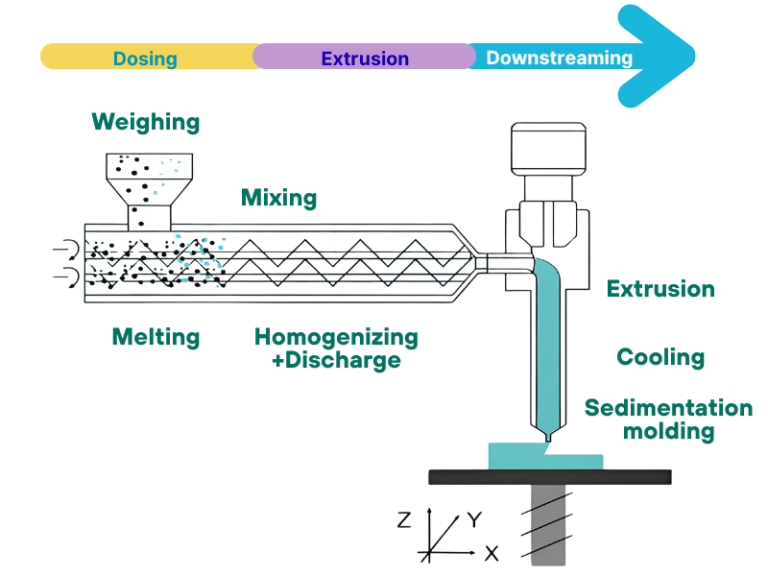

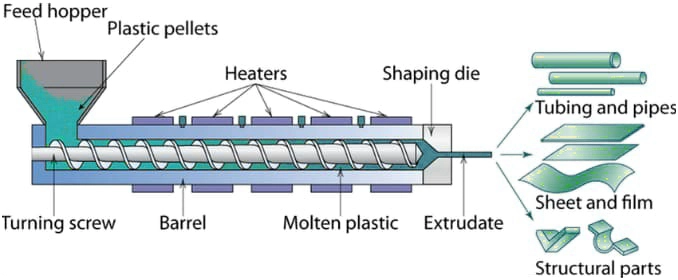

The operation process of a single screw extruder is a continuous process of material state transformation and directional conveying. It is divided into four core stages overall, with each stage seamlessly connected and functioning in synergy:

1.Feeding Stage: After raw materials enter the barrel from the hopper, they move directionally toward the front end of the barrel along the screw channel under the action of the spiral thrust generated by the screw’s rotation. During this stage, the materials remain in a solid state, and only preliminary conveying and slight pre compression are completed. The temperature of this barrel section is kept low to prevent premature melting and caking of materials, which could disrupt the feeding process.

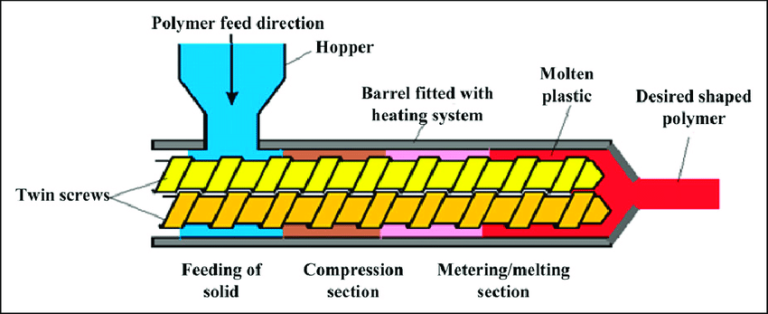

2.Compression Stage: As the depth of the screw channel gradually decreases from the rear to the front, the extrusion pressure on the materials increases continuously. At the same time, the barrel heating system transfers heat consistently, creating a dual effect of compression and heating. In this stage, the solid materials gradually soften and melt, completing the transition from a solid state to a uniformly molten state. Meanwhile, air trapped in the materials is expelled to improve plasticization quality.

3.Metering Stage: The depth of the screw channel at the front end of the screw remains constant. The plasticized molten materials are pushed to the die head at a fixed volume and pressure. During this stage, the screw’s pushing speed and pressure stay stable. Its core function is to ensure a uniform flow rate and constant pressure of the extruded materials, laying a stable foundation for subsequent precise forming and preventing issues such as uneven thickness and density variations in the finished products.

4.Forming Stage: The molten materials pass through the die head for flow guidance and pressure enhancement before entering the customized die. Inside the die, they form a preform with the same shape as the final product. After being extruded, the preform is rapidly cooled and shaped by an external cooling system (air cooling, water cooling, or sizing sleeve). It is then processed by traction and cutting devices, ultimately becoming a finished product that meets the specified requirements.

Application Fields of the Single Screw Extruder

Thanks to its strong versatility, simple operation and high cost performance, the single screw extruder is widely used in multiple industrial fields, covering both basic processing and end product manufacturing:

1.Rubber and Plastic Processing Industry: This is its core application field. It can produce a variety of products such as plastic pipes, profiles, films, cable sheaths, plastic threads and blow molded products. It can also complete rubber extrusion molding and pre vulcanization treatment. Compatible with a range of rubber and plastic raw materials including polyethylene, polypropylene, PVC and ABS, it serves as essential equipment for rubber and plastic processing enterprises.

2.Food Processing Industry: It is suitable for the production of grain puffed foods (such as potato chips and rice cakes), pet food, noodles, vermicelli and vegetarian products. Through the extrusion process, it achieves material cooking, sterilization, molding and puffing. Equipment materials must comply with food hygiene standards. Some models support automated continuous production, which improves the efficiency of food processing.

3.Chemical Industry: It can be used for the mixing, stirring and extrusion of viscous materials such as coatings, pigments, adhesives and sealants. It can also realize the granulation, molding and modification of chemical raw materials, helping chemical enterprises complete intermediate material processing or end product manufacturing. It is suitable for high viscosity chemical materials with low corrosiveness.

4.Building Materials Industry: It is used to produce construction related products such as plastic door and window profiles, plastic water supply and drainage pipes, thermal insulation materials, waterproof membranes and decorative strips. Equipment must meet the building materials industry’s requirements for product specification accuracy, durability and environmental friendliness, supporting energy saving and efficient construction in architectural projects.

Advantages and Disadvantages of the Single Screw Extruder

Advantages of the Single Screw Extruder

It features a simple structure with few core components, resulting in low manufacturing costs. Additionally, its post maintenance processes are straightforward and maintenance costs are controllable, delivering outstanding cost performance. This makes it an ideal choice for procurement by small and medium sized enterprises and easy for distributors to promote, boasting high market acceptance.

It offers extremely strong versatility. By replacing the screw and die and adjusting process parameters, it can quickly adapt to a wide range of materials and product types. There is no need to configure separate dedicated equipment, allowing for flexible and extensive application scenarios that meet the requirements of multi category processing.

It has a low operation threshold. The equipment operates stably and reliably with a moderate level of automation. No complex debugging or professional operation skills are required, and operators can master the operation after simple training, which reduces the labor costs of enterprises.

The equipment has a relatively compact volume and small floor space, with low requirements for production sites. This facilitates enterprises in arranging production lines, making it particularly suitable for small and medium sized factories with limited space.

Disadvantages of the Single Screw Extruder

Its material plasticization uniformity is relatively inferior to that of twin screw extruders. For high end products requiring high precision and high uniformity such as precision pipes and high end films, its adaptability is insufficient, making it difficult to meet stringent processing standards.

Its extrusion output is relatively low. The thrust provided by the single shaft drive of the screw is limited. Compared with twin screw extruders, its production efficiency is lower in large scale continuous production scenarios, making it difficult to adapt to high capacity requirements.

Its adaptability to high viscosity and heat sensitive materials is limited. High viscosity materials are prone to unsmooth extrusion and inadequate plasticization, while heat sensitive materials are likely to decompose and discolor due to excessively high local temperatures, which affects the quality of finished products.

Its material mixing effect is average, and it is difficult to achieve precise and uniform mixing of multiple materials. It has weak adaptability for the processing of materials that require compound modification.

How to Choose the Right Single Screw Extruder for Your Business

Choosing the right single screw extruder requires aligning with your specific business needs, application scenarios and long term development plans. Focus on the key considerations below to ensure optimal equipment compatibility and practicality:

1.Clarify your core application industry: Requirements for equipment vary significantly across different industries. For example, the food industry prioritizes models made from food grade materials such as 304 stainless steel and designed with hygienic cleaning features. The rubber and plastic industry focuses on heating power, screw wear resistance and temperature control accuracy. Lock in the appropriate equipment type based on your core business scenarios.

2.Define your production capacity requirements: Select equipment with matching power and screw diameter based on your production scale, order volume or target market demand. Generally, larger screw diameters and higher drive power translate to greater production capacity. Avoid overcapacity which leads to resource waste or insufficient capacity which impacts order fulfillment.

3.Consider material characteristics: Choose the corresponding screw and barrel configuration based on the viscosity, heat sensitivity and hardness of your materials. For instance, heat sensitive materials work best with gradual transition screws and segmented temperature control models. High viscosity materials are better suited for abrupt transition screws and high power drive models. This ensures stable material plasticization and extrusion.

4.Evaluate key equipment configurations: Pay close attention to the materials of the screw and barrel such as alloy steel and stainless steel and their surface treatment processes, as these directly impact equipment wear resistance and service life. Also, focus on the drive system’s power stability and the heating and cooling system’s temperature control accuracy. These configurations determine equipment performance and long term maintenance costs.

5.Assess manufacturer strength and support: For distributors, prioritize manufacturers with robust product quality control, reliable supply capacity, comprehensive technical support including installation and commissioning and troubleshooting and maintenance and strong after sales support. This ensures the market competitiveness and reputation of the products you represent. For end user enterprises, additionally consider the manufacturer’s customization capability to meet special production processes and product requirements.

6.Consider future scalability: Select models with room for expansion such as those supporting accessory upgrades and adjustable production capacity. This allows for flexible adjustments to production configurations as your business grows and market demands change, avoiding waste from redundant equipment purchases.