Heating Stability

Compliance Certifications

Energy Savings

Cutting Accuracy

UET Machine PVC Extruder Solutions

UET PVC Extruder Solutions, adapt to various PVC material formulations

To address size deviation and over tolerance in PVC extrusion profiles precise temperature control and die adjustment enhance molding stability ensure size compliance and improve batch production qualification rate.

To resolve uneven PVC plasticization and loose internal structure optimize screw configuration and temperature control curves improve plasticization uniformity and ensure product mechanical properties and surface finish.

To tackle high energy consumption and cost pressure in PVC production optimize equipment power systems and extrusion processes reduce energy use per unit output and balance efficient production and cost control.

To address high scrap rates and material waste in PVC processing optimize extrusion parameters and material compatibility reduce molding losses and improve comprehensive utilization rate of PVC raw materials.

To resolve cumbersome mold changes and long downtime in multi specification PVC production optimize mold base structure and positioning design shorten mold change cycles and improve production line switching efficiency.

To address PVC equipment’s corrosion prone and rapid part wear optimize machine materials and wear part configuration improve corrosion and wear resistance and extend service life and maintenance cycles.

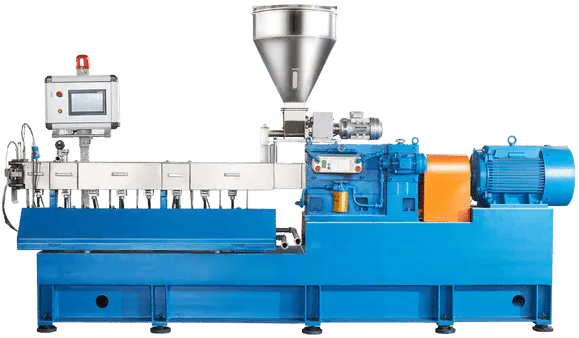

PVC Extruders for Sale

UET Machine provides reliable PVC extruders that accommodate the processing needs of various PVC materials, are easy to operate, and support long term stable operation.

Precision Temp Control Extruder

It adopts precision temp control and die fine tuning size tolerance ≤ ±0.02mm suitable for rigid flexible PVC and other materials. Supports multilingual operation complies with UL standards simplifies maintenance meets high precision needs for profiles and pipes.

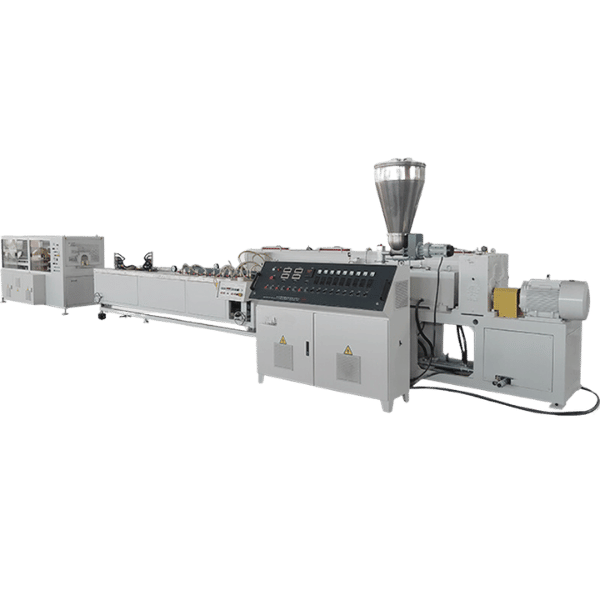

High Efficiency Energy Saving Extruder

Optimizes screw design and energy saving motor energy consumption 16% lower than traditional models supports 24 hour continuous operation. Mold change ≤12 minutes noise ≤72dB meets CE standards enhances production efficiency and cost effectiveness.

Multi Material Compatible Extruder

Compatible with PVC U PVC C and 10+ materials equipped with intelligent parameter system for quick access to 120+ process schemes. Corrosion resistant body adapts to complex conditions widely used in building materials home appliance parts.

UET PVC Extruder Specifications

| Feature | Specification |

|---|---|

| Screw Design | Single-screw (high-efficiency mixing type, optimized for PVC plasticization) |

| Screw L/D Ratio | 28:1 |

| Processable Materials | Rigid PVC, Flexible PVC, Foamed PVC (compatible with PVC compounds) |

| Product Diameter Range | 20 mm – 300 mm (adjustable via die head replacement) |

| Production Capacity | 100 – 300 kg/h (varies by product type & material) |

| Adjustable Screw Speed | 120 – 200 rpm |

| Main Motor Power | 45 kW |

| Automation Features | Closed-loop temperature control (±1℃ accuracy), automatic feed rate adjustment, material breakage alarm |

| Screw Material | 42CrMo (nitrided surface treatment, wear resistance ≥ 600HV) |

| Dimensions (LWH) | 6.5m * 1.8m * 2.0m (compact layout for workshop space saving) |

| Warranty & Support | 1-year full machine warranty; 2-year core components (motor/gearbox) warranty; lifetime spare parts supply |

| Quality Assurance | Pre-delivery plasticization efficiency test, dimensional accuracy inspection, pressure resistance test |

| Applicable Products | PVC pipes, construction profiles, window frames, electrical cable ducts |

| Applicable Industries | Construction material manufacturing, electrical equipment production, furniture component processing |

Different Models of UET PVC Extruders

| Model | Screw Diameter (mm) | Screw L/D Ratio | Production Capacity (kg/h) | Adjustable Screw Speed (rpm) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| UET-50 | 50 | 25:1 | 50–100 | 100–180 | 18 |

| UET-65 | 65 | 28:1 | 100–200 | 120–200 | 30 |

| UET-80 | 80 | 30:1 | 200–350 | 100–160 | 45 |

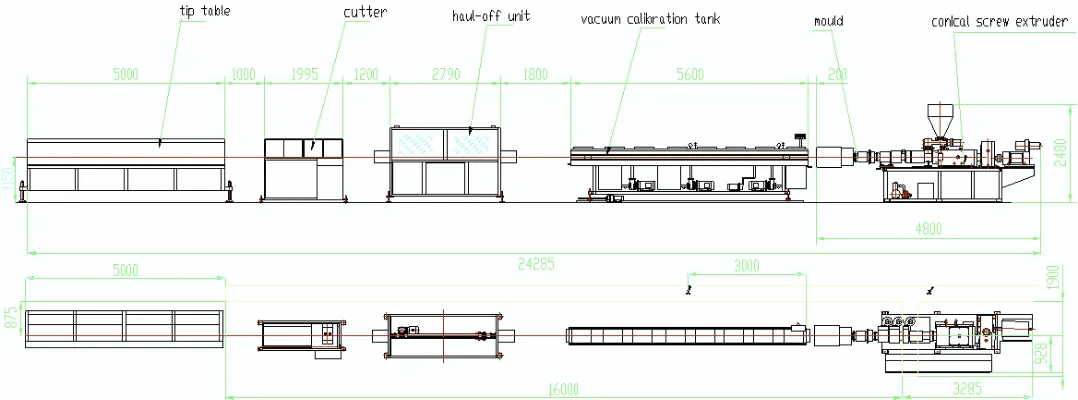

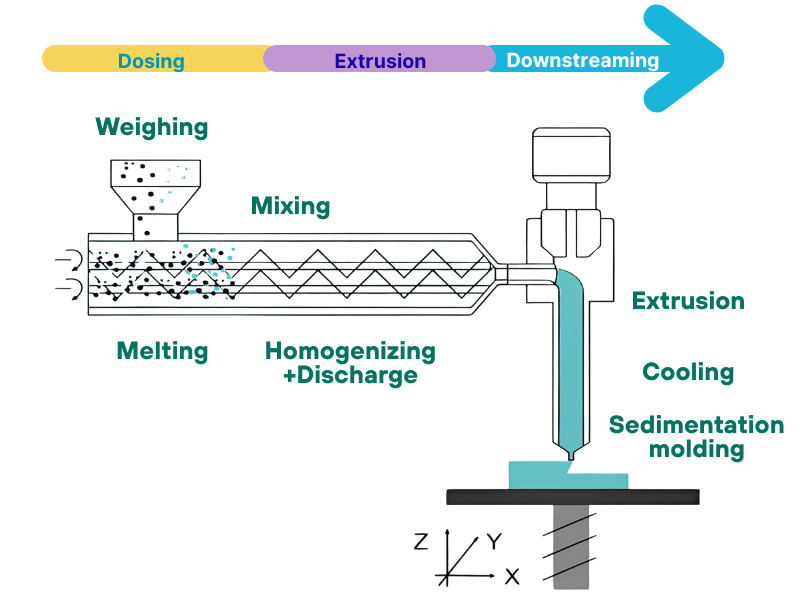

PVC Extruder Flow Chart

PVC Extruder Flow Chart

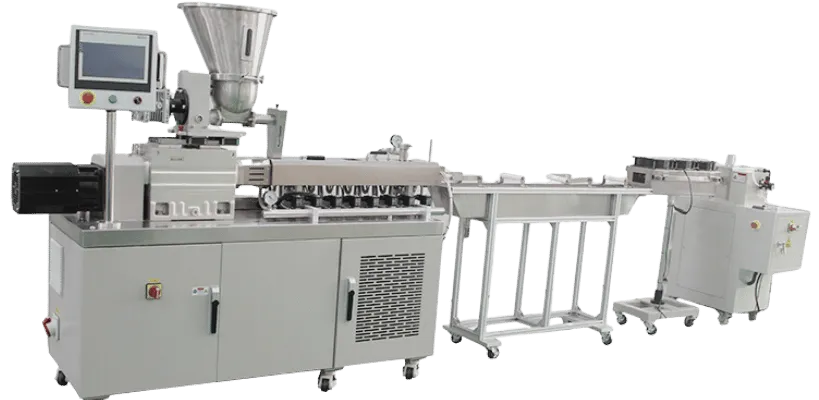

UET PVC Extruder Factory

Welcome to UET PVC Extruder Factory. Our PVC extruders are stable and reliable and we invite you to schedule an on site visit.

Customer Reviews for UET PVC Extruders

Review the authentic customer feedback for UET PVC Extruders and find out how we help customers meet their stable mass production needs for rigid PVC pipes.

We use the UET PVC Extruder for eight months. The equipment runs continuously and stably without faults, and the extrusion precision of PVC pipes fully meets municipal engineering standards. Production capacity has increased by 25% vs our old equipment. After sales support is responsive and problem solving efficient, delivering an excellent overall experience!

Leo Carter ,Plant Production Supervisor

Our team compared multiple PVC extrusion machines and ultimately selected UET. The equipment delivers excellent plasticizing effects for rigid and foamed PVC. Finished window frame profiles have a smooth blemish free surface and require no secondary sanding. Precision intelligent temperature control significantly reduces product defect rates. Highly recommended!

Sophia Mendez ,Quality Control Manager

We bought three UET PVC Extruders each for our Asian and South American factories. The equipment supports modified PVC composite processing and its modular design enables quick and easy process switching. Operating costs are 12% lower than those of comparable equipment, offering outstanding cost performance. We will continue to cooperate and purchase in the future!

Jasper Hale ,Global Procurement Manager

The UET PVC Extruder has helped us achieve stable mass production of precision PVC electrical conduits with dimensional tolerance strictly controlled within 0.08mm. The equipment features a simple and user friendly operation interface, allowing new employees to master it quickly. The wear resistant screw design extends component life and reduces maintenance downtime!

Mia Torres ,Process Engineering Specialist

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:The core differences lie in screw structure and temperature control systems. Flexible PVC extruders have lower compression ratio screws with larger pitch to adapt to highly elastic materials. Rigid PVC extruders feature screws with stronger shearing force and more precise temperature control systems to prevent material thermal decomposition. In addition there are differences in mold design and auxiliary equipment configuration between the two types.

A:Standard PVC extruders can efficiently process modified PVC composites with low filler content. For high filler and high viscosity modified materials it is necessary to replace dedicated screws optimize temperature control curves and adjust the feeding structure. This ensures uniform plasticization of materials and avoids unstable discharge or equipment malfunctions.

A:The selection is mainly based on product cross sectional size and output requirements. Small cross section products such as thin pipes and sealing strips are suitable for small diameter screws with high rotation speed to ensure precision. Large cross section products such as thick plates and large diameter pipes require large diameter screws with low rotation speed to guarantee plasticization quality. Material fluidity must also be matched accordingly.

A:The core steps include thoroughly cleaning residual materials in the screw barrel and mold after production checking the accuracy of the temperature control system and the operating status of electrical circuits tightening the bolts of all connecting components lubricating the transmission mechanism and bearings and regularly inspecting the screw wear condition and the aging degree of seals.

A:The key influencing factors include the abrasiveness and filler content of processed materials with higher abrasiveness leading to shorter service life the rationality of operating parameters such as excessively high temperature or fast rotation speed which accelerates wear the frequency of daily maintenance where timely cleaning and lubrication can extend service life and the screw material and surface treatment process.

A:Common causes include damp and agglomerated materials or uneven particle size distribution which prevent smooth feeding excessively high temperature at the feed inlet leading to premature melting and bonding of materials mismatched screw rotation speed and feeding speed where the feeding volume exceeds the extrusion volume and wear or jamming of feeding device components which affects feeding continuity.

A:A standard PVC extruder can produce a variety of common products including pipes profiles plates films wire and cable sheaths sealing strips and decorative strips. Different products require matching dedicated molds and auxiliary equipment. Some simple products can be directly produced with standard configurations without additional modifications.

A:This can be achieved through the following methods optimize temperature control and screw rotation speed to ensure uniform material plasticization and reduce product dimensional deviation regularly calibrate molds and extrusion parameters to improve qualified product rate adopt in line dimension inspection and automatic cutting devices and recycle qualified edge and corner materials in a certain proportion for reprocessing.