Scrap Reduction

Temp Uniformity

Energy Cut

Core Concentricity

UET Machine Wire & Cable Extruder Solutions

UET Wire & Cable Extruder Solutions, adapt to a wide range of wire and cable materials

To address wire diameter deviation and dimensional dispersion in cable extrusion precise temperature control and die fine tuning ensure wire diameter tolerances meet standards enhancing product specification consistency and factory qualification rate.

To resolve substandard core concentricity that impacts transmission performance optimize extrusion parameters and positioning mechanisms improve concentricity pass rate and ensure stable electrical performance of cables.

To tackle high production energy use and operational cost pressure optimize equipment power systems and extrusion processes reduce unit energy use and achieve synergy between efficiency and economy.

To address material waste and high scrap rates in cable production optimize material compatibility and extrusion stability reduce processing losses and improve comprehensive utilization rate of wire materials.

To solve cumbersome equipment maintenance processes and excessive downtime optimize machine structure and wear part design extend maintenance cycles and lower operational costs and technical thresholds.

To overcome limitations in multi material cable compatibility optimize screw configuration and temperature control systems widen equipment material compatibility and stably adapt to various wire extrusion processes.

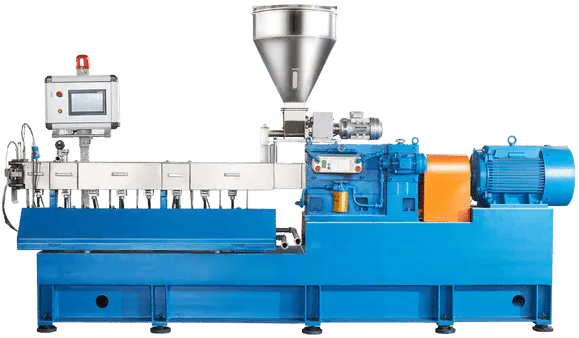

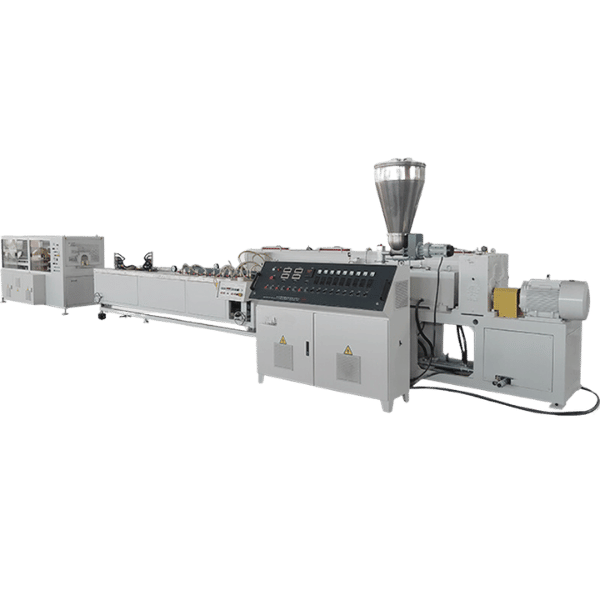

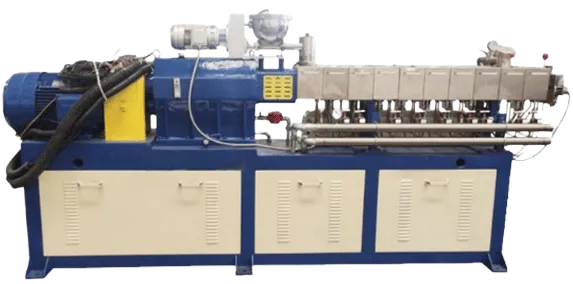

Wire & Cable Extruders for Sale

UET Machine offers high performance wire and cable extruders that can meet the processing needs of a wide range of cable materials.

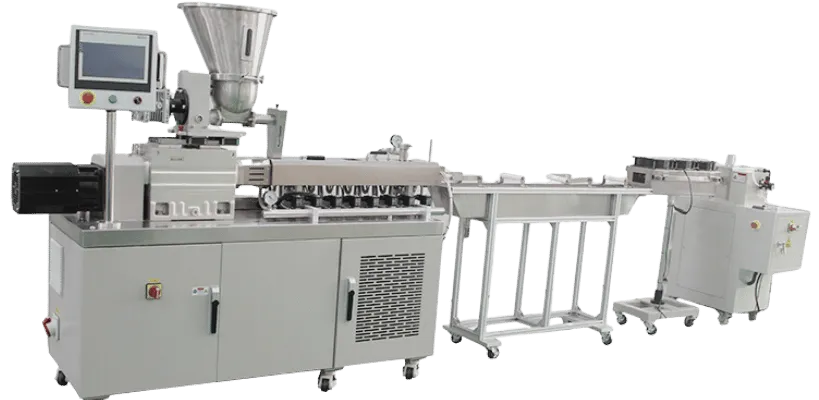

Precision Wire Diameter Extruder

It adopts smart diameter control and precision temp regulation diameter tolerance ≤ ±0.01mm suitable for copper aluminum cores and other conductors. It supports multilingual operation complies with UL standards simplifies maintenance meets high precision needs for power and communication cables.

High Efficiency Cable Extruder

It optimizes screw design and energy saving motor with energy consumption reduced by over 18% compared to traditional models supporting 24 hour continuous operation. Mold change takes ≤12 minutes with noise ≤70dB complying with CE environmental standards to enhance production efficiency and cost effectiveness.

Multi Material Compatible Extruder

It is compatible with XLPE PVC PE and over 12 cable insulation materials equipped with an intelligent parameter system for quick access to 150+ process schemes. The corrosion resistant body adapts to complex working conditions and is widely used in new energy and building cables.

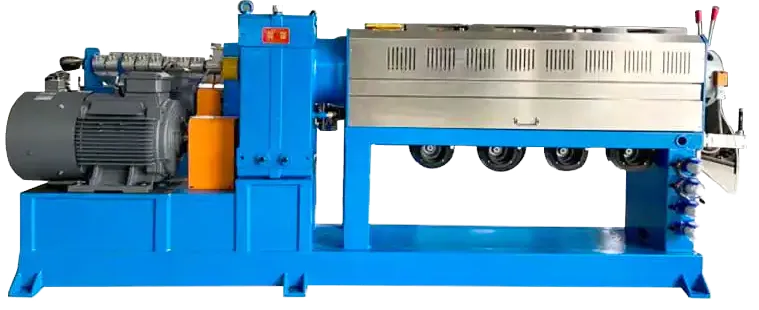

UET Wire & Cable Extruder Specifications

| Feature | Specification |

|---|---|

| Use | Cable Insulation & Sheath Extrusion |

| Place of Origin | China |

| Brand Name | UET |

| Wire Core Diameter Range | 10–60 mm |

| Extruded Product Outer Diameter | 15–70 mm |

| Screw Diameter | 90 mm |

| Screw L/D Ratio | 24:1 |

| Screw Rotation Speed (Adjustable) | 100–200 r/min |

| Main Motor Power | 90 kW |

| Max. Traction Speed | 60 m/min |

| Insulation Material Compatibility | PVC, PE, XLPE, Low-smoke Halogen-free Materials |

| Product Precision Tolerance | ±0.1 mm |

| Cooling System Efficiency | ≤5 min (full cooling for extruded products) |

| Pay-off & Take-up Range | 1000–2000 mm |

Different Models of UET Wire & Cable Extruders

| Model | Pay Off Type | Pay Off Spool (mm) | Screw Diameter (mm) | Screw L/D Ratio | Extrusion Output (kg/h) | Master Machine Power (HP) |

|---|---|---|---|---|---|---|

| UET-55 | Single-spool type | 350–500 | 55 | 24:1 | 80 | 18 |

| UET-65 | Double-spool type | 450–600 | 65 | 24:1 | 120 | 28 |

| UET-75 | Double-spool type | 500–650 | 75 | 26:1 | 160 | 35 |

| UET-85 | Double-spool type | 550–700 | 85 | 26:1 | 210 | 45 |

| UET-95 | Heavy-shaft type | 650–850 | 95 | 28:1 | 270 | 60 |

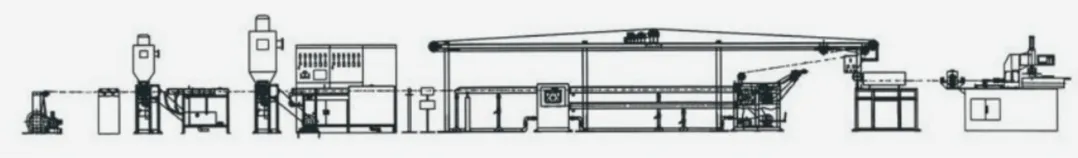

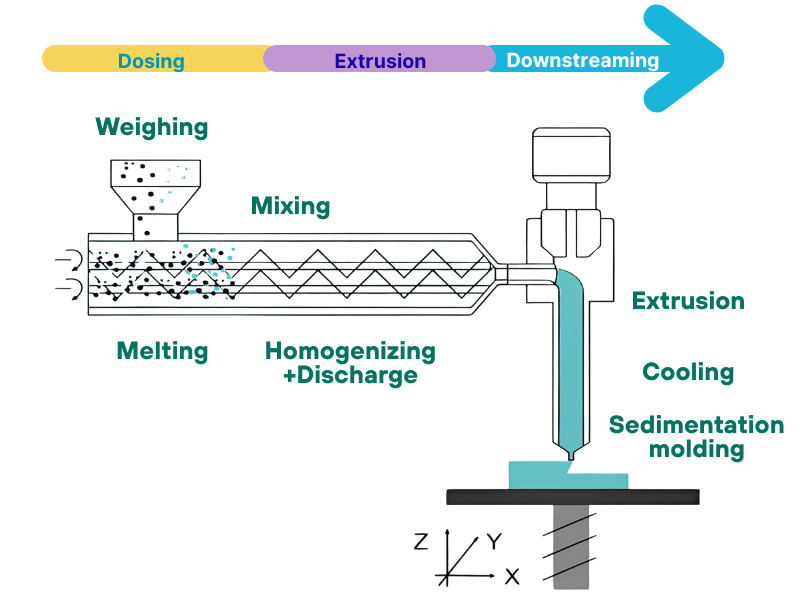

Flowchart of the Wire & Cable Extruder

Flowchart of the Wire & Cable Extruder

UET Wire & Cable Extruder Factory

Welcome to UET Wire and Cable Extruder Factory. Take a tour of our production workshop to learn how we manufacture our extruders.

Customer Reviews for UET Wire & Cable Extruders

Learn about the authentic user reviews for UET Wire and Cable Extruders and check out the real feedback from users after they use our extruders.

We have used this wire and cable extruder for three months and it has run with zero breakdowns. Its extrusion precision is far higher than that of our old equipment and the reject rate has dropped by 15 percent. The interface is simple and new employees can master it in half a day. After sales response is fast and it fully meets our mass production rhythm.

Mike Wilson ,Production Manager

This equipment has excellent compatibility and can adapt to all our wire specifications. Its temperature control is precise and the finished product consistency is extremely good. Production capacity has increased by 20 percent since commissioning and no additional production line modification is needed. Its cost performance is better than all previous models we evaluated.

Emma Carter ,Technical Supervisor

We compared three suppliers before choosing this model. Its body is solid and durable its energy consumption is lower than the industry standard and its operation noise is low. The installation team is professional and efficient. The later maintenance cost is clear and controllable and this investment is really worthwhile for our production needs.

Carlos Rodriguez ,Purchasing Director

We have used the equipment for six months and it has not had any major breakdowns. Its extrusion speed adjustment range is wide and it can flexibly match different orders. The pre sales custom solution is thoughtful and the after sales technical support is available on demand. It is a reliable production helper for our team.

Sophia Chen ,Factory Manager

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:To adapt to different sheath materials such as PE and PVC adjust the screw structure for example use low shear screws for PE and high dispersion screws for PVC optimize the temperature control curve to match the melting temperature of each material replace the corresponding feeding device and adjust screw speed and pressure parameters. Also pair with dedicated molds to ensure uniform plasticization of different sheath materials.

A:Standard models can process low filler low smoke zero halogen materials. However for high flame retardant high filler materials it is necessary to replace with dedicated screws to enhance shear dispersion upgrade the temperature control system to prevent decomposition and add a vacuum venting device. Otherwise issues like poor plasticization and substandard cable mechanical properties may occur.

A:Core operations include cleaning residual materials from the screw barrel and mold after production checking the accuracy of the temperature control system and electrical circuits lubricating transmission components such as bearings and gearboxes tightening connection bolts regularly measuring screw wear and replacing aging seals to prevent material leakage and equipment failures.

A:Small cable diameters (e.g. ≤10mm) pair with small diameter screws (45 65mm) using high speed to ensure precision. Large cable diameters (e.g. ≥50mm) pair with large diameter screws (90 120mm) using low speed to ensure plasticization quality. Also match production capacity needs to avoid overloading small screws.

A:It mainly relates to screw specifications larger diameter screws consume more energy operating load full load is more energy efficient temperature control efficiency poor insulation increases energy consumption motor energy efficiency high efficiency motors reduce energy use and operating parameters excessive heating or high speed operation increases energy consumption.

A:Core differences lie in screw design high speed models use low compression ratio screws temperature control systems high precision closed loop temperature control feeding devices volumetric high speed feeding and transmission systems high torque motors. These enable much higher extrusion speeds up to 2 to 5 times that of standard models while maintaining cable dimensional stability.

A:Configure an automatic tension control system to match extrusion speed equip the winder with variable frequency speed regulation use an in line diameter detection device to adjust winding tension in real time keep the cable surface clean and free of impurities and regularly maintain the winder’s tension rollers and cable arranging mechanism.