Scrap Reduction

Noise Level

Client Satisfaction

Power Reduction

UET Machine Rubber Extruder Solutions

UET Rubber Extruder Solutions,enhance your rubber extrusion efficiency

To address rubber extrusion precision deviation and unstable dimensions precise temperature control and screw optimization ensure product tolerances meet standards enhancing molding consistency and overall qualification rate.

To solve high production energy consumption and increased operating costs optimize the equipment power system reduce energy use per unit output and control costs reasonably while maintaining production efficiency.

To resolve complex and time consuming mold change processes simplify operation steps shorten equipment downtime and adapt to rapid production switching of multi specification products.

To tackle high waste rates and serious material loss in rubber processing optimize extrusion processes and material compatibility reduce production waste and improve comprehensive material utilization rate.

To meet the core needs for reducing cumbersome and frequent equipment maintenance optimize machine structure extend maintenance cycles and effectively lower daily operational difficulty and labor costs.

To solve poor compatibility of different rubber formulas and key production limitations reliably widen equipment material compatibility and stably meet production needs of diverse formulas.

Rubber Extruders for Sale

UET Machine offers professional grade rubber extruders that can meet the processing needs of various rubber materials. They are easy to operate and ensure long term operational reliability.

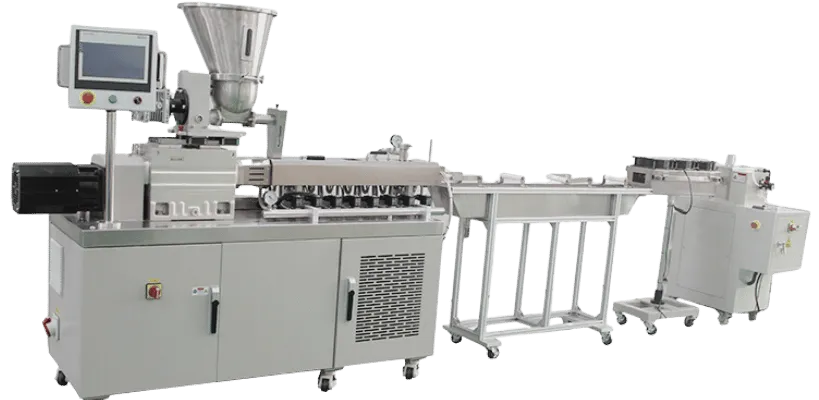

High Precision Smart Rubber Extruder

It adopts precision temperature control and die fine tuning technology with wire diameter tolerance of ≤ ±0.02mm, suitable for natural rubber synthetic rubber and other materials. It supports a multi language operation interface simplifies maintenance processes effectively reduces production loss and labor costs and meets the precision processing standards for high end seals and pipes.

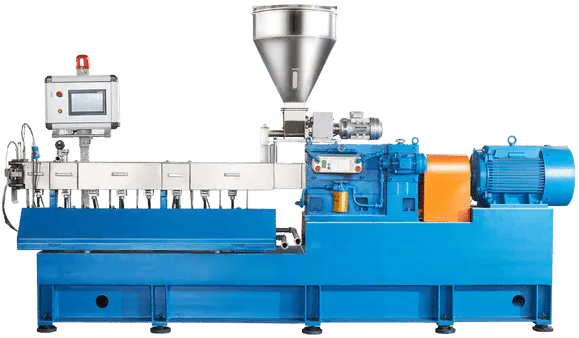

High Efficiency Energy Saving Rubber Extruder

It optimizes screw configuration and power system with energy consumption reduced by over 15% compared to traditional equipment supporting 24 hour continuous stable operation. Mold change process takes ≤15 minutes complying with CE environmental standards with noise ≤75dB balancing production efficiency and workshop environment to help enterprises strengthen market competitiveness.

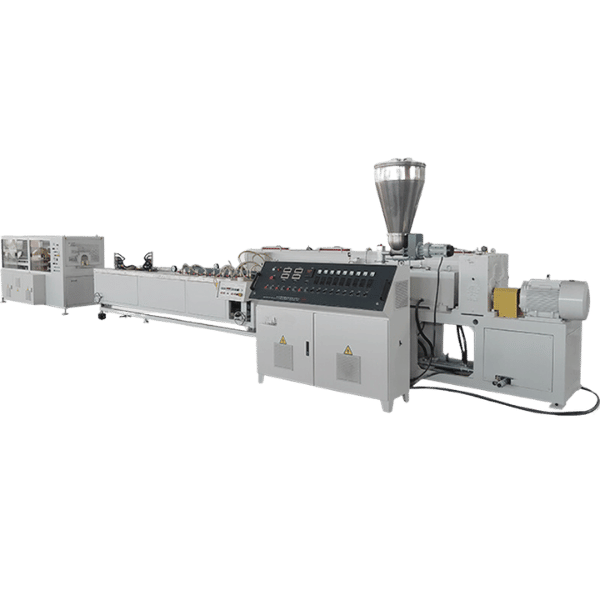

Multi Material Compatible Recycled Plastic Extruder

It is compatible with over 10 rubber formulas such as EPDM NBR and silicone equipped with an intelligent parameter storage system that can quickly call up more than 100 process schemes. The machine body adopts corrosion resistant materials suitable for complex working conditions and widely used in auto parts building seals and other fields to improve production flexibility.

UET Rubber Extruder Specifications

| Attribute | Details |

|---|---|

| Name | UET Rubber Extruder |

| Core Components | High-efficiency Motor, Precision Gearbox, Pressure Stabilizing Pump |

| Automation Features | Auto Feeding, Intelligent Temperature Control |

| Certifications | CE Certification, ISO 9001 Certification |

| Warranty & Support | 1-Year Warranty for Core Components; Lifetime Spare Parts Supply |

| Applicable Industries | Automotive (Seals), Construction (Gaskets), Electrical (Cable Insulation) |

| End Products | Precision Rubber Strips, Hoses, Gaskets |

| Quality Assurance | Pre-delivery Video Inspection & Test Report Provided |

| End Product Precision Tolerance | ≤±0.02 mm |

Different Models of UET Rubber Extruders

| Model | Screw Diameter (mm) | Screw L/D Ratio | Screw Speed (rpm) | Capacity (kg/h) |

|---|---|---|---|---|

| UET60 | 60 | 16:1 | 1800 | 80-150 |

| UET75 | 75 | 16:1 | 1500 | 120-220 |

| UET90 | 90 | 18:1 | 1200 | 200-350 |

| UET105 | 105 | 18:1 | 1000 | 300-500 |

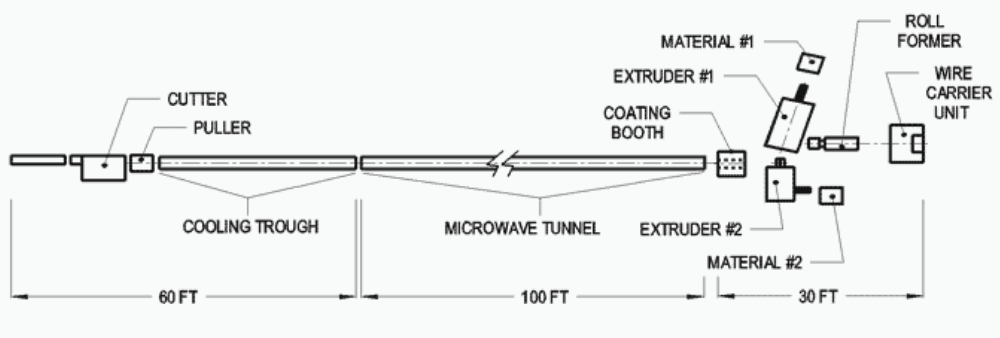

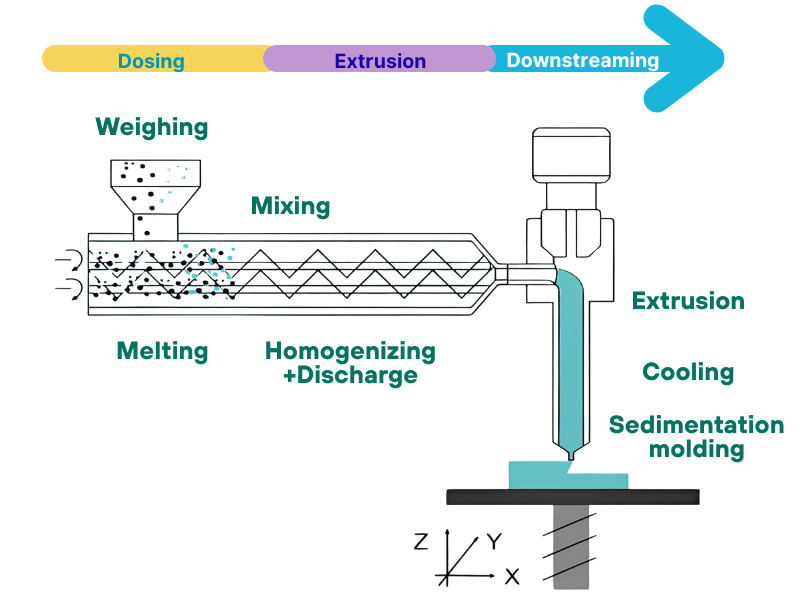

Flowchart of the Rubber Extruder

Flowchart of the Rubber Extruder

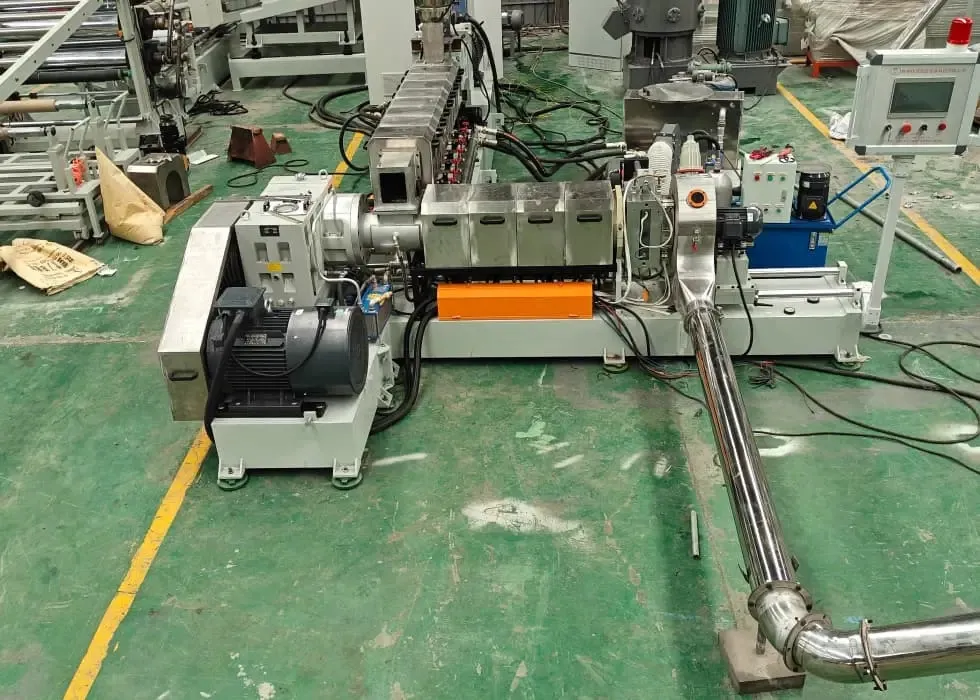

UET Rubber Extruder Factory

Welcome to UET Rubber Extruder Factory. We maintain rigorous standardized quality inspection procedures to ensure the stability and reliability of each piece of equipment.

Customer Reviews for UET Rubber Extruders

Review the authentic customer feedback for UET Rubber Extruders and learn how UET equipment helps customers meet their stable mass production needs for special rubber products.

We use the UET Rubber Extruder for one year. The equipment has an extremely low failure rate during continuous operation and the extrusion precision of specialty rubber seals fully meets the standards for automotive components. Production capacity has increased by 30% vs our old equipment. After sales support is responsive and problem solving is efficient. We are very satisfied!

Oliver Hayes ,Plant Operations Manager

Our team tested multiple rubber extrusion machines and ultimately chose UET. The machine delivers excellent plasticizing effects for fluororubber and silicone rubber. The finished products have a smooth burr free surface and require no secondary processing. The intelligent temperature control is precise, effectively reducing the product defect rate. Highly recommended!

Chloe Reed ,R&D Technical Lead

For the processing needs of 50 percent calcium carbonate high fill recycled materials the equipment achieves uniform plasticization with extrusion stability far exceeding expectations. It has 25 percent higher capacity than the previous brand with low noise easy cleaning prompt after sales response and professional technical support.

Ethan Morse ,Global Sourcing Director

The UET Rubber Extruder has helped us achieve stable mass production of large diameter rubber pipes with dimensional tolerance controlled within 0.1mm. The machine features a user friendly operation interface, allowing new employees to master it quickly. The wear resistant screw design extends component service life and reduces unplanned downtime for maintenance!

Luna Voss ,Production Process Engineer

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:The main types suitable for silicone rubber processing are cold feed single screw extruders and dedicated silicone rubber extruders. These machines are equipped with precise temperature control systems and low shear screws to adapt to the high viscosity characteristics of silicone rubber. Some models also integrate in line vulcanization units to meet the processing needs of different products such as silicone rubber seals and profiles.

A: Improving extrusion precision requires multiple measures optimize the mating tolerance of screws and barrels, adopt a closed loop temperature control system to stabilize material temperature, configure volumetric feeding devices to ensure uniform feeding, regularly calibrate mold dimensions, and maintain good equipment lubrication to reduce the impact of operational vibration on product tolerances.

A:Standard rubber extruders can process modified rubber composites with low filler content. However, for high filler and high viscosity modified materials, it is necessary to replace dedicated screws, optimize the temperature control system and adjust the feeding structure. Otherwise, unstable discharge, substandard mechanical properties of products or equipment jamming may occur.

A:The core differences lie in the state of the fed raw materials and equipment structure. Cold feed machines can directly process room temperature rubber compounds without preheating. They have a complex structure but are energy efficient and high performance. Hot feed machines need to be paired with rubber mixers for preheating rubber compounds. They have a simple structure and high processing efficiency, suitable for mass production of low precision rubber products.

A:everal measures can be taken to reduce energy consumption install insulation layers on the equipment to reduce heat loss, optimize the temperature control curve to avoid overheating, reasonably match motor power with production load, regularly clean up rubber deposits on screws and barrels, and ensure good lubrication of transmission components to reduce mechanical friction losses.

A:Daily maintenance requires the following steps clean up residual rubber materials in screws, barrels and molds after production, check the temperature accuracy of the temperature control system, tighten the bolts of all connecting components, lubricate bearings and transmission mechanisms, inspect the operating status of motors and circuits, and replace aging seals in a timely manner.

A:The service life depends on the characteristics of the processed materials and frequency of use. When processing ordinary rubber materials, the typical service life of screws and barrels is 3 to 5 years. If processing high filler and highly abrasive materials, the service life will be shortened to 1 to 2 years. Standard operation and regular maintenance can effectively extend their service life.

A:Rubber extruders can be fully integrated into fully automated production lines. It is necessary to match auxiliary equipment such as automatic feeding systems, in line dimension inspection devices, automatic cutting machines, continuous vulcanization systems and finished product palletizing machines. The PLC control system is used to realize the linkage of each process, improving production efficiency and consistency of product quality.