Reactive Conversion Rate

Continuous Operation Uptime

Reactive Mixing Uniformity

Reactive Product Purity

UET Machine Reactive Extruder Solutions

UET Reactive Extruder Solutions Addressing Your Production Pain Points

Delivers 99.2%+ product purity via precise process control and uniform mixing, meeting global strict quality standards.

Ensures full EU REACH and FDA compliance, providing certified solutions for international market access.

Features wear resistant screws and self diagnostic systems, cutting annual maintenance costs by 30%.

Handles 5+ reactive material types with flexible parameter adjustment, ensuring stable complex formulation performance.

Integrates food grade parts and sealed chambers, eliminating cross contamination in production.

Achieves 99.5%+ uptime with robust design and real time monitoring, supporting 24/7 continuous production.

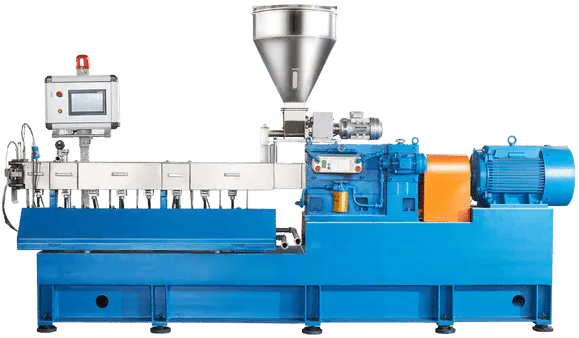

Reactive Extruders for Sale

UET Machine delivers high quality reactive extruders, compatible with a wide range of reactive process requirements, offering easy maintenance and reliable performance.

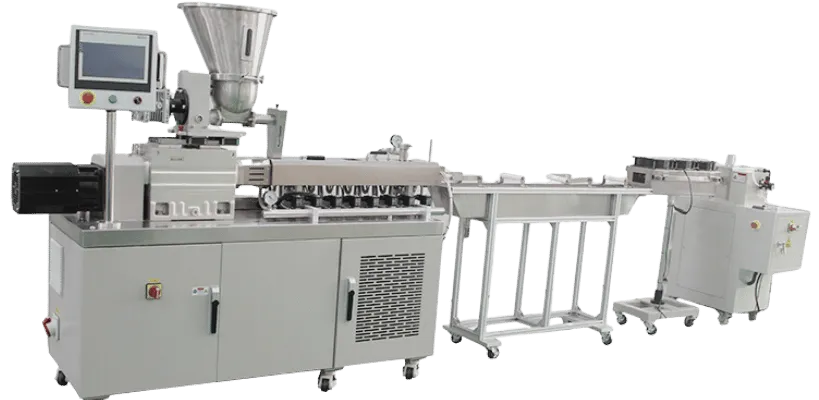

Laboratory Scale Reactive Extruder

Ideal for R&D and pilot studies, supports 10-500g per batch small-scale reactions, ±1℃ precision temperature control, rapid recipe changeover within 30 minutes, compatible with PLA and biobased material grafting processes, facilitating fast formulation iteration and process validation.

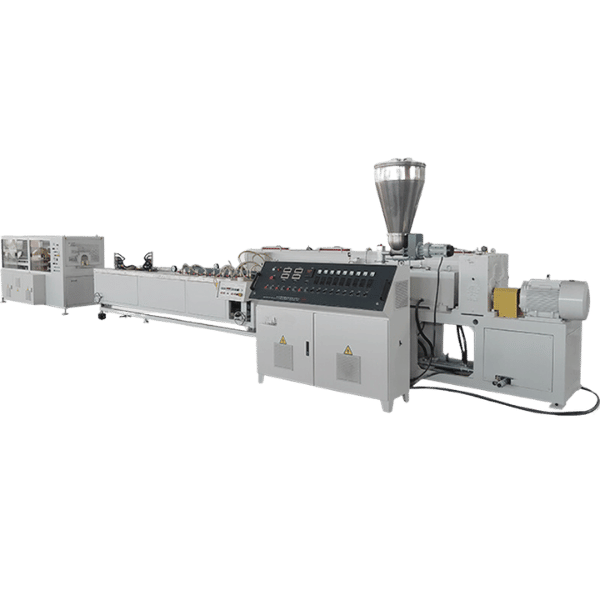

Intermediate Pilot Scale Reactive Extruder

Bridges R&D and mass production, capacity 50-500kg/h engineered for seamless pilot scaling, adjustable 10-60s precision-tuned reaction residence time, compatible with multi component reactive feedstocks, fully meets EU REACH standards, significantly minimizing risks in large-scale production.

Industrial Production Reactive Extruder

Designed for large-scale manufacturing, capacity ranges 2-20t/h, reaction conversion rate over 98%, stable 99.5% continuous operation rate, wear resistant screws with energy saving design, FDA REACH compliant, boosting efficiency while controlling energy costs.

UET Reactive Extruder Specifications

| Specification | Details |

|---|---|

| Output (kg/h) | 1,000 – 15,000 kg/h |

| Reactive Materials Processed | Biobased polymers, TPE, functionalized plastics (PLA, PP-g-MAH) |

| Reaction Temperature Range | 150 – 300°C (±2°C precision) |

| Reaction Residence Time | 10 – 90s (adjustable) |

| Condition | New |

| Compliance Report | ISO 9001-certified test docs |

| Core Component Warranty | 24 Months |

| Core Components | Precision PLC, high-torque gearbox, energy-efficient servo motor |

| Weight | 6,000 kg |

| Applicable Industries | Specialty plastics, biobased materials factories |

| Voltage | Customized (220V/380V/480V, 50/60Hz) |

| Screw Design | Co-rotating Twin Screw (wear-resistant coating) |

| Final Product | Functional polymer pellets, modified biobased granules |

| After-sales Support | Video technical assistance; paid on-site service |

Different Models of Reactive Extruders

| Model | Diameter (mm) | Max. Speed (rpm) | Motor (kW) | L/D | Output (kg/hr) |

|---|---|---|---|---|---|

| UET-RX100 | 30 | 800 | 7.5 | 40 | 2-10 |

| UET-RX500 | 50 | 600 | 37 | 44 | 50-250 |

| UET-RX800 | 65 | 550 | 110 | 46 | 500-2000 |

| UET-RX2000 | 75 | 500 | 160 | 48 | 2000-6000 |

| UET-RX3000 | 90 | 450 | 250 | 50 | 6000-12000 |

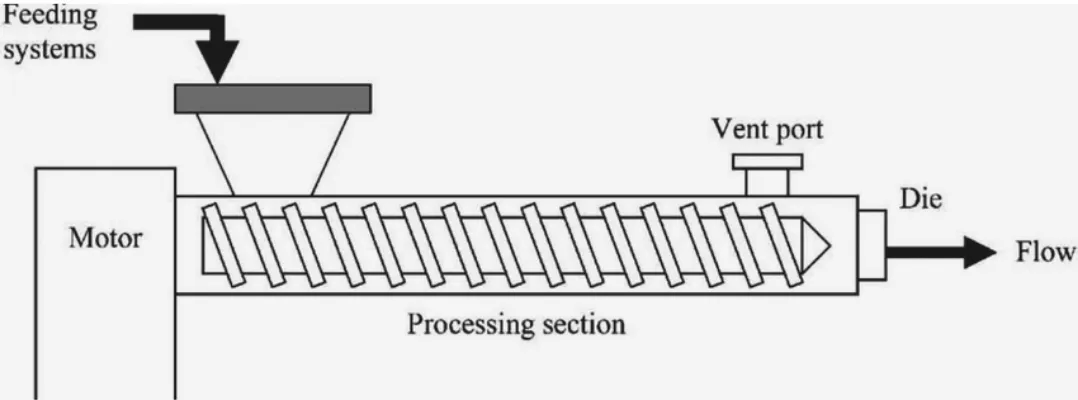

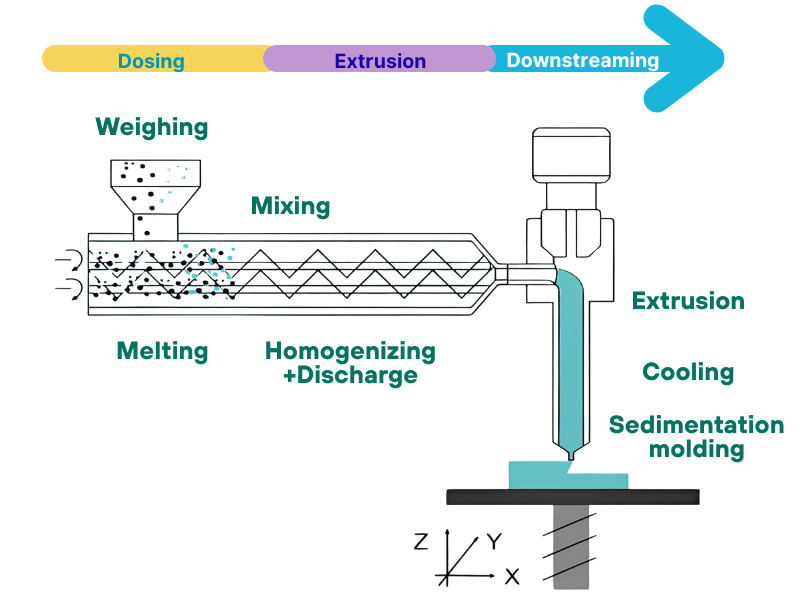

Schematic Representation of a Reactive Extrusion System

Schematic Representation of a Reactive Extrusion System/Image Source:researchgate.net

UET Reactive Extruder Factory

Welcome to UET Reactive Extruder Factory. We have equipped specialized processing systems tailored for multiple reaction systems, and adhere to standardized quality inspection procedures. These steps ensure our equipment is compatible with various reactive feedstocks, and maintains consistent reliable operational performance.

Customer Reviews for UET Reactive Extruders

Check out the real customer reviews for our UET Reactive Extruders to learn how UET equipment solves formulation processing issues for its customers.

Previous equipment caused uneven biobased material reactions and high rework rates. With UET, temperature control is accurate to ±1℃, product performance fluctuation is within 2%, and capacity meets specs. The intuitive interface lets new staff learn fast; it’s run 4 months without issues.

Noah Foster ,Production Workshop Supervisor

No frequent parameter adjustments needed when switching multi component feeds. Wear resistant screws handle high fill materials like glass fiber filled PP. Runs stably 12 hours under high load, capacity up 5% from rated, zero failures in 6 months, 20% higher efficiency.

Luna Hart ,Chemical Process Specialist

We compared three suppliers; UET had a fair price and 6 extra months of core warranty (total 24 months). Installation and commissioning were smooth, hitting design capacity in a week. Easy to operate, stable batch data in 7 months, and quick service responses.

Owen Reese ,Equipment Procurement Manager

We use UET equipment for TPE reactive formulations. Its adjustable residence time fits our process needs, raw material conversion rate rose 15%, and mass production performance remains stable. We faced parameter debugging issues last time, but after sales support resolved it quickly via video guidance.

Mia Bennett ,Polymer R&D Engineer

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

A:The UET Reactive Extruder offers comprehensive customization services. It can adjust production capacity, screw configuration, barrel material and temperature control precision according to customer process requirements. It also provides customized accessories such as feeding systems and venting devices. Whether for pilot scale R&D or mass production lines, it can adapt to special scenarios like multi component reaction and high fill processing, meeting personalized process needs.

A:It can process general purpose plastics such as PP, PE, ABS and PC, thermoplastic elastomers like TPE/TPU, biobased polymers, degradable materials, as well as functional materials including glass fiber/carbon fiber reinforced modified materials and flame retardant masterbatches. It is compatible with high viscosity, heat sensitive and multi component blending systems, and can adapt to various reaction processes such as polymerization, grafting and crosslinking, covering the needs of automotive, electronics, packaging and other industries.

A:The UET Reactive Extruder has obtained CE certification and complies with the EN 1114 safety standard, meeting the requirements of EU Machinery Directive and Low Voltage Directive. It has also passed UL certification to ensure electrical safety performance. The product fully meets international market access specifications and complies with standards in terms of safety, environmental protection and electromagnetic compatibility.

A:Its core advantages lie in precise reaction control capability, with adjustable residence time of 10-60 seconds and temperature control precision of ±1℃, ensuring reaction stability. The modular screw design adapts to various processes, and wear resistant materials extend service life. It also features seamless transition from pilot scale to mass production, coupled with a 24 month warranty for core components and fast after sales response, offering outstanding overall cost effectiveness.

A:We provide professional on site installation and commissioning services. Our technical team completes equipment positioning, pipeline connection, parameter calibration and trial production verification on site. Meanwhile, we offer supporting operator training covering equipment operation, daily maintenance, troubleshooting and other content. The entire service process is efficient and convenient, helping users put into production quickly.

A:We support small scale testing and prototype testing services. Customers can send raw materials to the UET laboratory, where professional engineers complete process testing according to requirements and provide key data such as conversion rate and product performance. We can also arrange on site testing for customers with their own materials to verify equipment adaptability.

A:The core function is to integrate chemical reaction with physical processing, completing reactions such as polymerization, grafting and crosslinking during the extrusion process, while realizing material plasticization, mixing and molding. By precisely controlling temperature, pressure and residence time, it improves reaction efficiency and product consistency, supports continuous production, reduces processing steps, and adapts to the functional processing of various polymer materials.

A:The Reactive Extruder is suitable for reactive raw materials such as thermoplastic elastomers (TPE), biobased polymers, modified plastics, glass fiber/carbon fiber filled materials and multi component blending materials. It is compatible with high viscosity, high fill and functional additive systems, and can meet the requirements of various reaction processes such as grafting, crosslinking and polymerization for raw materials, adapting to most reactive material processing scenarios in industrial production.

A:The adjustable range of reaction residence time for the Reactive Extruder is usually 10-60 seconds, and some customized models can be extended to 5-120 seconds. Precise control is achieved by adjusting screw speed, barrel structure and feeding rate, which can adapt to the kinetic requirements of different reaction systems. It provides stable residence time control for both fast and slow reaction processes.

A:The production capacity range of the Reactive Extruder is wide. Laboratory scale models can reach a capacity of 5-50kg/h, pilot scale models 50-500kg/h, and industrial mass production models can achieve more than 500-5000kg/h. Users can select models with corresponding capacity according to their own production scale (R&D, pilot scale, mass production). Some manufacturers support capacity customization to match special process requirements.

A:The Reactive Extruder can produce functional polymer materials such as graft modified polymers (e.g., PP g MAH), blending modified materials, biodegradable plastics, functional film substrates, flame retardant/reinforced modified plastics, thermoplastic elastomers (TPE/TPR) and polymer alloys. It is widely used in the production of high performance materials for automotive, packaging, electronics, medical and other industries.

A:The core difference is that the Reactive Extruder has in situ reaction capability. Through specially designed screw structure, precise temperature control system and adjustable residence time, it can complete chemical reactions such as polymerization, grafting and crosslinking during the extrusion process. In contrast, ordinary extruders only responsible for material plasticization and molding, without the ability to adapt to reaction processes. In addition, the Reactive Extruder has higher requirements for parameter control precision and equipment tightness.

A:The conventional industry warranty period for the core components (screw, barrel, reducer, motor) of the Reactive Extruder is 12-24 months. High quality manufacturers can provide extended warranty services (some up to 36 months). The warranty scope usually covers failures caused by manufacturing defects, excluding those due to improper manual operation and normal wear of consumable parts. Specific terms are subject to the manufacturer’s after sales agreement.

A:The installation and commissioning process of the Reactive Extruder is not complicated. Professional manufacturers usually provide full process technical support: after delivery, equipment positioning, pipeline/electrical connection are carried out first, then technical personnel perform parameter calibration and no load test run, and finally verify process adaptability through small batch trial production. The entire process generally takes 3-7 days, and operators can get started after simple training.

A:The consumable parts of the Reactive Extruder mainly include screw, barrel (long term contact with high wear materials), filter screen (easy to clog when filtering impurities), seals (easy to age under high temperature and pressure), heating coils (wear from long term operation) and feeding screws. The replacement frequency of these consumable parts is related to processed materials and production capacity. The replacement of conventional consumable parts is simple, and manufacturers provide compatible accessories with controllable replacement costs.