Filler Masterbatch Compounding Extruder

High Quality Filler Masterbatch Compounding Extruder Manufacturer in China

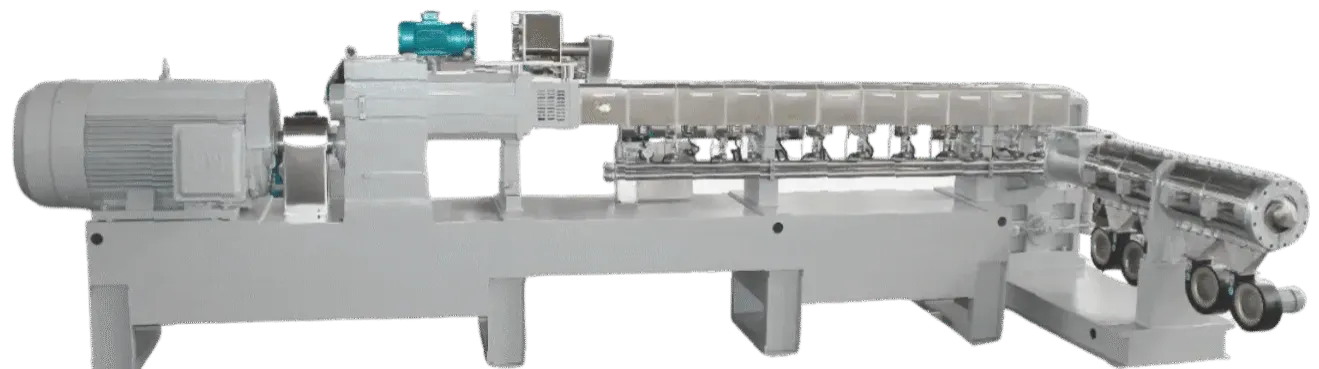

UET Machine’s filler masterbatch compounding extruder is engineered for high-proportion fillers (e.g., calcium carbonate, talc), ideal for mass-producing filler masterbatches for general-purpose plastics. It delivers consistent, uniformly filled color and functional masterbatches. Simplified operations enable new staff to work independently quickly. Versus industry peers, it boosts filler dispersion uniformity by 18%, cuts maintenance costs by 25%, and lowers energy consumption by 12%. With minimal post-startup adjustment downtime, it fully meets filler masterbatch manufacturers’ large-scale production needs.

95%+

Filler Coating Rate

98%

Batch Pass Rate

30+ Types

Compatible Filler Types

22%

Maintenance Cost Cut

UET Machinery Filler Masterbatch Compounding Extruder Solutions

Whether you need to process any type of filler masterbatch or pursue high compatibility between fillers and base materials, UET Machine’s filler masterbatch compounding machine delivers professional and reliable processing solutions.

High-proportion filler masterbatches (CaCO3, talc): legacy agglomeration/uneven spread fixed. Special compounding boosts dispersion by 18%—ensuring masterbatch uniformity/stability for overseas high-end specs.

Filler masterbatch compounding is simplified with an intuitive smart interface. New employees work independently after short training, cutting line training costs significantly. It fits flexible staffing/rotation needs of overseas lines.

Large-scale filler masterbatch production: startup/debug optimized—cuts adjustment downtime, supports 800+hrs continuous compounding. 15% higher capacity vs legacy gear, matches overseas bulk order delivery.

Against wear from high-abrasion fillers (talc), we use tungsten carbide-coated screws/wear-resistant barrels, extending core component life 30%. Lowers spare part replacement and cross-border downtime costs for overseas users.

Solves compounding compat between plastic substrates (PP, PE, ABS) and fillers. Adjustable shear strength adapts to filler masterbatches for diverse substrates—covering mainstream overseas rubber/plastic scenarios.

Uses closed feeding & high-eff exhaust filtration system, controlling workshop dust concentration within 0.5mg/m³. Meets EU occupational health/safety standards, enhancing production environment for overseas users.

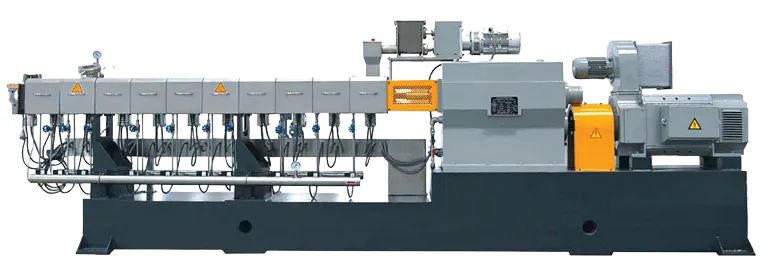

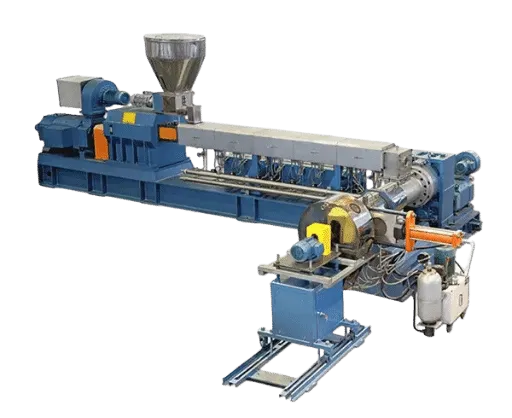

Filler Masterbatch Compounding Extruder For Sale

We offer filler masterbatch compounding extruders that are ideal for all your compounding operations. Contact us to learn more.

High Capacity Large Scale Filler Masterbatch Compounder

With an hourly output of 3000-7000kg, it is equipped with a high specific torque screw and ±1℃ precision temperature control. The compounding uniformity reaches ≥98%, it saves 15% energy and extends core component service life by 50%. It solves issues like low efficiency and uneven finished products in large scale production, suitable for mass production of calcium carbonate and glass fiber filled masterbatches in the automotive, packaging and construction materials industries.

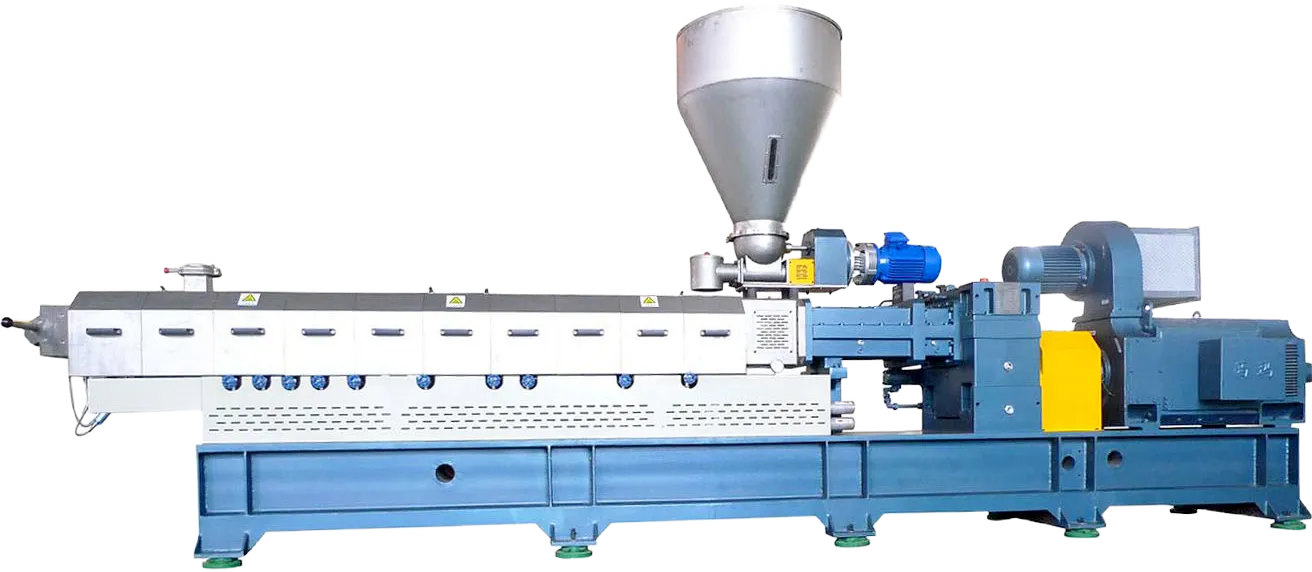

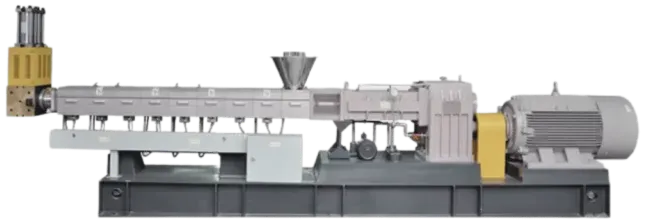

Multifunctional Compatible Filler Masterbatch Compounder

It is compatible with all types of fillers such as calcium carbonate and bio based materials. The screw kneading elements can be freely combined, reducing formula change and cleaning time by 40% and supporting multi language formula storage. It addresses the pain points of difficult multi formula adaptation and complex operation for small and medium enterprises, suitable for multi category orders including color masterbatches, flame retardant masterbatches and functional masterbatches.

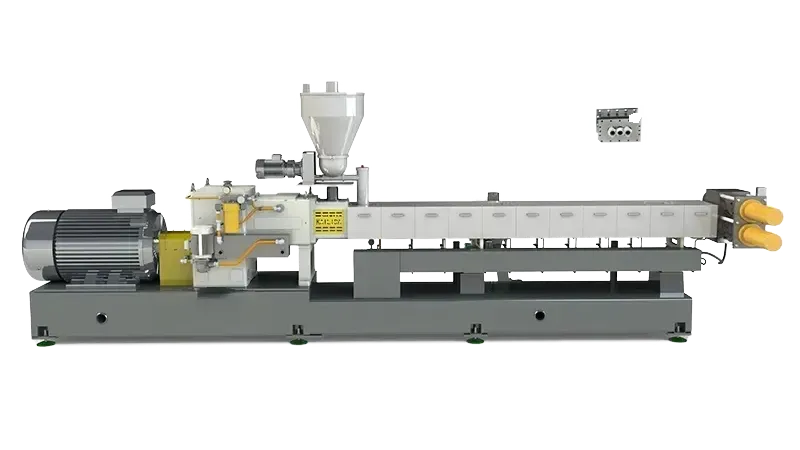

Specialty Material Dedicated Filler Masterbatch Compounder

It adopts high chromium corrosion resistant alloy and ceramic liners, with a wide temperature process suitable for processing from room temperature to 400℃. The dispersion particle size deviation is <1%. It overcomes processing challenges of high filling, corrosive and temperature sensitive materials, suitable for the production of high end specialty masterbatches such as long fiber reinforced and nano filled ones, meeting the customized needs of the aerospace and new energy industries.

Technical Specifications for UET Filler Masterbatch Compounding Extruders

We offer multiple models of Filler Masterbatch Compounding Extruder and can also provide customized solutions based on your specific requirements

| Type | Length-diameter Ratio (L/D) | r/min (RPM) | Total power (KW) | Capacity (kg/h) |

|---|---|---|---|---|

| UET55 | 34-38 | 450/600 | 55/75 | 180-280 |

| UET65 | 36-40 | 500/650 | 80/95 | 300-400 |

| UET75 | 38-42 | 500/600 | 120/145 | 500-650 |

| UET85 | 36-40 | 550/650 | 180/200 | 800-1000 |

| UET95 | 40-44 | 500/600 | 260/320 | 950-1200 |

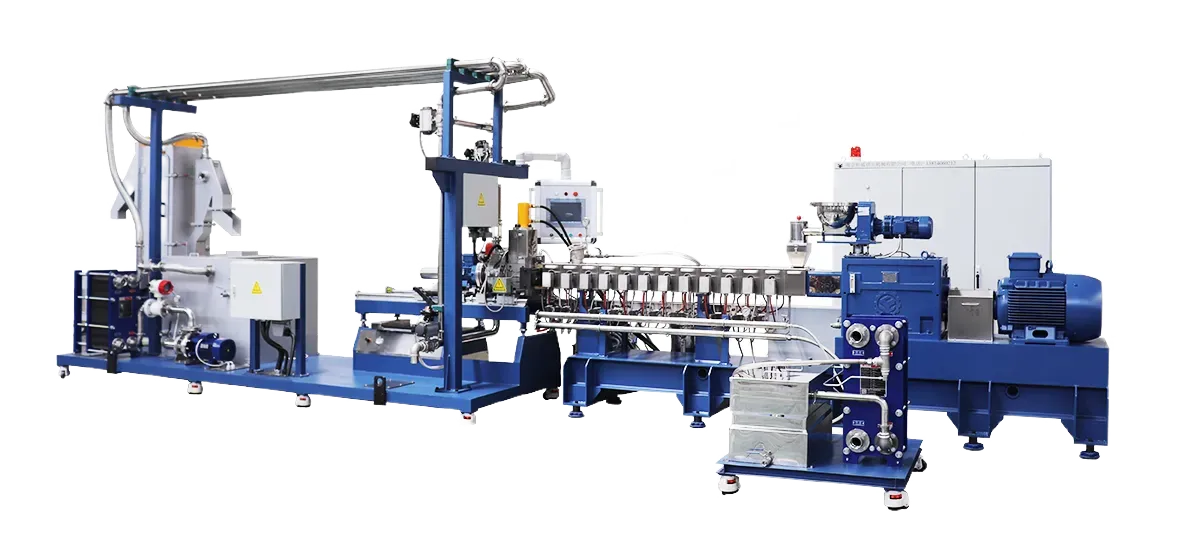

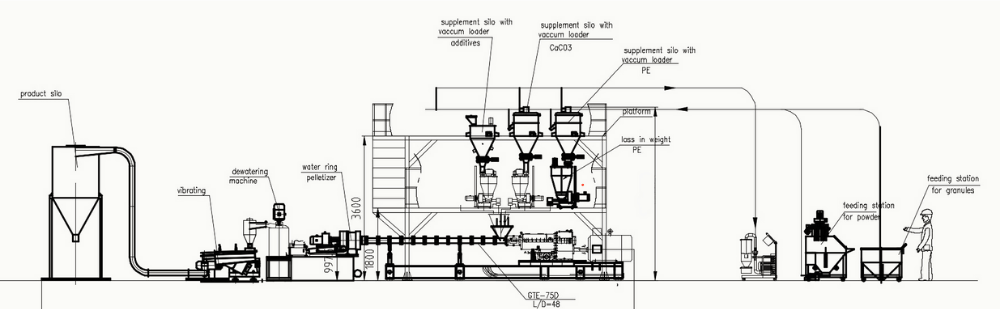

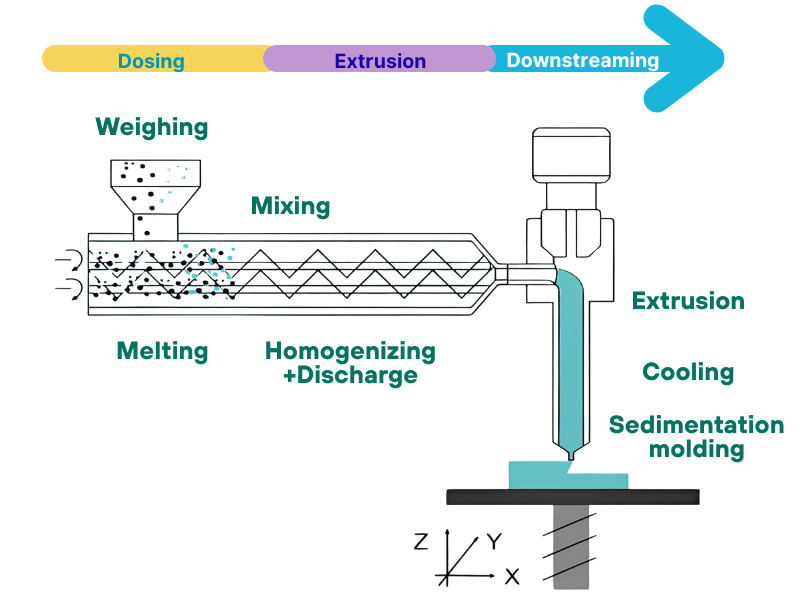

Flowchart of the Filler Masterbatch Compounding Extruder

Flowchart of the Filler Masterbatch Compounding Extruder

UET Filler Masterbatch Compounding Extruder Factory

Welcome to the UET Filler Masterbatch Compounding Extruder Factory. We are equipped with customized processing equipment that accommodates multiple types of fillers as well as an end to end quality inspection system. We ensure the equipment’s compatibility with complex fillers and its reliable operation.

Customer Reviews for UET Filler Masterbatch Compounding Extruders

Check out the genuine customer reviews for our filler masterbatch compounding extruders and learn about the problems solved by UET extruder solutions for users.

Our previous equipment had uneven compounding when handling 60% calcium carbonate filling and production capacity never met standards. The high specific torque screw and precision temperature control of UET extruders are impressive. Filler dispersion uniformity exceeds 98% hourly production capacity has increased by 30% and it saves 15% energy fully meeting our large scale production needs.

Emma Carter

We need to frequently switch between different filler formulas such as glass fiber and bio based materials. Our previous equipment required 2 hours for changeover and was prone to residue. The UET multifunctional model takes only 40 minutes for changeover and cleaning and the formula storage function is extremely practical. The equipment has been in operation for a year without any malfunctions.

Sophia Rodriguez

As a manufacturer of food contact grade masterbatches we have extremely high requirements for equipment environmental protection and stability. UET extruders comply with REACH and RoHS standards. The stainless steel body is easy to clean with no risk of material contamination. Precision temperature control avoids degradation of temperature sensitive materials and the product qualification rate has increased from 92% to 99%.

Olivia Wilson

Our previous equipment had severe screw wear processing high filling flame retardant masterbatches needing 3 month replacements. UET extruders’ high chromium wear resistant alloy components are durable with just 5% wear rate after 8 months. It has dispersion particle size deviation under 1% produced long fiber reinforced masterbatches meet standards cutting maintenance costs by 30% with cost performance far superior to competitors.

Michael Brown

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

These are the frequently asked questions about filler masterbatch compounding extruders and they can address most of your questions regarding such equipment.

A:Need to consider production capacity, filler type such as calcium carbonate and glass fiber, and compounding uniformity requirements. Prioritize length diameter ratio, screw structure and wear resistant materials to match your production scale and formula characteristics. Also refer to equipment energy consumption and after sales support.

A:Yes. Select a high specific torque screw and wear resistant bushings, paired with a precision temperature control system. Control processing temperature and rotational speed to avoid filler agglomeration. It can stably handle 50% to 70% high proportion calcium carbonate filling and ensure compounding uniformity.

A:Optimize the combination of screw kneading elements, achieve precise temperature control of ±1℃, and use a side feeding device for uniform feeding. Pre dry the filler to reduce caking. Adjust screw speed and material residence time to ensure full integration of the filler into the base material.

A:Key factors include screw speed, length diameter ratio, motor power and material fluidity. Reasonably match speed and power, select an appropriate length diameter ratio of 36 to 44D, ensure materials are dry and free of impurities, and avoid blockages to maximize production capacity.

A:Clean residual materials in the compounding chamber and screw daily, and check the accuracy of the temperature control system. Tighten connectors and inspect lubricant levels weekly. Examine screw wear and seal conditions monthly, and replace aging parts in a timely manner to avoid downtime due to failures.

A:Screws and bushings: 1 to 2 years (can be shortened to 1 year for high load production). Bearings: 6 to 12 months. Seals: 3 to 6 months. Regularly check wear levels and replace immediately if material compounding becomes uneven or leaks occur.

A:The former is optimized for filler dispersion with more screw kneading elements, stronger wear resistant materials, higher temperature control accuracy of ±1℃, and support for side feeding devices. Standard extruders focus on plasticization and extrusion with weak compounding capabilities, making them difficult to adapt to high filling requirements.

A:Control processing temperature within the material’s tolerance range, reduce screw speed to minimize shear heat, and optimize the exhaust system to remove volatile substances. Use temperature resistant components to avoid local overheating and shorten processing residence time for temperature sensitive materials.