Plastic Compounding Machine

Top Tier Plastic Compounder Manufacturer in China

The plastic compounding machine from UET Machine is specifically engineered for the high-efficiency compounding of general-purpose and engineering plastics, suitable for the mass processing of modified plastics, functional masterbatches, and recycled plastics. It consistently delivers high-quality products such as uniformly compounded plastic substrates and modified plastic semi-finished goods. Featuring a user-friendly operation interface, the equipment allows new operators to achieve proficiency after basic training. Compared to the industry average, it reduces the compounding cycle by 20%, improves material uniformity by 15%, and lowers maintenance costs by 28%. It can quickly enter stable production after startup, perfectly meeting the large-scale production needs of plastic processing enterprises.

98%+

Compounding Uniformity

20%↓

Energy Saving Ratio

≤0.3%

Batch Rejection Rate

1.5x Longer

Screw Part Lifespan

UET Plastic Compounding Machinery Solutions

For large-scale compounding needs of plastic processors, UET Plastic Compounding Machines offer continuous stable compounding and large-batch silo compatibility. Increasing single-batch capacity by 25% without material stratification in continuous use, they’re ideal for large-scale scenarios like granulation and modification.

For your production scale and material traits, we customize rotor meshing clearance, mixing chamber structure and temp control precision to meet personalized compounding needs of high filling and high elasticity materials.

Covering thermoplastics, rubber blends, high filling modified materials, biodegradable materials & others, it stably processes high viscosity, hard to disperse materials, breaking traditional compounders’ material limits.

Over 20 years manufacturing industrial grade compounding equipment: core parts use wear resistant alloy. It runs steadily under high temperature, high load conditions, keeping mass production uninterrupted.

Solving uneven dispersion in high filling modified materials, we use a special meshing rotor, ensuring filling dispersion uniformity over 98%. Ideal for mass compounding of high filling materials like calcium carbonate and glass fiber.

For corrosive materials with flame retardants, strong acid additives & others, mixing chamber has corrosion resistant ceramic liners. Core parts’ corrosion life extends 50%, suiting long-term compounding of high-corrosive specials.

We offer 24-hour multilingual online tech support. With global regional spare parts hubs, regular parts ship globally in 7 days, core parts include extended warranties. We also offer equipment operation & maintenance training.

Plastic Compounding Machines For Sale

UET’s reliable plastic compounding machines can help boost your production efficiency. Reach out to us today or schedule a visit to learn more!

Heavy Duty High Fill Compounding Machine

Designed for 50% to 80% high proportion fillers such as calcium carbonate and glass fiber it adopts wear resistant alloy screws and reinforced mixing chambers effectively solving filler agglomeration and uneven dispersion with uniformity ≥98%. Suitable for masterbatch preparation and high fill modified plastic production it is durable supports large scale continuous processing and meets high fill production needs.

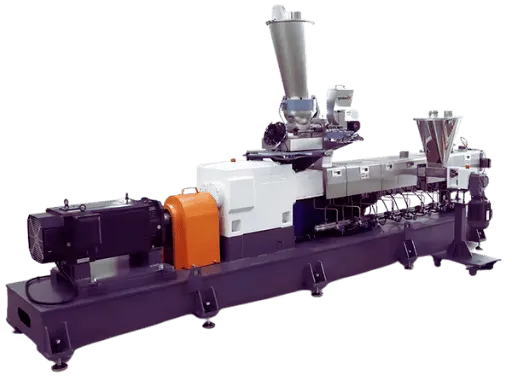

Twin Screw Multi Function Compounding Machine

Equipped with twin screw meshing structure and ±1℃ precision temperature control it integrates plasticization mixing and exhaust processes solving the problems of difficult multi material adaptation and cumbersome model change. Suitable for processing plastics elastomers and composites it enables easy changeover and cleaning boosts capacity by 25% and applies to modified plastics recycled material processing and special material compounding.

Energy Saving Efficient Compounding Machine

Optimized for motor and transmission systems it reduces energy consumption by 15% to 20% compared with traditional models solving high energy consumption and low output pain points. With intelligent frequency conversion control and rapid heating technology it boosts production efficiency by 30% operates at ≤75dB and meets environmental standards suitable for large scale processors and eco friendly modified material production.

Technical Specifications of UET Plastic Compounding Machines

| Attribute | Details |

|---|---|

| Processable Materials | ABS, PA, PBT, PP, HDPE, PC, flame-retardant plastics, biodegradable plastics |

| Applications | Automotive interior substrate, electronic housing pellets, packaging film masterbatch, construction profile raw material |

| Machine Weight | 4500 kg (medium-duty model) |

| Warranty | 1 year for whole machine; 2 years for core components |

| Key Selling Points | Precise material dispersion (uniformity ≥98%), 18% energy saving vs. industry average, quick mold change (≤30 mins) |

| Applicable Industries | Automotive manufacturing, electronic & electrical, packaging industry, building material processing |

| Outgoing Inspection (Video) | 100% full-process video documentation |

| Core Components | Siemens motor, SKF bearings, Schneider PLC, wear-resistant alloy screws |

| Brand Name | UET |

| Voltage | 480V 60Hz (North American standard) or customizable |

| Screw Configuration | Single/double screw optional; wear-resistant alloy screw material |

| Equipment Type | Plastic Compounding Extruder |

| Product Grade | Premium Industrial Grade |

Different Models of UET Plastic Compounding Machines

| Model | L/D Ratio | Max. Screw Speed (rpm) | Reference Capacity (kg/hr) |

|---|---|---|---|

| UET120 | 32-38 | 500 | 2000-3000 |

| UET150 | 36-42 | 450 | 4000-5500 |

| UET190 | 40-46 | 350 | 8000-10000 |

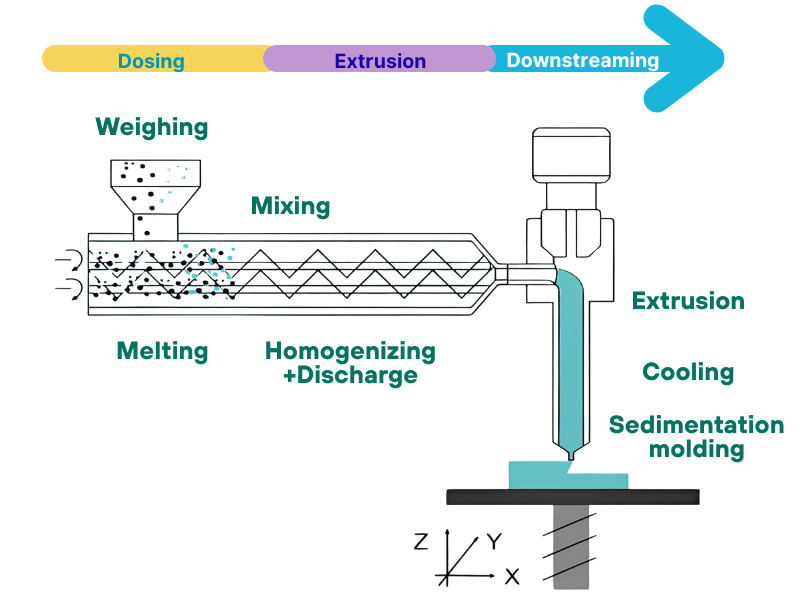

Flowchart of the Plastic Compounding Machine

Flowchart of the Plastic Compounding Machine

UET Plastic Compounding Machines Factory

Welcome to the UET Plastic Compounding Machines Factory. We have 12 standardized production lines with a monthly capacity of up to 80 units of various plastic compounding machines to meet the fast delivery needs of bulk orders. Visiting our factory allows you to see firsthand the efficient processes of large scale production and our delivery reliability.

Customer Reviews of UET Plastic Compounding Machines

Explore the genuine customer reviews of UET Plastic Compounding Machines. These reviews cover the full lifecycle experience from equipment selection to implementation. We are committed to providing professional technical support to help customers successfully complete equipment deployment and quickly transition to stable production.

When processing high calcium carbonate filled materials the UET plastic compounding machine delivers uniform dispersion. Monthly output aligns with our production schedule and delivery speed is twice as fast as competitors helping us reliably secure bulk orders from key North American clients.

Liam Carter

Plastic Modification Processing Industry

The ±1℃ temperature control accuracy of the UET twin screw model is impressive. The color deviation of the modified material for automotive instrument panels compounded by it is controlled within 0.5. Our unit has been running continuously at full load for three months without any failures.

Noah Bennett

Automotive Interior Plastic Production Industry

After evaluating three reputable manufacturers we chose UET. The equipment offers the best cost performance with an intuitive user friendly operation interface. New employees can get up to speed after just half a day of free professional online training from the manufacturer’s engineers.

Olivia Reed

Packaging Material Manufacturing Industry

The compounding parameters for PLA based biodegradable materials are highly precise and the finished product degradation rate meets standards. The after sales engineers provided video remote guidance within 72 hours helping us optimize screw speed matching and increase production efficiency by 15%.

Ethan Moore

Biodegradable Plastic Processing Industry

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

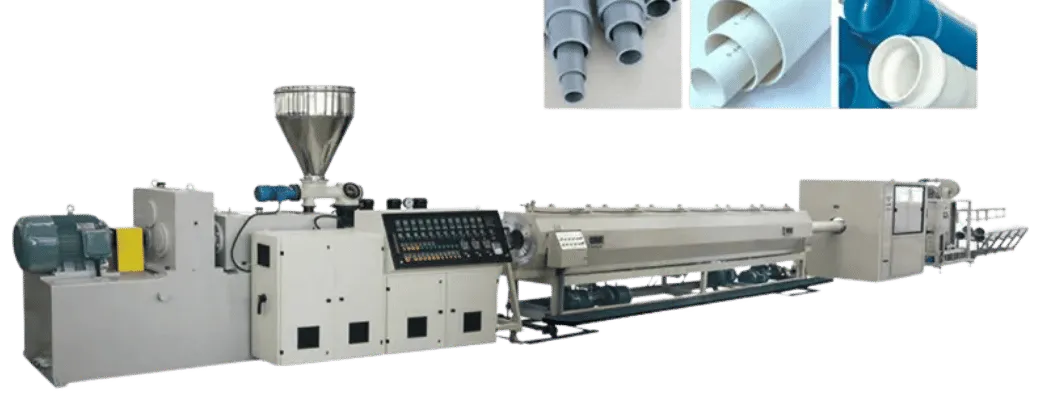

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

Frequently Asked Questions (FAQs)

We have compiled FAQs about plastic compounding machines, which cover most questions related to these machines. Should you have additional questions or need further details, please feel free to contact us.

A:Selection should consider material properties such as filling rate viscosity and fiber content. High filling materials require high torque twin screw models glass fiber reinforced materials need special screw elements and biodegradable materials prioritize temperature control accuracy. UET offers customized screw structures and equipment configurations providing targeted selection solutions to ensure optimal compounding results and production efficiency.

A:Yes. UET plastic compounding machines are optimized for biodegradable materials like PLA and PHA with enhanced temperature control systems and screw speed matching. They precisely regulate processing temperatures to prevent degradation ensuring uniform material dispersion and meeting finished product degradation rate standards. UET has accumulated numerous successful cases in biodegradable plastic processing adapting to various production needs.

A:UET plastic compounding machines feature durable core components with a regular maintenance cycle of 3 to 6 months including screw cleaning lubricant replacement and seal inspection. 易损件 such as filters and seals should be inspected every 1 to 2 months based on production load. Each machine comes with a maintenance guide for easy operation effectively minimizing downtime.

A:Single screw models have a simple structure and lower cost suitable for single material and low requirement compounding. Twin screw models offer higher compounding efficiency and better dispersion uniformity capable of processing complex materials like high filling and glass fiber reinforced plastics. UET twin screw compounding machines adopt a modular design with wider adaptability meeting high difficulty material processing and large scale production needs.

A:The delivery time for standard models is 30 to 45 days while customized models including screw customization and configuration upgrades take 45 to 60 days. UET operates 12 standardized production lines with a monthly capacity of 80 units and a stable supply chain. We can optimize production schedules based on order requirements to ensure on time delivery without affecting your production plans.

A:Prices vary based on production capacity configuration and customization level. Standard models range from 50 000 to 120 000 US dollars while high capacity and customized twin screw models cost between 120 000 and 200 000 US dollars. For a detailed quotation list please contact us and we will provide a clear price and configuration breakdown.

A:Compare from four key aspects: core parameters such as temperature control accuracy dispersion uniformity and torque industry certifications customer testimonials and after sales support. UET equipment holds CE and ISO9001 certifications with core components meeting international standards. We have numerous benchmark customer cases in various industries and provide a 2 year warranty plus full lifecycle technical support offering significant advantages.

A:In addition to compounding uniformity and temperature control accuracy consider energy consumption operational ease and maintenance costs. UET has optimized equipment structure for packaging material production with energy consumption 12% lower than the industry average. The intuitive operation interface allows new employees to quickly get started and sufficient supply of wearing parts ensures controllable maintenance costs.