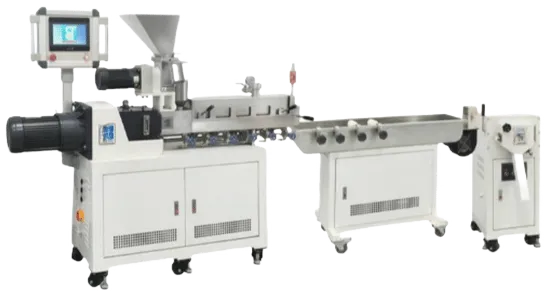

Laboratory Extruder

Professional Laboratory Extruder Manufacturer in China

The laboratory extruder from UET Machine is specifically engineered for plastic formulation development and small-batch trial production scenarios. It is suitable for the pilot-scale processing of polyethylene, polypropylene, and special modified materials. The machine can stably produce finished products for R&D purposes, such as specimen bars for formulation validation and small experimental articles. Boasting a simple and intuitive user interface, it enables R&D personnel to master operations quickly without extensive training. Compared with conventional laboratory equipment, it delivers a 20% improvement in parameter control precision and a 40% reduction in material changeover and cleaning time. This high-efficiency performance strongly supports rapid formulation iteration, perfectly meeting the pilot-scale testing requirements of research institutions and corporate R&D departments.

±0.3℃

Lab Temp Precision

99%

Data Recording Accuracy

80+

Formulation Compatibility

≤0.5%

Material Residue Rate

UET Machine Laboratory Extruder Solutions

Whether in the innovative exploration phase of materials R&D, the pilot-scale formulation testing stage for plastics, or the preliminary performance validation process for new products, UET Machine’s laboratory extruders are engineered to precisely meet your small-batch trial production needs and deliver tailored, high-efficiency solutions.

We offer micro single screw laboratory extruders, small twin screw pilot extruders, micro feeding laboratory extruders, and more—designed to meet diverse laboratory R&D scenarios such as material research pilot tests and micro formulation adjustments.

Based on your specific and detailed sample volume requirements and material properties, we provide customized and optimized tailor made screw parameters and feeding modules, precisely matching the personalized needs of small batch laboratory pilot production.

Our equipment processes common lab raw materials including thermoplastics, functional masterbatches, and modified composite materials. It supports pilot production of micro tubes, films, other small samples, breaking the limitations of single material pilot production.

Our laboratory extruders hold international certifications such as CE and ISO, and comply with relevant standards for laboratory safe operation and low emissions—ensuring compliance and reliability throughout the experimental process.

With a footprint of ≤0.8㎡ and operating noise as low as 65dB, the equipment fits seamlessly into compact, low disturbance laboratory environments. Equipped with a sealed feeding hopper, it prevents dust emission, guaranteeing clean and safe experimental operations.

Featuring a 7 inch touchscreen interface preloaded with 10 sets of common pilot scale process templates, the equipment supports one click start/pause. Operations are simplified to within 3 steps, lowering the operational threshold for laboratory personnel.

Laboratory Extruders for Sale

UET Machine’s reliable laboratory extruders deliver precise solutions tailored to your specific needs.

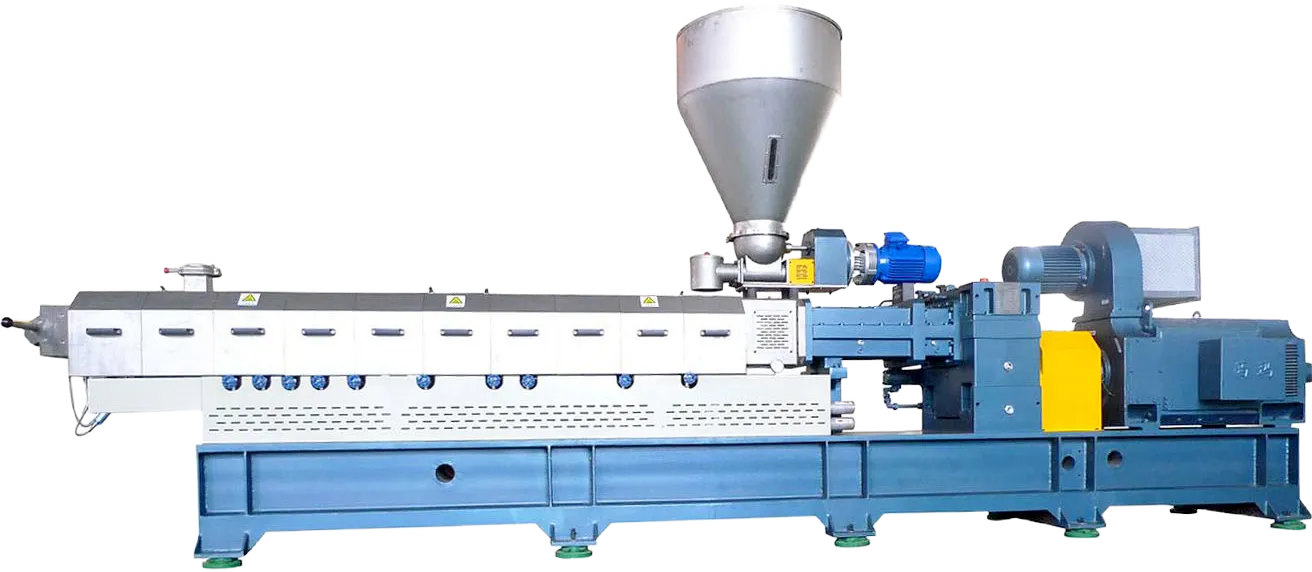

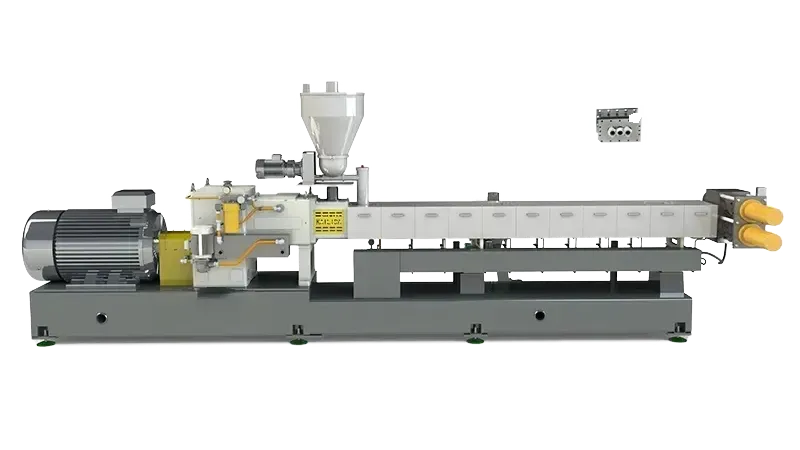

Laboratory Single Screw Extruder

This versatile model fits compact lab spaces and limited budgets, costing only 1/3 of twin screw models. Compact and space saving, it features ultra simple operation and maintenance, covering a plasticizing range from room temperature to 350℃. It reliably supports pilot tests of tubes and sheets, adapts to formulation validation for basic plastics like PE and PP, and serves as a practical choice for educational experiments and low threshold R&D for small and medium enterprises.

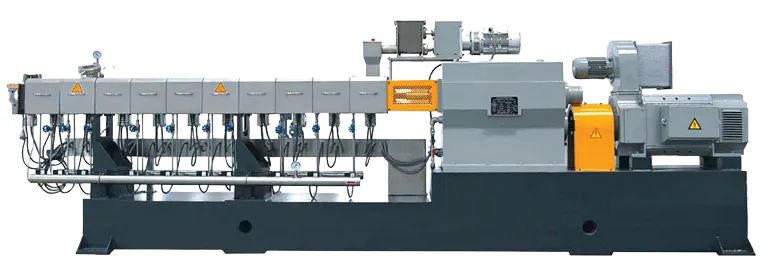

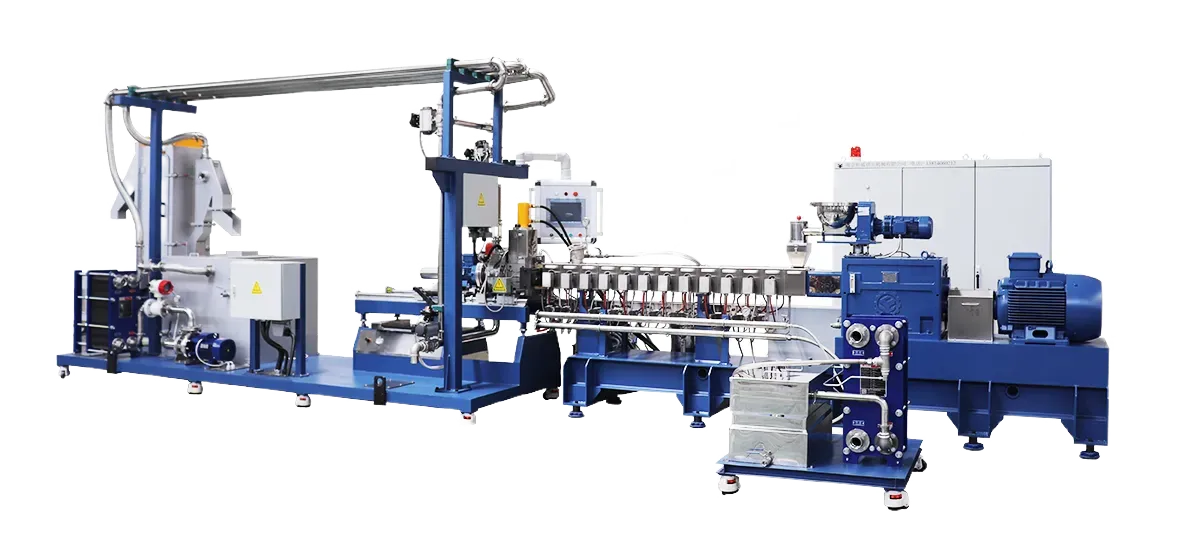

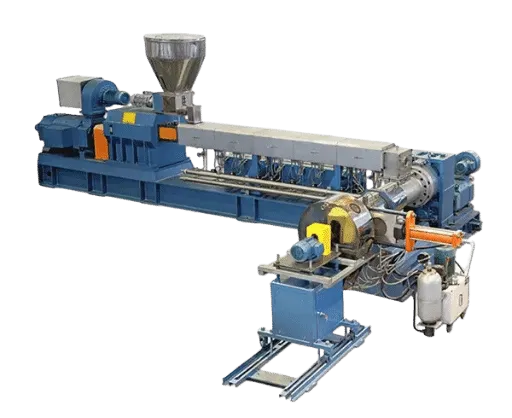

Laboratory Twin Screw Extruder

This precision model addresses pain points in complex formulation R&D, adopting a high precision twin screw compounding structure with over 95% mixing uniformity and 30% improved data repeatability. It supports advanced processes like blending modification and reactive extrusion, paired with switchable modules for multi formulation R&D, and acts as core equipment for research institutes developing biodegradable materials and engineering plastic alloys.

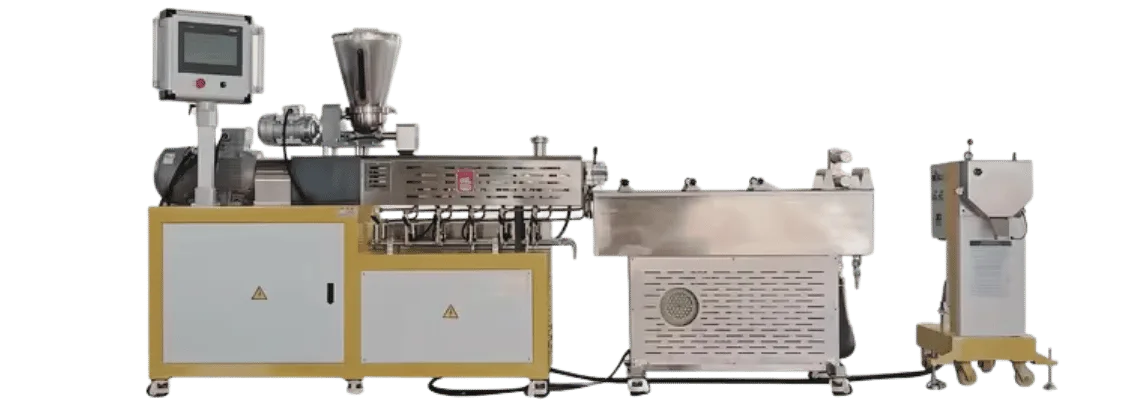

Specialized Laboratory Extruder

This heat sensitive model suits small scale pilot tests of different high viscosity and heat sensitive materials, featuring a low shear structure and ±1℃ precise temperature control to effectively reduce material degradation by 40%. Its self cleaning design avoids material blockage risks, adapts to PVC and other medical grade polymer processing, supports the rubber and hot melt adhesive modification R&D, and serves as specialized equipment for stable experiments in niche fields.

UET Machine Laboratory Extruder Specifications

UET Machine offers three series of twin screw extruders. In addition, we provide customized equipment and deliver tailored twin screw extruder solutions to meet your specific production needs.

UET Twin-Screw Laboratory Extruder

| Model | Diameter(mm) | L/D | Speed(rpm) | Power(kw) | Output(kg/h) |

|---|---|---|---|---|---|

| UET20B | 20 | 26-75 | 55-700 | 2/3 | ~12 |

| UET20D | 20 | 26-75 | 55-750 | 4/5 | ~22 |

| UET20-Max | 20 | 26-75 | 55-800 | 5/6 | ~32 |

| UET25B | 25 | 26-75 | 55-700 | 4/5 | ~25 |

| UET25D | 25 | 26-75 | 55-750 | 6/7 | ~40 |

| UET25-Max | 25 | 26-75 | 55-800 | 7/8 | ~55 |

| UET31B | 31 | 26-75 | 55-700 | 6/7 | ~45 |

| UET31D | 31 | 26-75 | 55-750 | 9/10 | ~70 |

| UET31-Max | 31 | 26-75 | 55-800 | 11/12 | ~95 |

| UET34B | 34 | 26-75 | 55-700 | 10/11 | ~80 |

| UET34D | 34 | 26-75 | 55-750 | 14/15 | ~120 |

| UET34-Max | 34 | 26-75 | 55-800 | 18/20 | ~200 |

UET Micro Laboratory Extruder

| Model | Screw Diameter (mm) | Screw Speed (rpm) | Motor Power (Kw) | Output (g/h) |

|---|---|---|---|---|

| UET-14 | 14 | 550 | 0.4/1.0 | 500-3500 |

| UET-15 | 15 | 650 | 0.5/1.3 | 2000-5000 |

Applications of UET Laboratory Extruders

We have only outlined selected application areas. If you wish to learn about the complete application solutions, industry-specific cases, and customized implementation pathways, please feel free to contact us. We will provide you with scenario-specific breakdowns, equipment selection guidance, and tailored solutions to efficiently support the successful implementation of your R&D and production needs.

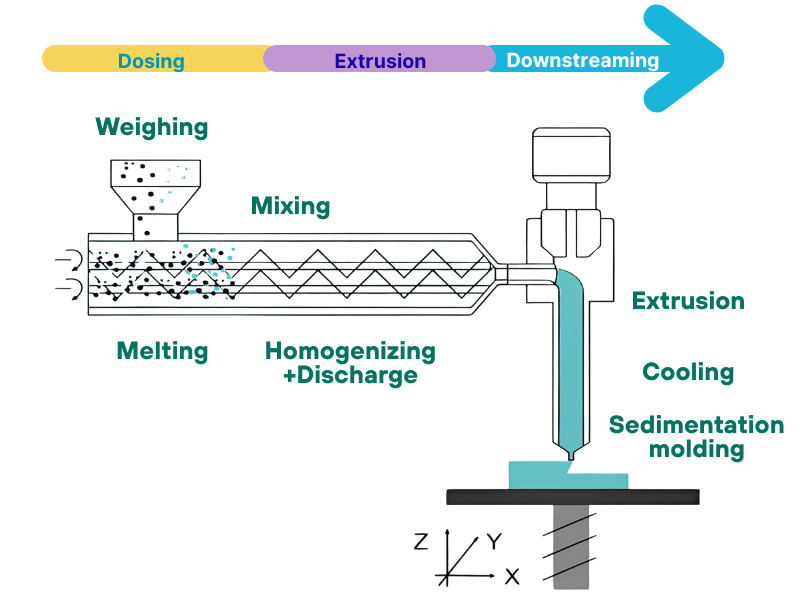

Polymer Material Formulation Pilot Testing

Conduct small-batch formulation compounding of polymer materials with UET laboratory extruders. By precisely regulating screw speed and temperature control ranges, we verify the dispersion uniformity and processing flowability of different raw material ratios, rapidly screen viable formulation directions, and deliver reliable pilot test data to support subsequent pilot-scale production.

Bio-Based Biodegradable Material R&D

For bio-based biodegradable materials such as PLA and PBAT, the laboratory extruder uses a gentle plasticization process. While preserving the material’s degradation activity, it achieves uniform compounding of modified additives; small-batch pilot production samples can be directly used for degradation performance testing, meeting the needs of laboratory low-carbon material R&D.

Functional Modified Material Validation

In the R&D of functional modified materials (e.g., flame-retardant, antioxidant), the laboratory extruder ensures uniform dispersion of functional additives in the base material through multi-zone independent temperature control and customized screw configurations; pilot test products can be used to test functional durability, helping R&D teams quickly validate the effectiveness of modification solutions.

Specialty Resin Performance Testing

For high-viscosity, heat-resistant specialty resins (such as specialty engineering plastic precursors), the laboratory extruder achieves small-batch plasticization and molding through stable screw transmission and precise process control. The prepared experimental samples can be used to test core indicators like the material’s heat resistance and mechanical strength, supporting application scenario evaluation of specialty resins.

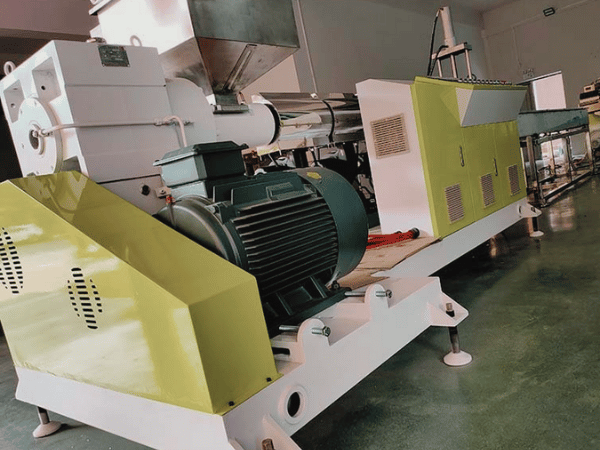

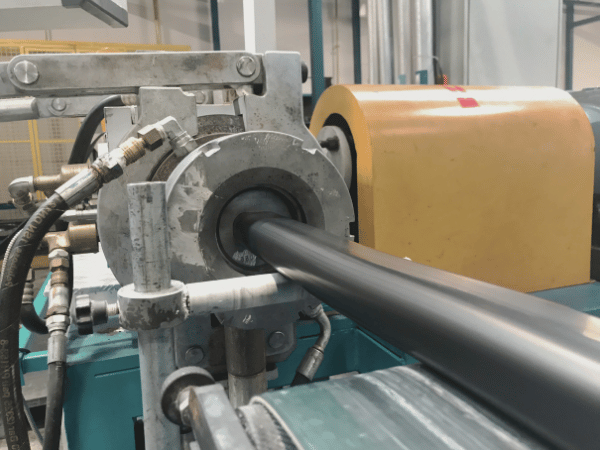

UET Twin Screw Laboratory Extruder Factory

Welcome to the UET Laboratory Extruder Manufacturing Facility. Equipped with precision machining production lines and an end-to-end quality control system exclusively designed for laboratory equipment, we ensure the precision and R&D scenario adaptability of every laboratory extruder through customized process debugging and pilot-scale scenario adaptation testing.

UET Laboratory Extruder User Reviews

Explore the genuine user reviews of UET’s laboratory extruders. These reviews originate from research teams in fields such as materials R&D and bio-based composite materials. We’re proud that UET’s twin-screw extruders, leveraging their robust product capabilities, have assisted researchers in overcoming the challenges associated with formulation debugging.

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

We’ve compiled the frequently asked questions (FAQ) for UET Laboratory Extruders. This FAQ covers key details relevant to R&D scenarios, including pilot-scale material compatibility, parameter precision, customized solutions, operational & maintenance ease, and R&D-exclusive technical support.

A:A laboratory extruder is a small-scale extrusion equipment specifically designed for small-batch R&D and formulation testing. It is mainly used for mixing, molding, and performance testing of materials such as polymers and bio-based materials. Compact in size to fit laboratory settings, it can precisely control process parameters, providing reliable data support for pilot-scale production and mass manufacturing. It is widely used in universities, research institutes, and corporate R&D departments.

A:Yes, we provide customized solutions and corresponding quotes. Simply inform us of key parameters such as your material type, experimental requirements, screw specifications, and temperature control range. Our professional team will conduct a rapid evaluation, issue a customized plan, and clarify configuration details, lead time, and pricing. Quotes are transparent with no hidden costs, and we support plan adjustments and synchronized quote updates based on your needs.

A:Yes, we can. We have global cases covering fields such as materials R&D, bio-based composite materials, and specialty chemicals, including practical application scenarios, test data, and feedback from university laboratories and R&D-oriented enterprises. All cases are anonymized to protect privacy, and we can provide targeted cases based on your industry to help you intuitively understand the equipment’s adaptability.

A:Our extruders are widely compatible with polymer materials, bio-based composite materials, biodegradable materials, specialty resins, modified plastics, high-viscosity composite materials, and more. Whether for formulation testing of conventional materials or small-batch R&D of special materials, requirements can be met by optimizing screw configurations and process parameters, adapting to most laboratory R&D scenarios.

A:The equipment delivers excellent data repeatability, relying on high-precision temperature control, stable screw transmission, and an accurate parameter control system. In repeated experiments, deviations of key data such as temperature, rotational speed, and extrusion volume are controlled within a reasonable range, effectively ensuring the reliability of experimental results and providing a solid foundation for subsequent data analysis and program optimization.

A:The temperature control system has a precision of ±1℃ and supports multi-zone independent temperature adjustment, which can accurately match the processing temperature requirements of different materials. With rapid system response and minimal temperature fluctuation, it effectively avoids material mixing and molding issues caused by temperature deviations, fully meeting the temperature control standards for high-demand laboratory small-batch testing and R&D scenarios.

A:The equipment achieves excellent mixing uniformity, with material dispersion uniformity reaching over 95%. Thanks to the optimized screw structure design and reasonable length-to-diameter ratio configuration, it can fully break up material agglomeration and achieve efficient mixing. For high-viscosity and difficult-to-mix materials, mixing uniformity can be further improved through customized screw configurations, adapting to stringent R&D requirements.

A:Yes, they can. The equipment adopts a high-strength screw and power system, combined with customizable screw configurations and process parameters, enabling effective handling of the transportation, mixing, and extrusion of high-viscosity materials. It operates with strong stability, free from issues such as material retention and uneven extrusion, meeting the needs of small-batch R&D and formulation testing of high-viscosity materials.

A:Yes, replacing wearing parts is convenient and does not require professional or complex tools. Common wearing parts (such as screws, barrels, and seals) are designed with standardization, featuring simple disassembly and installation processes supported by detailed operation manuals. Additionally, we provide rapid supply services for wearing parts, significantly reducing downtime and avoiding impacts on R&D progress.

A:Designed specifically for laboratory environments, the equipment is compact in size. Standard models require approximately 0.8-1.2 square meters of floor space, which can be flexibly placed on laboratory workbenches or designated areas. For customized special specifications, dimensions will be optimized during the plan design phase to ensure compatibility with limited laboratory space without affecting the layout of other equipment.

A:During the warranty period, we provide free on-site inspections, replacement of parts (for non-human-induced damage), technical troubleshooting, and remote guidance services. If the equipment encounters quality issues, we will respond promptly. Overseas customers can enjoy online technical support and expedited delivery of spare parts, while domestic customers receive on-site maintenance services. We fully guarantee the normal operation of the equipment and address post-sales concerns.