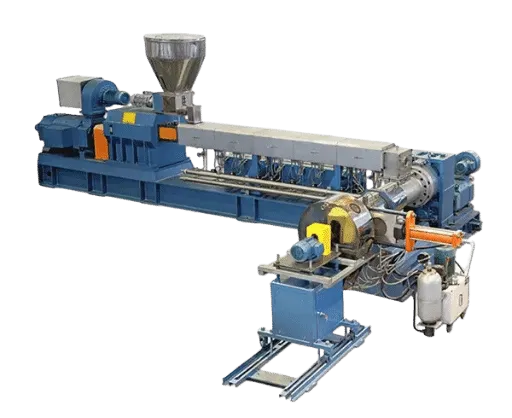

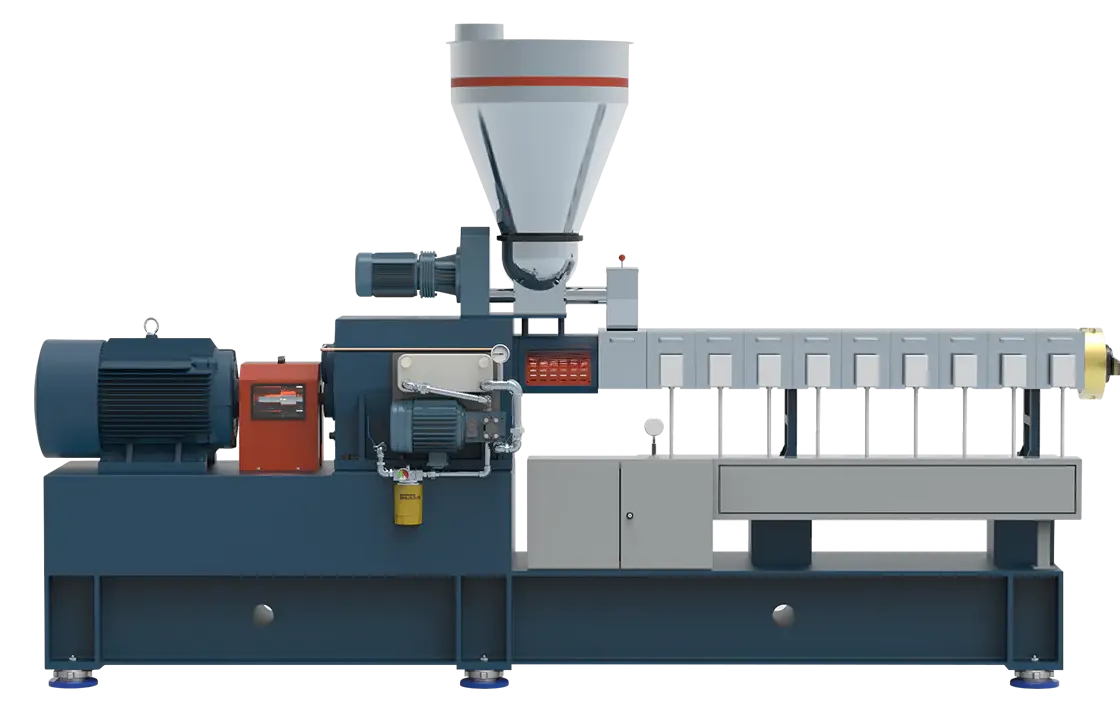

Triple Screw Extruder

Leading Triple Screw Extruder Manufacturer in China

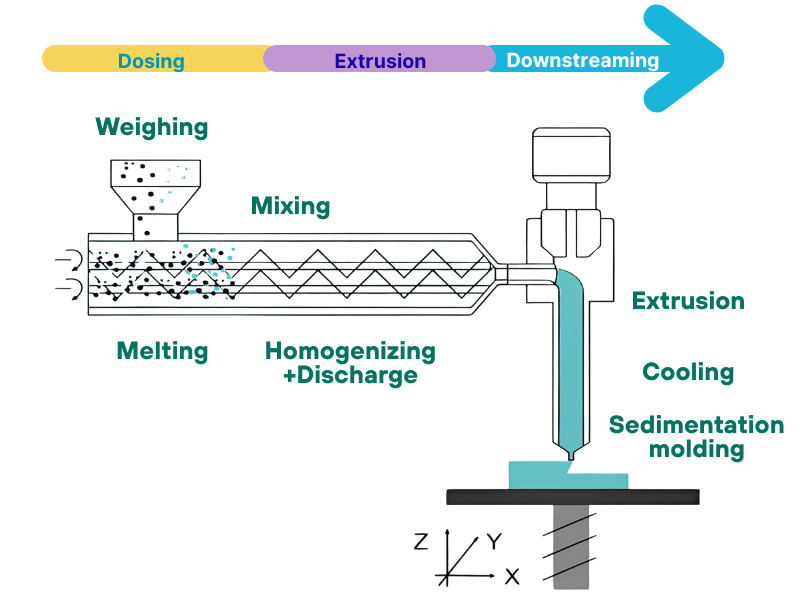

Engineered specifically for the high-end processing of multi-component and high-fill plastic materials, the triple screw extruder from UET Machine is ideal for precision compounding of modified plastics, composite materials, and functional masterbatches. It delivers consistent production of high-end products such as highly dispersible modified pellets and composite plastic substrates. Equipped with an intelligent compounding control system, the equipment allows new operators to master proficient operation after simple guidance. Compared to industry-standard twin screw extruders, it increases material dispersion uniformity by 25%, reduces energy consumption by 20%, and extends continuous stable operation time after startup by 30%, precisely meeting the large-scale production needs of high-end plastic processing.

98%+

Dispersion Uniformity

0.02mm

Screw Rotation Precision

75%

Max Filler Ratio

99.9%

Operation Stability Rate

UET Machinery Triple Screw Extruder Solutions

UET Triple Screw Extruder boasts exceptional material conveying and mixing capabilities, delivering more uniform heat transfer and consistent end products. It is suitable for applications such as polymer blending, masterbatch, composite materials, thermoplastics and more.

Designed with accessible components and simpler structures, our extruders enable quick inspection and repair. Minimize downtime, cut maintenance costs, ensure continuous stable production for your business.

Ideal for plastic modification, composite materials, biodegradable products, and more. Our extruders adapt to diverse raw materials and production processes, meeting the specialized needs of various manufacturing sectors.

Our extruders meet international quality and safety standards, holding recognized certifications. Ensure regulatory compliance in your production, avoiding operational risks and facilitating market access for your products.

Crafted with premium materials and precision manufacturing, our extruders offer long service life and consistent performance. Resist wear and tear, reduce failure rates, and deliver reliable output for long-term production needs.

Our professional team tailors extruder configurations, specifications, and functions to your specific production requirements. Solve unique challenges, optimize production efficiency, and achieve optimal results for your targeted applications.

Equipped with advanced screw designs and energy-saving systems, our extruders deliver high output while reducing energy consumption. Boost production throughput, lower unit costs, and enhance your market competitiveness.

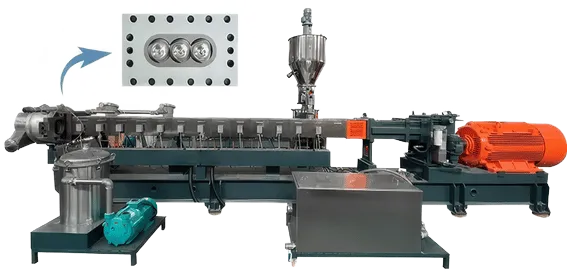

Triple Screw Extruders for Sale

UET Machine offers high quality triple screw extruders with high output and low energy consumption.

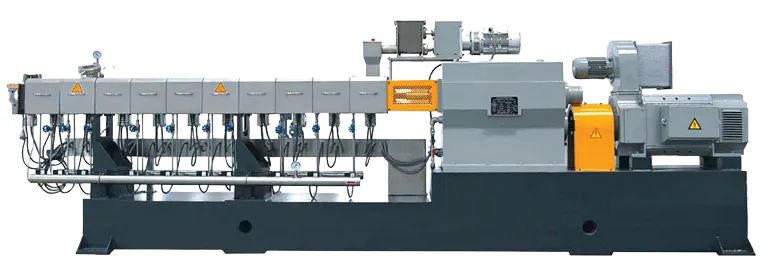

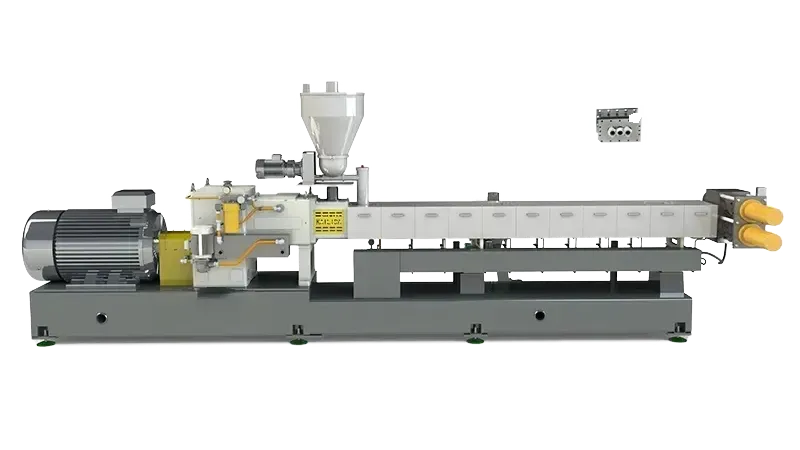

High Torque Triple Screw Extruder

High torque and strong performance with optimized screws and precise temperature control. Low shear design preserves material properties, efficiently mixing high fill viscosity materials. It stably makes glass filled materials, masterbatches, and biodegradable plastics, ideal for large scale continuous production with 30% better mix uniformity.

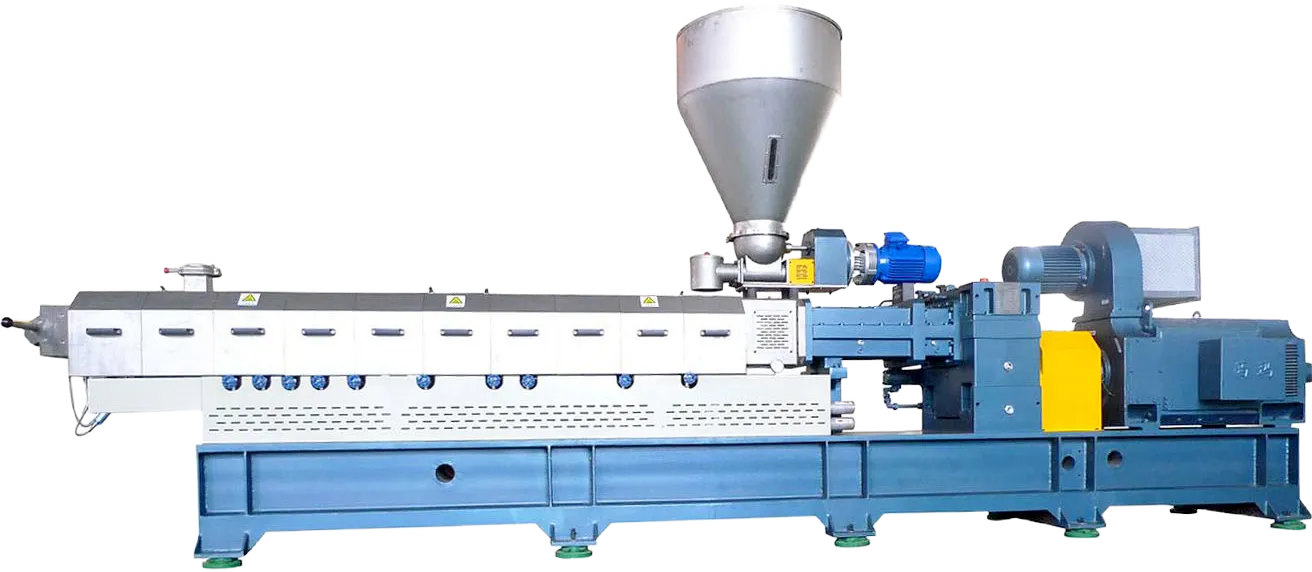

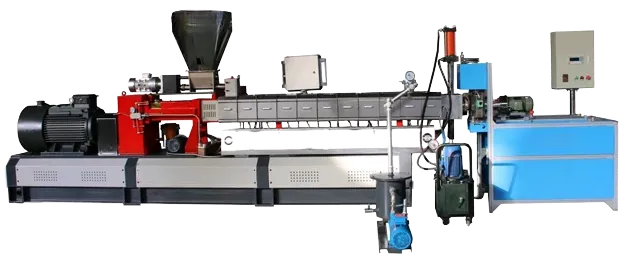

Composite Triple Screw Extruder

Twin screw forced feeding and modular screw design solve the problem of material bridging. It features high plasticizing efficiency, precisely forming composite materials, rubber plastic blends, and co extruded films. Suitable for the production of multiple varieties and special products, it enables flexible formula switching with pressure fluctuation ≤5%.

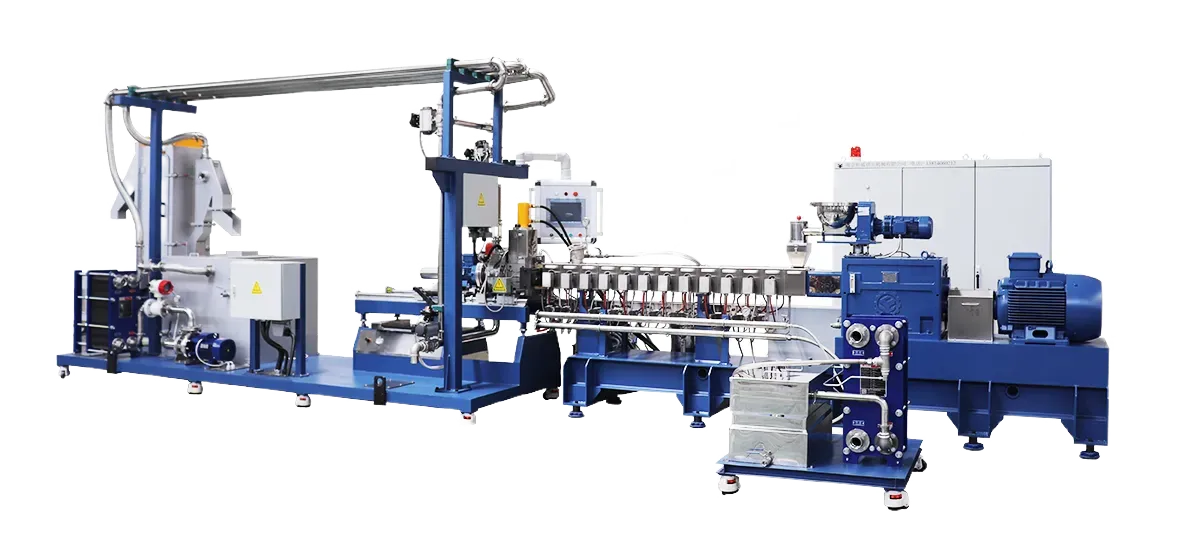

Lab Scale Triple Screw Extruder

Compact and space saving with only 1.2 square meters. Equipped with intelligent temperature control and traceable parameters, it has multiple screw diameter options. With precise efficient mixing, it supports universities, research institutions, and enterprises in developing new materials, accelerating formula iteration and scaling from lab trials to pilot production.

UET Triple Screw Extruder Technical Specifications

UET Machine offers a range of triple screw extruder models. We also provide custom tailored equipment based on your specific production requirements.

| No. | Model | Speed(rpm) | Diameter (mm) | L/D | Power(kw) | Output(kg/h) |

|---|---|---|---|---|---|---|

| 1 | UET-29 | ~550-650 | 29.0 | 26-85 | 14 | 50~90 |

| 2 | UET-37 | ~550-650 | 37.4 | 26-85 | 31 | 130~180 |

| 3 | UET-45 | ~550-650 | 45.2 | 26-85 | 46 | 220~320 |

| 4 | UET-53 | ~550-650 | 53.1 | 26-85 | 88 | 550~750 |

| 5 | UET-63 | ~550-650 | 63.3 | 26-85 | 128~155 | 780~1100 |

| 6 | UET-74 | ~550-650 | 74.5 | 26-85 | 205~235 | 1350~1850 |

| 7 | UET-92 | ~550-650 | 92.8 | 26-85 | 370~410 | 2300~3300 |

Applications of UET Machine Triple Screw Extruders

The solutions for UET Machine triple screw extruders are widely applicable across multiple industries, including packaging material modification, bio based composite materials, wire sheathing compounds, and food contact grade plastics — as well as high efficiency compounding processing for high filler materials.

Filler Masterbatch

When producing filler masterbatch with UET triple screw extruders, their multi screw coordinated shear structure ensures deep fusion between ultra high load fillers and base materials. The finished product offers superior dispersibility, significantly enhancing product rigidity while maintaining excellent processing flowability.

Color Masterbatch

When processing color masterbatch with UET triple screw extruders, multi zone precise temp control and triple screw intermeshing structure enable uniform coating of high concentration pigments in resin. The finished color masterbatch delivers extreme tinting strength, ensuring zero color variation consistent hues in mass production.

Additive Masterbatch

When preparing additive masterbatch with UET triple screw extruders, their three stage compounding modules and synchronized triple screw conveying ensure full dispersion of functional additives (e.g., antioxidants) with carrier resin. The final masterbatch offers better dosage stability and longer lasting effectiveness.

Engineering Plastics

When processing engineering plastics (e.g., PBT) with UET triple screw extruders, their ultra stable high temp plasticization system and triple screw high compounding force enable full integration with high strength fillers. The finished material boasts enhanced mechanical strength, suitable for making higher precision electronic components.

Biodegradable Plastic

When processing biodegradable plastics with UET triple screw extruders, the gentle yet efficient triple screw plasticization process preserves resin activity while enabling full compounding with modified additives. The final product has stable degradation performance, suitable for producing all biodegradable packaging products.

Thermoplastic Elastomers

When processing thermoplastic elastomers with UET triple screw extruders, the triple screw gradient shear and coordinated fusion structure enable uniform blending of elastic components and modified materials. The finished product offers a wider controllable hardness range, smooth texture, and superior aging resistance.

Cable Compounding

When processing cable compounds with UET triple screw extruders, dead zone free full area compounding and triple screw dense plasticization ensure tight fusion of conductor coatings and components. The finished product delivers superior insulation performance, meeting needs for high end new energy and communication cables.

PVC Compounding

When processing PVC compounds with UET triple screw extruders, the low shear and high torque screw configuration achieves uniform plasticization and dispersion of additives. The finished PVC compounds feature stable performance and excellent processability, ideal for producing pipes, profiles and other PVC products.

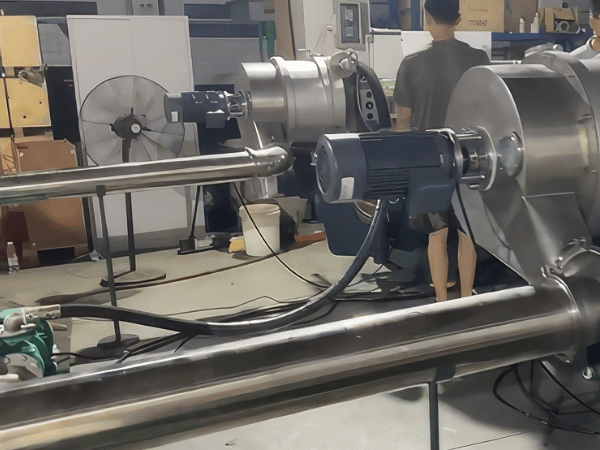

UET Machine Triple Screw Extruder Factory

Welcome to the UET Machinery Triple Screw Extruder Factory. We have invested in ultra precision machining equipment specifically for the barrels and screws of triple screw extruders. We have also established a component fatigue testing platform. Through long term continuous operation validation, we ensure the long service life of the core components in each unit.

UET Triple Screw Extruder Customer Reviews

Read real reviews of UET triple screw extruders from our customers. We take pride in helping client enterprises achieve business growth.

We chose UET triple screw extruders for processing high filler engineering plastics, and their compounding uniformity and production efficiency exceeded our expectations. The equipment has operated continuously for three months without failures, reducing material waste by 18% and helping us gain a firm foothold in the high end market competition.

Ethan Carter

Medical materials have extremely high requirements for equipment cleanliness and stability, and UET triple screw extruders fully meet these needs. Precise temperature control and gentle compounding ensure stable resin performance, increasing the qualified rate of finished products from 96% to 99.2%, and daily operations have become much easier.

David Smith

UET triple screw extruders are the core equipment of our production line. When processing high viscosity cable compounds, the output is stable and the insulation performance meets standards. Maintenance downtime has been reduced by 25%, production capacity has increased significantly, greatly lowering unit production costs, and the cost performance is far superior to similar equipment.

Sophia Miller

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

Before purchasing our Triple Screw Extruder, you are likely to have many questions. We have compiled the commonly asked questions from customers when buying a Triple Screw Extruder to help you better understand our products and services.

A:The UET Triple Screw Extruder is compatible with mainstream polymers such as polyethylene, polypropylene, polyamide, polyester, ABS and PC. It also works with special materials including modified plastics, biodegradable materials and high viscosity resins. With a wide compatibility range and optimized screw configuration, it ensures stable material conveying and uniform mixing, meeting the processing needs of various industries.

A:Compared to twin screw extruders, the UET Triple Screw Extruder’s core advantage lies in its triple meshing structure. It improves mixing uniformity by over 30% with better heat transfer efficiency and consistent material residence time. Its output is 20% to 40% higher than that of twin screw extruders of the same specification. It can handle high fill and high viscosity materials with stronger operational stability, reducing production energy consumption and raw material waste.

A:We fully support customized equipment services. We can customize screw length, diameter, speed range, die head structure and control system according to your production capacity, material characteristics, product specifications and other requirements. We also provide personalized process solutions to ensure the equipment is fully compatible with your production line, maximizing production efficiency and product quality.

A:The UET Triple Screw Extruder has excellent high fill material processing capability. It can stably handle composite materials with a fill level of 60% to 80% such as calcium carbonate, talc powder and glass fiber filled materials. Through optimized screw meshing design and feeding structure, it prevents material agglomeration, ensures uniform dispersion of fillers and guarantees stable final product performance.

A:The UET Triple Screw Extruder comes with an 18 month overall warranty. Core components such as screws and barrels have an extended warranty of 24 months. During the warranty period, we provide free maintenance and parts replacement services. We have established a 24 hour rapid response mechanism, with a professional technical team to promptly resolve equipment issues and ensure continuous stable operation of your production line.

A:We offer free full process equipment installation and commissioning services. Professional technical engineers will visit your site to guide installation, positioning and commissioning, ensuring the equipment reaches optimal operating conditions. We also provide on site training for operators, explaining operating specifications, daily maintenance points and common problem handling methods to help you master equipment usage quickly.

A:The delivery time for standard specification triple screw extruders is 45 to 60 working days. For customized equipment, the delivery time ranges from 60 to 90 working days depending on complexity. With a sound supply chain and strict production management system, we closely monitor production progress to ensure on time delivery. We also provide real time production progress updates to keep you informed of the equipment status.

A:For thermoplastic processing, the equipment features a dedicated screw design with optimized groove depth and lead to improve plasticization effect and conveying efficiency. It is equipped with a precise temperature control system with a temperature accuracy of ±1℃ to prevent material degradation. The die head flow channel is also optimized to reduce pressure loss, ensuring uniform product dimensions and lower energy consumption.

A:The UET Triple Screw Extruder adopts a compact structural design. Compared with traditional models of the same output, it saves 15% to 20% of floor space, facilitating workshop layout. The mainstream specification (Φ65 model) has an approximate floor space of 4.5m × 2.0m (length × width), which can flexibly adapt to production workshops of different sizes and effectively save plant space resources.