Single Screw Extruder

Cost-Effective Single-Screw Extruder Manufacturer from China

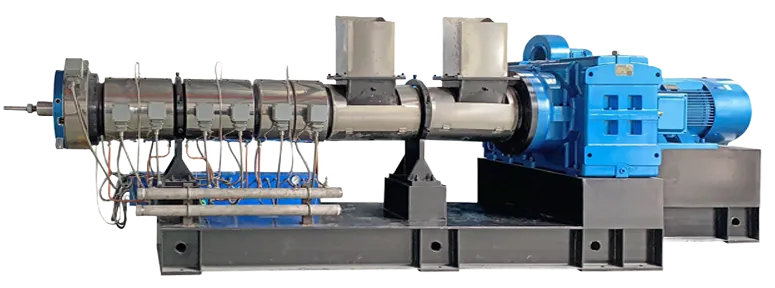

UET Machine’s Single Screw Extruders are designed for basic processing of commodity plastics like polyethylene (PE) and polypropylene (PP). They ensure consistent production of standard products such as water supply and drainage pipes, PE heat shrinkable film and wire coating. With a low operational threshold new operators master the equipment quickly. Maintenance costs are 30% below industry average and energy use 15% lower ensuring stable production right after startup with minimal downtime perfectly suited for mass production.

98%+

Gen Plastics Fit Rate

12000H+

Screw Wear Life

±0.05mm

Basic Process Precision

80%+

Repeat Purchase Rate

UET Machine Single Screw Extruder Solutions

We recommend UET Machine’s single screw extruder which is reliable stable and energy efficient with high performance. UET’s single screw extruder specializes in efficiently melting and extruding basic materials.

We offer industrial single screw extruders small lab single screw ones and more. These fit different production experimental scenarios including large scale continuous production formula small batch R&D.

We use a multi zone independent temp control system. It precisely regulates material melting temperature range adapts to the melting characteristics of different base materials and ensures extrusion process stability.

We use wear resistant consumable parts and a modular structure. Replacing consumable parts does not require specialized tools which significantly reduces the time and financial costs of long term equipment maintenance.

It is equipped with an intuitive touch operation panel. It supports basic one click parameter presets and automatic adjustments allowing new operators to work independently after short term training.

Backed by 20 years of single screw equipment manufacturing experience our machines can operate stably for long periods under working conditions such as high temperature and heavy load reducing the risk of unplanned downtime.

The single screw structure is suited for quick switching between small batch orders. It can complete extrusion processing of materials with different formulas without complex debugging enhancing production flexibility.

Single Screw Extruders For Sale

UET Machine’s reliable single screw extruders are the cornerstone for boosting production efficiency ensuring product quality and controlling operational costs.

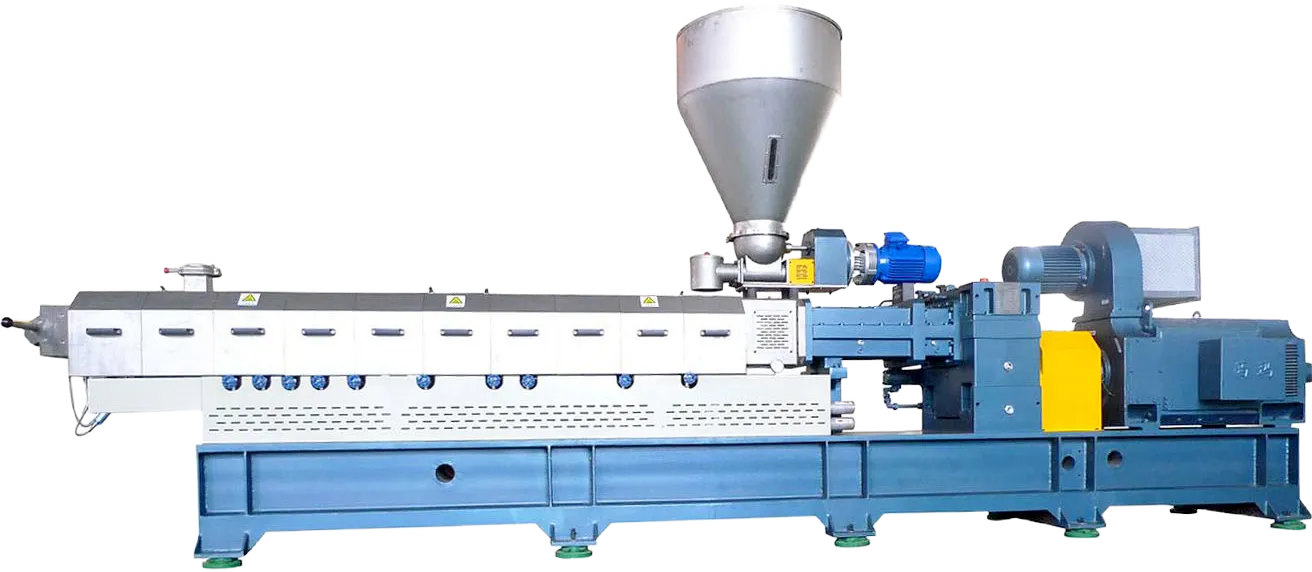

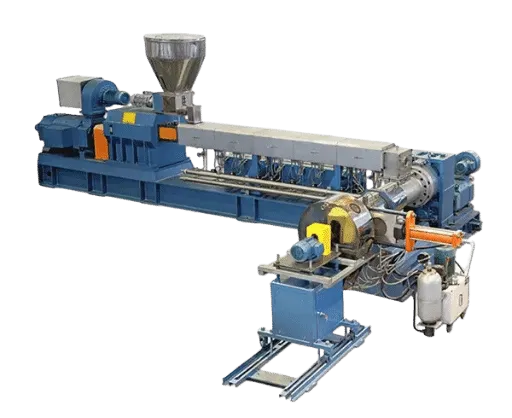

General Type Single Screw Extruder

Suited for producing various products such as plastic pipes profiles and small films it uses a general tapered screw design. It can quickly switch to processing common plastics like PP PE and PVC. The operation interface supports multilingual switching making it a cost effective all in one option for small and medium sized production businesses.

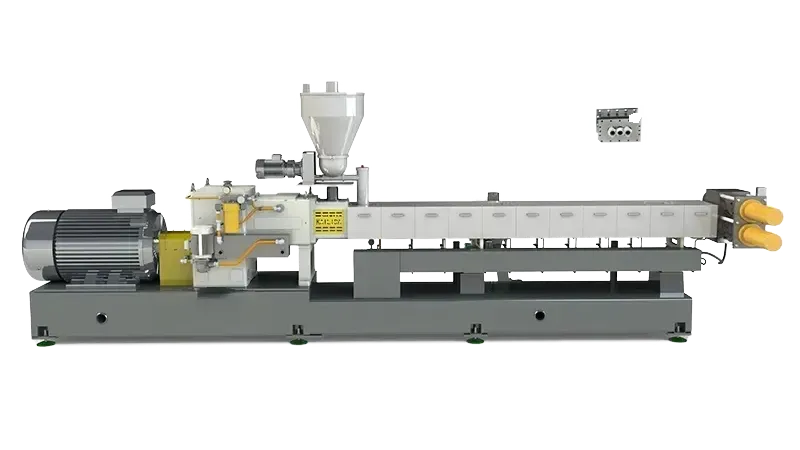

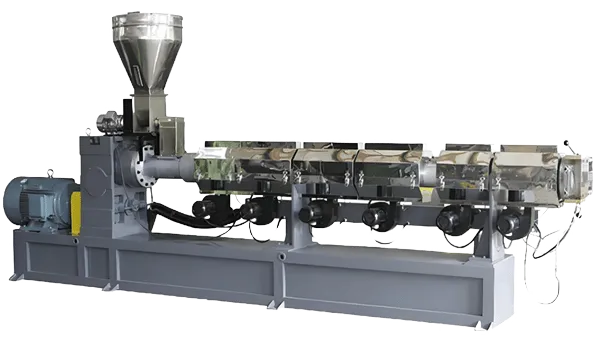

Flexible Small Batch Single Screw Extruder

Designed for small batch multi run production scenarios this machine is compact in size to fit small workshops. Material changeover and setup time is as short as 15 minutes. It is equipped with a simple touch control panel easy for new operators to master and can process lightweight products such as daily plastic accessories and small packaging materials.

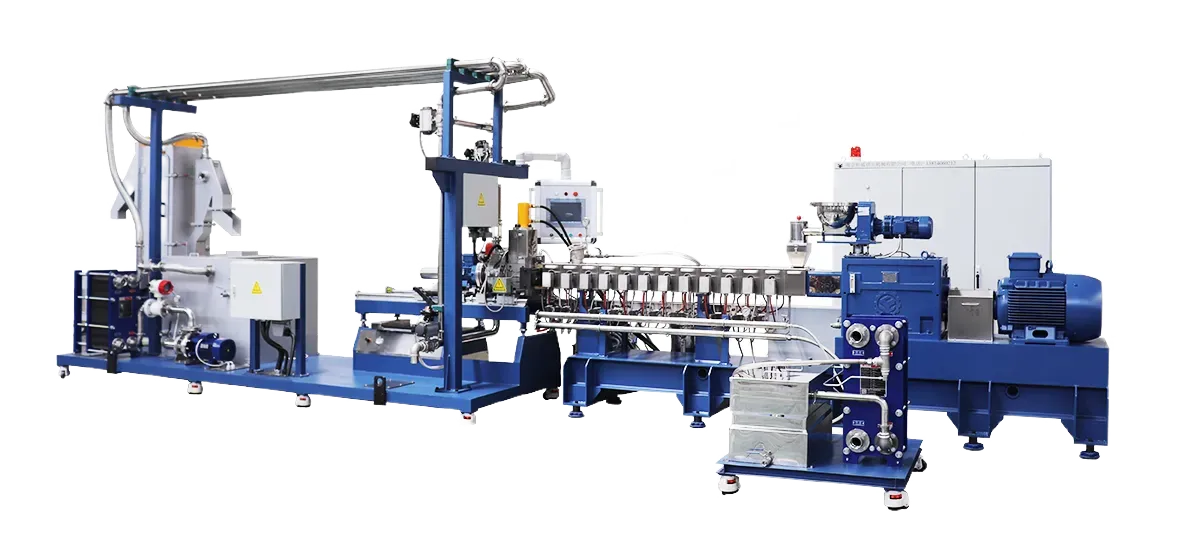

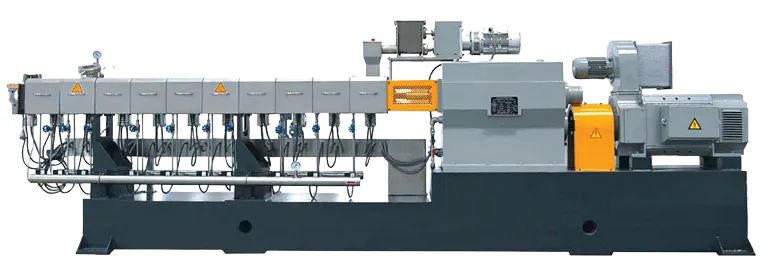

Energy Efficient General Single Screw Extruder

Equipped with a high efficiency energy saving motor (energy consumption 20% lower than the industry average) the barrel features heat insulating design to reduce heat loss. It can stably process general plastics and recycled pellets. It balances production efficiency and cost control making it a mainstream suitable model for regular plastic processing.

Technical Specifications of UET Mechanical Single Screw Extruder

| Feature | Specification |

|---|---|

| Brand Name | UET |

| Screw Design | High-Efficiency Single-screw |

| Condition | New |

| Plastic Processed | PE, PP, PVC, ABS |

| Application | Industrial Granulation, Plastic Recycling Pelletizing |

| Warranty | 2 Years (Extended Technical Support) |

| Key Selling Points | Energy-Efficient, Stable Performance, Low Maintenance Cost |

| Applicable Industries | Plastic Processing Plants, Recycling Facilities |

| Video Outgoing-Inspection | Available |

| Core Components | Siemens Motor, ABB Inverter, High-Wear Bearing |

| Machinery Test Report | Provided (With Performance Verification Data) |

| Screw Material | 42CrMo (Nitrided Surface, High Durability) |

| Screw Diameter (mm) | 110 |

| Screw Speed (rpm) | 50-180 rpm (Stepless Adjustable) |

| Screw L/D Ratio | 30:1 |

| Voltage | 380V/220V (Customizable for Global Markets) |

| Dimension (LWH) | 2500mm x 1000mm x 1600mm |

| Power (kW) | 85 (Energy-Saving Design) |

| Function | Plastic Granulation, Post-Consumer Plastic Recycling |

| Input Material | Crushed PE/PP Films, Pellet Scrap, Post-Consumer Plastic Waste |

| Cutting Type | Strand Cutting (Adjustable Speed) |

| Water Tank | 3800 mm (Temperature-Controlled) |

| Certification | CE, ISO 9001 |

Different Models of UET Single Screw Extruder

| Type | Screw diameter (mm) | Max. Speed(rpm) | Motor(KW) | Length of Screw (L/D) | Output(kg/h) |

|---|---|---|---|---|---|

| UET25 | 25 | 95 | 4 | 18-35 | 8-15 |

| UET70 | 70 | 95 | 35 | 18-35 | 90-110 |

| UET125 | 125 | 90 | 170 | 18-35 | 550-650 |

| UET160 | 160 | 90 | 220 | 18-35 | 750-950 |

| UET190 | 190 | 90 | 300 | 18-35 | 900-1400 |

| UET210 | 210 | 85 | 370 | 18-35 | 1300-1600 |

| UET250 | 250 | 85 | 480 | 18-35 | 1600-2200 |

Applications of UET Machine Single Screw Extruders

UET Machine single screw extruder solutions cater to a wide range of production scenarios spanning general plastic processing small packaging products construction pipe fittings daily plastic part manufacturing as well as laboratory formula trials and recycled plastic reprocessing and other areas.

Filler Masterbatch

Producing filler masterbatch on UET single screw extruders the tapered screw ensures stable blending and melting of high load fillers and bases. Uniform dispersion occurs without complex shear structures. The finished product retains good processability while boosting rigidity ideal for mass producing conventional packaging and building materials.

Color Masterbatch

Processing color masterbatch on UET single screw extruders precise temp control + steady extrusion speed lets high concentration pigments coat resin evenly. Single screws’ easy material change supports small batch multi color switching. Final color masterbatch delivers stable tinting strength ensuring no visible color variation in end products.

Additive Masterbatch

Preparing additive masterbatch on UET single screw extruders the gentle screw mixing rhythm enables uniform integration of functional additives like antioxidants with carrier resins. Finished masterbatch has stable additive dosage making it suitable for the uniform release of additives in conventional plastic processing.

Engineering Plastics

Processing engineering plastics like ABS on UET single screw extruders high torque screw enables stable plasticization of medium low melting point engineering materials ensuring their mechanical properties. Finished product suits molding conventional engineering products like home appliance housings and small mechanical parts.

Biodegradable Plastic

When processing biodegradable plastics with UET single screw extruders precise zoned temperature control preserves the activity of degradable resins while enabling uniform compounding with modified materials. The finished raw material is suitable for producing fully biodegradable packaging bags disposable tableware and other products.

Thermoplastic Elastomers

Processing thermoplastic elastomers on UET single screw extruders low shear screw preserves native elastic properties of elastomer while ensuring uniform integration with modified materials. Finished product has controllable hardness and wear resistance making it suitable for producing daily seals and soft rubber accessories.

Cable Compounding

Processing cable composite materials on UET single screw extruders stable screw conveying enables uniform mixing of insulation materials and fillers while precise temp control ensures their insulation performance. Finished material suits insulation coating for small cables and low voltage wires meeting conventional cable performance needs.

PVC Compounding

Using UET single screw extruders for PVC compounding its tapered screw design enables uniform blending and melting of PVC resin with additives such as plasticizers and stabilizers. The consistent extrusion process produces customized PVC materials suitable for manufacturing various products including pipes films and cables.

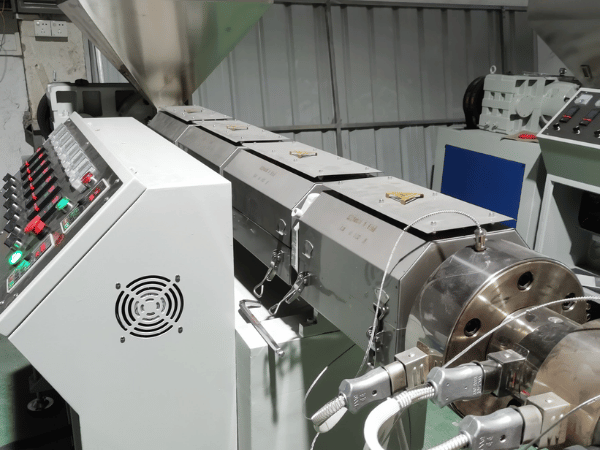

UET Machine Single Screw Extruder Factory

Welcome to UET Machinery Single Screw Extruder Factory. We have a well-established production process for high-quality single screw extruders, and our core technologies rank among the top tier in the industry. We sincerely invite you to visit our factory in person for an on-site inspection.

Customer Reviews for UET Single Screw Extruders

Check out real reviews from some users who have used UET single screw extruders. These reviews come from customers across various industries. We’re proud to leverage our equipment’s low maintenance costs and durability to help customers control production expenses and maintain consistent, long-term processing output.

Extruder Blog Posts

Twin Screw Compounding Extruder: Everything You Need to Know

The twin screw mixing extruder is a core processing equipment in the rubber plastic and chemical industries. It integrates the functions of mixing conveying plasticizing…

PVC Twin Screw Extruder: Everything You Need to Know

The PVC Twin Screw Extruder is the core equipment for PVC plastic processing, designed specifically for material plasticization, mixing and extrusion molding. Understanding this type…

Twin Screw Extruders: A Basic Understanding and Definition

The twin-screw extruder is a core equipment in the industrial material processing field. Its efficient material handling capacity and wide adaptability make it a key…

What Are the Types of Twin Screw Extruder?

Understanding the types of twin-screw extruders is a crucial prerequisite for accurate model selection and improved production efficiency. It also provides a core basis for…

How Does a Twin Screw Extruder Work? Understanding Its Principle

Twin Screw Extruders are core equipment in industrial material processing. Their stable and efficient operation relies on scientific working principles. This article will break down…

What Are the Advantages of Single Screw Extruder

Single Screw Extruders are core equipment in the industrial molding sector. Their advantages directly determine production efficiency, cost and compatibility. This article will break down…

Relevant extruders offered by UET Machine

UET is a leading manufacturer of extruders with over 20 years of industry experience, and we offer a full range of extrusion molding equipment.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs) about UET Twin Screw Extruders cover core information including product compatibility, performance specifications, installation, operation and maintenance, and after-sales support.

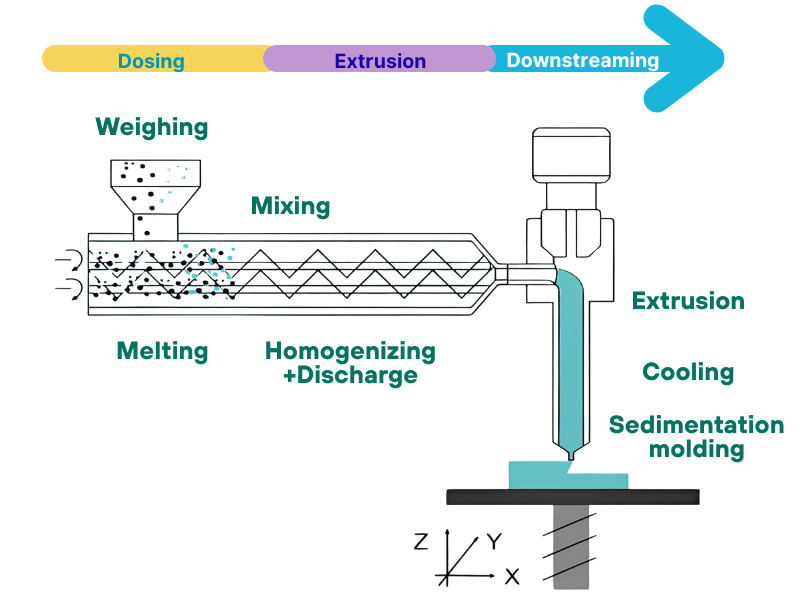

A:A single screw extruder is a device that conveys melts plasticizes and continuously extrudes materials into shape through the rotation of a single screw. It consists of a screw barrel drive system and control system as its core components. UET single screw extruders feature a streamlined structure and easy operation suitable for processing various materials. They are widely used in producing pipes films profiles and other products offering both stability and efficiency.

A:The core differences lie in the screw structure and application scenarios. A single screw extruder operates with one screw featuring a simple structure and cost effectiveness. It is suitable for continuous extrusion of single materials with easy operation and maintenance making it ideal for small to medium batch production. A twin screw extruder uses two intermeshing screws offering stronger mixing and plasticizing effects suitable for multi material blending or complex formula processing but with higher costs and operational difficulty. UET single screw extruders focus more on cost performance and flexible adaptability.

A:Yes UET single screw extruders support comprehensive customization services. We can customize core parameters such as screw diameter length to diameter ratio and drive power based on your production requirements. They can also be adapted to specific processing materials capacity demands and product specifications such as pipe diameter and film thickness. The customization process is professional and efficient. Our technical team will provide full time support to ensure the equipment accurately matches your production scenario and meets personalized processing needs.

A:The production capacity of UET single screw extruders varies by model covering a range of 50 to 500 kg per hour. Small models are suitable for small batch production with a capacity of approximately 50 to 150 kg per hour. Medium models have a capacity of 150 to 300 kg per hour ideal for regular batch production. Large models can reach a capacity of 300 to 500 kg per hour meeting large scale processing needs. You can choose based on your own capacity planning or adjust capacity parameters through customization.

A:UET single screw extruders have strong compatibility and can process various thermoplastics rubbers and modified materials including polyethylene (PE) polypropylene (PP) polyvinyl chloride (PVC) ABS nylon (PA) polyester (PET) and more. They also support the processing of some functional materials such as filled modified materials and flame retardant materials. For special materials the processing effect can be optimized by customizing the screw and barrel structure.

A:Absolutely. UET single screw extruders are easy to operate and adjust. No complex modifications are needed when switching production types allowing quick adaptation to small batch and multi variety production needs. The equipment features low maintenance costs and a compact footprint requiring no large scale supporting facilities. With flexible startup and shutdown it can effectively reduce cost losses in small batch production making it a cost effective choice for small to medium batch processing.

A:The lead time for standard UET single screw extruder models is 3 to 4 weeks. Customized models require 4 to 6 weeks depending on the complexity of customization. We have a standardized production workshop and sufficient inventory of core components enabling quick response to order production. If you have urgent needs expedited production can be arranged through an exclusive communication channel. The specific delivery time will be clearly informed after order confirmation to ensure on time delivery.

A:Yes UET offers comprehensive installation and commissioning services. After equipment delivery we will dispatch professional technical personnel to provide on site or remote guidance to assist with equipment installation positioning parameter debugging and trial operation ensuring the equipment reaches optimal production status. Meanwhile key operating points and precautions will be explained to operators to address various issues during installation and commissioning supporting your quick production launch.

A:UET single screw extruders come with a 1 year whole machine warranty and an extended 18 month warranty for core components including the screw barrel and drive system excluding wearing parts. During the warranty period if the equipment experiences non human induced failures we will provide free repair services and replace damaged components along with 24 hour technical support. After the warranty expires lifetime maintenance services and preferential spare parts supply are still available.

A:The maintenance frequency of UET single screw extruders depends on operational intensity. Under regular production conditions basic maintenance is recommended monthly including equipment cleaning inspection of screw and barrel wear and tightening of connectors. In depth maintenance should be performed every 6 months involving oil replacement inspection of electrical systems and seals. A comprehensive overhaul is suggested annually to ensure long term stable operation of the equipment. The maintenance process is simple with low costs.

A:Yes UET offers professional operation training services. Training formats include on site training remote video training and written operation manual guidance. The content covers core knowledge points such as equipment operation processes parameter setting daily maintenance and troubleshooting. Training is conducted by experienced technical personnel ensuring operators quickly master operational skills and can independently complete production tasks and basic maintenance supporting efficient production launch.