The twin-screw extruder was developed based on the single-screw extruder and is mainly used in the plastics, rubber, food, and pharmaceutical industries. This article will explain in detail the working principle, main components, and industrial applications of twin-screw extruders. After reading this article, you will have a better understanding of everything related to twin-screw extruders.

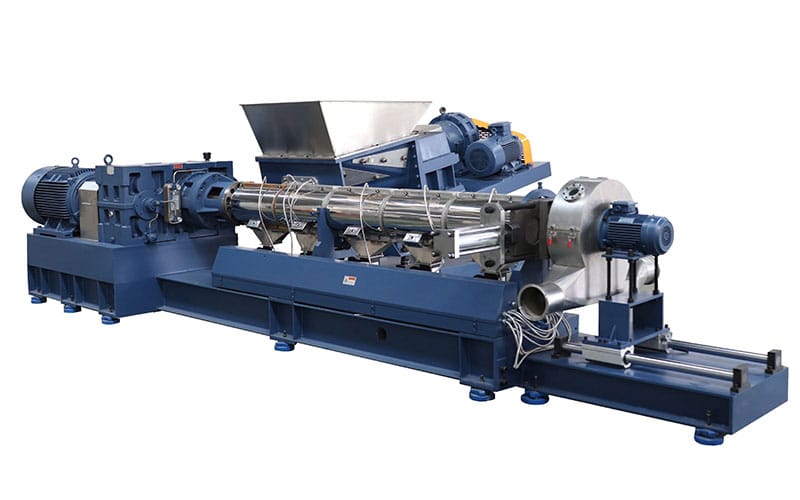

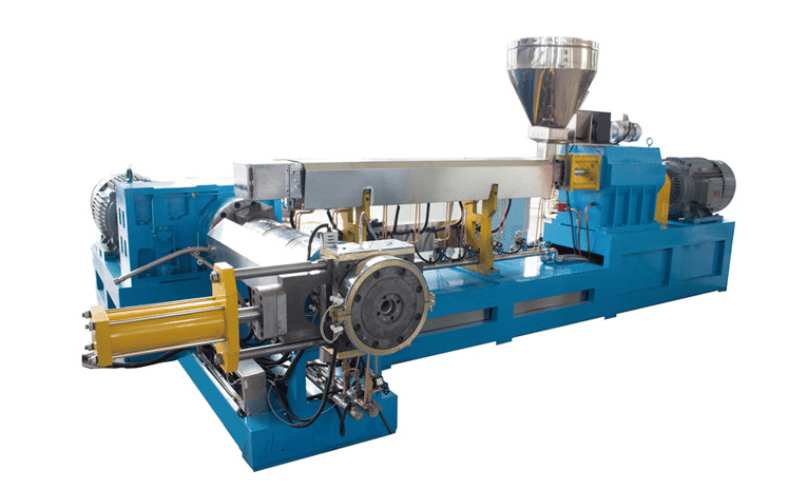

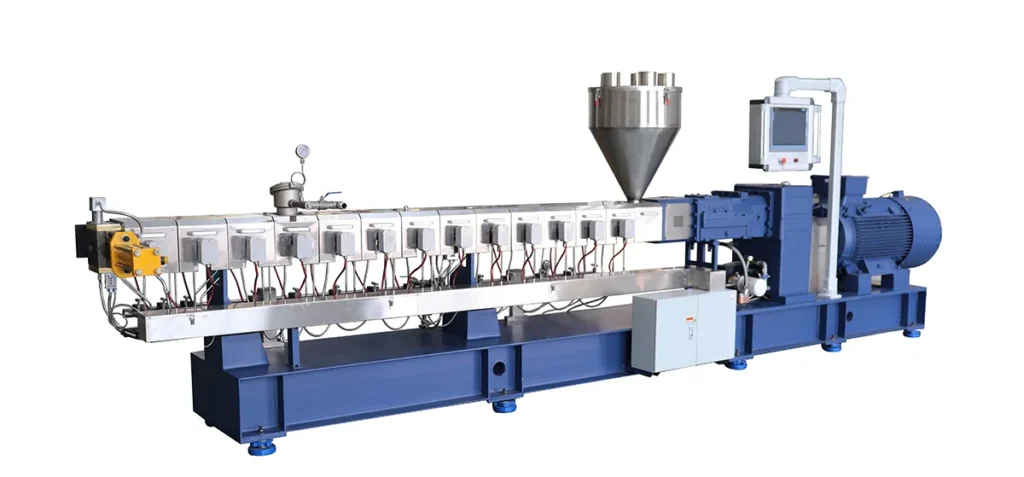

What is a twin-screw extruder?

A twin-screw extruder is an indispensable piece of machinery in modern industry. Its barrel contains two screws that rotate (either in the same direction or in opposite directions) to convey and mix materials. Compared to single-screw extruders, which rely on friction to feed materials, twin-screw extruders are more efficient and achieve better material mixing. As a result, they are the preferred choice for most industrial processing applications.

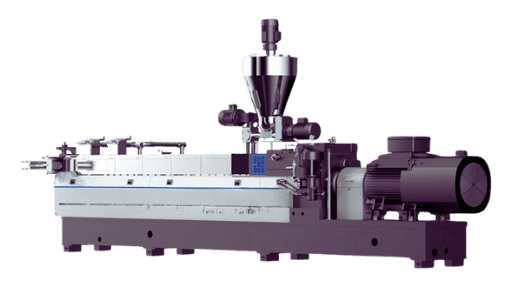

Types of twin-screw extruders

To meet different industrial needs, there are many types of twin-screw extruders. Common types of twin-screw extruders include co-rotating screws, counter-rotating screws, and meshing screws.

- Co-rotating screws: Two screws rotate in the same direction, suitable for applications requiring high mixing efficiency, such as the uniform dispersion of additives in plastic modification and the preparation of composite materials.

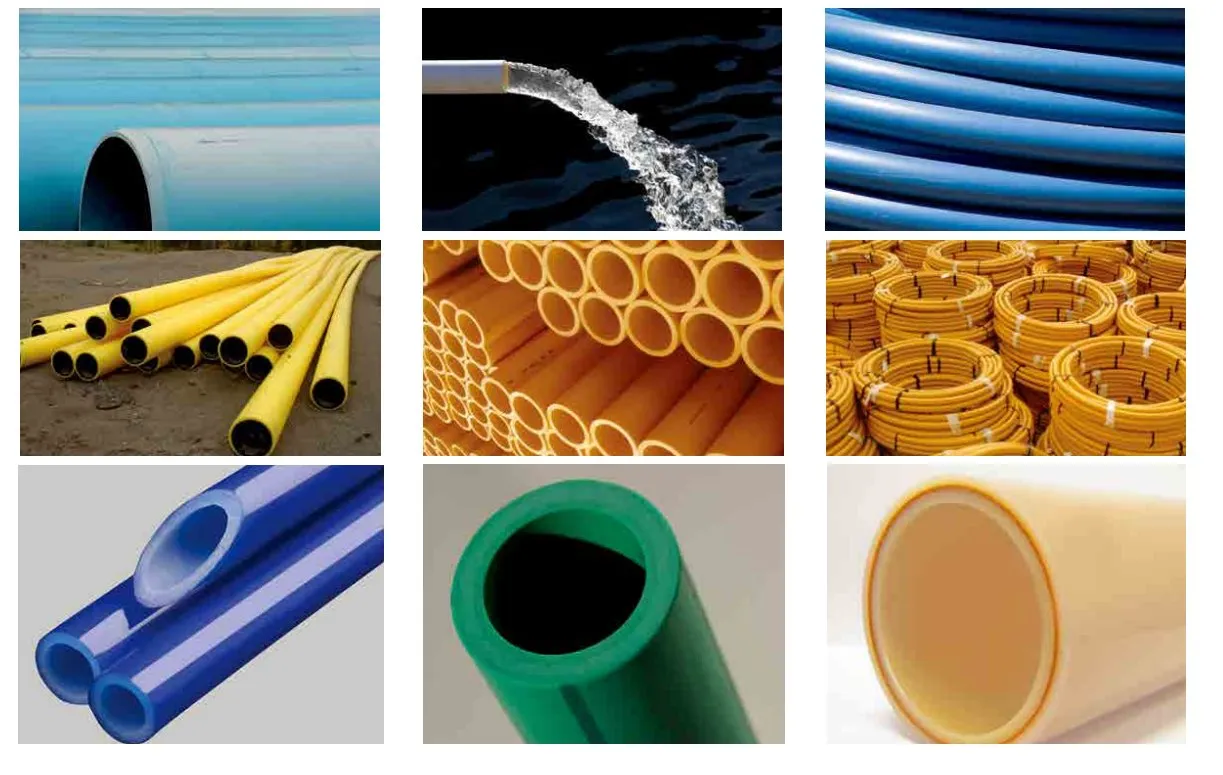

- Counter-rotating screws: Two screws rotate in opposite directions, suitable for processes requiring high compression force, such as the extrusion molding of PVC pipes and other profiles.

- Intermeshing screws: The screws feature a special tooth profile and screw groove design to maximize interaction between the two screws. They are widely used in production processes with strict requirements for material mixing and plasticization, such as engineering plastic pelletization and processing of heat-sensitive materials.

Working principle of twin-screw extruders

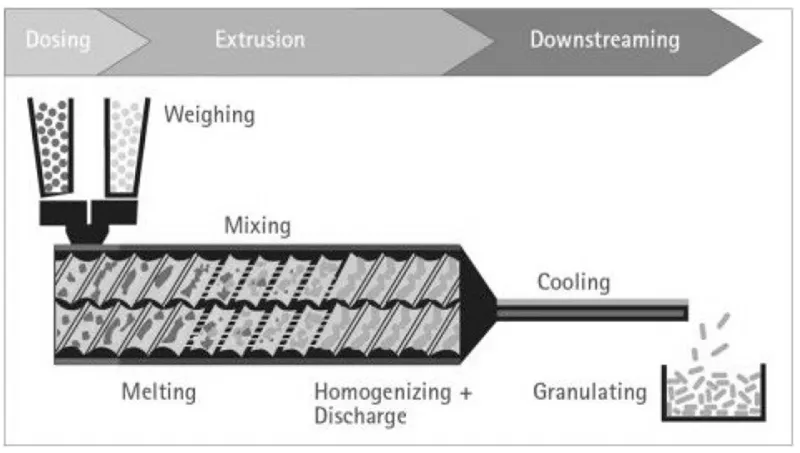

Twin-screw extruders process raw materials primarily through the rotation of the screws within the barrel (which can rotate in the same or opposite directions) and the setting of parameters. The following section will detail the detailed process of a twin-screw extruder.

1. Feeding

The material (typically granules, powder, or recycled scrap) enters the barrel through the hopper, falls into the meshing area of the two screws, and is then pushed forward by the rotation of the screws.

2. Melting and Mixing

As the material continues to move forward within the barrel, the solid material gradually melts due to the rotation of the screws and the increase in temperature, and is mixed as the screws rotate.

3. Venting

Some advanced extruder types are equipped with venting ports. As the material passes through these ports, air and moisture generated during the melting and mixing process are expelled under the negative pressure created by the screw rotation, ensuring the quality of the final product.

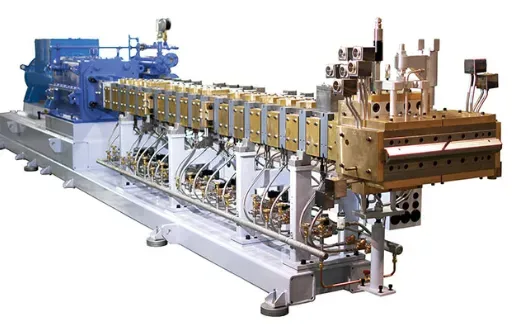

4. Molding

After melting, mixing, and degassing, the material is pushed to the end of the barrel. Under the screw’s pressure, the material passes through the mold at a uniform pressure. The mold shapes the melted material into the desired form, such as tubes, sheets, or profiles.

5. Cooling and solidification

After exiting the mold, the material is cooled and solidified via an air or water cooling system. It is then further processed or cut according to the product’s specific requirements.

By gaining a deep understanding of these processes, people will be able to appreciate how twin-screw extruders work through the coordinated operation of their various components, from raw material modification to the formation of finished products.

Applications of twin-screw extruders in industry

1. Plastic modification field

Common raw materials include polypropylene, polyethylene, and other base resins, combined with additives such as glass fiber, carbon fiber, or talc. In the automotive manufacturing and home appliance production industries, these raw materials are mixed and modified using twin-screw extruders to enhance the strength and heat resistance of plastics, such as for manufacturing car dashboard frames and refrigerator drawer slides.

2.Masterbatch production field

Polyethylene and polypropylene are used as carrier resins, with the addition of pigments and dispersants. In the plastic coloring industry, masterbatches produced by twin-screw extruders can be used to color products such as packaging films and plastic toys, ensuring uniform and stable color.

3.Recycled plastic field

The raw materials are recycled PET bottle flakes, PE film fragments, and other waste plastics, with a small amount of toughening agent added. In the recycled plastic industry, the recycled material obtained after processing can be used to produce plastic crates, trash cans, and other products, achieving resource recycling.

4.Rubber products industry

Commonly used materials include natural rubber and styrene-butadiene rubber, combined with carbon black, vulcanizing agents, and accelerators. In the tire and seal ring manufacturing industry, twin-screw extruders can thoroughly mix these raw materials, enhancing the rubber’s wear resistance and elasticity, for use in producing tire treads and mechanical seal rings.

5.Cable material production field

Polyvinyl chloride and polyethylene are used as base materials, with the addition of antioxidants, insulating agents, and flame retardants. In the wire and cable industry, the produced cable materials can be used to make cable insulation layers and sheaths, ensuring the cable’s insulation performance and flame retardant effects, suitable for power transmission and communication lines.

6.Food additive field

Raw materials include sodium carboxymethyl cellulose, maltodextrin, and other powdered food additives, which may be mixed with a small amount of water or edible alcohol as a binder. In the food processing industry, the resulting granular additives are convenient for storage and use, and are applied in the production of beverages, pastries, and other foods.

7.Biomass materials sector

Using biomass fibers such as straw powder and wood chips, combined with biodegradable plastics like PLA and PBAT. In the environmental materials industry, the resulting composite materials can be used to manufacture disposable food containers, packaging films, and other products, which can naturally degrade after disposal, thereby reducing environmental pollution.

8.Pharmaceutical excipient sector

Commonly used pharmaceutical excipients such as hydroxypropyl methylcellulose and microcrystalline cellulose may be combined with active pharmaceutical ingredients. In the pharmaceutical industry, the resulting granules can be used to produce sustained-release tablets, enteric-coated tablets, etc., ensuring stable drug release and absorption.

9.Hot-melt adhesive production field

Using EVA resin and SBS rubber as base materials, combined with rosin, paraffin, and tackifying resins. In the packaging and wood processing industries, the produced hot-melt adhesives can be used for cardboard box sealing, wood panel joining, etc., featuring strong adhesion and rapid curing.

10.Composite materials field

Raw materials include engineering plastics such as nylon and polycarbonate, combined with reinforcing agents like aluminum powder, carbon fiber, and glass fiber. In the aerospace and sports equipment industries, the produced composite materials can be used to manufacture drone housings, golf clubs, etc., featuring both high strength and lightweight properties.

Frequently Asked Questions (FAQ)

Q: Do the two screws of a twin-screw extruder have to be meshed?

A: Not necessarily. Twin-screw extruders are divided into meshed and non-meshed types. Meshed screws have a small gap (typically 0.1–0.5 mm) and rely on screw flute engagement to forcefully convey material, making them suitable for precise mixing. non-meshing screws have larger spacing and rely on friction for material feeding, making them suitable for processing large pieces or highly filled materials, and less prone to blockages.

Q: Which type of twin-screw extruder—co-rotating or counter-rotating—provides better mixing performance?

A: Co-rotating screws provide better mixing performance. Co-rotating screws create vortex shear at the meshing points, repeatedly kneading the material like “kneading dough,” enabling more uniform mixing of multi-component raw materials (such as plastics and additives); counter-rotating screws focus on compression, suitable for applications requiring high-pressure molding (such as PVC pipes).

Q: How should the temperature be set for a twin-screw extruder?

Answer: Temperature settings should be adjusted in segments based on material properties: lower temperatures in the feed section (to prevent premature melting and clumping of raw materials), gradual temperature increase in the compression section (to promote melting), and stable temperatures in the metering section (to prevent overheating and degradation). For example, when processing PVC, the overall temperature should be kept below 180°C, while PE processing can reach 200–230°C.

Q: How does screw speed affect extrusion performance?

A: Speed directly impacts material residence time and shear strength: at high speeds, material spends less time in the barrel and experiences greater shear force, suitable for rapid mixing but requiring careful temperature control; at low speeds, plasticization is more thorough, suitable for heat-sensitive materials (such as certain pharmaceutical excipients), but efficiency is lower.

Q: Can twin-screw extruders process materials with high moisture content?

A: Yes, but they must be equipped with a venting system. The vacuum venting port in the middle of the barrel can extract moisture and volatiles after the material melts, preventing bubbles in the final product. For example, when processing recycled plastics, venting can reduce moisture content to below 0.1%, ensuring the quality of the recycled material.

Q: Which is more energy-efficient, a twin-screw or a single-screw extruder?

A: Twin-screw extruders are more energy-efficient when processing high-viscosity, multi-component materials. Due to their forced conveying characteristics, they do not rely on high-friction feeding like single-screw extruders, resulting in energy savings of 10%-30%, particularly advantageous in plastic modification and composite material production.

Q: Can the screw blocks of a modular twin-screw extruder be replaced arbitrarily?

A: Yes, but matching principles must be followed. Different screw blocks (conveying blocks, shearing blocks, kneading blocks) have distinct functions, and replacement must be based on process requirements: use wide-pitch conveying blocks for filler masterbatch production, and dense-tooth shearing blocks for reaction extrusion. Additionally, ensure compatibility between screw blocks, shaft diameter, and barrel clearance.

Q: What common issues can arise with twin-screw extruders? How can they be resolved?

A: Common issues include material blockage (due to excessive feed rate or screw wear), material degradation (due to high temperatures), and fluctuations in extrusion volume (due to unstable screw speed or uneven feeding). Solutions include controlling the feed rate, regularly inspecting screw wear, calibrating the temperature control system, and ensuring the feeder matches the screw speed.

Q: What factors determine the output of a twin-screw extruder?

A: Output is primarily determined by screw diameter, speed, and material properties: larger diameters (e.g., 65mm vs. 35mm) and higher speeds increase output; however, high-viscosity materials (e.g., rubber) reduce output, requiring adjustments to screw groove depth and motor power for compatibility.

Q: What should beginners be mindful of when operating a twin-screw extruder?

Answer: First, familiarize yourself with the material properties (such as melting point and viscosity). Preheat the barrel according to procedures (to avoid damaging the screw during cold starts). Start the machine at low speed and gradually increase the speed. Before shutting down, empty the material to prevent residual material from cooling and hardening. Regularly clean the barrel and screw to avoid residue buildup that could affect future production.