Extruders are essential equipment in today’s industry. Single-screw extruders and twin-screw extruders are the two most commonly used types in most industries. This article will take you to a deeper understanding of these two types of extruders, guide you to understand their differences, application areas, their respective characteristics and uses, and help you buy an extruder that suits you.

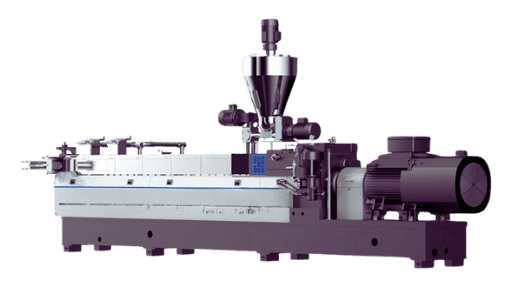

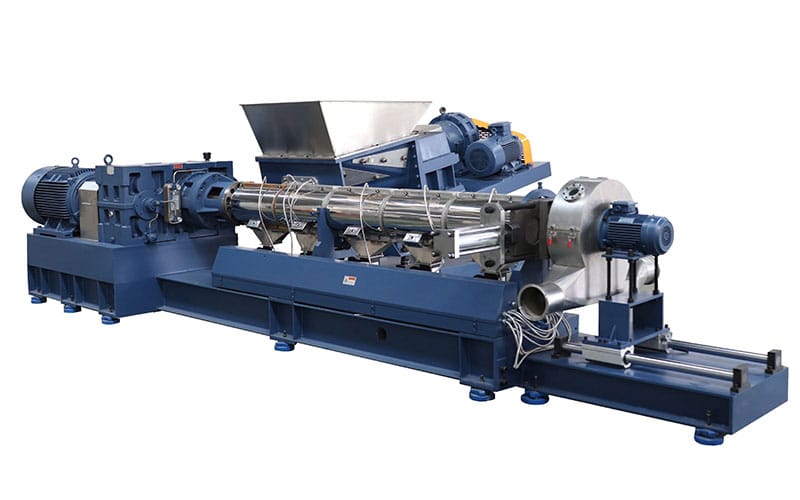

Understanding Single Screw Extruder

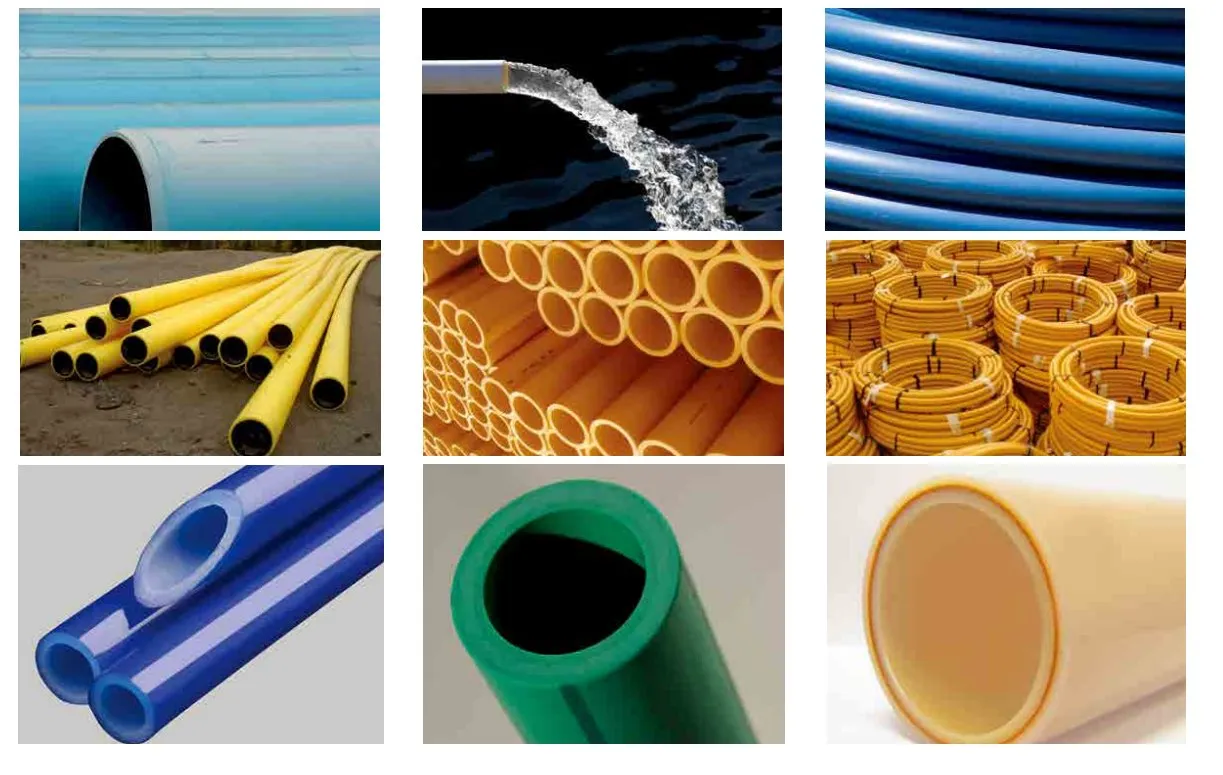

A single-screw extruder refers to an extruder with only one screw. The material is conveyed, melted, plasticized and extruded by rotating the screw. Since the structure is not complicated, it is also very convenient to maintain. It is very suitable for processing products with simple raw materials and low requirements for mixing uniformity, such as plastic insulation layers, plates, pipes and other products of wires and cables.

- Low manufacturing cost

The price of a single-screw extruder is 30%-60% cheaper than that of a twin-screw extruder. This is because its simple structural design results in much fewer parts than a twin-screw extruder, which also makes the price cheaper.

- Simple operation

Due to its simple characteristics, even a novice can easily operate the equipment after a few days of training.

- Wide range of uses

Single-screw extruders can produce different products such as films, pipes, rods, monofilaments, etc. Due to their strong adaptability, they can be widely used in different industries.

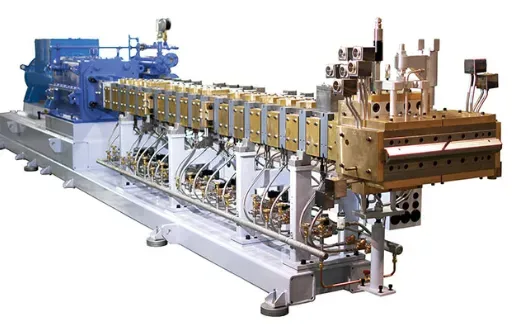

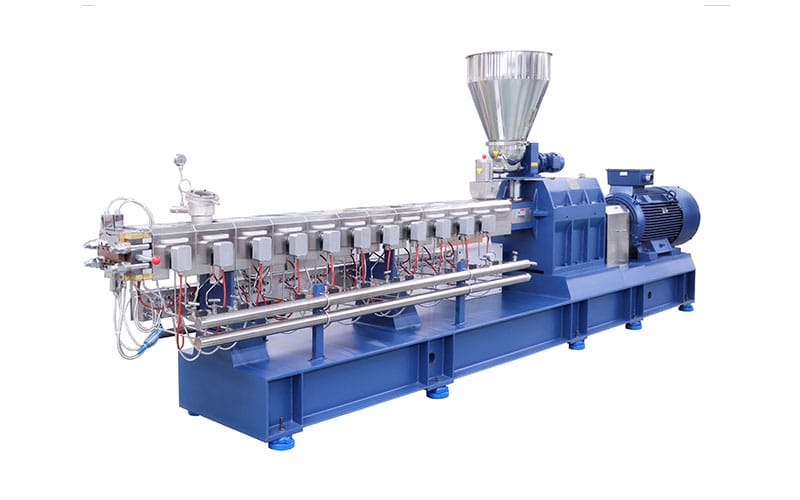

Understanding Twin-Screw Extruder

Twin-screw extruder is developed on the basis of single-screw extruder. Because it has two screws, it has strong mixing and kneading ability. It is usually used for production equipment structure with large extrusion volume and strong mixing ability. It is widely used in manufacturing, plastics, food and other industries.

- Strong raw material adaptability

It can process “complex materials” that are difficult to handle with a single screw extruder, such as heat-sensitive resins, high-viscosity elastomers, biodegradable plastics, pharmaceutical-grade polymer materials, etc.

- Super strong mixing ability

Twin-screw extruder can fully mix materials through the meshing, shearing and extrusion of two screws, which is very important for the quality of extruded products.

- Efficient and stable output

Twin-screw extruder relies on the meshing of two screws to force pushing, and is not limited by the friction between the material and the barrel. Even high-viscosity and high-filling materials can be stably transported, which is an ideal choice for large-scale production.

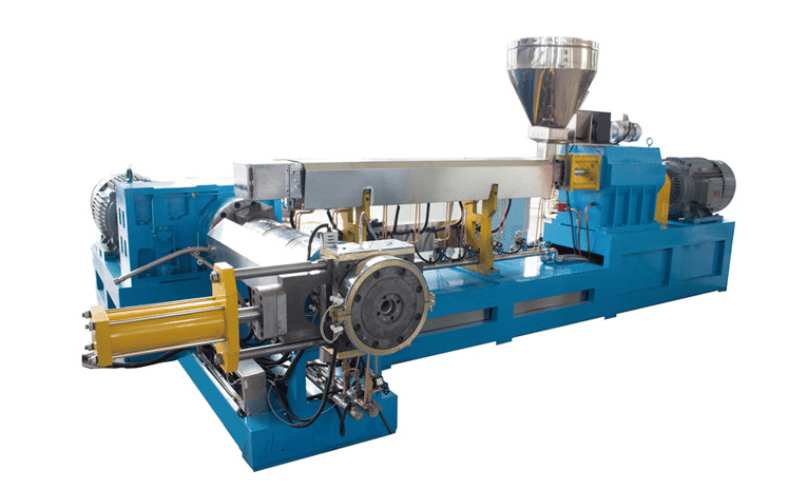

The main difference between single screw extruder and twin screw extruder

The twin-screw extruder relies on the meshing of two screws to force the extruder to push, and is not limited by the friction between the material and the barrel. Even high-viscosity and high-filling materials can be stably transported, making it an ideal choice for large-scale production.

To understand the difference between a twin-screw extruder and a single-screw extruder, you need to understand it from multiple aspects. The following content lists the main differences between the two extruders:

- Equipment price

Twin-screw extruder: The complex design and super performance of the twin-screw extruder make the purchase and maintenance costs high.

Single-screw extruder: The single-screw extruder is cheaper to purchase and has lower maintenance costs than the twin-screw extruder.

- Processing capacity

Twin-screw extruder: The twin-screw extruder has efficient processing capacity and is suitable for the mixing and processing of complex raw materials. It is often used in large-scale production with complex raw materials and high product requirements.

Single-screw extruder: The single-screw extruder is suitable for simple and easy-to-process materials, such as ordinary plastics and low-filling materials. It is mainly used for the processing of low-mixed materials.

- Operation complexity

Twin-screw extruder: The twin-screw extruder has high requirements for operators and requires complex parameters to be adjusted.

Single-screw extruder: The single-screw extruder mainly controls simple parameters such as speed and temperature. It is simple to operate and relatively friendly to newcomers.

- Application scenarios

Twin-screw extruder: It is mostly used in high-end processing scenarios, such as modified plastic production, composite material preparation, functional masterbatch processing, high-performance material extrusion, etc.

Single screw: mostly used for basic product processing, such as pipes, films, plates, ordinary profiles and other single resin extrusion.

In general, the performance, efficiency and mixing capacity of twin screw extruders are stronger, and they are suitable for large-scale standardized production. Single screw extruders are cheap and easy to operate, and are suitable for simple processing of raw materials.