Top Printing Paper Machine Manufacturers in China

UET TECH has advanced printing paper machines, which use fully automated processes to help factories improve productivity and profitability. The equipment is reliable and can produce continuously and efficiently. Contact us now to improve your production efficiency.

- Competitive prices

- Support global delivery

- Customizable solutions

- Serving over 1,200 customers

Contact us now to get 20% discount

Factory direct sales

On-time delivery

Cost Pricing

High-quality service

Home » Printing Paper Machine

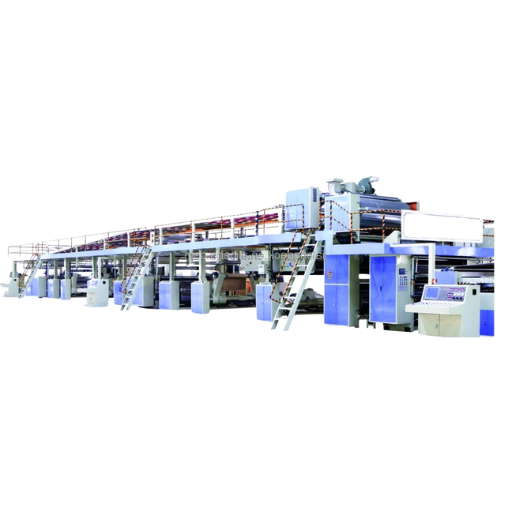

UET TECH printing paper machine, ultra-high productivity and intelligent design

UET TECH printing paper machine solutions are redefining the production paradigm of the modern paper industry through the triple innovation of “technological breakthrough – efficiency revolution – value reconstruction”. Our printing paper machines adopt automated and digital design to achieve a fully automated process from pulp forming to finished product output without excessive manual intervention, far exceeding the industry level in terms of high-speed production, resource efficiency and product adaptability.

UET TECH printing paper machine parameters

| Attribute | Details |

|---|---|

| Processing Type | High-speed Intelligent Coating & Printing Paper Machine |

| Voltage | 380V/440V Three-phase AC |

| Production Capacity | 50-350 tons/day |

| Warranty | 2-year full machine warranty + 3-year core components warranty |

| Origin | Hebei, China |

| Brand Name | UET Machinery |

| Power (kW) | 450 kW |

| Dimensions (L×W×H) | Standard configuration: 35m×12m×9m (customizable) |

| Mechanical Test Report | Provided with third-party authoritative testing report |

| Video Inspection for Shipment | 48-hour continuous operation video + quality inspection report |

| Core Components | Intelligent Central Control System, Servo Motor, Vacuum Dewatering Module, Precision Coating Roller, Automatic Roll Changing Device |

| Raw Materials | Bamboo pulp, bagasse pulp, wood pulp, mixed recycled pulp (recycled ratio 30%-60%) |

| Finished Products | High-grade coated paper, food packaging base paper, special label paper, lightweight coated paper |

| Basis Weight | 50-150 g/m² |

| Trim Width (mm) | 2000-4500 |

Why choose UET TECH's printing paper machine?

It is compatible with a variety of raw materials such as bamboo pulp and recycled pulp, and can easily switch to produce packaging paper, printing paper and other categories, making it more flexible to respond to market demands.

Equipped with an intelligent control system, it automatically stabilizes production parameters, reduces manual intervention, and achieves higher consistency in finished product quality.

The core components are of reliable quality and have a long service life, which reduces the trouble of frequent maintenance and replacement, and is more cost-effective for long-term use.

The product specifications can be switched quickly, and small batch and multi-category orders can be completed efficiently without delaying delivery.

Compatible with voltage standards of multiple countries, no additional circuit adjustment is required during installation, saving time and effort. Energy consumption is lower than traditional equipment, and long-term use can save a lot of costs.

Visit UET TECH's factory

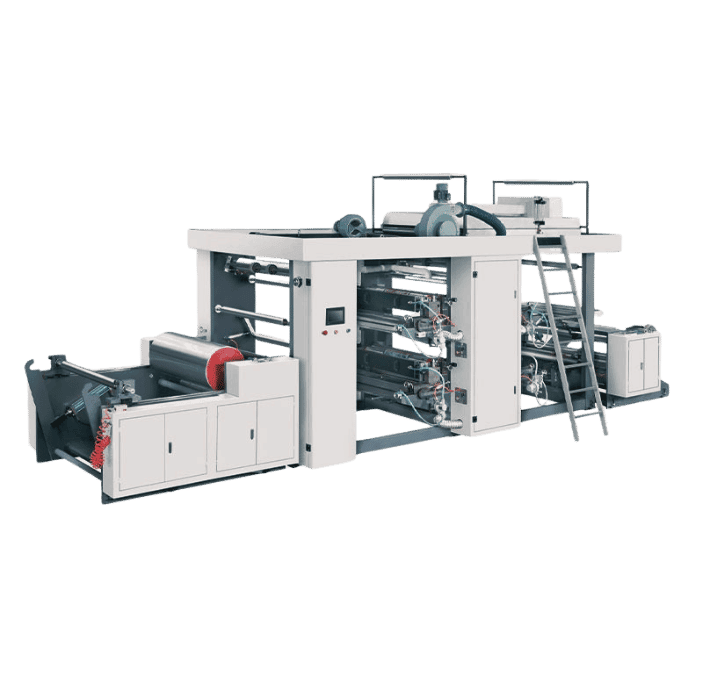

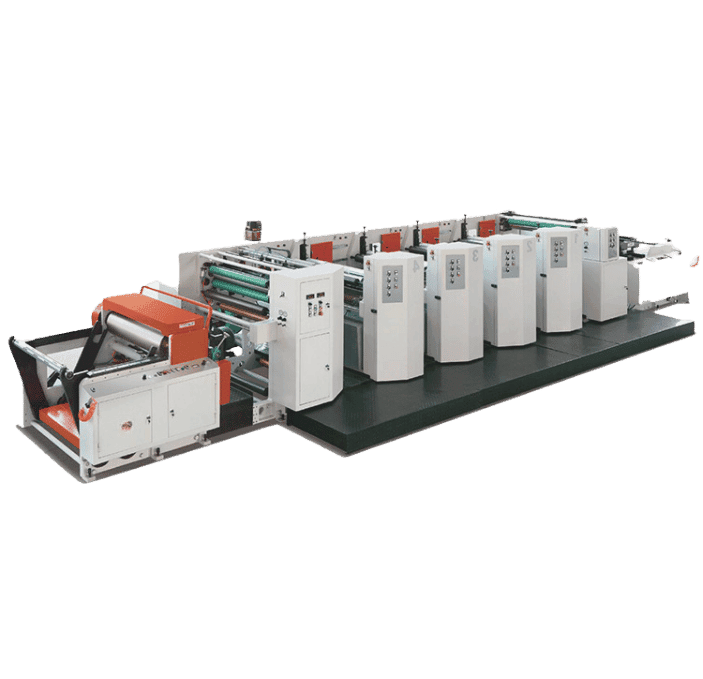

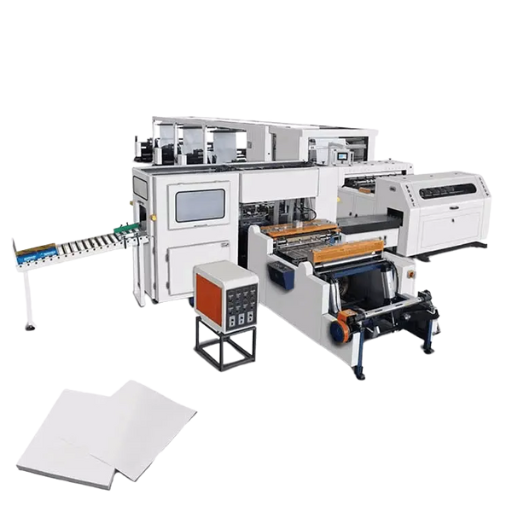

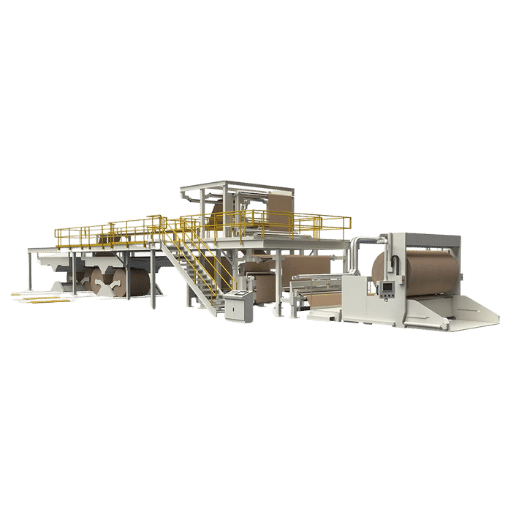

Products related to UET TECH paper machines

Tissue paper machine

Adaptable to diverse packaging requirements, supports customized production, is easy to operate and maintain, has strong production continuity, and the finished products have outstanding texture

A4 Copy Paper Machine

The copying effect is clear and stable, the material compatibility is strong, the operation is simple and easy to use, it is compatible with global voltage standards, and the production continuity is good.

Corrugated Paper Machine

Adapt to a variety of packaging specifications, strong equipment durability, save packaging material costs, stable production efficiency, short installation and commissioning cycle

Fourdrinier Paper Machine

Suitable for large-scale continuous production, wide range of paper products, flexible raw material adaptability, fully automated process, stable production

Get the price of UET TECH printing paper machine

Are you looking for a durable printing paper machine? We have printing paper machines that can adapt to your various production needs. Our professional team will tailor a production plan for you based on your actual situation. Contact us at any time! Get a suitable quotation.

Sales countries

Serve customers

Years of experience

Factory building area

Customer review

Check out the real reviews from customers after using our tissue paper machines.

Printing paper machineFrequently Asked Questions

A:Printing paper machine is an industrial equipment specially used to produce paper suitable for printing. Through a series of processes, raw materials such as wood pulp and recycled pulp are processed into paper products that can be directly used for printing. It is widely used in publishing, packaging, cultural supplies and other fields, and is a key equipment connecting the papermaking and printing industries.

A:Basic equipment costs about $200,000 to $500,000, and high-end intelligent models cost $800,000 to $1.5 million. Due to its simple structure, the cost of flexographic printing machines is 30-50% lower than that of gravure printing equipment, and the investment payback period is about 18-24 months.

A:The paper produced by printing paper machines has a wide range of applications: newsprint and journal paper are used in publishing industries such as newspapers and magazines; coated paper and matte powder paper are suitable for exquisite printing such as picture albums, posters, and high-end advertisements; offset paper and writing paper serve the production of books, notebooks, and office stationery; packaging paper (such as white cardboard and kraft paper) is used in packaging scenarios such as food, electronics, and express delivery; special paper (such as anti-counterfeiting paper and label paper) is used in pharmaceutical labels, luxury packaging, certificate printing and other fields, covering multiple industries such as publishing, packaging, office, and cultural and creative industries.

A:

Printing machines are mainly divided into four categories according to the printing method:

- Lithographic printing machine (offset printing machine): suitable for fine printing of books, magazines, posters, etc., realized through the principle of oil-water separation;

- Letterpress printing machine: commonly used for packaging labels, bills, and the printing plate is raised;

- Gravure printing machine: suitable for large-area printing such as plastic films and wallpapers, and the printing plate is sunken;

- Screen printing machine: can print on special materials such as glass and metal, and print through the screen.

- In addition, there are digital printing machines that support small-batch variable data printing and are used in the field of personalized customization.

UET TECH: China's top printing paper machine manufacturer

Want to know more? Feel free to leave your contact information! Our expert will contact you within 12 hours to answer your questions one-on-one.