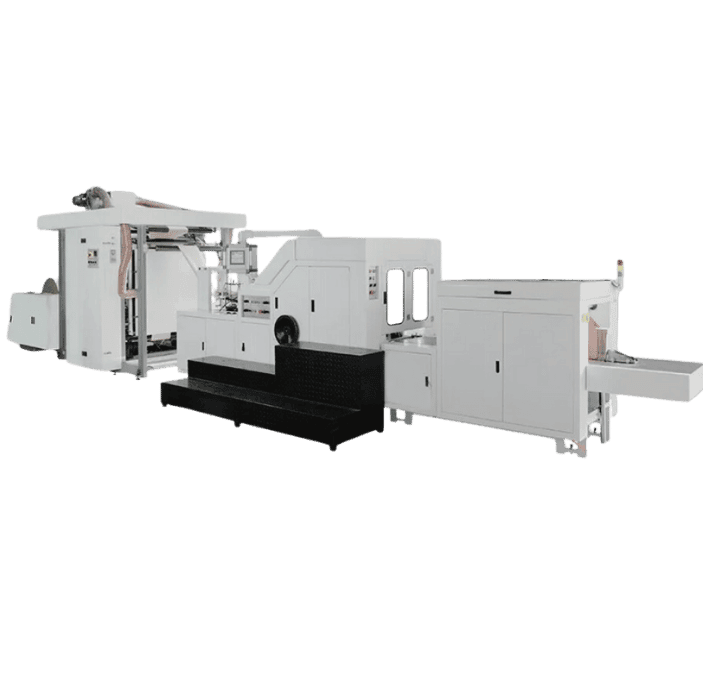

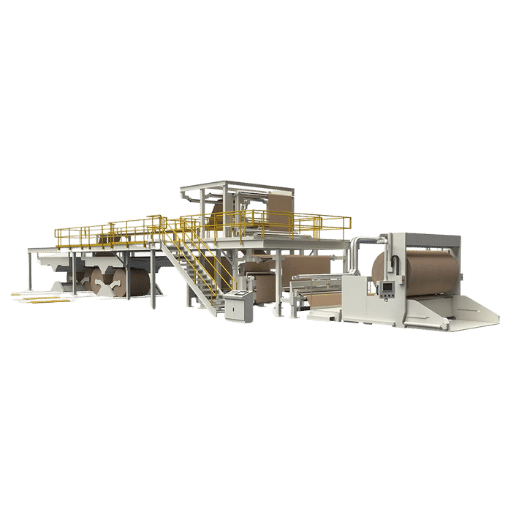

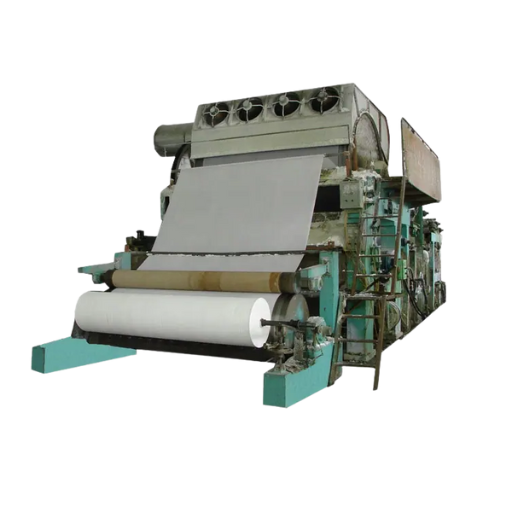

Kraft Paper Machine

High-quality kraft paper manufacturer in China

UET TECH is an outstanding manufacturer of kraft paper machines in China. Our kraft paper machines are your best choice, which can help you improve production quality and efficiency. Contact us immediately! Get precise solutions.

Save at least 35% or more on your purchase.

Factory direct sales

On-time delivery

Cost Pricing

High-quality service

Home » Paper Making Machine » Kraft Paper Machine

Why choose UET TECH Kraft Paper Machine

UET TECH kraft paper machine takes improving production capacity and product quality for customers as its starting point, and reduces the risk of investment with advanced technology and low maintenance costs, helping customers to obtain considerable profits.

Efficient production capacity

Through years of industry development, UET TECH has mastered advanced technology, which can ensure the production capacity and quality of products while the equipment is running stably.

The equipment is durable.

The core components are made of high-quality materials and combined with advanced manufacturing processes, which can ensure stable operation of the equipment, a long service life, reduce maintenance downtime, and guarantee the continuity of production.

Perfect after-sales support

We have a professional after-sales technical team. No matter what problems you encounter when using the UET TECH kraft paper machine, our professional technicians can respond and handle them in a timely manner.

Automated system

The equipped automatic control system, through real-time online detection, can precisely regulate the production process. It enables fully automated production and can stably produce high-quality products without extensive human intervention.

Convenient operation

The operation interface is simple and easy to understand, and the process design is also very concise. Even beginners can quickly get started, which can significantly reduce labor costs.

Thoughtful user experience

Every detail of our equipment design takes into account users' usage habits to ensure smooth operation and clear fault prompts, making the production process smoother and more worry-free.

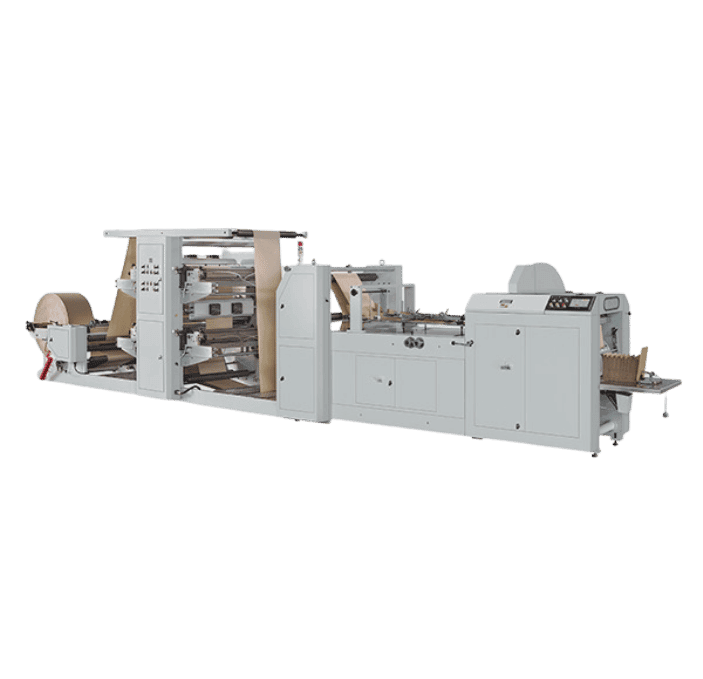

The main components of UET TECH kraft paper machine

These components each perform their own duties while also working in coordination to jointly support the efficient production of the kraft paper machine and ensure the high quality of the products.

Press Felt

Made of high-strength composite fibers, it is flexible and wear-resistant, with a fast water absorption rate, strong water retention, and is not prone to caking. Its service life is over 30% longer than that of ordinary felt, and it is suitable for various pressing pressure scenarios.

Guide Roll

Made of high-strength composite fibers, it is flexible and wear-resistant, with a fast water absorption rate, strong water retention, and is not prone to caking. Its service life is over 30% longer than that of ordinary felt, and it is suitable for various pressing pressure scenarios.

Water Ring Vacuum Pump

The vacuum degree is stable and controllable, with low operating noise. It is made of corrosion-resistant materials and is not easily damaged by water vapor corrosion. Its energy consumption is 15% lower than that of traditional vacuum pumps, making it suitable for humid production environments.

Drum Pulper

The drum design is highly efficient and energy-saving, with uniform crushing force. It can adapt to various raw materials such as virgin pulp and recycled pulp, thoroughly separate impurities, operate stably without clogging, and is easy to maintain.

Pulp Pump

It adopts an anti-clogging flow channel design, ensuring stable flow without pulsation. The wear-resistant impeller is suitable for high-concentration slurry. It features low operating noise and a low failure rate, and can work continuously without interruption.

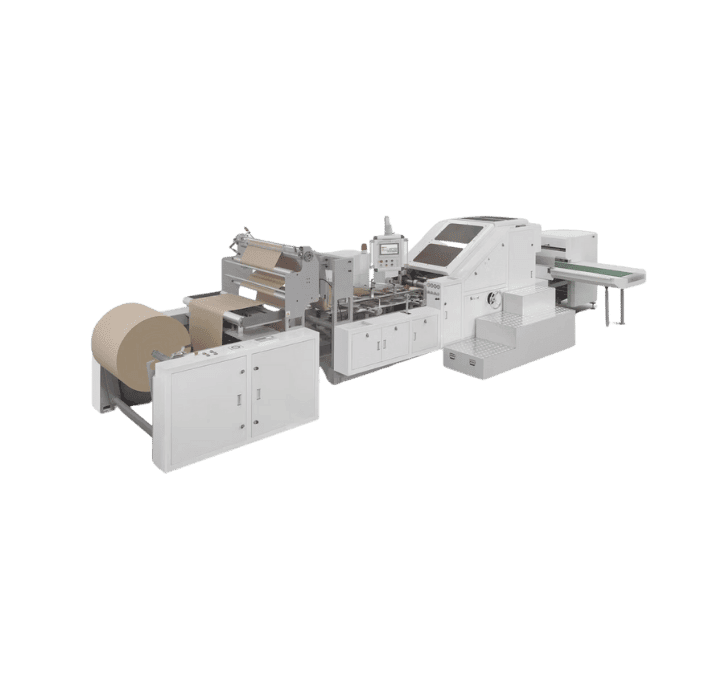

UET TECH Kraft Paper Machine Detailed Parameters

| Category | Details |

|---|---|

| Raw Material | Recycled paper (e.g., old newspapers, waste cartons), wood pulp (optional) |

| Output Paper Style | Corrugating base paper, kraft paper, special industrial paper (e.g., coated kraft paper, reinforced paper) |

| Output Paper Weight | 100-250 g/m² |

| Net Paper Width | 2400 mm |

| Production Capacity | 15 tons/day |

| Speed | 80-160 m/min (working speed), 220 m/min (design speed) |

| Basis Weight Range | 30-230 g/m² |

| Drive System | AC inverter speed control + sectional drive (precise synchronization control of each unit, energy saving ≥15%) |

| Cylinder Mold Section | Stainless steel cylinder mold (Φ1600mm×2000mm), wear-resistant and corrosion-resistant, suitable for high-consistency pulp forming |

| Press Section | Includes marble rolls (Φ550mm×2000mm) and rubber-coated rolls with hardness 90±2 (high-efficiency dewatering + paper sheet protection) |

| Dryer Section | Cast iron dryer cans (Φ2600mm×2000mm), rubber-coated touch rolls with hardness 90±2 (uniform drying and anti-wrinkling) |

| Rail Gauge | 2400 mm |

| Key Features | - 6-zone dilution headbox with Holey roll (paper sheet uniformity improved by 20%) |

| - Closed white water system with on-line turbidity monitoring (water saving ≥30%) | |

| - Multi-dryer system (thickness/strength consistency ±2%) | |

| - Telescoping beams (wire change time <1 hour, maintenance efficiency improved by 50%) | |

| - Automatic tension control system (paper web deviation rate <0.5%) | |

| Additional Features | - Powder-coating finish for the whole machine (corrosion and rust resistance, service life extended to 15+ years) |

| - U-type/S-type doctor combination (cleaning efficiency improved by 30%) | |

| - Auto and manual web guide assemblies (adapting to different production scenarios) | |

| - Digital control panel (real-time monitoring of 12 key parameters) | |

| Maintenance Efficiency | Quick wire changes <1 hour |

| Quick-detach design for key components (bearing/seal replacement time reduced by 40%) | |

| Application Fields | - Packaging materials (corrugated cartons, heavy-duty packaging bags) |

| - Industrial papers (cement bags, anti-rust paper) | |

| - Specialty papers (food-grade kraft paper, coated label paper) | |

| Energy Efficiency | Waste heat recovery system (thermal energy utilization rate of dryer section improved by 25%) |

| Full closed circulation of white water (water consumption per ton of paper <8m³) |

The application of kraft paper machines

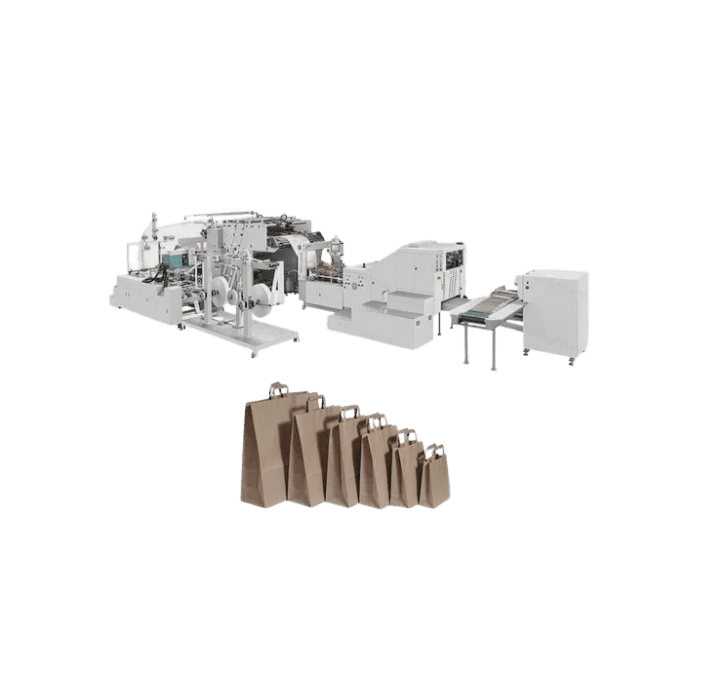

Kraft paper machines have a wide range of applications, covering multiple scenarios such as industry, logistics, consumption, and cultural creativity. Through the technical advantages of “environmental protection + customization”, they are gradually replacing plastic packaging, covering all scenarios from industrial heavy loads to consumer-grade fine packaging.

Packaging Industry

Kraft paper production can be used in the packaging industry, such as corrugated boxes are common packaging materials

Electronics and precision items

Kraft paper is widely used in packaging fragile items such as electronic products and handicrafts. It has a beautiful texture and can also be used as a lining for gift boxes to enhance the packaging texture.

Food packaging and the catering industry

Kraft paper production is widely used in food packaging, such as for catering and snacks.

Home decoration

Kraft paper production can be used for background walls, partitions and other home decorations to create a natural and environmentally friendly space atmosphere.

Electronics and precision items

Kraft paper machine can produce 1-4 layers of kraft paper bags, suitable for bulk material packaging in the chemical and cement industries

Handicrafts and handcrafts

It is used for artistic creations such as paper-cutting, origami, and three-dimensional handicrafts, or for making home decorations like storage boxes and lampshades, taking advantage of its stiffness and plasticity to achieve various shapes.

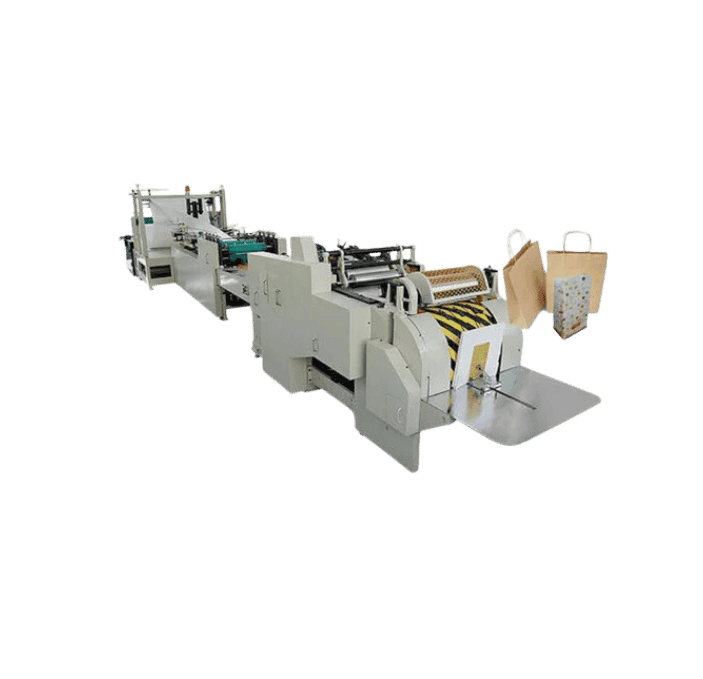

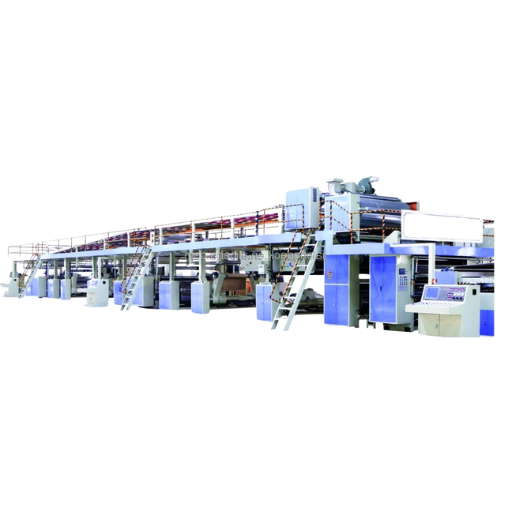

Products related to UET TECH paper machines

Printing Paper Machine

UET TECH paper printing machine, precision manufacturing, printing leading an efficient future

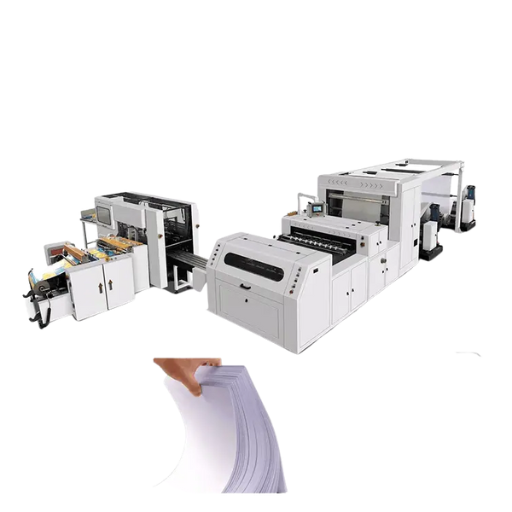

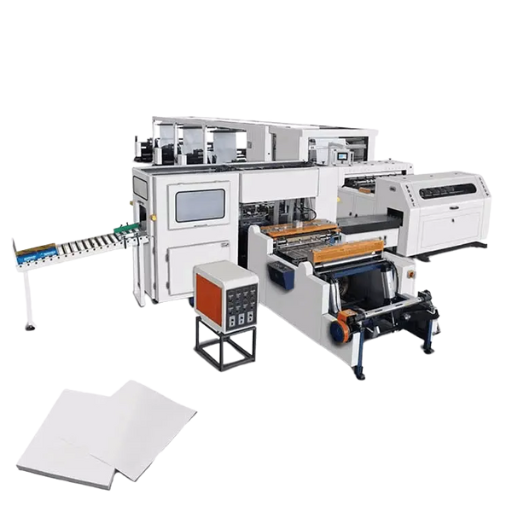

A4 Copy Paper Machine

UET TECHA4 copy paper machine helps improve production efficiency and achieve efficient production.

Corrugated Paper Machine

The UET TECH corrugated paper machine integrates automated corrugating, laminating and cutting systems, precisely controlling multiple corrugation types such as A, B and C

Suction Former Tissue Machine

The UET TECH suction type toilet paper machine is specially designed for high-speed and high-quality output

Crescent Former Tissue Machine

The UET TECH Crescent toilet paper machine is an efficient choice for the mass production of high-end household paper.

Toilet Paper Machine

UET TECH toilet paper machines focus on the large-scale production of toilet paper with a fully automated process.

Cylinder Mould Paper Machine

The UET TECH circular screen paper machine is a cost-effective solution for customized production of niche paper types, featuring stability, reliability and ease of operation.

Fourdrinier Paper Machine

UET TECH long wire paper machine, with full-process digital monitoring, is the preferred equipment for large-scale and multi-category papermaking.

Why choose UET TECH kraft paper machine

Are you looking for kraft paper machine equipment? Contact us immediately! Get a satisfactory price. Our high-quality equipment can meet all your papermaking needs. Whether you are building a new production line or upgrading your existing equipment, we can provide a perfect solution.

Sales countries

Serve customers

Years of experience

Factory building area

Customer review

Check out the real reviews from customers after using our kraft paper machine equipment.

About Kraft Paper MachineFrequently Asked Questions

A: The raw paper machine is used to produce kraft paper. It can turn industrial waste paper, wood pulp and other raw materials into kraft paper through a series of processes.

A: Kraft paper machines are mainly classified into: circular wire paper machines, long wire paper machines, sandwich wire paper machines and slitting and rewinding machines. The application scenarios and production volumes of different types of equipment vary greatly

A: The circular screen machine has a small output, but its structure is simple and easy to maintain. Long net machines have high output and high precision, but their structure is relatively complex and they are not as easy to maintain as round net machines.

A: The papermaking machine is a device for producing kraft paper. It uses waste paper, wood pulp and other raw materials to manufacture packaging paper, paper bags and other products through complex processes.

A corrugated paper machine is a device that processes raw paper (including kraft paper) into corrugated cardboard, and is generally used for carton packaging, etc.

A: If daily maintenance is done properly, it can basically be used for 10 to 15 years, but the core components (such as circular screens, etc.) need to be replaced every 5 years or so.

A: Extruders, like automobiles, also require maintenance. If properly maintained, the lifespan of industrial-grade models is around 10 to 15 years. However, core components (screws, barrels) need to be replaced approximately every 5 to 8 years

UET TECH: Excellent Chinese supplier of extruders and paper machines

Want to know more? Feel free to leave your contact information! Our expert will contact you within 12 hours to answer your questions one-on-one.