Fourdrinier Paper Machine

China’s top Fourdrinier paper machine manufacturers

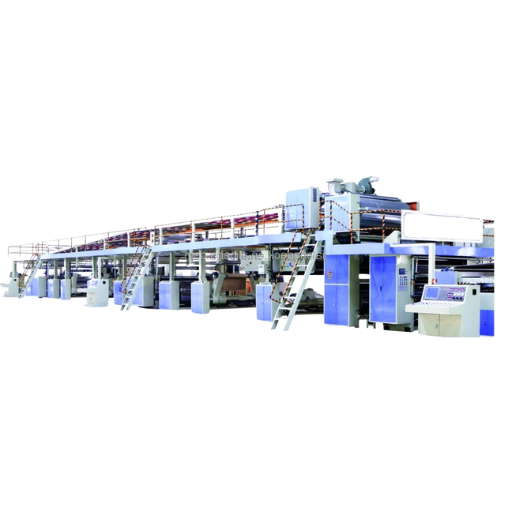

The Fourdrinier papermaking machine is the core model of the modern papermaking industry. Our fully automated Fourdrinier papermaking machine supports fully automated process production, enabling large-scale batch processing of various types of paper, effectively improving paper production efficiency and meeting multi-scenario needs.

- Competitive prices

- Support global delivery

- Customizable solutions

- Serving over 1,200 customers

Contact us now to get 20% discount

Factory direct sales

On-time delivery

Cost Pricing

High-quality service

Home » Paper Making Machine » Fourdrinier Paper Machine

UET TECH Fourdrinier Papermaking Machine Solutions

UET TECH Fourdrinier Papermaking Machine Main Components

The stable operation of a Fourdrinier papermaking machine depends on the coordinated operation of its core components. These components have clear divisions of labor, from pulp mixing to finished product winding, and are closely linked, directly affecting paper quality and production efficiency.

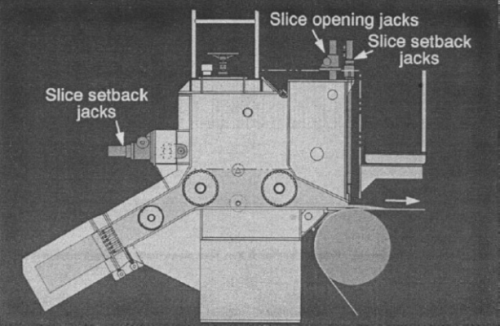

Headbox

Responsible for evenly conveying pulp to the Fourdrinier wire. Its internal structure ensures smooth pulp flow, precisely controlling flow and pressure to ensure a consistent thickness of pulp as it is spread across the wire, fundamental to paper sheet formation.

Forming Fabric

Like a circulating filter, it carries the pulp and performs initial dewatering. Fibers intertwine on the fabric to form a wet paper sheet. Its air permeability and operational stability directly impact the quality of the formed paper sheet.

Pressing Rollers

Using the squeezing action of upper and lower rollers, the paper is further dehydrated. This action also strengthens the paper fibers, increasing its strength and playing a key role in improving paper dryness.

Pressing Felt

This circular felt, composed of multiple layers of fabric, covers the surface of the press rolls. It transmits pressure and absorbs moisture during the pressing process, while also protecting the wet paper from damage. Its air permeability and elasticity must be tailored to the paper grade’s characteristics.

Drying Cylinder Group

The steam-heated cylinder evaporates the remaining moisture from the paper through heat transfer. Multiple drying cylinder groups operate sequentially, gradually drying the paper to the desired dryness and ensuring a stable paper shape.

Calenders

Composed of multiple rollers, these machines apply pressure to smooth the surface of paper sheets. This reduces surface roughness, improves printing suitability, and ensures the paper is more suitable for specific applications.

Paper Winding Machine

Rolls dried paper into neat rolls. Adjusts the winding tension based on the paper’s characteristics, ensuring a tight roll with a smooth end surface for easy storage and processing.

Why choose UET TECH Fourdrinier paper machine as your solution?

Key components such as the headbox and press rolls are independently developed, enhancing adaptability and reducing the likelihood of failure. Combined with an intelligent control system, the paper basis weight deviation is controlled within ±1%, consistently improving paper quality.

We invest 35% of our annual revenue in R&D. In the past three years, we have launched five core technology upgrades, such as the new shoe press, which increases wet paper dryness by 3%, helping customers maintain their production technology leadership.

We can flexibly adjust equipment parameters and configurations based on the customer's raw materials (wood pulp, waste paper pulp, etc.) and production line requirements, precisely matching production capacities from 50 to 800 tons/day.

We have provided equipment to over 1,500 companies in 120 countries, including industry leaders such as Nine Dragons and Stora Enso. 80% of these customers have been partners for over five years, and our equipment's stability has been proven through large-scale production.

UET TECH Long Wire Paper Machine Factory Gallery

UET TECH Fourdrinier Papermaking Machine Detailed Parameters

| Parameter Category | Parameter Details | Low-speed Type (Low Efficiency) | Medium-speed Type (Medium Efficiency) | High-speed Type (High Efficiency) | Description |

|---|---|---|---|---|---|

| Basic Information | Applicable Paper Types | Specialty paper, small-batch cultural paper | Regular cultural paper, packaging paper | Large-scale newsprint, packaging paper | Covers different production needs |

| Basis Weight Range (g/m²) | 30-300 | 40-400 | 40-400 | Includes common ranges for cultural, packaging and specialty papers | |

| Net Paper Width (mm) | 1880, 2640 | 2640, 3200, 4400 | 3200, 4400, 4600 & custom | Standard widths + customization options | |

| Production Efficiency | Operating Speed (m/min) | 80-250 | 250-600 | 600-1500 | Corresponds to different capacity requirements |

| Daily Output (tons) | 10-50 (depending on paper type & width) | 50-150 (depending on paper type & width) | 150-300 (depending on paper type & width) | Calculated based on 120g/m² container board | |

| Performance Parameters | Drive Type | AC frequency conversion sectional drive | AC frequency conversion sectional drive | AC frequency conversion sectional drive + PLC precise control | Ensures stable operation |

| Drying Degree - Wire Section | 18%-20% | 19%-21% | 20%-22% | Gradually improves dewatering efficiency | |

| Drying Degree - Press Section | 38%-42% | 40%-43% | 42%-45% | Pressing effect matching the speed | |

| Drying Degree - Dryer Section | 90%-92% | 92%-94% | 93%-95% | Guarantees finished paper quality | |

| Energy Consumption Parameters | Steam Pressure (MPa) | 0.3-0.5 | 0.3-0.5 | 0.4-0.6 | Adjustable according to working conditions |

| Steam Consumption (tons/ton paper) | 2.0-2.2 | 1.8-2.0 | 1.5-1.8 | High-efficiency models with waste heat recovery system | |

| Total Installed Power (kW) | 800-1500 | 1500-2000 | 2000-3000 | Increases with width and speed | |

| Equipment Specifications | Overall Dimensions (L×W×H mm) | 30000×6000×5000 | 45000×8000×6000 | 50000×10000×7000 | Includes operating space and maintenance access |

| Equipment Weight (tons) | 150-200 | 200-300 | 300-400 | Key components made of high-strength materials for stability |

Get prices for UET TECH Fourdrinier paper machines

Are you looking for the right Fourdrinier papermaking machine? We offer a Fourdrinier papermaking machine that meets all your needs. Our experts will tailor a solution to your specific needs. Contact us now! Get the price you want.

Sales countries

Serve customers

Years of experience

Factory building area

Customer review

Read real customer reviews of our Fourdrinier paper machines.

Fourdrinier Paper MachineFrequently Asked Questions

A: It is suitable for producing newsprint, fine paper, and packaging paper. Its Fourdrinier wire structure ensures even fiber distribution, resulting in excellent paper strength and uniformity. It is particularly well-suited for mass production of low- to medium-weight papers and meets most general printing and packaging needs.

A: The Fourdrinier papermaking machine relies on the Fourdrinier wire section for dewatering, resulting in higher paper uniformity and strength, making it suitable for high-quality paper. The rotary papermaking machine, on the other hand, is simpler in structure and slower in speed, producing thicker paper weights but slightly less uniform. It is also more cost-effective and is primarily used for packaging board and other paper products.

A: A typical Fourdrinier machine has a speed of 500-1200 m/min, depending on the paper type and machine specifications. Thin papers (such as newsprint) are produced faster, while thicker paperboard is produced slower. Advanced machines can improve stability through wire optimization.

A: Small and medium-sized units take approximately 2-4 months, while large lines take 6-10 months. This includes equipment installation, piping connections, and electrical commissioning. This time may be longer if there are many customized components or the site is complex.

A: They primarily process wood pulp, waste paper pulp, and straw pulp. They are well-suited to pulps with moderate fiber lengths. When processing waste paper pulp, enhanced screening and purification are required to prevent impurities from affecting wire operation and paper quality.

A: Not very high. The main costs are in wire cloth replacement, roller maintenance, and drive system maintenance. Regular cleaning of the wire and inspection of bearings can reduce the failure rate. Compared to a rotary wire machine, maintenance is slightly more complex due to the larger number of components, but the machine has a longer lifespan.

A: If your budget is limited, consider a used machine in good condition. Check the wire wear, transmission accuracy, and control system aging. It's best to have a professional evaluate it to avoid high subsequent repair costs.

A: Slightly more, due to the Fourdrinier's higher speed and the need for additional equipment (such as a vacuum dewatering system). However, technologies like variable frequency motors and waste heat recovery can narrow the energy consumption gap, and the higher efficiency can even improve energy consumption per unit of output.

China's top Fourdrinier paper machine manufacturers

Want to know more? Feel free to leave your contact information! Our expert will contact you within 12 hours to answer your questions one-on-one.