Filler Masterbatch Compounding Extruder

High Quality Triple Screw Extruder Manufacturer

Do you plan to purchase a compounding extruder for filling masterbatch? UET TECH has 12 years of experience in manufacturing compounding extruders for filling masterbatch. Our equipment has uniform mixing without agglomeration, stable masterbatch melt index, high production capacity, and low energy consumption, meeting your full-scenario needs from conventional filling to functional masterbatch. Contact us now! Get a tailor-made solution.

- Competitive prices

- Customized solutions

- Over 2,000 units installed

- Worldwide shipping available

You can save at least 30% or more when purchasing.

Factory direct sales

On-time delivery

Cost Pricing

High-quality service

Home » Extruder Machine » Filler Masterbatch Compounding Extruder

Filler Masterbatch Compounding Extruder Solution

UETTECH Filler Masterbatch Compounding Extruder adopts advanced compounding integration technology to accurately achieve the melt plasticization and molecular-level mixing of polymers and fillers, ensuring that the performance and appearance of the output masterbatch are higher than the industry standard.

Our equipment has high-intensity continuous production capacity and can run stably for 16 hours continuously. The hourly production capacity is stable at 2-3 tons. The production efficiency is extremely high, and it can easily cope with large-volume order needs and deliver orders quickly.

We attach great importance to the safety of equipment. UETTECH filling masterbatch compounding extruder adopts a fully enclosed protection design. There is no exposed risk point in the whole process from raw material feeding to finished product discharging. The emergency stop button is set in the operation area, and the response time is ≤0.5 seconds, which can effectively avoid safety accidents caused by misoperation.

UETTECH filling masterbatch compounding extruder is equipped with variable frequency energy-saving motor and waste heat recovery system, which reduces power consumption by more than 20% compared with similar equipment. The screw and barrel adopt optimized meshing structure to reduce useless power loss, and use the waste heat generated during the production process to preheat the raw materials. Long-term operation can save a lot of electricity costs for enterprises.

Our equipment can ensure that the filler and polymer are fully melted, evenly dispersed, and have consistent color through precise segmented temperature control and efficient mixing capabilities.

Our main components (screw, barrel, etc.) are made of high-strength alloy with a hardness exceeding HRC60. They have ultra-high wear resistance and can withstand long-term grinding of high-filling materials.

We can provide customized filling masterbatch compounding extruders according to customers' production needs. Whether it is to adapt to the transformation and upgrading of existing production lines, or to meet the production needs of new functional masterbatches (such as antibacterial and flame retardant filling masterbatches), we can provide the best solutions.

Filler Masterbatch Compounding Extruder for Sale

We are selling filling masterbatch compounding extruder, let’s see if there is one that meets your needs.

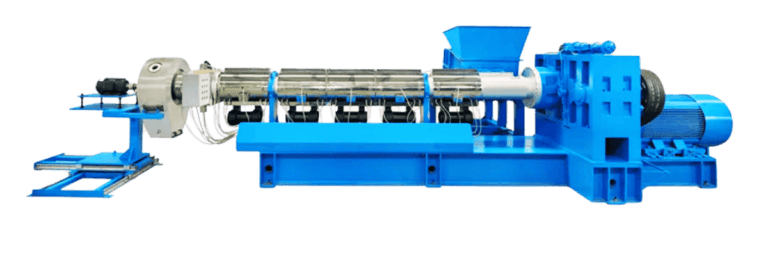

Filling masterbatch machine

- UET TECH

- Hebei, China

Filling masterbatch machine can help you reduce costs and increase efficiency in plastic production, which is a very practical solution. It uses three-screw extrusion technology to mix materials evenly, control energy consumption well, and stabilize actual production capacity. By adding more inorganic fillers such as calcium and talcum powder, the cost of raw materials can be greatly reduced. It can also be used to produce common plastic products such as films, packaging bags, pipes, and injection molded parts.

Power efficiency: 110kW to 600kW

Output: 3~1200kg/h

Material processing: mixing – granulation – cutting – drying

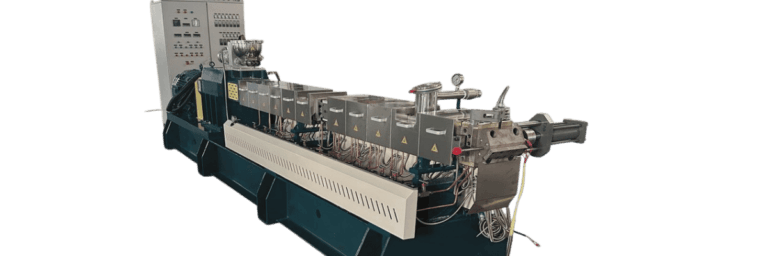

PP Filler Masterbatch Compounding Twin Screw Extruder for Plastic

- UET TECH

- Hebei, China

PP Filler Masterbatch Compounding Twin Screw Extruder is specially used to produce filler masterbatch such as calcium carbonate, talc, barium sulfate, etc. It is compatible with a variety of materials, equipped with advanced volumetric or weightless feeding devices, solid technical specifications, high production efficiency, and can produce 1600 kg of material per hour.

The machine uses a co-rotating screw with an underwater pelletizing system and a variety of layout options. It is easy to mix materials, which can reduce costs and improve material performance.

Processing plastics: PP/PA/PS/PT/PBT/PVC/ABS, etc.

Application: Granulation production

Performance: Corrosion resistance

Main selling point: High productivity

Filler Masterbatch Extruder

- UET TECH

- Hebei, China

The filling masterbatch extruder can efficiently produce filling masterbatch to meet the needs of different industries. The twin-screw design can more efficiently disperse the filler evenly and achieve high-quality output.

Voltage: 220V or customized

Power (kW): 200

Dimensions (length × width × height): 6200mm × 1350mm × 2100mm

Color Masterbatch Extruder

- UET TECH

- Hebei, China

Masterbatch extruder is mainly used for mixing and terminal processing of high-quality masterbatch. It has a wide range of application areas, such as granulation, pelletizing and composite material production, especially suitable for PP, PE, ABS, PA polymers.

Output range: 600-1000kg/h

Automation level: fully automatic

Certification: ISO, SGS, RoHS

Core technology: twin-screw self-cleaning design, vacuum degassing module, involute screw element

Functional Masterbatch Extruder

- UET TECH

- Hebei, China

The functional masterbatch extruder independently developed by UET TECH is an innovative equipment designed to improve the production efficiency and quality of masterbatch. It is suitable for a variety of substrates such as PP, PE, ABS, etc., and can produce special color masterbatches such as fluorescent and pearlescent, which are widely used in the coloring processing of end products such as films, fibers, and pipes.

Output range: 500-1200 kg/h

Certification: ISO 9001, SGS, RoHS

Automation level: Fully automatic (supports recipe preset and one-click color change)

Core technology: Involute screw element, self-cleaning mixing section, melt pressure closed-loop control

UET TECH single-screw extruder specifications

| Model | Diameter (mm) | Length-Diameter Ratio | Power (kW) | Max Speed (rpm) | Torque Coefficient (T/A) | Output (kg/h) |

|---|---|---|---|---|---|---|

| UES FM-25 | 25 | 30-65 | 5.5-18 | 350-1000 | 11.0 | 20-70 |

| UES FM-35 | 34.8 | 30-65 | 15-45 | 350-1000 | 10.8 | 50-180 |

| UES FM-45 | 44.5 | 32-68 | 22-75 | 350-1000 | 11.5 | 90-280 |

| UES FM-55 | 54.2 | 32-68 | 45-120 | 350-1000 | 11.7 | 180-550 |

| UES FM-65 | 64.0 | 35-70 | 90-250 | 350-1000 | 12.1 | 300-900 |

| UES FM-75 | 74.5 | 35-70 | 160-380 | 350-1000 | 11.6 | 500-1800 |

| UES FM-85 | 84.2 | 35-70 | 200-550 | 350-1000 | 11.3 | 700-2300 |

| UES FM-95 | 94.0 | 38-70 | 315-800 | 350-1000 | 11.9 | 1200-3000 |

| UES FM-125 | 124.8 | 38-70 | 800-2500 | 350-1000 | 12.2 | 3000-9000 |

UET TECH Filling Masterbatch Compounding Extruder Expert Guide

Customers who purchase our filling masterbatch compounding extruder often consult us with many questions, so we have sorted out the questions that customers ask most frequently to help you better understand our products and services before purchasing.

Common calcium carbonate (CaCO₃), talcum powder, and barium sulfate (BaSO₄) can all be stably processed. It also supports special fillers such as mica powder and glass beads, and is suitable for most filling masterbatch formulas.

Our core components are made of 38CrMoAl nitrided steel, which has a hardness of HRC60 or above after surface hardening treatment. Its wear resistance is 40% higher than that of ordinary materials, and high-filling materials are not prone to wear even in long-term production.

Two systems are standard: underwater pelletizing and air-cooled strand pelletizing. They can be switched according to needs. The pellet shapes support cylindrical (diameter 2-4mm), oblate, etc., which are suitable for different downstream processing technologies.

Yes. We support customized services, such as adjusting the screw aspect ratio for high-viscosity formulas, or adding a premixing section for easily agglomerated fillers to ensure stable production of the formula.

Yes. The professional technical team will provide free debugging services according to the customer's formula (such as filler type and proportion) until qualified masterbatch is produced; formula optimization suggestions can also be provided later.

Yes. By adjusting parameters such as screw speed and feed rate, it can be flexibly adjusted within the rated output range of the equipment (such as 20-3000kg/h), which can be adapted to both small-batch trial production and large-scale production.

UET TECH provides advanced filling masterbatch compounding extruder solutions

UET TECH is a Chinese manufacturer of filling masterbatch compounding extruders. We have served more than 2,000 companies around the world and have been recognized by customers. If you plan to buy an extruder, please contact us to get a more favorable price.

Sales countries

Serve customers

Years of experience

Factory building area

What Our Client Says

Our filling masterbatch compounding extruder has been recognized by many customers

Filler Masterbatch Compounding ExtruderFrequently Asked Questions

A: Filler masterbatch compounding extruder is a device specially used for masterbatch production. Filler masterbatch plays a vital role in the production of plastic products.

A: Answer: After optimizing the screw combination, the advanced twin-screw extruder can stably handle 85% of fillers such as calcium carbonate.

A: Answer: The new twin-screw machine with variable frequency motor and waste heat recovery saves 15-20% of electricity compared with the traditional single-screw machine. The power consumption per ton of masterbatch is 80-150 degrees, and the long-term cost reduction is obvious.

A: Entry-level models (output 20-200kg/h) start at $30,000-80,000, and high-output models (1,000-3,000kg/h) are priced at $200,000-500,000. The specific price is affected by the configuration (twin screw/reciprocating), automation level, and whether it is customized. Customized screws or special functions will be slightly more expensive.

A: Not much. The current equipment is equipped with a fully enclosed feeding system and a negative pressure dust collection device. The dust concentration in the workshop can be controlled within 2mg/m³, which is far lower than the international standards such as OSHA (8mg/m³). Food-grade masterbatch production can also use stainless steel casing, which fully meets environmental protection and hygiene requirements.

UET TECH: China's leading supplier of filling masterbatch compounding extruders

We are the source factory of filling masterbatch compounding extruder and do not charge any middleman commission. Please feel free to leave your contact information! Our experts will contact you within 12 hours to answer your questions one-on-one.