In core areas of modern society such as power transmission, communication networks, and industrial automation, cables are indispensable, and cable extrusion machines are the key equipment for shaping cables. From the formation of the conductor insulation layer to the outer sheath, the extrusion process directly determines the performance, reliability, and lifespan of the cable.

This article serves as a comprehensive guide to cable extrusion processes, systematically analyzing the definition, core features, and key components of cable extruders. It provides an in-depth breakdown of the complete extrusion process, process types, and applicable materials, offering practitioners and learners a comprehensive reference from equipment understanding to process implementation. This guide aims to enhance understanding of this core technology that underpins the power and telecommunications industries.

What is a cable extruder?

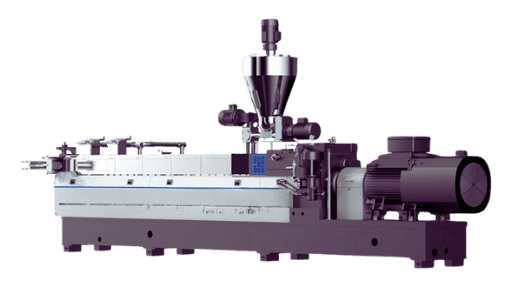

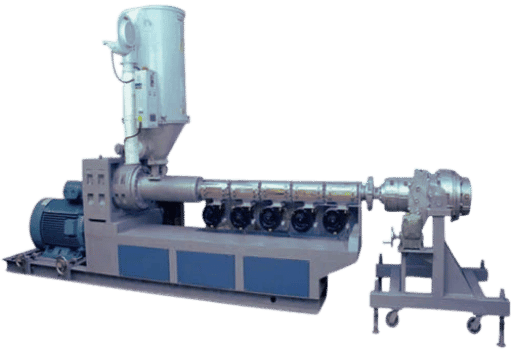

A cable extruder is a core piece of equipment in cable manufacturing, primarily used to melt and extrude high-molecular-weight materials such as plastics and rubber, then continuously and uniformly coat them onto conductors (such as copper or aluminum wires) to form insulation layers, shielding layers, or jackets, ultimately producing wires and cables with specific electrical properties and mechanical strength. From household wires to high-voltage cables, from communication optical cables to industrial control cables, the formation of their insulation and sheaths almost entirely relies on this equipment. It serves as the “shaper” connecting conductors to the external environment, directly influencing the cable’s insulation performance, weather resistance, and service life.

Main Features of Cable Extruders

- High-precision coating capability: It can precisely control the thickness of the insulation layer or sheath, with errors controlled within an extremely small range, ensuring stable electrical performance of the cable. For example, uneven thickness of the insulation layer in high-voltage cables may cause localized over-strength electric fields, leading to breakdown.

- Strong material adaptability: Can process various materials such as PE, PVC, XLPE (cross-linked polyethylene), and rubber. By adjusting parameters such as screw speed and temperature, it can adapt to the melting characteristics of different materials (e.g., PVC requires control within an appropriate temperature range, while XLPE requires higher temperatures combined with cross-linking processes).

- High continuous production efficiency: Fully automated from conductor unwinding to finished product winding, a single production line can operate continuously for extended periods, accommodating bulk production requirements. It can reliably process everything from fine electronic wires to thick high-voltage cables.

- Strong process controllability: By integrating temperature, pressure, and speed sensors, the machine can real-time adjust material melting state, coating tension, and cooling rate, reducing defects caused by fluctuations in material flowability (such as bubbles or off-center issues).

Main components of the cable extruder

- Unwinding device: Consisting of an unwinding reel and a tension controller, it is responsible for stabilizing the unwinding of the conductor (bare wire or pre-treated core wire), preventing conductor stretching or slackening — unstable tension can cause coating layer eccentricity, affecting cable roundness.

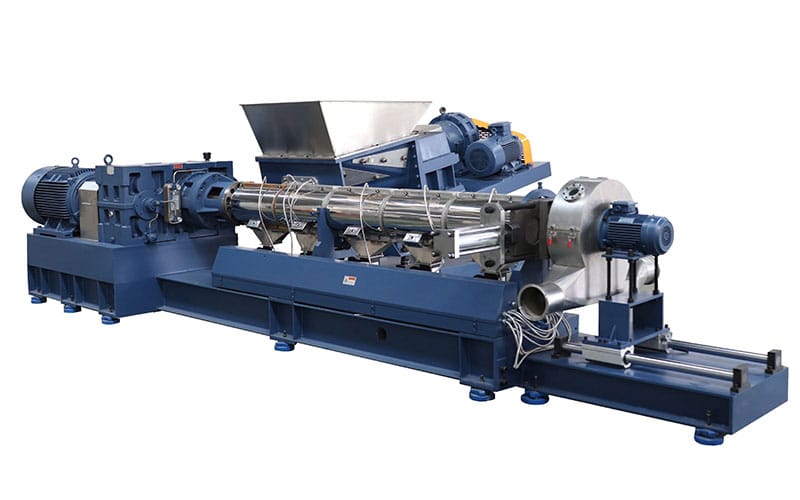

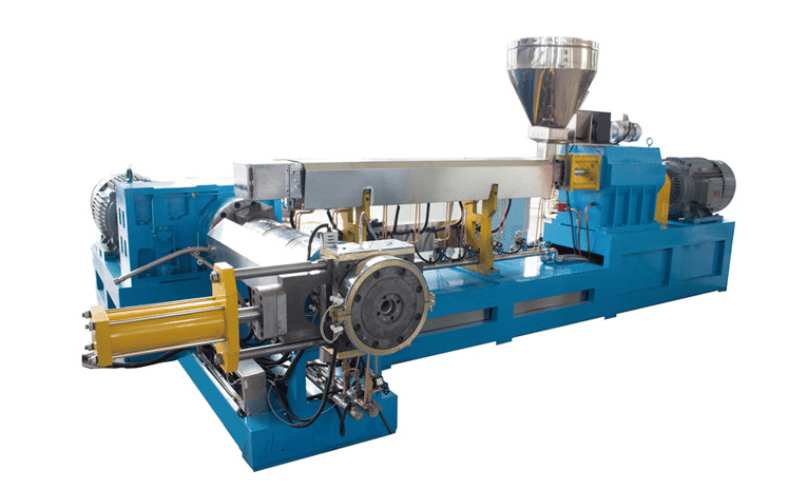

- Extrusion system: The core components are the screw and barrel. The screw is responsible for conveying, compacting, and heating the solid raw material to melt it (by heating through heating rings outside the barrel), and generating pressure to push the melt toward the die head; the inner wall of the barrel is typically treated for wear resistance (e.g., nitrided steel) to reduce material wear and screw damage.

- Die head and mold: The die head is the “convergence point” where the melt meets the conductor. The mold (including the core and sleeve) determines the shape and thickness of the coating layer — the core guides the conductor to pass through centrally, while the sleeve controls the melt coating range. The precision of their coordination directly affects the concentricity of the insulation layer.

- Cooling system: Typically water baths or air cooling devices, the freshly coated molten material is rapidly solidified and shaped through cooling to prevent deformation during subsequent stretching. Cooling temperatures must match material properties (e.g., water cooling for PE, gradual cooling for rubber to prevent cracking).

- Tensioning device: Composed of a tensioning wheel and a pressure wheel, it uses friction to drive the cable forward at a constant speed. The speed is synchronized with the extrusion speed and winding speed to ensure the coating layer is not stretched or piled up (e.g., if the tensioning is too slow, the sheath will bulge; if too fast, it will become too thin).

- Winding device: Neatly winds the formed cable onto the winding drum, equipped with tension feedback functionality to prevent over-tight winding causing cable deformation or over-loose winding causing unwinding chaos, facilitating subsequent cutting and packaging.

What is the cable extrusion process?

The cable extrusion process is the critical step in transforming “conductors” into “functional cables.” In simple terms, it involves using equipment to heat materials such as plastic and rubber into a flowing melt, which is then uniformly applied to conductors like copper or aluminum wires to form an insulating layer or protective sheath. After cooling and setting, the result is a cable capable of conducting electricity, preventing electrical leakage, and withstanding external damage. From household wires to outdoor high-voltage cables, this process is essential — it not only determines the quality of the cable’s insulation and durability but also directly impacts safety and stability during operation.

Wire and Cable Extrusion Process Steps

- Preparation: First, clean the oil stains and oxide layer from the surface of the conductor to ensure that the material can adhere tightly; at the same time, check the dryness and purity of the raw materials to avoid impurities mixing in and affecting the insulation effect.

- Extrusion Coating: After entering the extruder, the raw material is heated and melted into a uniform melt. Inside the die head, it combines with the passing conductor. Through the cooperation of the mold, the melt is uniformly coated around the conductor to form an insulation layer or sheath of the specified thickness.

- Cooling and Setting: The freshly coated material is hot and soft, so it must immediately enter a cooling device (water tank or air cooling) for rapid solidification to fix its shape and dimensions and prevent deformation.

- Tensioning and Winding: The cooled cable is uniformly pulled by a tensioning device at a speed matching the extrusion speed to avoid thinning or piling of the material; finally, it is neatly wound onto a reel by a winding device for subsequent processing.

- Online inspection: During the process, the thickness, roundness, and surface condition of the coating layer are observed. Any deviations are promptly adjusted by modifying equipment parameters to ensure stable product quality.

Types of Cable Extrusion Processes

By Number of Coating Layers

- Single-layer extrusion: A single layer of insulation or sheathing is completed in one pass, such as the insulation layer of ordinary household wires, with a simple and direct process.

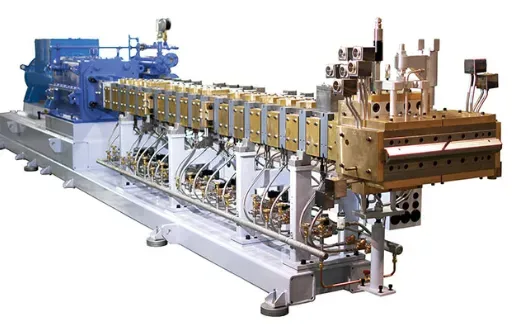

- Multi-layer co-extrusion: Multiple layers of different materials are simultaneously coated using a special die head, such as the insulation layer + semiconductive layer of high-voltage cables, reducing processes and achieving tighter interlayer bonding.

By material properties

- Thermoplastic extrusion: Uses materials such as PE and PVC, which are heated and melted for coating, then cooled to set, suitable for low-voltage cables.

- Cross-linked extrusion: Uses materials like XLPE, which must be heated after extrusion to cross-link the molecular structure, enhancing heat resistance and strength, commonly used for high-voltage cables.

Special processes

- Semiconductive layer extrusion: Coating the inner and outer surfaces of the insulation layer with semiconductive material to balance electric field distribution, commonly used in high-voltage cables.

- Foam extrusion: Introduces bubbles into the material to reduce the dielectric constant, commonly used in communication cables to minimize signal loss.

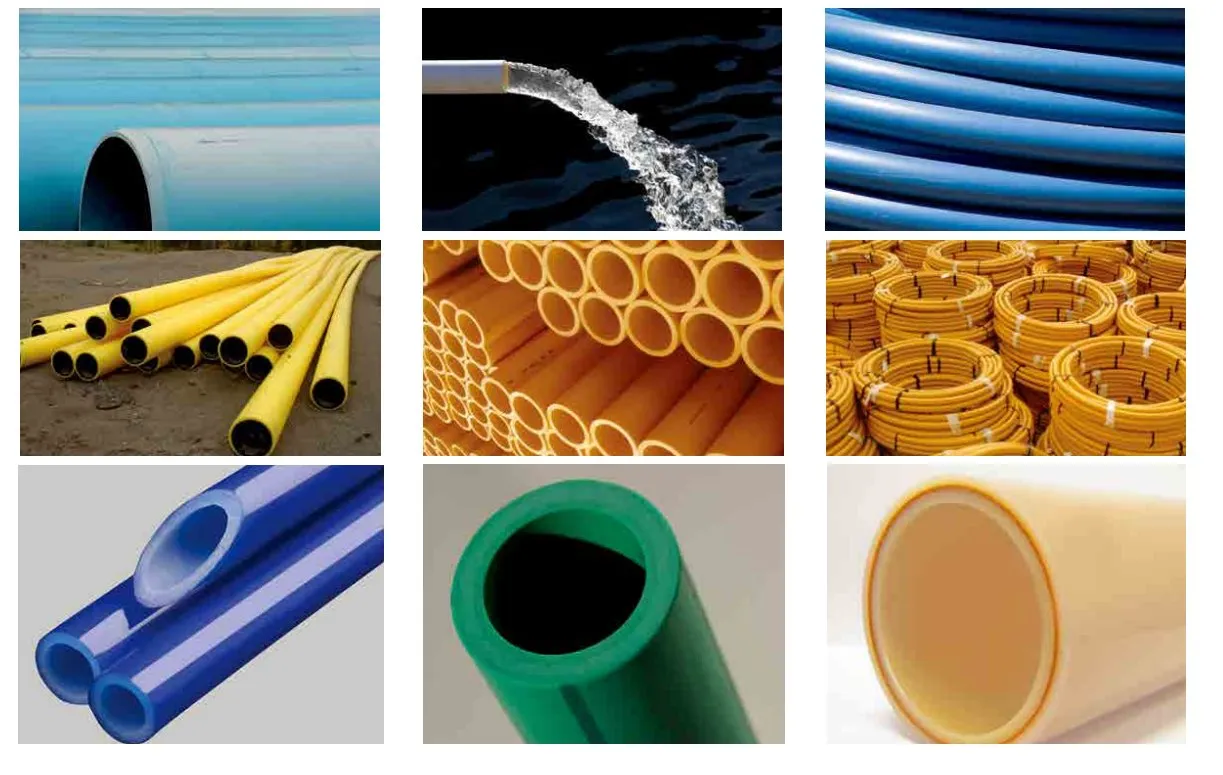

Materials Used in Cable Extrusion

- Polyethylene (PE): Excellent insulation properties, resistant to water and chemical corrosion, moderate cost, commonly used as the insulation layer for low-voltage power cables and communication cables.

- Polyvinyl chloride (PVC): High mechanical strength, good flame resistance, low cost, but average heat resistance, suitable for the insulation layer and sheath of household wires.

- Cross-linked polyethylene (XLPE): After cross-linking treatment, heat resistance and aging resistance are significantly improved, capable of withstanding high voltages, and is the primary insulation material for high-voltage power cables.

- Rubber: Includes natural rubber, nitrile rubber, etc., with good elasticity and resistance to bending, suitable for manufacturing movable cables such as machine tool cables and automotive wires.

- Auxiliary materials: Semiconductor materials are used to balance electric fields, flame-retardant additives enhance fire resistance, and fillers can strengthen material strength or reduce costs, with flexible addition based on cable application.

Conclusion

Cable extrusion machines and extrusion processes are core components of cable manufacturing, with equipment and processes closely interlinked. Extrusion machines, characterized by high-precision coating and strong material adaptability, collaborate through components such as unwinding, extrusion, cooling, and traction to transform materials like plastic and rubber into the insulation layers or sheaths of cables. Extrusion processes are categorized into single-layer or multi-layer co-extrusion based on requirements, accommodating thermoplastic or cross-linked materials, and supporting the production of both standard and specialized cables such as high-voltage and communication cables. The appropriate selection of materials like polyethylene, PVC, and XLPE further ensures the insulation and weather resistance performance of cables. It is this synergy between equipment, processes, and materials that underpins the stable operation of industries such as power transmission and communication networks, providing a critical foundation for the efficient functioning of modern society.

Frequently Asked Questions (FAQs)

Q: How should I handle lumps or bubbles on the surface of extruded cables?

A: Lumps on the cable surface may be caused by insufficient plasticization due to low temperature. Adjust the barrel temperature appropriately. If the raw material contains impurities, clean the hopper and filter screen. Bubble issues typically stem from moisture in the raw material or insufficient cooling. The raw material should be dried (e.g., by baking for 4 hours), and the cooling water tank level should be adjusted to ensure the cable is fully submerged. Additionally, inspect the mold for gaps that may allow air ingress, and promptly repair or replace worn components.

Q: How should single-screw and twin-screw extruders be selected for cable production?

A: Single-screw extruders have a simple structure and low cost, making them suitable for processing low-viscosity materials (such as PVC), but they have weaker mixing performance; twin-screw extruders improve mixing uniformity through the meshing of two screws, making them more suitable for high-viscosity materials (such as XLPE) and complex processes (multi-layer co-extrusion), but they have higher maintenance costs. Single-screw extruders are suitable for low-voltage cables, while twin-screw extruders are preferred for high-voltage or specialty cables to ensure material uniformity and process stability.

Q: How can bubbles in the cable insulation layer be avoided?

A: The primary causes of bubbles are moisture in the raw material, localized overheating, or insufficient cooling. Solutions include: pre-drying the raw material, controlling the cooling water tank temperature between 20-30°C and ensuring the cable is fully submerged, and inspecting the mold for air leaks. Additionally, regularly clean the extruder filter screen and screws to prevent impurities or residual material from affecting plasticization.

Q: How should extrusion materials be selected for cables with different applications?

A: Low-voltage cables (e.g., household wires) can use PVC, which is cost-effective, flame-retardant, but has average heat resistance (≤70°C); high-voltage cables (e.g., 110kV and above) require XLPE, which offers strong heat resistance (long-term 90°C, short-circuit 250°C) and is environmentally friendly and halogen-free. Rubber materials (such as nitrile rubber) are recommended for mobile device cables (such as automotive wires) due to their good elasticity and resistance to bending. For special environments (such as high temperatures or chemical corrosion), silicone rubber or fluoroplastics can be considered.

Question: What impact does cooling speed have on cable quality?

Answer: Excessively fast cooling can cause surface rapid cooling, leading to internal stress and potential cracking; overly slow cooling may result in deformation or uneven thickness of the plastic layer. Optimization methods include segmented cooling (e.g., 70°C in the front section and ambient temperature in the rear section), controlling the uniformity of cooling water temperature, and using soft water to prevent scale buildup in nozzles. For high-voltage cables, an online thermal stress relaxation system can be added to eliminate internal stress in the insulation layer.

Q: What are the core differences between cross-linked polyethylene (XLPE) and PVC?

A: XLPE forms a network structure through chemical cross-linking, with a long-term operating temperature of 90°C, short-circuit resistance up to 250°C, a lifespan of approximately 40 years, and halogen-free, low-smoke combustion, meeting environmental requirements. PVC has lower heat resistance (≤70°C), releases toxic gases when burning, and has a lifespan of approximately 20 years. XLPE has gradually replaced PVC as the mainstream material for high-voltage cables, while PVC is still used in residential and low-voltage applications.

Q: What are some tips for temperature control in an extruder?

A: Segmented temperature control is key: the feed section has a lower temperature (120-150°C), the homogenization section has the highest temperature (180-220°C), and the die temperature is slightly lower than the homogenization section. If the current meter fluctuates significantly, it may be due to uneven temperature causing changes in melt viscosity; check if the heating elements are damaged. PE processing temperatures are lower than XLPE, and PVC must be strictly controlled between 160-190°C to prevent decomposition. Regularly calibrate temperature sensors to ensure display values match actual temperatures.

Q: What issues can arise from improper mold adjustments?

A: An oversized core may cause insufficient melt pressure, leading to eccentricity or leakage; worn sleeves can increase surface roughness, causing scratches or bumps. When adjusting, manually fine-tune the mold first, observe the uniformity of the extruded layer thickness, then secure the screws. High-voltage cables require the use of a combination extrusion mold to ensure smooth interfaces between the three co-extruded layers (conductor shielding, insulation, and insulation shielding) and reduce air gaps.

Q: What are the special requirements for high-voltage cable extrusion?

A: High-voltage cables must use a three-layer co-extrusion process, simultaneously covering the insulation layer and the semiconductive shielding layer to balance the electric field distribution. Materials must use ultra-clean XLPE (impurities ≤ 100 μm) and ultra-smooth semiconductive material. During vulcanization, temperature must be controlled between 250-280°C, and insulation thickness must be monitored in real-time using an online thickness gauge. Additionally, the degassing process (70°C heating for 7 days) eliminates cross-linking byproducts, enhancing insulation stability.

Q: How can I extend the service life of an extruder?

A: Daily maintenance includes cleaning debris from the hopper at the end of each shift and inspecting the gap between the screw and barrel (replace if wear exceeds 0.5mm). Regular maintenance tasks include changing the gearbox lubricant every 500 hours, cleaning resin buildup from the filter screen, and inspecting the insulation performance of the heating elements. Before prolonged shutdowns, thoroughly clean the screw and die head with a specialized cleaner to prevent plastic carbonization. For twin-screw extruders, regularly inspect the screw meshing clearance to ensure stable mixing performance.