The extrusion screw is the “heart” of the extruder, directly determining whether materials can be fully melted and whether the finished product meets quality standards. Whether producing standard PE pipes or high-end glass-fiber reinforced materials, selecting the right screw type saves time and effort—for instance, single screws cannot handle highly filled materials, twin screws excel at mixing, while triple screws are suited for precision R&D. Below, we break down each type to clarify the characteristics and suitable applications of every screw configuration.

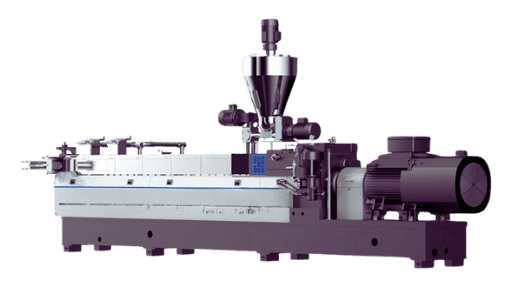

1.Single-Screw Extruder

The single-screw extruder is the most fundamental type, relying solely on a single screw working in conjunction with the barrel. Its core design features a “three-section screw groove”: the feed section has deeper grooves to ensure stable conveying of granular or powdered raw materials; the compression section gradually features shallower grooves, using shear force to compact and partially melt the material; the metering section has the shallowest grooves, thoroughly mixing the melted material before conveying it to the die.

Its advantages are significant: simple structure, low procurement cost (industrial models typically range from $7,000 to $21,000), and ease of operation. It is particularly well-suited for small to medium-sized factories processing common materials. For applications like PE water pipes, PP strapping bands, or PVC wire insulation, as long as the raw material is uncomplicated, the single-screw’s production capacity and stability fully meet the requirements.

However, its limitations are also evident: weak mixing capability, leading to uneven dispersion when processing multi-component materials containing glass fiber or flame retardants; and susceptibility to localized overheating or incomplete melting when handling high-viscosity or heat-sensitive materials (e.g., PVC), making it unsuitable for producing high-end modified plastics.

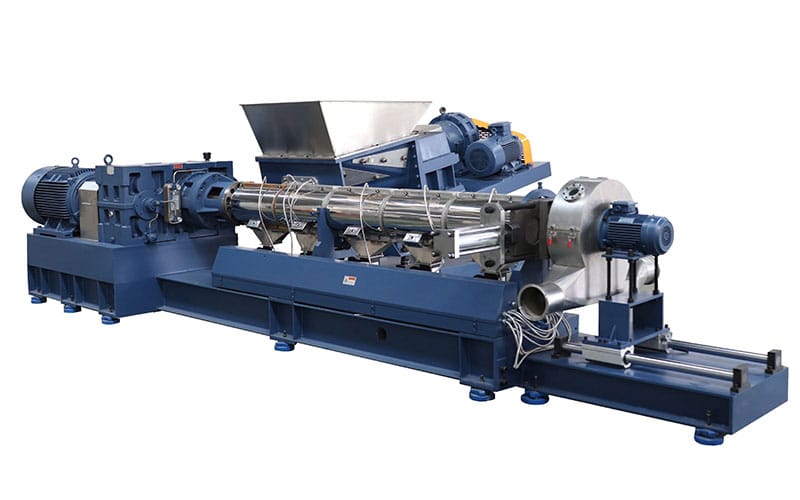

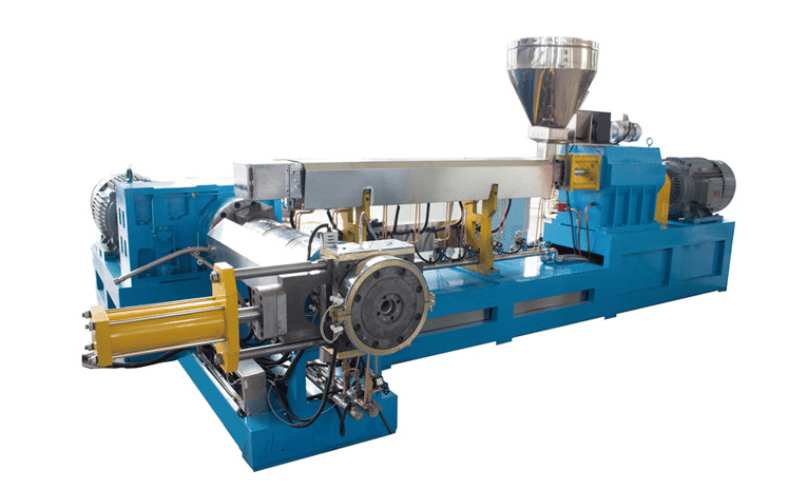

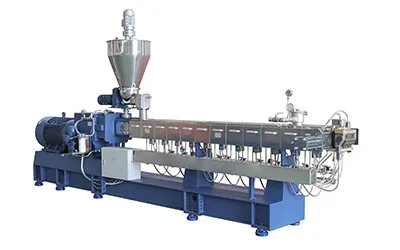

2. Twin-Screw Extruder

Twin-screw extruders feature two intermeshing screws. Based on screw arrangement, they are categorized into parallel twin-screw and conical twin-screw types. Their core advantages lie in “superior mixing capability and rapid plasticization.” As the twin screws rotate, they repeatedly knead and shear the material. This ensures uniform mixing and thorough melting, whether processing reinforced PA containing 50% glass fiber or heat-sensitive PVC. Simultaneously, it reduces material residence time within the barrel, preventing decomposition.

Parallel twin screws see broader application, excelling in high-volume production of modified materials like flame-retardant ABS for automotive use or reinforced PP for appliances. At equivalent specifications, their throughput exceeds single screws by 20%-30%. Tapered twin screws, however, are better suited for small-batch processing of high-viscosity materials such as silicone rubber cable jackets. Featuring a large feed inlet and small discharge outlet, they enable precise temperature control.

However, it has drawbacks: complex structure, high procurement cost (typically $14,000–$70,000), and challenging cleanup during material changeovers. Residual material easily gets trapped in the gap between the two screws, requiring disassembly and specialized tools for cleaning. This makes it more suitable for factories with stable modification needs, while small and medium-sized workshops find it less cost-effective.

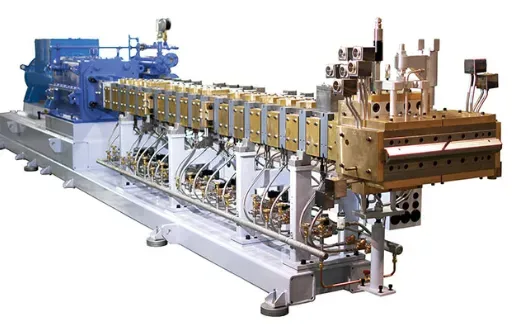

Triple-Screw Extruder

The triple-screw extruder is classified as a “precision-grade” device. Its three screws are arranged in a triangular configuration, adding an extra layer of shear and mixing action compared to twin-screw extruders. This design specifically addresses the processing challenges of “high-difficulty materials.” For instance, when producing nanomaterials (such as graphene-composite PE), conventional twin-screws often cause nanoparticle agglomeration. The triangular configuration of the triple-screw system achieves more thorough material refinement, improving dispersion uniformity by over 40%. When processing highly filled materials (e.g., wood-plastic composites containing 60% mineral powder), its powerful extrusion ensures material compaction without clumping.

Another major advantage is its high precision and stable temperature/pressure control, making it suitable for lab R&D or small-batch production of high-end materials like precision medical tubing or specialty plastics for aerospace applications. However, its drawbacks are significant: low output (over 50% lower than twin-screws) and high acquisition cost (typically $28,000–$140,000). Rarely used in industrial mass production, it primarily serves research institutions and high-end modification plants.

Other Extrusion Screw Types

Beyond single-screw, twin-screw, and triple-screw designs, several highly specialized “special-purpose” screws address specific processing challenges:

Ventilation Screws: Featuring venting channels in the screw’s mid-section, these screws work with vacuum pumps on the barrel to extract moisture and volatile components from the material. For instance, when producing PET preforms, high moisture content in raw materials often causes bubbles. Venting screws effectively resolve this issue, commonly used in food packaging and transparent plastic processing.

Barrier Screws: “Barrier ridges” added to the compression section separate unmelted solids from the melt. This forces the melt through narrow gaps, ensuring complete melting. When producing engineering plastics like PA66, barrier screws prevent unmelted particles in the final product, enhancing material strength.

Separation Screws: Featuring diverging ribs in the compression zone that divide the screw groove into “solid zones” and “melt zones,” these screws specialize in processing difficult-to-plasticize materials. For instance, they accelerate melting rates while reducing localized overheating in PVC-C high-temperature pipe compounds.

Applications of Different Extrusion Screw Types

When selecting screws, don’t get hung up on “price points.” The key is whether they “meet your needs.” Choose based on actual scenarios for the most hassle-free solution:

Mass production of standard plastics (e.g., PE pipes, PP films, basic PVC profiles): Prioritize single-screw extruders for low cost and strong stability—sufficient for small to medium factories.

Production of Modified Materials (e.g., glass-fiber reinforced compounds, flame-retardant blends, color masterbatches): Twin screws are the preferred choice for uniform mixing and high efficiency, suitable for automotive and appliance component factories.

Precision R&D or Production of High-End Materials (e.g., nanocomposites, highly filled compounds, specialty plastics): Opt for triple screws or barrier screws to ensure processing accuracy, commonly used in research institutions and high-end modification plants.

Processing materials with high moisture content (e.g., PET, recycled materials, wood-plastic composites):Vapor-extraction screws are essential to remove moisture and prevent bubbles in finished products.

Processing difficult-to-plasticize or heat-sensitive materials (e.g., PVC-C, POM):Select separation-type or step-change single screws to achieve rapid melting while preventing material decomposition.