Cable extrusion is a core process in cable manufacturing, primarily responsible for coating conductors or cable cores with insulation and sheathing layers. It directly impacts the electrical insulation and mechanical protection capabilities of cables. Whether it’s low-voltage household cables, high-voltage power cables, or communication cables, none can function without this process. This article will help you understand the essence and advantages of this process, as well as the commonly used extruder types.

What is the cable extrusion process?

The cable extrusion process is essentially an integrated technology for continuous forming and functional coating of polymer materials. Its core logic forms a closed-loop system centered around three key stages: “material plasticization – precise coating – curing and shaping.”

Raw Material Pre-treatment Stage: PVC, PE, XLPE polymer pellets (or rubber compounds) undergo drying and impurity removal before entering the extruder. Through segmented barrel heating (160-220°C, adjusted per material) and screw shear force, solid raw materials are transformed into uniform melt, ensuring no bubbles or unmelted particles.

Precision Coating Stage: Metal conductors (copper/aluminum wires) or multi-core cable cores pass through the extrusion die at a constant speed. Under screw pressure (5-30 MPa), the melt uniformly coats the conductor’s exterior along the die flow channels. The concentricity of the die core/die sleeve directly determines coating thickness deviation (industry requirement ≤±5%).

Curing and Setting Stage: The coated cable enters a water-cooled (or air-cooled) system, rapidly cooling below the material’s glass transition temperature (e.g., PVC at approximately 80°C). This solidifies the insulation/sheath layer while maintaining stable tension via a traction machine to prevent stretching deformation.

Throughout this process, three critical parameters—temperature, pressure, and speed—must be synchronously controlled. This ensures “gap-free adhesion between the conductor and the coating layer,” meeting dual standards for electrical insulation (breakdown voltage ≥10kV/mm) and mechanical protection (tensile strength ≥12MPa).

What are the advantages of wire and cable extrusion?

From an industrial application perspective, the advantages of cable extrusion technology lie in three key dimensions: scalability, performance stability, and cost control. These capabilities enable the cable industry to cover the entire spectrum—from low-voltage to high-voltage applications, and from residential to specialized scenarios:

Continuous production meets mass-scale demands: Unlike batch processing, extrusion enables 24/7 uninterrupted production. A single line can achieve daily output of 5,000–20,000 meters. Switching specifications requires only mold and parameter adjustments, ensuring high changeover efficiency to swiftly fulfill bulk orders for home renovations, grid construction, and more.

Dimensional precision ensures electrical safety: Through “mold shaping + real-time monitoring by inline diameter gauges,” coating thickness deviation is controlled within ±0.1mm, preventing breakdown risks caused by localized thinning. For instance, a 0.2mm thin spot in low-voltage wire insulation could lead to leakage over time due to concentrated electric fields.

Material adaptability covers all application needs: Whether standard PVC (household wiring), weather-resistant PE (outdoor cables), high-temperature fluoroplastics (aerospace cables), or flame-retardant, low-smoke, halogen-free compounds (subway/tunnel cables), all can be adapted by adjusting extrusion temperature and screw speed. The process even enables multi-layer co-extrusion (“insulation-shielding-sheath”), streamlining production workflows.

Cost optimization supports industrial competitiveness: Raw material utilization exceeds 95% (scrap can be crushed and recycled), while mainstream equipment like single-screw extruders features low operational barriers and controllable maintenance costs. Compared to other forming processes, this reduces unit manufacturing costs by 15%-20%, a key factor in the affordability of consumer cables.

Types of Wire and Cable Extruders

Different cable applications demand significantly varying extruders in terms of “plasticizing capacity, temperature control precision, and material adaptability.” The industry primarily categorizes extruders into three main types, each corresponding to distinct technical characteristics and application scenarios:

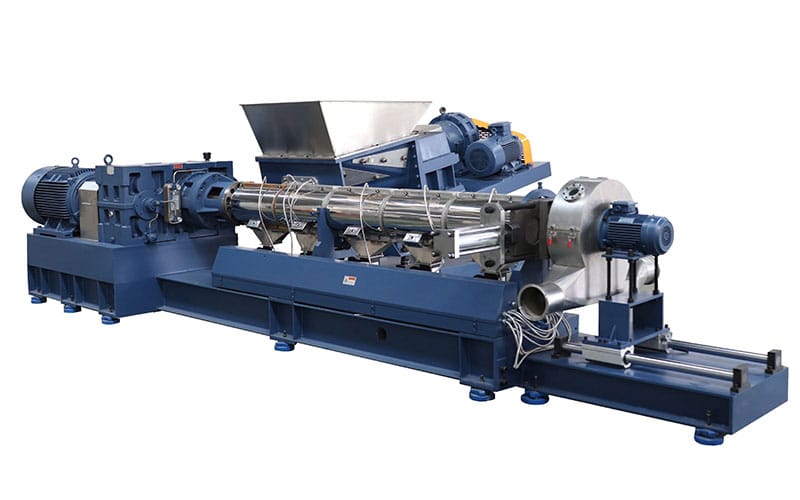

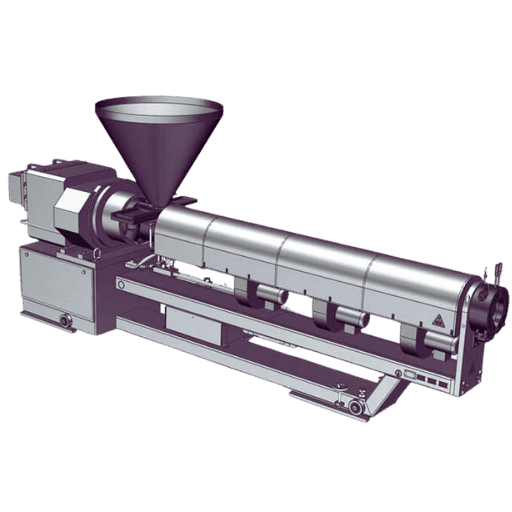

Single-Screw Extruder: Mainstream Choice for Civilian Cables

Features a single screw with tapered grooves (deep feed section, shallow metering section). Plasticization relies on friction between the screw and barrel. Advantages include simple structure, low failure rate, and manageable procurement costs (around $10,000–$20,000 for industrial-grade models). Primarily used for PVC wire and standard PE power cable insulation/sheath extrusion, suited for low-filler, easily plasticized conventional materials. Over 80% of small-to-medium cable manufacturers utilize this type.

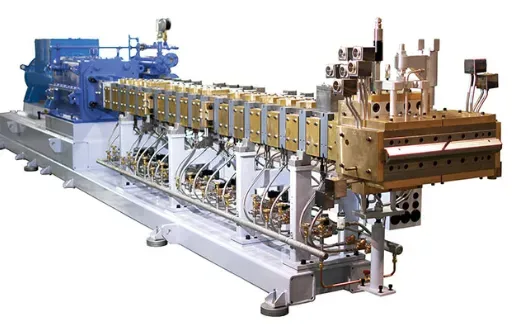

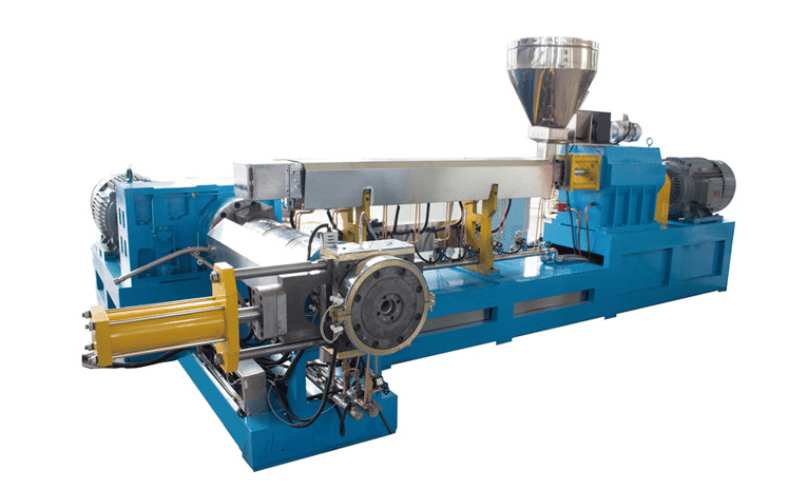

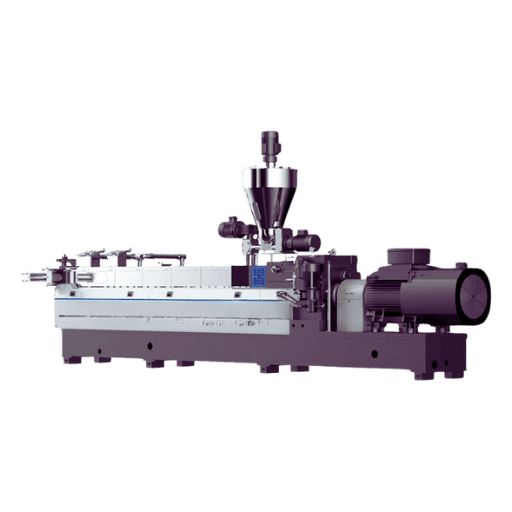

Twin-Screw Extruder: Specialized for Complex and Specialty Materials

Features two intermeshing screws (parallel or conical), delivering 2-3 times the shear force of a single screw. Enables uniform mixing of multi-component materials (e.g., PE + flame retardant + antioxidant) while reducing dwell time for heat-sensitive materials (e.g., PVC, EVA) through rapid conveying, preventing decomposition. Primarily used for extruding sheaths for flame-retardant cables and low-smoke, zero-halogen cables, as well as processing highly filled materials (e.g., glass fiber-reinforced compounds). Industrial-grade equipment costs approximately $20,000–$80,000 USD and is widely adopted in large-scale modified cable manufacturing plants.

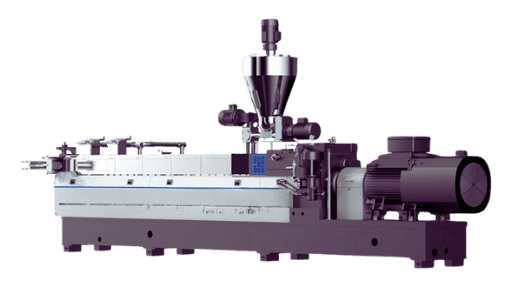

Specialized Cable Extruders: Custom Solutions for Demanding Applications

Engineered for extreme-environment cables, typical examples include:

– Fluoroplastic extruders (barrel temperatures 280-320°C, compatible with high-temperature materials like FEP and PTFE) for new energy vehicle high-voltage cables and aerospace cables;

– Silicone rubber extruders (equipped with hot-air vulcanization systems) for medical-grade high-temperature-resistant cables and oven-internal wiring. These machines require custom high-pressure and high-temperature resistant screws and seals, typically priced between $30,000 and $130,000 USD. Their high technical barriers limit production to only a few specialized manufacturers.

Common Issues in Cable Extrusion Process

Q: How to resolve bubbles in the insulation layer after extrusion?

A: This is most likely caused by moisture in the raw material, insufficient plasticization, or poor mold venting. First, dry the raw material in a dryer for 2-4 hours (PE material at 80°C, PVC material at 60°C); Then increase the barrel metering section temperature by 5-10°C to ensure complete melt fusion; finally, disassemble the mold to clean vent holes and prevent impurities from blocking them. This should generally resolve the bubble issue.

Q: Should I choose a single-screw or twin-screw extruder for cable production?

A: For household PVC wires and standard PE power cables, a single-screw extruder is sufficient. It’s structurally simple and cost-effective, sufficient for small to medium-sized factories. For flame-retardant cables, highly filled cables (e.g., containing over 40% mineral powder), or thermosensitive materials (prone to high-temperature decomposition), a twin-screw extruder is necessary. It provides uniform mixing and prevents material buildup, though it comes at a higher cost.

Q: How should cable extrusion machines be maintained to minimize breakdowns?

A: After each material change, clean the screw and barrel with hot cleaning compound while still warm to prevent residue buildup. Weekly inspections should check heating elements for loose connections or lack of heat, and seals for leaks. Monthly lubrication of transmission components—like gear oil in the reducer—is essential. Don’t wait for wear to occur before repairing, as this disrupts production.

Q: How can I tell when an extruder screw needs replacement?

A: Inspect the screw flutes—if the flute tips become pointed or show significant wear marks, material plasticization will be poor. Measure the gap between the screw and barrel; if it exceeds 0.1mm, extruded material will exhibit streaks. Examine the product: if the insulation layer surface remains consistently rough despite temperature adjustments, the screw is likely worn out and needs replacement.