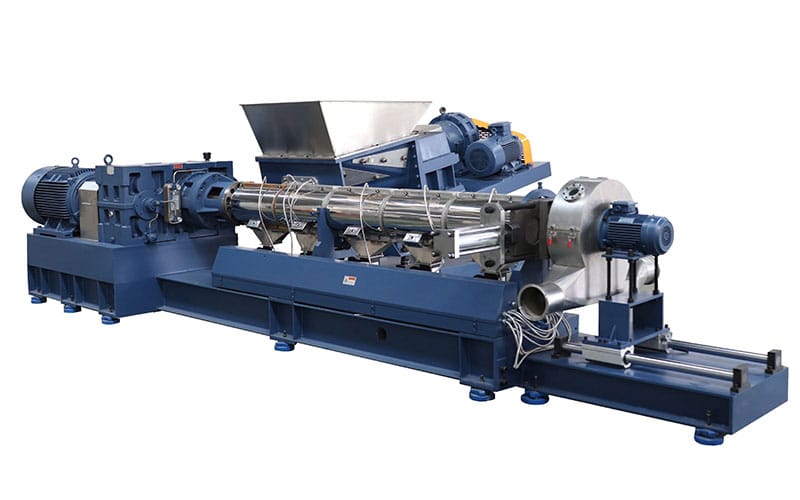

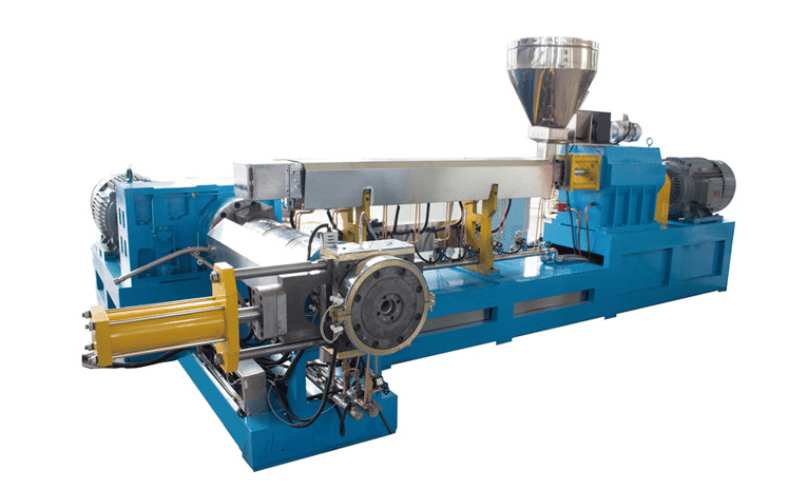

Twin-screw extruders are now common equipment in plastic modification and multi-component compounding processes. Unlike single-screw extruders that rely solely on a single screw for material feeding, twin-screw extruders operate with two meshing screws, making them more adept at handling complex raw materials. However, they are not without limitations. Below, we will discuss their specific advantages and disadvantages, as well as how they compare to single-screw extruders.

Advantages of Twin-Screw Extruders

High Mixing Uniformity: The intermeshing of two screws generates strong shear forces and turbulence, ensuring exceptionally thorough mixing whether adding glass fiber or flame retardants to plastics, or blending multiple resins. For instance, when processing filled materials with over 50% mineral powder, the finished products exhibit uniform filler distribution without agglomeration and stable mechanical properties.

Strong Material Adaptability: Capable of processing materials challenging for single-screw extruders, such as heat-sensitive PVC (prone to localized overheating and decomposition), high-viscosity engineering plastics (e.g., PEEK), and recycled materials with high moisture content. It reduces material residence time in the barrel through segmented temperature control and rapid conveying, preventing scorching or incomplete melting.

Stable production and high efficiency: Feed is minimally affected by raw material flow properties. Even powders or irregular granules feed steadily without frequent stoppages common in single-screw systems. It simultaneously handles mixing, degassing, and plasticizing. For complex formulations of equivalent specifications, processing efficiency exceeds single-screw systems by 20%-30%.

High-Filler Processing Capability: For materials with fillers exceeding 40% (e.g., glass-fiber reinforced PA), single-screw extruders often struggle with insufficient shear or uneven dispersion. The intermeshing structure of twin-screw extruders firmly embeds fillers into the base material, resulting in finished products with minimal powder shedding and sufficient strength.

Disadvantages of Twin-Screw Extruders

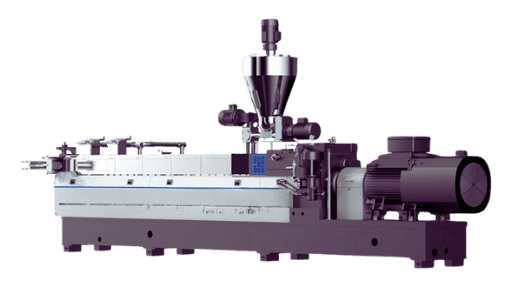

High cost and significant initial investment: Both the equipment itself and its components are considerably more expensive than single-screw extruders. Industrial-grade twin-screw extruders typically range from $10,000 to $100,000, while single-screw models cost only $2,000 to $10,000. Additionally, replacing a set of worn screws and barrels incurs high expenses, making them cost-ineffective for small workshops or simple processing applications.

Complex structure, difficult operation: Unlike the simple components of a single-screw machine, a twin-screw features two intermeshing screws along with complex drive and temperature control systems. Debugging requires expertise in parameter coordination (e.g., screw speed, zone temperatures), making it difficult for novices to master quickly. Incorrect parameters can easily lead to material issues.

Cleaning is troublesome, and material changeovers are time-consuming: Residual material easily gets trapped in the gap between the two screws, especially when switching to dark-colored or high-viscosity materials. This requires disassembling the screws and repeatedly extruding with dedicated cleaning compounds, taking 1-2 hours per cycle. Single-screw extruders, on the other hand, can be switched over with a quick wipe and some cleaning compound—far more convenient.

High maintenance costs: Screw meshing clearance requires regular inspection. Once wear exceeds the limit (over 0.1mm), repairs are necessary to prevent compromised mixing efficiency. Wear-prone components like bearings and seals also require more frequent replacement than in single-screw extruders. Over time, these maintenance expenses add up significantly.

Advantages and Disadvantages of Twin-Screw Extruders Compared to Single-Screw Extruders

Comparative Advantages

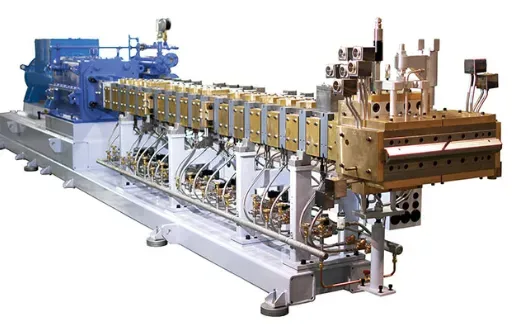

Superior Mixing Capability: Single-screw extruders rely solely on friction between material and barrel to advance feedstock, with mixing achieved through simple shear action in screw grooves. Multi-component materials tend to segregate. Twin-screw extruders utilize two intermeshing screws for thorough blending, capable of processing materials with three or more components (e.g., plastic + glass fiber + flame retardant + antibacterial agent). Dispersion deviation can be controlled within ±1%, a level unattainable with single-screw systems.

Handling Complex Materials: Single screws struggle with heat-sensitive materials (which decompose upon heating) and highly filled compounds (where excessive filler prevents thorough melting). Twin screws utilize gentle shear and rapid conveying to process PVC and highly filled mineral-filled compounds with exceptional stability. Single screws processing these materials often result in either scorched spots on the finished product or agglomerated filler particles.

More stable production: Even minor feed fluctuations (e.g., raw material moisture changes) cause single-screw output to fluctuate wildly, with deviations exceeding ±5%. Twin screws maintain “pressure stability” through dual screw action, limiting flow fluctuations to ±2%. This produces more uniform finished product dimensions and reduces the need for frequent adjustments.

Disadvantages Compared

Lower cost-effectiveness, unsuitable for simple processing: For straightforward materials like pure PE pipes or PP strapping bands, using a twin-screw is wasteful—a single-screw can handle it cheaply and easily. The twin-screw’s high cost fails to deliver advantages and instead increases production expenses.

More complex operation and maintenance: Single-screw extruders feature simple structures. Even minor issues like material jams can be resolved by novices through disassembly and cleaning. Twin-screw systems require professional technicians for tasks like screw removal and meshing gap adjustment. Maintenance takes 2-3 times longer than single-screw systems. Small factories lacking maintenance expertise may face significant production delays.

Higher energy consumption: Twin screws require driving two screws while maintaining high shear forces, resulting in 15%-20% higher energy consumption than single screws for equivalent specifications. For prolonged daily production, electricity costs significantly exceed those of single screws. This proves uneconomical for manufacturers producing low-margin, simple products.