Introduction to Laboratory Extruders

Primary Applications of Laboratory Extruders

2.Process Parameter Optimization: Experimenting with different barrel temperatures and screw speeds to assess their impact on material plasticization. For example, determining the optimal temperature range where PVC fully melts without decomposition, providing data for subsequent mass production.

3.Sample Preparation: Extruding small-scale tubing, film, or profiles for subsequent tensile strength and temperature resistance testing. For instance, developing medical-grade catheters involves creating prototypes to assess biocompatibility.

4.Education and Research: University laboratories utilize it to demonstrate extrusion principles, allowing students to visually observe the transformation from solid to molten to formed material. It also facilitates extrusion performance studies for novel materials like bio-based plastics.

Types of Laboratory Extruders

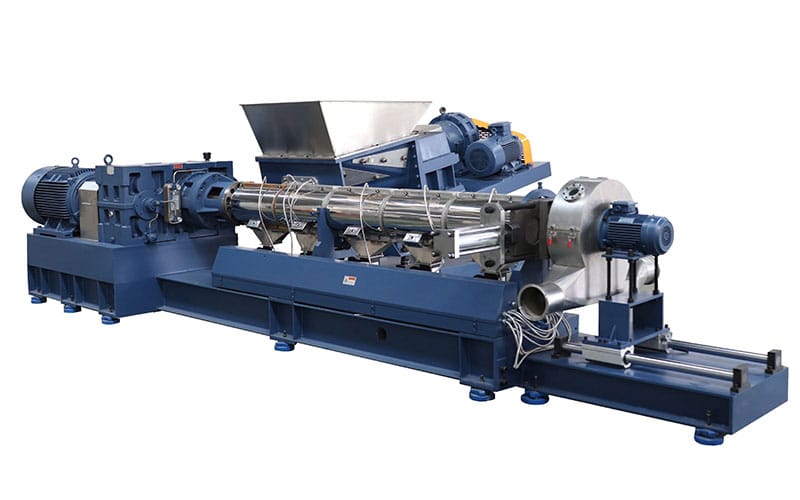

1.Single-screw laboratory extruder: The simplest design featuring a single screw, ideal for fundamental testing such as melt flow performance of pure resins or basic masterbatch compounding. It is also cost-effective, typically priced between 50,000 and 150,000 yuan.

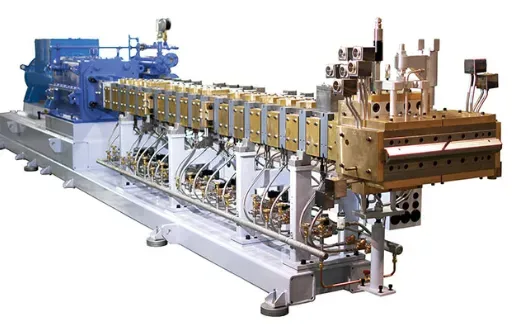

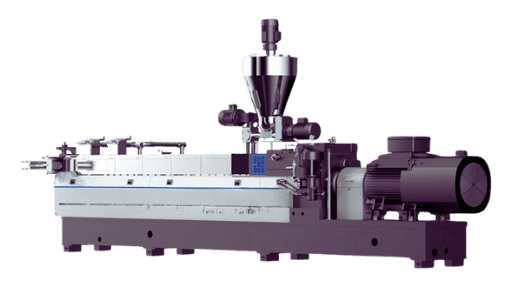

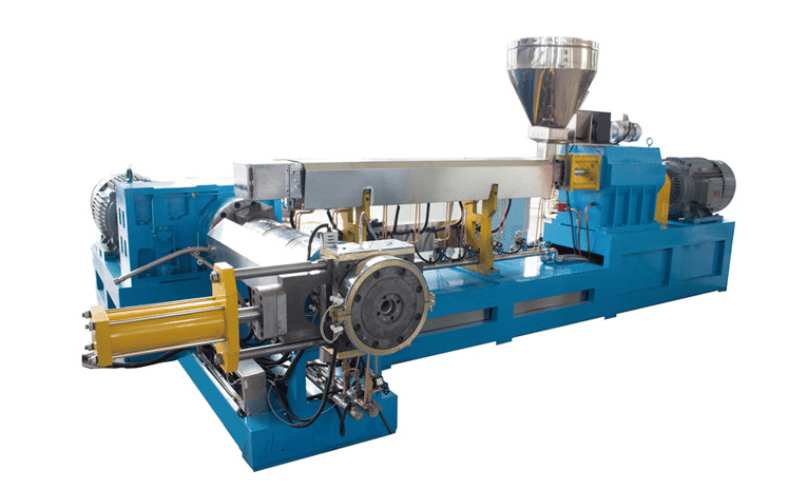

2.Twin-Screw Laboratory Extruder: Features two meshing screws, offering superior mixing capability compared to single-screw models. Ideal for multi-component material testing, such as blending plastics with glass fiber and antioxidants, preventing composition inconsistencies. Commonly used in modified material R&D.

3.Micro Multi-Screw Laboratory Extruder: Primarily three-screw configurations, featuring the smallest footprint and highest precision. Ideal for testing nanomaterials and highly filled compounds, such as dispersion testing of graphene-reinforced PE, effectively reducing agglomeration issues. However, they come at a higher price point, typically ranging from ¥200,000 to ¥500,000.

The Difference Between Laboratory Extruders and Standard Extruders

1.Production Capacity Differences:

Laboratory models offer a capacity of 0.5-20 kg/h, processing a few kilograms of raw material at a time, ideal for trial-and-error testing.

Standard extruders (industrial-grade) deliver 50-500 kg/h, designed for continuous mass production to meet factory-scale manufacturing demands.

2.Size and Installation:

Laboratory models are compact, occupying just 1-2 square meters. Plug-and-play operation requires no complex installation. Standard machines are larger and require auxiliary equipment like feeders, coolers, and winders, necessitating dedicated workshop space.

3.Parameter Control: Laboratory machines emphasize “flexible adjustability,” allowing precise fine-tuning of parameters like temperature and speed, with real-time data logging for analysis. Standard machines prioritize “stability,” maintaining consistent parameters over extended periods to prevent fluctuations during mass production.

4.Different Applications: Laboratory machines serve as “R&D tools” for testing formulations, evaluating processes, and producing small samples. Standard machines function as “production equipment” for batch manufacturing finished products like pipes and sheets, prioritizing efficiency and cost control.

Common Questions About Laboratory Extruders

Q: Should I choose a single-screw or twin-screw laboratory extruder?

A: Depends on testing requirements: Single-screw extruders feature simpler construction and lower cost, making them suitable for basic tests like pure resin melt testing or simple masterbatch compounding. Twin-screw extruders offer superior mixing capability, handling multi-component materials (e.g., plastic + glass fiber + additives) or highly filled compounds, making them ideal for modified material R&D. Prioritize twin-screw for complex formulations; single-screw is more cost-effective for basic material testing.

Q: What capacity is appropriate for a lab extruder?

A: Common capacities range from 0.5-20 kg/h. Selection depends on testing objectives: For formulation trial-and-error or small-batch performance testing, choose a 0.5-5 kg/h micro-extruder to conserve materials. For preparing multiple samples (e.g., multiple tensile test specimens), select a 10-20 kg/h model. Avoid pursuing high capacity; matching the single-test batch size is paramount.

Q: What is the approximate price range for laboratory extruders?

A: Single-screw lab extruders cost ¥50,000–150,000 RMB, suitable for basic testing; twin-screw models range from ¥150,000–300,000 RMB for multi-component R&D; micro multi-screw (e.g., triple-screw) units cost ¥200,000–500,000 RMB, primarily for high-precision nano-material testing. Pricing depends on capacity, temperature control accuracy, and automation features—select based on needs without blindly pursuing high-end configurations.

Q: Can laboratory extruders process food-grade materials?

A: Yes, but select dedicated food-grade models: components contacting materials (screws, barrels) must be 304/316 stainless steel with no dead corners for easy cleaning. The heating system must prevent lubricant leakage and comply with FDA certification. Thoroughly clean equipment before testing to avoid plastic residue contaminating food materials. Clean promptly after testing to prevent bacterial growth.