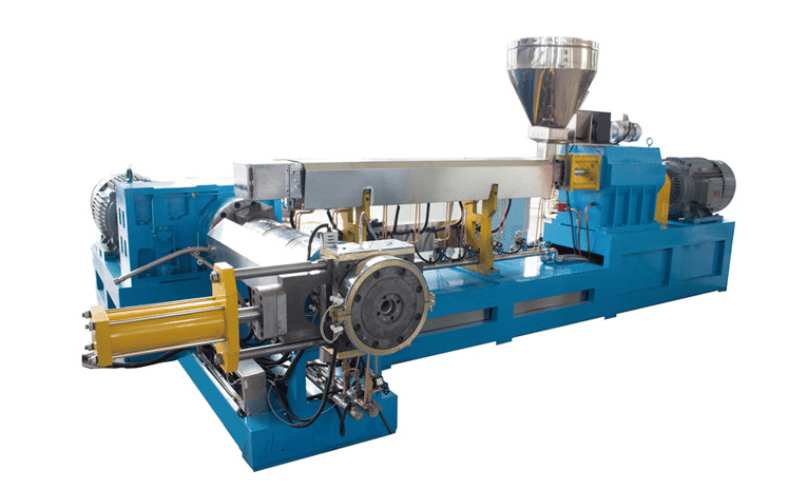

Extruders are core equipment in the field of material processing and are widely used in many areas. This article will give you a comprehensive understanding of the basic concepts, working principles, and main components of extruders, allowing you to fully understand extruder equipment.

Understanding Extruders

Extruders are extremely important equipment in the industrial field. They primarily process raw materials (such as pellets and powders) into specific shapes through processes such as melting and mixing. Common products include pipes, sheets, and profiles.

Extruders are widely used in industries such as plastics, rubber, and construction materials. Factories use the standardized processes of extruders to mass-produce products.

Working Principle of an Extruder

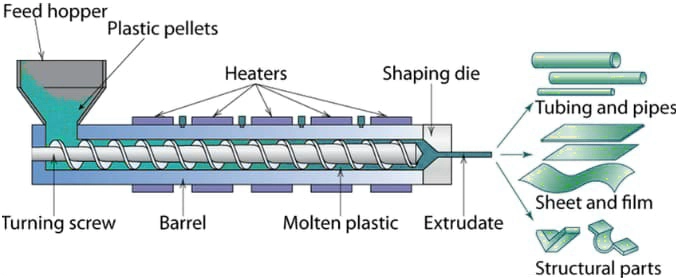

An extruder primarily processes raw materials into finished products through standardized processes by rotating the screw and heating the barrel. After undergoing processes such as conveying, melting, and mixing, the raw materials are finally transported to the mold, where they are cooled and shaped into finished products.

1.Raw Material Conveying

First, raw materials (such as pellets or powders) are loaded into the feeding system (hopper + feeding screw). The screw then rotates to quantitatively push the raw materials forward.

2.Melting and Plasticization

The barrel is heated in sections in conjunction with the screw’s shear force to melt the raw material into a melt. The melt is then compressed and mixed through changes in the screw groove depth. Some models have a venting function, which removes bubbles and other impurities from the melt during this step, ensuring the raw material is uniform and free of contaminants.

3.Pressurized Extrusion

The uniformly mixed melt is pushed to the end of the barrel and then forced through the mold’s flow channels by the pressure generated by the screw’s rotation, finally forming the blank according to the mold’s shape (e.g., pipe mold, sheet mold).

4.Cooling and Setting

Finally, the material is transported to the cooling system (water cooling tank or air cooling jacket), where it is cooled and solidified to form the finished product.

Main Components of an Extruder

1.Screw

The screw is one of the most critical components of an extruder, made from high-strength alloy steel. It plays a vital role in material transportation and mixing throughout the extruder.

2.Barrel

The barrel features a segmented design, with each segment equipped with an independent heating module, enabling precise control of internal temperature and uniform heating and melting of the material.

The interior is lined with wear-resistant materials,

3.Feeding System

Comprising a hopper, feed screw, and drive motor, the feed system is responsible for quantitatively conveying raw materials into the barrel, controlling feed rate, and ensuring stable material supply.

4.Drive System

Includes the main motor, reducer, and torque protector. The motor provides power, which is then converted into the required torque for the screw via the reducer. The torque protector automatically shuts down the system when load exceeds limits, preventing damage to the screw or motor.

5.Temperature Control System

Comprising temperature sensors, a PLC controller, and actuators (heating coils, cooling fans), this system monitors the barrel and mold temperatures and dynamically adjusts them to ensure the melt flows within the optimal temperature range.

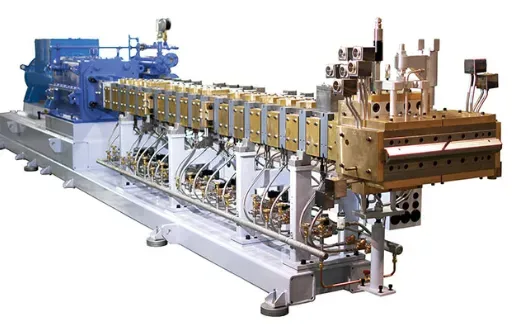

6.Mold

The mold is installed at the end of the barrel. After undergoing processing and melting, the raw material is finally delivered to the mold to form the final shape (e.g., pipe mold, sheet mold, profile mold).

7.Cooling and Forming

At the mold outlet, the product temperature is rapidly reduced through water cooling (water tank, spray system) or air cooling (fan, cooling jacket) to complete the product’s forming.

8.Ventilation System

Some machine models have vacuum venting ports in the barrel to extract volatile substances (moisture, low-molecular-weight impurities) from the melt. This reduces issues like bubbles and pinholes, improving the quality of the finished product.

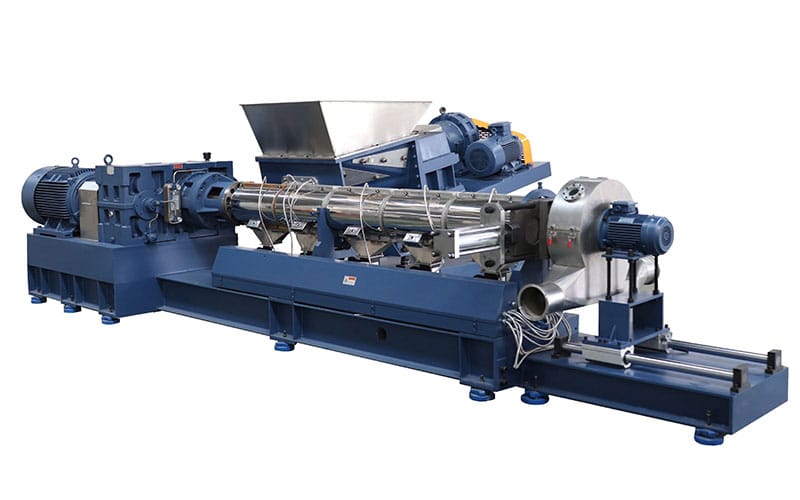

Classification by Number of Screws

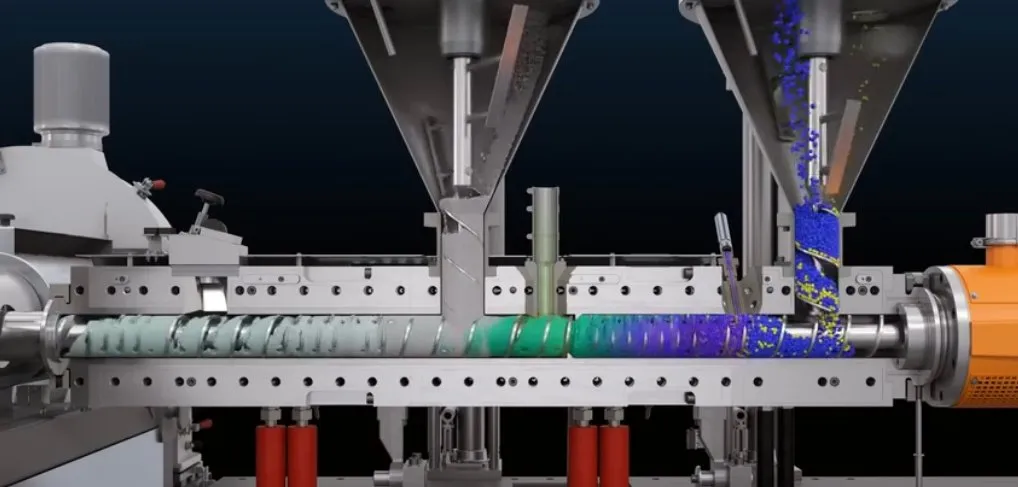

- Single-screw extruder: The most common type, with just one screw rotating in the barrel. Its simple structure and low price make it suitable for processing pure resin pellets or simple recycled materials, such as common PE pipes and PP sheets. However, its mixing capacity is average, making it somewhat difficult to process highly filled materials.

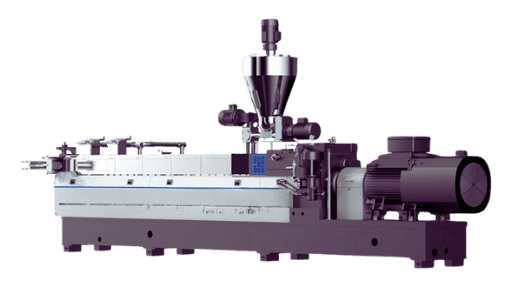

- Twin-screw extruder: Its two screws rotate in an intermeshing manner, providing much greater shear force than a single-screw extruder. It can process multi-component blends, such as glass fiber reinforced plastics and masterbatches, achieving better mixing uniformity. It is currently the most widely used in plastics modification workshops.

- Multi-screw extruder: It primarily features three screws arranged in a triangular pattern, resulting in more intensive cross-shearing. It is specialized for processing challenging materials, such as nanopowder composites, modified materials with over 50% filler content, and heat-sensitive PVC and POM. It is less prone to scorching and offers high precision, but the equipment cost is higher.

By Application

- Plastic Extruder: The most common type, used to produce everything from everyday plastic bottle preforms and strapping to industrial engineering plastic profiles. Different models are compatible with various plastics, including PE, PP, and ABS.

- Rubber Extruder: With slow screw speeds and low barrel temperatures, it’s specialized for processing rubber raw materials. Applications like automotive weather strips and tire treads are extruded using this extruder, ensuring the rubber’s elasticity and strength.

- Specialty Extruders: For example, food extruders can turn grain powder into puffed snacks and pasta. Building materials extruders, specifically designed for producing PVC pipes and aluminum-plastic composite panels, offer greater specificity.

By Structural Features

- Conical Twin-Screw Extruder: With two screws, one thicker at one end and one thinner at the other, it’s suitable for processing hard PVC, minimizing material degradation. Parallel twin-screw extruders are more suitable for plastic modification, offering high speeds and efficiency.

- Venting extruder: The barrel is equipped with a vent to extract moisture and volatiles from the raw materials. It is particularly useful for recycling recycled materials and highly transparent plastics, and the finished product is less likely to have bubbles.

Applications of Extruders

1. Plastic Industry

The plastic industry is the most common application. From everyday PE water pipes and PP strapping bands to ABS sheets used in home appliance casings, and agricultural films such as ground covers and greenhouse films, all are formed using extruders. For example, high-transparency PET beverage bottle preforms are produced by specialized extruders that melt PET pellets into a melt, which is then extruded through a mold to form the desired shape. Plastic trim strips and dashboard frames in automobiles are also produced by extruding modified plastics into specific shapes, balancing strength and lightweight design.

2. Rubber Industry

Rubber product manufacturing also relies on extruders. The EPDM seals for car windows and doors are produced by rubber extruders, which extrude the mixed rubber compound into strips and then vulcanize them into shape. The tread rubber for tires is also produced by extruders, which control the density and uniformity of the rubber compound to ensure the tire’s durability and traction.

3. Building Materials Industry

Common building materials such as PVC drainage pipes and aluminum-plastic composite panels are all produced using extruders. When manufacturing PVC pipes, extruders precisely control wall thickness and roundness to ensure the pipes’ pressure resistance. For aluminum-plastic panels used in integrated ceilings, extruders firmly bond the plastic layer and aluminum foil into a single unit, balancing waterproofing and flexibility.

4. Medical Industry

Medical-grade IV tubes and oxygen tubes require high cleanliness and dimensional accuracy. Extruders use medical-grade PE and PVC raw materials to produce tubes with uniform wall thickness, completely avoiding contamination throughout the process to meet medical-grade hygiene standards. Plastic forceps and trays used in surgery are also processed and formed using extruders.

5. Food Processing

The food industry also utilizes extrusion technology, such as in the production of puffed snacks (e.g., shrimp crackers, potato chips), where food-grade extruders heat and compress grain flour to expand and shape the raw material; various pasta shapes are also formed through different molds, ensuring both efficiency and uniformity in shape.

6. New Energy Sector

Separators for new energy batteries (e.g., PP/PE composite films) are produced by extruders mixing resins and additives uniformly, then extruding them into ultra-thin films to control breathability and puncture resistance. EVA adhesive films in photovoltaic modules are also processed by extruders to ensure consistent film thickness and prevent bubbles when adhering to photovoltaic panels.

Common Issues with Extruders

Q: How should I choose between single-screw and twin-screw extruders?

A: Single-screw extruders are suitable for simple raw materials (such as pure plastic pellets), featuring a simple structure and low cost; twin-screw extruders have strong mixing capabilities and are suitable for multi-component, high-filler materials (such as glass-fiber reinforced materials). Choose based on your needs: single-screw for basic processing, twin-screw for complex modification.

Q: What materials can an extruder process?

A: Extruders can process plastics (PE, PP, PVC), rubber, food ingredients (grain flour), construction materials, etc. Different machine models are suited for different materials, such as rubber extruders specifically for rubber, and food-grade models for edible materials.

Q: What should be noted for daily maintenance of extruders?

A: Regularly clean the screw and barrel to prevent residual material from hardening; check that the heating elements and temperature control system are functioning normally; Lubricate the transmission components to prevent wear. After processing high-filler materials, clean promptly to extend equipment lifespan.

Q: What is the approximate price of an extruder?

A: Small single-screw extruders cost approximately 10,000–50,000 yuan, industrial-grade twin-screw extruders cost 100,000–500,000 yuan, and multi-screw extruders (e.g., triple-screw) cost 300,000–2,000,000 yuan. Prices vary based on capacity and configuration (e.g., automation level), with custom models being more expensive.

Q: What should be done if the extruder becomes clogged?

A: First, shut down the machine and allow it to cool. Disassemble the barrel to clean out residual material. Check if the feed rate is too fast or the temperature is too low. Daily operations should control feed volume, ensure raw materials are dry, and prevent hard impurities from entering the barrel.

Q: What special requirements are there for food-grade extruders?

A: Food-grade stainless steel (such as 304) must be used for contact components, ensuring easy cleaning with no dead corners; the heating system must be leak-free and comply with FDA standards; lubricant contamination of raw materials must be avoided, and the machine must be suitable for processing snacks, pasta, etc.

Q: What factors affect the output of an extruder?

A: Screw speed (higher speed increases output but must match plasticizing capacity), raw material flowability, barrel temperature (affects melting speed), and mold resistance. Proper parameter adjustment can balance output and product quality.

Q: What is the difference between an extruder and an injection molding machine?

A: An extruder continuously produces profiles (tubes, sheets, etc.) by continuously pushing the melt through the screw; an injection molding machine intermittently produces three-dimensional parts (such as plastic shells) by injecting material under pressure into the mold cavity. They have different application scenarios and significant differences in structure and principles.