Three-screw extruders, with their advantage of multi-screw coordination, have become key equipment for processing highly complex materials. Compared to single- and twin-screw extruders, they offer superior mixing precision and material adaptability. This article will start with basic knowledge, analyze the structure and working principle of three-screw extruders, introduce their application scenarios in the processing of special materials, and compare them with other types of extruders to give readers a better understanding of the characteristics of three-screw extruders.

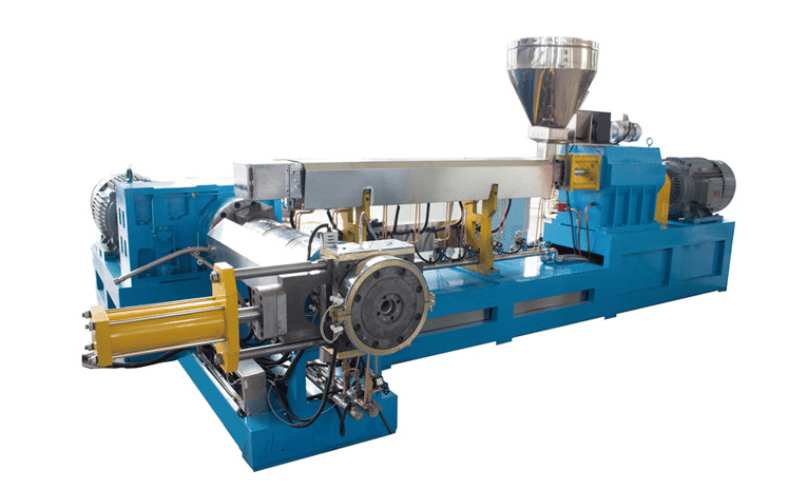

Introduction to Three-Screw Extruders

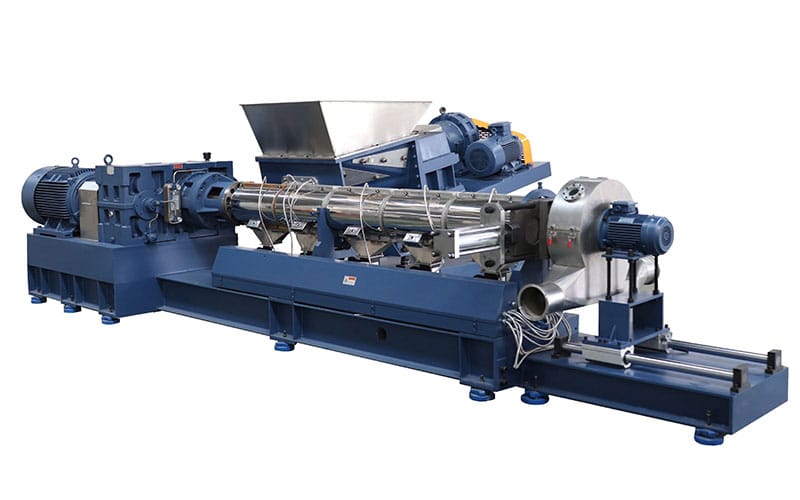

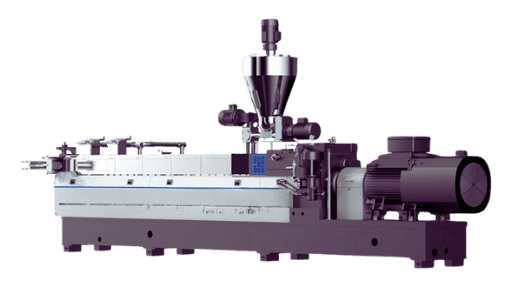

Three-screw extruders are specialized machines designed to meet the demands of complex plastic processing, particularly suited for handling challenging materials. Their core advantage lies in the coordinated operation of three screws arranged in a triangular pattern. As these screws rotate, they create dense shear and mixing zones, enabling thorough blending of raw materials with differing properties. Even difficult-to-disperse components such as high-filler glass fiber and nano-powders can be uniformly distributed throughout the base material.

Compared to the simple conveying function of single-screw extruders and the limited mixing capability of twin-screw extruders, the triple-screw extruder excels in multi-component blending and the processing of heat-sensitive materials. Applications include reinforced plastics for automotive lightweight components, composite materials for medical-grade precision tubing, and separator materials for new energy batteries, all of which can achieve stable plasticization and reduce product defects caused by uneven mixing.

For production scenarios prioritizing material performance stability, the precise temperature control and efficient dispersion capabilities of three-screw extruders can address the bottlenecks encountered by traditional equipment when processing complex formulations, making them particularly suitable for high-end manufacturing sectors with stringent requirements for product precision and consistency.

Core components of a triple-screw extruder

1. Screw assembly

The screw is the core component of a three-screw extruder, typically arranged in a triangular configuration and meshing with each other. Made from high-strength alloy materials with wear-resistant surface treatment, it can withstand continuous friction from high-filler materials. Different sections (feed section, compression section, metering section) have varying pitch and groove depth designs, which, when rotating, create dense shear zones to enhance material mixing and plasticization, making it particularly suitable for processing high-viscosity or multi-component raw materials.

2. Barrel

The barrel interior is made of wear-resistant and corrosion-resistant materials (such as nitrided steel or dual-metal coatings) and features a segmented design, with each segment equipped with an independent temperature control module to precisely regulate temperatures in different zones, preventing localized overheating of heat-sensitive materials. A special flow channel structure guides the material to circulate repeatedly between the screws, improving mixing uniformity.

3. Feeding System

The feeding system typically employs a forced feeding device, comprising a hopper, screw feeder, and variable-frequency motor. For high-filler, bridge-prone materials (such as glass-fiber-reinforced compounds), the feeder stabilizes feed rate control to prevent uneven material supply caused by poor flowability. Some models are equipped with vacuum feeding assistance to reduce dust contamination, meeting clean production requirements.

4. Drive System

Comprising a high-power motor, reducer, and torque limiter, this system provides synchronized rotational power to the three screws. The reducer features a hard-tooth surface design to ensure precise transmission and impact resistance, adapting to dynamic changes in screw load. The torque limiter automatically shuts down during overload conditions to protect the screws and motor from damage.

5. Temperature Control System

Includes heating elements (such as electromagnetic heating or resistance heating), cooling water lines, and temperature sensors. The PLC control system monitors the temperature of each section of the barrel in real time, with temperature differences controlled within ±1°C. For different material properties (e.g., PVC requires low-temperature processing to prevent decomposition, while PE requires high-temperature melting), the temperature control curve can be quickly adjusted to ensure stable plasticization.

6. Venting System

Some models feature a vacuum venting port in the middle of the barrel, which works with a vacuum pump to extract volatile components (such as moisture and low-molecular-weight volatiles) released during material melting. This design is particularly important for processing recycled materials or raw materials with high moisture content, as it reduces bubbles and pinholes in the finished product and improves material mechanical properties.

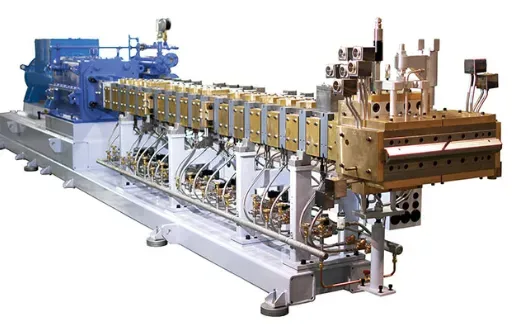

7. Molds and Screen Change Devices

Molds are custom-made according to the shape of the finished product (e.g., pipes, sheets, or profiles) and precisely aligned with the extruder outlet. Screen change devices are typically hydraulic automatic systems that allow for screen replacement without stopping the machine, removing impurities from the material and avoiding production interruptions caused by screen changes. This is suitable for continuous mass production scenarios.

Applications of Triple-Screw Extruders

1. Automotive Lightweight Material Processing

Suitable for producing high-glass fiber-reinforced composite materials such as PA and PP. The tri-screw’s strong shear and dispersion capabilities ensure uniform distribution of glass fiber throughout the substrate, resulting in high-strength and lightweight bumpers and chassis components. For low-VOC materials used in automotive interiors, its precise temperature control reduces volatiles, meeting environmental requirements.

2. Medical Precision Products

Used for processing PVC and PE composite tubing containing antimicrobial agents, the multi-screw synergistic mixing ensures uniform dispersion of the antimicrobial ingredients, avoiding localized concentration deficiencies. When producing thin-walled products such as infusion sets and catheters, its stable plasticizing capacity ensures dimensional accuracy and complies with medical-grade cleanroom standards.

3. New Energy Material Production

In the processing of battery separator materials (such as PP/PE composite films), the blend ratio of different resins can be precisely controlled, improving the separator’s puncture resistance and air permeability. When processing conductive slurries for positive electrode materials, it can evenly disperse nano-sized conductive powders and reduce agglomeration.

4. Environmentally Friendly Recycled Material Modification

For mixed waste plastics (such as PE/PP blends), the powerful mixing capability of the three-screw extruder breaks down material interfaces, producing stable recycled modified materials for applications such as packaging pallets and building formwork. When processing impure recycled materials, an exhaust system removes odor and volatiles.

5. Special Functional Masterbatch Manufacturing

When producing high-concentration color and flame-retardant masterbatches, it thoroughly disperses additives such as pigments and flame retardants into the carrier resin, avoiding color spots or uneven flame retardancy. It is particularly suitable for compounding nano-functional powders (such as graphene and montmorillonite), resulting in masterbatches that are easily dispersed in downstream processing.

6. Aerospace Material Processing

When processing high-temperature-resistant engineering plastics such as PEEK and PI, precise temperature control and low-shear design minimize material degradation, enabling the resulting structural parts to withstand high-temperature and high-pressure environments. When processing carbon fiber-reinforced composites, it balances fiber retention length with dispersion uniformity, improving the mechanical properties of the finished product.

Advantages of Three-Screw Extruders

1. Superior Mixing and Dispersion Capability

For high-filler applications (e.g., glass fiber or mineral powder content exceeding 50%), multi-component blends, or nano-scale additives, the triangular meshing structure of the three screws creates a dense shear flow field, enabling difficult-to-disperse components to be uniformly embedded into the base material. Mixing uniformity is improved by over 30% compared to twin-screw extruders, reducing fluctuations in product mechanical properties caused by local agglomeration. This makes it particularly suitable for the production of high-end modified plastics.

2. Wide material adaptability

It can stably process heat-sensitive materials (such as PVC and POM), high-viscosity materials (such as PEEK and PI), and easily degradable materials. Through segmented temperature control and gentle shear design, it avoids local overheating and decomposition of materials, while also accommodating recycled mixed materials, bio-based plastics, and other special raw materials, covering processing needs from general-purpose plastics to engineering plastics.

3. Outstanding production stability

Three screws work together to maintain stable pressure, keeping material flow fluctuations within ±2%, far below single/double screws (±5% or more). The finished product has high dimensional accuracy and mechanical property consistency, suitable for applications with strict precision requirements such as medical catheters and aerospace components, reducing rework rates caused by parameter fluctuations.

4. High-efficiency multi-functional integration

Integrating feeding, melting, mixing, degassing, and plasticization into one unit, it can process complex formulations (such as flame-retardant modification and antimicrobial composites) without additional auxiliary equipment. Compared to single/double-screw systems requiring multiple machines to collaborate, it reduces the production process by 30% and increases single-line production capacity.

5. Significant long-term cost advantages

Although the initial investment is higher than traditional models, the high mixing uniformity improves raw material utilization by 10%-15%. Additionally, the screws and barrels are made of wear-resistant dual-metal materials, extending their service life by 2-3 times and reducing overall maintenance costs by over 20%. This makes it particularly suitable for mass-producing high-value-added products.

Common Questions About Three-Screw Extruders

Q: What materials are three-screw extruders best suited for processing?

A: Three-screw extruders are particularly suitable for high-filler modified materials (such as PP and PA with glass fiber/mineral powder content of 30%-60%), multi-component blends (such as plastic + flame retardant + antimicrobial agent composites), nano-composite materials (e.g., graphene-reinforced PE), as well as heat-sensitive materials (e.g., PVC, POM) and high-viscosity engineering plastics (e.g., PEEK, PI). They can avoid issues such as uneven mixing or overheating degradation that are common in traditional machine types.

Q: Compared to twin-screw extruders, which is more suitable for high-filler modification?

A: Three-screw extruders are more suitable for high-filler modification. Twin-screw extruders tend to cause material degradation due to localized excessive shear when the filling ratio exceeds 50%, and the dispersion is uneven; the triangular meshing structure of the triple-screw extruder ensures more uniform shear force, enabling high-proportion fillers (such as 60% mineral powder) to be uniformly embedded into the base material, with mixing uniformity improved by over 30%, resulting in more stable mechanical properties of the finished product.

Q: What is the price range for a three-screw extruder?

A: Small laboratory-use three-screw extruders (output 5-20 kg/h) cost approximately 100,000 to 300,000 yuan; Industrial-grade production models (output 50-500 kg/h) vary in price from 800,000 to 3,000,000 yuan depending on configuration (e.g., temperature control precision, automation level), which is 20%-40% higher than similarly specified twin-screw extruders, but the long-term comprehensive cost for processing complex formulations is lower.

Q: Are the screws of a three-screw extruder prone to wear? How should they be maintained?

Answer: Screw wear is lower than in twin-screw extruders. This is due to the use of dual-metal alloy coatings (e.g., tungsten carbide), which enhance wear resistance by 50%. When processing high-filler materials, the service life can reach 2-3 years. Maintenance requires regular (every 3 months) cleaning of residual material in the screw grooves using a specialized cleaner, checking the meshing clearance (recommended ≤0.1 mm), and preventing hard contaminants from entering the barrel.

Q: Is it necessary to use a three-screw extruder for small-batch production?

A: If processing high-complexity formulations (such as multi-component blending or nano-modified materials), it is recommended even for small batches. Although the initial investment for a three-screw extruder is high, it can avoid mixing defects associated with single- or twin-screw extruders, reduce rework waste, and is particularly suitable for small-batch, high-precision production in industries such as medical and aerospace that demand stringent material performance requirements. The first-pass yield rate is over 15% higher than that of a twin-screw extruder.

Q: When selecting a three-screw extruder, how should the length-to-diameter ratio be chosen?

A: The length-to-diameter ratio (screw length/diameter) should be selected based on material properties: for high-filler materials or those requiring deep mixing (e.g., glass-fiber-reinforced PA), choose 36:1–40:1 to extend mixing time; for heat-sensitive materials (e.g., PVC), choose 28:1–32:1 to reduce residence time and prevent degradation; for general modifications, choose 32:1 to balance mixing efficiency and performance.