Plastic extrusion is a core process in plastic processing. It primarily involves heating raw materials to melt them, then conveying them through a screw to a mold where they are extruded into finished products such as pipes and films. Plastic extrusion is widely used in everyday items and industrial applications. This article serves as a detailed guide, introducing the basic concepts, application scenarios, and common types of extrusion machines used in plastic extrusion, to help readers gain a deeper understanding of the plastic extrusion process.

Advantages of Plastic Extrusion Process

1. Continuous production capacity suitable for large-scale demand

From raw material input to finished product output, the entire process is uninterrupted. A single production line can operate continuously for 24 hours, stably producing thousands of meters of pipe, film, and other products. Due to the continuous stability of process parameters (temperature, pressure), there is minimal variation between product batches. For example, in the production of PE drainage pipes, continuous extrusion reduces the number of joints, enhancing engineering reliability—a capability that intermittent processes like injection molding cannot match.

2. Material compatibility spans a wide range of applications

It can process granular virgin resin, as well as directly process powdered materials and recycled scrap (by removing impurities through screw shearing). Whether it is low-viscosity PE, PP, high-viscosity PC, PPS, or even modified materials with glass fiber or flame retardants, it can be adapted by adjusting the temperature and screw speed. For example, recycled plastic bottle scrap can be directly extruded into recycled pellets without complex pretreatment, reducing raw material costs.

3. Form flexibility supports diverse product design

By changing molds, it can produce a variety of products, from simple round pipes to complex automotive profiles, and from micron-level films to thick-walled sheets. Combined with co-extrusion technology, it can also form multi-layer composite structures in one step (such as medical catheters with an inner layer that is antibacterial and an outer layer that is wear-resistant), eliminating the need for post-processing lamination and expanding the functional boundaries of the product.

4. Cost control advantages throughout the entire process

Raw material utilization exceeds 95%, and scrap material can be directly reused in production; high automation reduces manual intervention; and processes such as extrusion, cooling, and cutting are integrated into one unit, eliminating the need for multiple equipment transfers. For example, in agricultural film production, continuous extrusion compared to segmented heat sealing not only improves efficiency by 30% but also reduces material waste.

5. Technological scalability adapts to industrial upgrades

It can be combined with processes such as mixing, modification, and degassing to achieve “in-line functionalization.” For example, when producing biodegradable PLA film, chain extenders can be added in-line to enhance toughness; when processing glass fiber-reinforced PP, the length of the glass fibers can be precisely controlled through screw shearing to ensure the mechanical properties of the product, making it a key conversion process for the industrialization of new materials.

Disadvantages of the plastic extrusion process

1. Strict raw material pretreatment requirements increase upfront costs

If raw materials contain impurities (such as metal particles), they can scratch the screw or clog the mold, necessitating additional screening equipment. Wet materials (with moisture content exceeding 0.5%) can cause bubbles in the finished product, requiring drying treatment. Especially when processing hygroscopic materials like PA and PC, the drying process accounts for over 30% of the production cycle, significantly increasing overall costs.

2. Strong mold customization limits flexible production.

Different products rely on dedicated molds, and the design and manufacturing cycle for non-standard cross-section molds often takes several weeks, with costs increasing exponentially with complexity (e.g., the unit price of an automotive seal mold can reach tens of thousands of dollars). Mold changes require downtime for calibration, and in small-batch, multi-variety orders, mold switching accounts for over 20% of the time, making it difficult to meet the rapid response requirements of customized orders.

3. Concentrated energy consumption and high long-term operating costs

Barrel heating requires maintaining a constant temperature of 150-300°C, and the energy consumption of the screw’s high-speed rotation drive and the water circulation of the cooling system adds up, resulting in daily electricity costs for a single production line that are 15%-20% higher than those of injection molding processes. Especially when processing high-viscosity materials (such as PPS), increasing the screw speed to ensure plasticization further increases energy consumption.

4. Product uniformity is affected by multiple factors, making quality control challenging

Fluctuations in melt temperature (±5°C can cause wall thickness deviations), screw wear (increased screw flute gaps leading to uneven material flow), and material buildup in mold channels can easily result in defects such as striations or depressions in the finished product. For example, in PVC profile production, dimensional accuracy must be sampled and tested hourly, increasing labor and time costs.

5. Significant environmental protection treatment pressure

When processing materials such as PVC and ABS, high temperatures release volatile substances such as HCl and benzene compounds, requiring配套activated carbon adsorption + catalytic combustion equipment (initial investment accounts for 10%-15% of the total equipment cost); if not properly handled, it not only poses the risk of environmental penalties but also affects the health of workshop operators.

6. Poor compatibility with heat-sensitive materials

Materials like PLA and POM, which degrade easily when heated, require strict control of melt residence time during extrusion (typically ≤1 minute). However, in continuous production, fluctuations in screw speed can cause localized overheating, leading to a decrease in molecular weight and a decline in mechanical properties of the finished product (e.g., a 10%-15% reduction in impact strength).

Applications of Plastic Extrusion

1. Construction and Building Materials

PE water supply pipes and PVC drainage pipes used in construction projects are produced through continuous extrusion to ensure consistent length and wall thickness, minimal joints, and strong pressure resistance. PVC profiles used in building decoration (window and door frames) rely on the precise cavity of the extrusion die to form complex cross-sections in a single operation, eliminating the need for later cutting and splicing, thereby improving construction efficiency. Functional building materials such as floor heating pipes and plastic gratings have also become mainstream choices due to the stability and scalability of the extrusion process.

2. Packaging and Daily Necessities

PE film used in food packaging and supermarket shopping bags are continuously produced through the extrusion blown film process, achieving precise thickness control and uniform transparency and toughness. Express delivery strapping (made of PP) relies on the extrusion stretching process to achieve a balance of high strength and low cost, ensuring stable production capacity on a single production line. Household plastic hoses (such as toothpaste tubes and facial cleanser tubes) are produced through multi-layer co-extrusion technology, creating a composite structure with an inner barrier layer and an outer printed layer.

3. Agriculture and Water Conservancy

Agricultural greenhouse film achieves a balance of light transmittance and weather resistance through the extrusion process, and anti-fog and thermal insulation additives can be added as needed. Drip irrigation tapes for irrigation feature drip holes formed simultaneously during extrusion, ensuring precise and even water flow. Aquaculture cage frames and anti-seepage membranes used in water conservancy projects are also widely used due to their aging and corrosion resistance.

4. Automotive and Industrial Parts

Automotive sealing strips (EPDM) are formed in a single step using a special-shaped extrusion die to create complex cross-sections with lips and grooves, achieving both sealing and shock absorption. Plastic air ducts and wiring harness sheathing in the engine compartment utilize the material adaptability of the extrusion process, using high-temperature-resistant engineering plastics such as PA and PPO to ensure long-term stability. Industrial conveyor belts and plastic chains rely on post-extrusion stretching to achieve sufficient strength and wear resistance.

5. Recycling and Reuse

Recycled plastic bottles and films, after being shredded, can be directly extruded and pelletized, without complex pretreatment, into recycled plastic pellets for reuse in production. Even mixed waste plastics can be blended through the intense shearing action of twin-screw extrusion to create products with low-performance requirements, such as trash cans and pallets, significantly reducing the cost of handling “white pollution.”

6. Medical and High-End Manufacturing

Medical IV and oxygen tubing are precision extruded to ensure minimal inner diameter deviation and biocompatible materials (such as PVC and TPU). In high-end applications, such as lithium battery separators, specialized extrusion and stretching processes create uniform micropores in ultra-thin films, achieving a balance between ionic conductivity and electronic insulation, making them key components in new energy technologies.

Types of Plastic Extruders

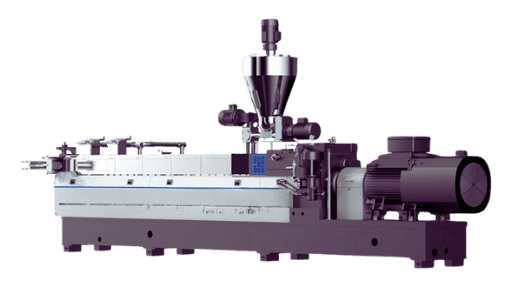

1. Single-Screw Extruder

The most common basic model, featuring a single spiral screw rotating inside the barrel. Material is pushed forward by friction between the screw and the inner wall of the barrel, while being fed and heated to melt. It has a simple structure with few parts, making maintenance easy. It is suitable for processing pure granules (such as PE, PP), and is widely used to produce basic products like ordinary pipes and packaging straps. Its drawback is average mixing capability, making it less effective with complex materials. However, its low cost and simple operation make it the most widely used by small and medium-sized enterprises.

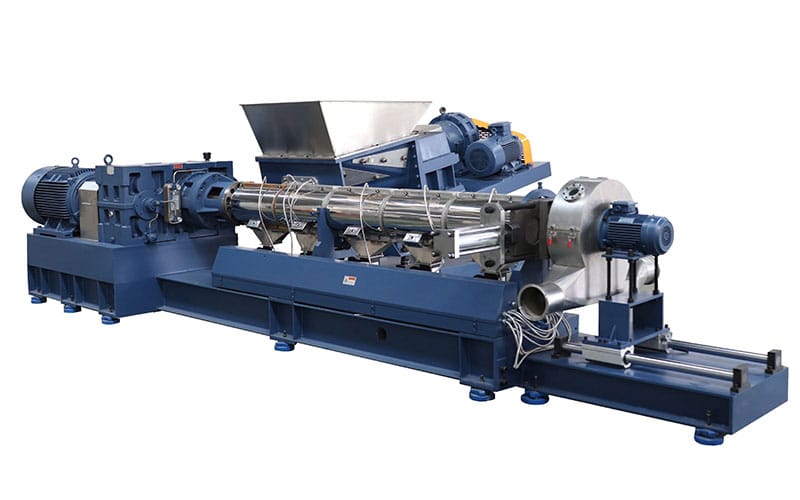

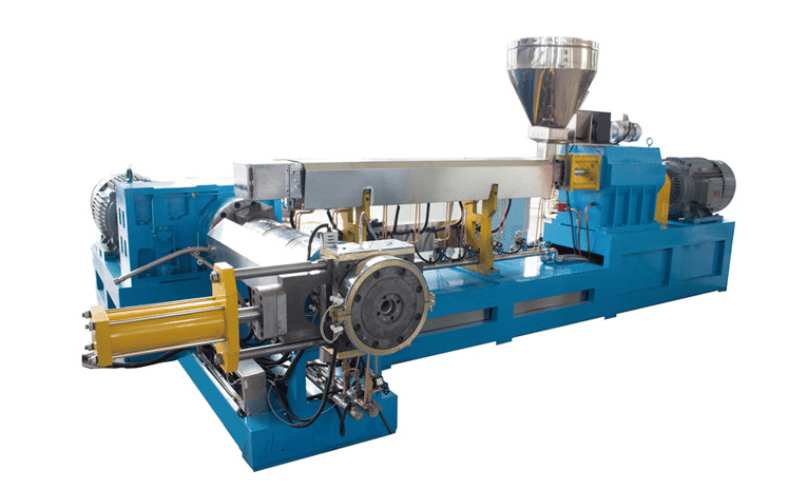

2. Twin-Screw Extruder

Features two intermeshing screws, akin to a pair of tightly meshed gears. During operation, it generates strong shear forces, effectively mixing powdered materials, wet materials, and even modified materials containing glass fiber or flame retardants. It is particularly suitable for processing recycled materials (containing impurities and moisture) and multi-component blends, such as producing color masterbatches and glass fiber-reinforced PP. Although the equipment is expensive and operation is more complicated, it offers excellent mixing performance. During material changes, the screws can scrape each other, leaving minimal residual material and enabling quick machine cleaning. It is indispensable in complex processes.

3. Planetary screw extruder

The structure is unique, with a central screw surrounded by a ring of smaller screws, resembling planets orbiting the sun. The smaller screws mesh with the teeth on the inner wall of the barrel, ensuring exceptionally uniform plasticization of the material. It is particularly suitable for high-viscosity materials, such as PVC paste or highly filled materials. However, it has many components, is difficult to repair when damaged, and has high maintenance costs, so it is only used in specific applications, such as producing soft PVC pipes.

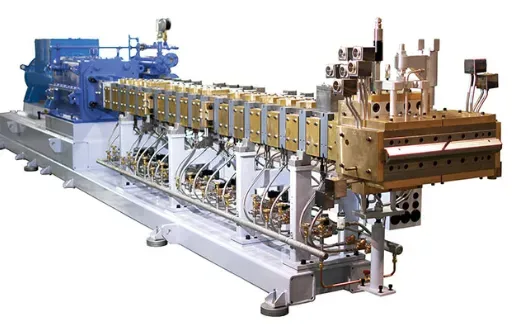

4. Multi-screw extruder

This type of machine features three or more screws arranged in parallel or in a triangular configuration. The screws provide more precise shearing and mixing, achieving extremely high dispersion accuracy, making it suitable for processing medical-grade plastics and nanomaterials. However, the equipment is extremely expensive, costing several times more than a twin-screw extruder, and is only used in high-end fields such as implantable medical devices, making it rarely seen in everyday applications.

Common Questions About Plastic Extrusion

Q: How do I choose the type of extruder based on material properties?

A:Single-screw extruder: Suitable for PE, PP, and other granular materials, with a typical output of 200–500 kg/h. It is cost-effective but has limited mixing capability.

Twin-screw extruder: When processing recycled materials or glass-fiber-reinforced materials, output can reach 500–1000 kg/h. The strong shear force improves blend uniformity by over 30%.

Multi-screw extruder: For medical-grade tubing (e.g., IV tubing), a multi-screw design is required to achieve an inner diameter deviation of ≤0.05 mm. Processing of nano-materials achieves dispersion precision of 99.9%.

Q: How can common defects be quickly addressed during the extrusion process?

A:Surface bubbles: When raw materials are insufficiently dried, they should be dried at 80–120°C for 2–4 hours, with moisture content controlled below 0.02%.

Uneven output: When screw wear causes production fluctuations exceeding 10%, replacing the screw can restore stability to ±3%.

Shark skin phenomenon: Increasing melt temperature by 5-10°C (e.g., PE from 180°C to 190°C) reduces surface roughness by 50%.

Q: How can extrusion efficiency be improved through process optimization?

A:Temperature control: Using a mold temperature controller to achieve ±0.5°C temperature control can increase line speed by 8-12% and reduce energy consumption by 15%.

Screw design: High-torque twin screws (e.g., TSS-75 type) with rotational speed increased from 50 rpm to 80 rpm can boost production capacity by 40% to 750-1250 kg/h.

Smart Scheduling: AI algorithms optimize parameters, improving yield rates from 82% to 95% and reducing raw material waste by 18%.

Q: What are the mainstream materials and performance metrics for different application scenarios?

A:Pipes: PE water supply pipes account for 60% of the municipal water supply pipe market, with a pressure rating of ≥1.6 MPa and a lifespan of 50 years; PVC drainage pipes account for 55% of the building drainage market, with corrosion resistance of 98%.

Packaging: PP strapping tape has a tensile strength of ≥180 MPa, with a daily production capacity of 5 tons; PE film thickness is controlled between 10-50 μm, with transparency >92%.

Medical: TPU IV tubing has a 100% pass rate for biocompatibility testing, with an inner diameter deviation of ≤0.05 mm.

Q: What are the key points for daily maintenance of extruders?

A:Cleaning cycle: Clean the screw/barrel weekly, with residual material content <0.1% to prevent degradation contamination.

Lubrication management: Replace gearbox lubricating oil every 500 hours, maintaining viscosity at 460 cSt (40°C).

Calibration requirements: Calibrate temperature instruments annually, with error controlled within ±1°C to prevent melt overheating and yellowing.