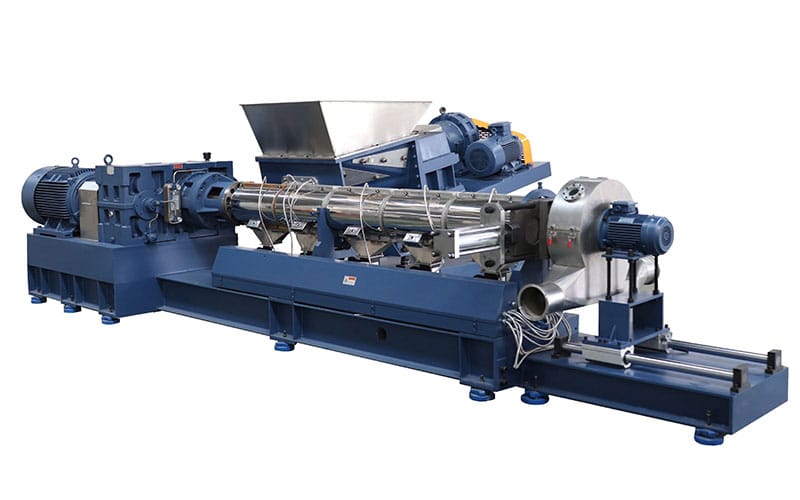

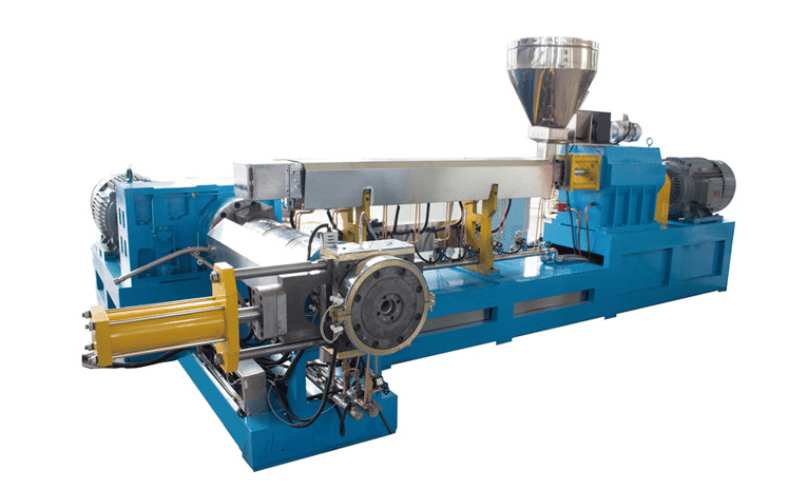

As a core piece of equipment in modern industry for processing multi-phase, highly complex materials, the twin-screw extruder achieves multifunctional integration—including material conveyance, mixing, plasticization, and degassing—through the coordinated meshing of its two screws. Compared to single-screw extruders, they offer significant advantages in mixing efficiency, material adaptability, and process flexibility. As a result, they are widely used across various industrial sectors, from plastic modification and food processing to environmental recycling and high-end composite material manufacturing.

This article will delve into the core advantages of twin-screw extruders—such as strong mixing capability, broad material adaptability, and high process controllability—and provide a detailed overview of their typical application scenarios across different industries. This aims to offer clear guidance for practitioners, purchasers, and researchers, helping them quickly grasp the core value and application scope of this equipment.

Key advantages of twin-screw extruders

1.Outstanding mixing and dispersion capabilities

The twin-screw design, with two screws meshing and rotating, generates stronger shear and compression forces, enabling particularly uniform mixing of multi-component materials (such as plastics with glass fiber, color powder, or resin additives). Even nano-sized fillers (like graphene or nano-calcium carbonate) can be dispersed more finely, preventing agglomeration—something that single-screw extruders struggle to achieve.

2. Wide material adaptability

Whether it’s thermoplastic plastics (PE, PVC), thermosetting resins (epoxy resin), special materials like rubber or starch, or even heat-sensitive bioplastics (like PLA), it can handle them all. This is achieved through segmented temperature control and screw speed adjustment, allowing the “gentleness” of processing to be tailored to material properties, thereby reducing material loss.

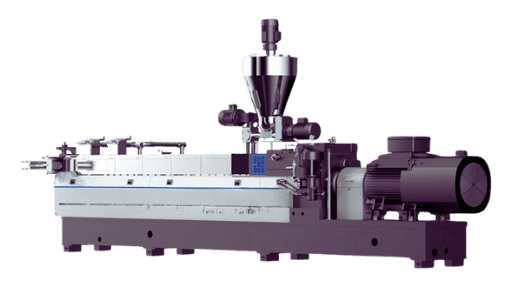

3. Flexible process adjustment

The screw is modular, and screw blocks and kneading blocks can be easily swapped out. For example, to increase shear force, add more kneading blocks; to speed up material flow, switch to screw blocks with larger pitch. There is no need to replace the entire screw. For instance, if you are doing blending today and want to switch to reaction extrusion tomorrow, simply replace a few parts to get started, minimizing trial-and-error costs.

4. High continuous production efficiency

From feeding to extrusion, the process can run continuously without stopping. Combined with a side feed port (for adding liquid additives or low-density fillers) and an exhaust port (for removing moisture and odors), the process is completed in one step, eliminating the need for pre-mixing materials as with single-screw extruders. For example, when producing masterbatch, simply add the pigment and resin, and the finished pellets come out directly, saving numerous steps.

5. Strong functional integration

It can mix and plastify simultaneously, while also removing moisture and solvents (devolatilization) from the material, and even perform online pelletization without requiring additional equipment. For example, when processing recycled plastic, the input is oily scrap material, and the output is clean pellets, without the need for intermediate processing.

Main Application Areas of Twin-Screw Extruders

1. Plastic Modification and Alloying

Most commonly used in the plastics industry, such as adding glass fiber or carbon fiber to PP and ABS base resins to enhance hardness, or adding flame retardants and impact modifiers to improve performance. For example, the impact-resistant PP used in car bumpers and the flame-retardant ABS used in appliance housings are primarily produced by uniformly blending various materials using a twin-screw extruder. Additionally, two different plastics can be blended into an alloy, such as PC and ABS, which retains the strength of PC while also having the processability of ABS.

2. Functional masterbatch production

Color masterbatches, anti-static masterbatches, and filler masterbatches—these “concentrated materials” are mostly produced using twin-screw extruders. For example, high-concentration color powders are mixed with carrier resins, ground to a very fine consistency, and formed into pellets. When used later, only a small amount is needed to uniformly color the plastic. The twin-screw’s strong mixing capability prevents issues like color spots or streaks.

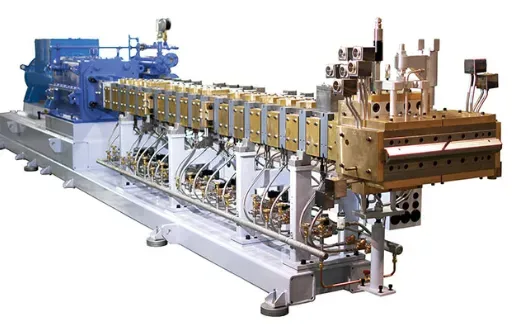

3. Composite Material Processing

For high-strength materials like glass-fiber-reinforced nylon and carbon-fiber-reinforced polypropylene, twin-screw extruders are the core equipment. They can cut glass fibers to the appropriate length and uniformly coat them with resin, preserving fiber strength while ensuring even stress distribution across the material. Composite materials used in drone frames and electric vehicle battery housings are often produced this way.

4. Environmental Protection and Recycling

It is particularly effective for processing waste plastics. For example, recycled PE film and PET bottle flakes, which contain oil residues and moisture, can be heated and melted by the twin-screw extruder while moisture and volatile substances are removed through the venting port, and impurities are filtered out. The resulting clean recycled pellets can be directly used to produce pipes and injection-molded parts.

5. Food and Pharmaceutical Industries

In the food industry, it can transform starch and grain flour into expanded pellets or knead plant proteins into fibrous “plant-based meat” through the screw’s shearing and extrusion shaping. In the pharmaceutical field, it is more precise, such as thermally melting and mixing drug active ingredients with carrier materials, extruding them into small pellets for subsequent tableting or slow-release formulations, ensuring more stable drug efficacy.

6. Bio-based and Degradable Materials

Biodegradable plastics like PLA and PBAT are mostly processed using twin screws. These materials are heat-sensitive and prone to degradation, but twin screws can precisely control temperature, slowly mix and plastify raw materials, and add chain extenders to adjust molecular weight, ensuring degradation performance meets standards. Many of the biodegradable plastic bags used in supermarkets today are produced this way.

7. Specialized Material Preparation

Twin-screw extruders are also used in the production of ceramic precursors (plastic materials used before ceramic firing), rubber compounding, and even the pretreatment of electrode slurry for lithium-ion batteries. For example, when sulfur and accelerators are added to rubber, twin-screw extruders ensure more uniform mixing, preventing localized over-sulfurization. Similarly, active materials and binders in electrode materials can be mixed into a uniform paste using twin-screw extruders, facilitating subsequent coating processes.

How to choose the right twin-screw extruder?

1. First, consider the characteristics of the material to be processed

Different materials have different requirements for equipment performance. For example, when processing glass-fiber-reinforced plastics, the screws and barrels must withstand fiber wear, so materials like nitrided steel or dual-alloy are more durable; when handling heat-sensitive biodegradable materials like PLA, temperature control precision is critical—multiple-zone temperature control must maintain stability within ±1°C, otherwise the material may yellow and become brittle.

2. Determine the machine size based on production capacity requirements

For laboratory formula testing and small-scale production, a machine with a screw diameter of 30–40 mm is sufficient, as it occupies less space and consumes less energy. For factory-scale production, calculate the average daily output—for example, if you need to produce 5 tons of pellets per day, you should select a large machine with a screw diameter of 65 mm or above. Avoid blindly opting for larger models; overly thick screws may result in uneven mixing at low material volumes and higher energy consumption.

3. Ensure screw configuration aligns with process requirements

Modular screws are standard, but the key lies in how the screw blocks are configured. For standard color masterbatch production, use screw blocks with larger pitch to ensure smooth material flow; for high-filler applications (e.g., adding 50% calcium carbonate), add screw blocks with larger misaligned angles to enhance shear force and incorporate the filler into the resin; for reactive extrusion (e.g., adding crosslinking agents), request the manufacturer to reserve interfaces for adding additives or vacuum extraction.

4. Auxiliary functions must be practical

For moist materials (such as recycled PET), dual exhaust ports are required to remove moisture and oil contamination; when adding liquid additives (such as plasticizers), a side feed device is needed to prevent liquid from clumping in the hopper; pelletizing methods also depend on the material—PVC, which is heat-sensitive, should use underwater pelletizing, while PE and PP can use air-cooled pelletizing, which is cost-effective and easy to maintain.

5. Do not overlook manufacturer service

Prioritize manufacturers that offer trial runs, using your own material to test the machine and assess pellet uniformity and the absence of burnt material—this is more reliable than relying solely on specifications. Also clarify after-sales support: How quickly can worn screws be replaced? Can technicians respond promptly if the equipment jams? Small workshops may offer lower prices but have slow after-sales service, which can cause production delays in the long run.

Common Questions About Twin-Screw Extruders

Q: How much more expensive are twin-screw extruders compared to single-screw extruders?

A: Generally, twin-screw extruders of the same specifications cost 2-3 times more than single-screw extruders. This is mainly because twin-screw extruders have a more complex structure, with higher requirements for screw meshing design, drive systems, and temperature control precision, making them suitable for processing complex materials. However, in the long run, their efficient mixing and multifunctional performance save process costs, making them more cost-effective for mass production.

Q: Can twin-screw extruders process wet materials?

A: Yes. Twin-screw extruders have built-in exhaust ports that can remove moisture and volatile substances from wet materials, such as recycled moist plastic scraps or moisture-containing starch raw materials. When processing, they are used in conjunction with a forced feeding device to prevent wet materials from clumping, resulting in significantly better processing performance than single-screw extruders, without the need for additional pre-drying.

Q:What is the difference between laboratory-use twin-screw extruders and industrial-use ones?

A: Laboratory-use extruders have smaller screw diameters (typically under 30 mm) and lower production capacity (a few kilograms per hour), but they offer more precise temperature control and speed adjustment, making them suitable for small-batch formula testing. Industrial-use extruders have larger screw diameters (over 50 mm) and higher production capacity (tens to hundreds of kilograms per hour), prioritizing continuous production stability and featuring more durable construction.

Q: Are twin-screw extruders noisy?

Answer: Not excessively so. Modern models achieve noise levels below 80 decibels through optimized gearbox design and soundproofing enclosures, comparable to standard machine tools. They are slightly louder than single-screw extruders, primarily due to the interaction of the twin screws and higher rotational speeds. However, proper vibration damping measures (such as rubber pads) can further reduce noise levels.

Q: Is it easy to clean a twin-screw extruder during material changes?

A: It is easier to clean than a single-screw extruder. The meshing area of the twin-screw has a self-cleaning effect. During material changeover, running a cleaning material (such as PP) through the system for 10–20 minutes can thoroughly clean it. Especially when changing colors or materials, there is minimal residue, unlike single-screw extruders that require disassembling the screw for cleaning, saving time and effort.

Q: Is a twin-screw extruder energy-intensive?

A: Compared to single-screw extruders, the power consumption per unit of output is actually lower. Although twin-screw extruders have higher power ratings (typically ranging from tens to hundreds of kilowatts), their higher mixing efficiency allows them to process more material in the same amount of time. For example, when processing high-filler plastics, a twin-screw extruder can produce 1.5 times the output of a single-screw extruder in one hour, resulting in lower power consumption.

Q: Is it easy for beginners to operate a twin-screw extruder?

A: Not difficult. Modern twin-screw extruders are equipped with PLC control systems, allowing parameters (temperature, speed, feed rate) to be set with a single button. Manufacturers provide basic operation training. As long as one understands material properties and basic parameter matching (e.g., reducing speed for high-viscosity materials), beginners can become proficient within 1-2 weeks. Daily operations primarily involve monitoring equipment status.

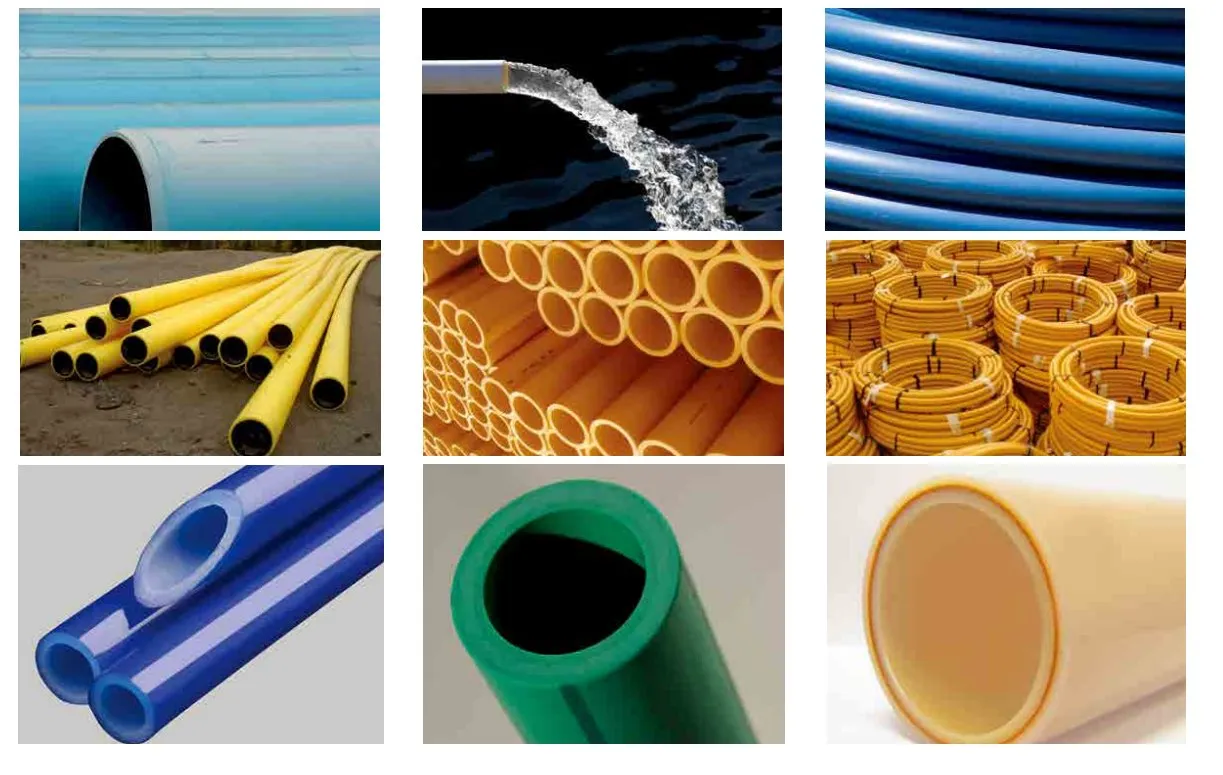

Q: Can twin-screw extruders produce pipes?

A: Yes, but they are more suitable for complex tubing. For example, multi-layer co-extruded tubing (with an inner layer for antibacterial properties and an outer layer for wear resistance) can be produced using a twin-screw multi-layer co-extrusion die head, which precisely controls the thickness of each layer and ensures uniform mixing. For ordinary single-layer tubing, a single-screw extruder is more cost-effective. The advantage of twin-screw extruders lies in their ability to produce multifunctional composite tubing.

Q: Are the bearings in twin-screw extruders prone to failure?

A: Not easily under normal maintenance. Regularly check the gearbox oil level, replace the specialized lubricant every 3,000 hours, and avoid overloading (e.g., sudden excessive feeding). Bearing lifespan can reach 1–2 years. For high-wear materials (e.g., glass fiber reinforcement), selecting a dual-alloy screw reduces bearing stress and enhances durability.

Q: Is a twin-screw extruder suitable for small factories?

A: It depends on the requirements. If only simple plastic processing is involved (e.g., standard PE pellets), a single-screw machine is sufficient; however, if the process involves modification, recycling, or multi-material mixing (e.g., adding flame retardants or color masterbatches), a twin-screw machine can enhance product quality, making it worthwhile even for small-batch production. There are now compact twin-screw models (e.g., 40mm machines) available at reasonable prices, making them suitable for small factories starting out.