Basic Knowledge of Twin-Screw Extruders

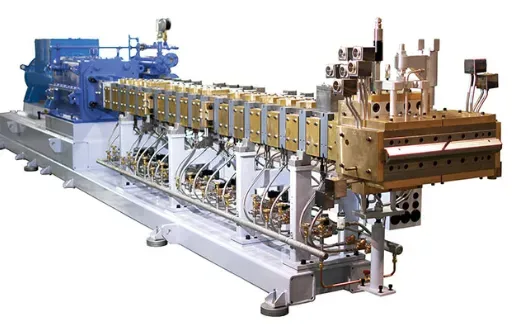

In modern industry, twin-screw extrusion machines play a crucial role. Their robust material handling capacity and efficiency make them the preferred equipment for large-scale mass production, particularly suited for processing and handling highly complex materials.

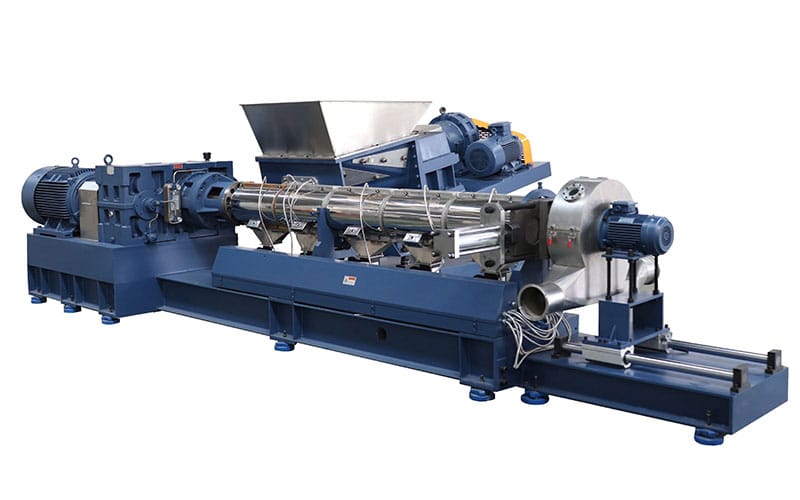

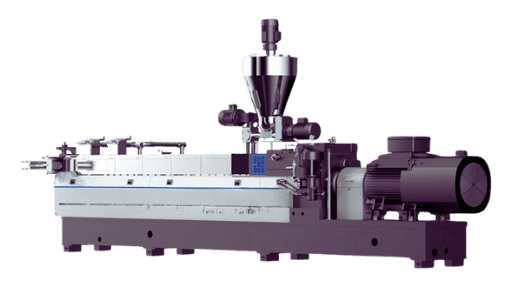

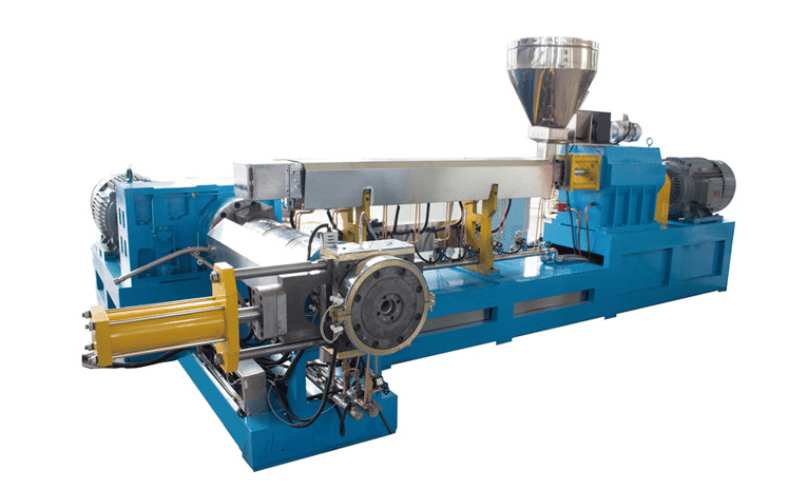

A twin-screw extruder is a device that uses two intermeshing screws rotating inside a barrel to achieve material conveyance, mixing, plasticization, and extrusion. It is widely applied in fields such as plastic processing and composite material preparation. Its core features are forced conveyance and efficient mixing, making it more suitable for processing complex materials compared to single-screw extruders.

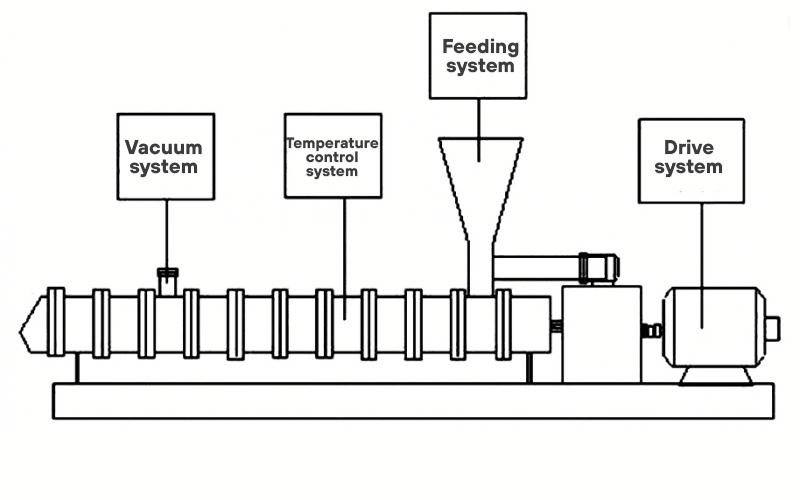

Basic structure of twin-screw extruders

1.Screw

Core component, typically arranged in parallel or conical configurations. Based on the meshing mechanism, screws are classified into meshing types (e.g., counter-rotating screws with tight meshing for strong mixing effects) and non-meshing types (with larger gaps, emphasizing material conveyance). The screw consists of feeding sections, compression sections, and metering sections, each with different pitch and groove depths: the feeding section conveys material, the compression section compacts and removes air, and the metering section completes plasticization and stabilizes melt conveyance.

2.Barrel

The barrel forms a sealed working space with the screw. Its inner walls are typically lined with sleeves made of wear-resistant materials (such as nitrided steel) to reduce wear. The barrel may be equipped with a main feed port (connected to the feeding system), side feed ports (for adding auxiliary materials), and vent ports (for removing moisture and volatile components from the material). Some models feature a split-design for easier cleaning and screw maintenance.

3.Feeding System

Responsible for steadily conveying material into the barrel, typically composed of a hopper and feeder (e.g., loss-in-weight or volumetric feeder). The feeding rate can be adjusted based on material characteristics (granules, powders, fibers) to ensure compatibility with the screw’s conveying capacity, preventing “material blockage” or “material shortage” within the barrel.

4.Drive System

Comprising a motor, reducer, etc., it provides power to the screw. Through gear transmission, it ensures that the two screws rotate synchronously (in the same direction) or in opposite directions at the set speed. The speed adjustment range is wide to accommodate the shearing and mixing requirements of different materials.

5.Heating and Cooling System

The barrel is equipped with heating coils (e.g., resistance heating, electromagnetic heating) on the exterior, and cooling water/air channels are installed internally or externally. Through segmented temperature control (each segment can be independently adjusted), the temperature of each zone within the barrel is precisely controlled to ensure the material remains in an optimal state during different stages (conveying, melting, plasticizing), preventing overheating degradation or insufficient plasticization.

6.Control System

The PLC integrates monitoring and regulation of parameters such as temperature, pressure, speed, and feed rate, providing real-time feedback and correction of deviations (e.g., temperature fluctuations, torque abnormalities) to ensure production stability. Some models are equipped with a human-machine interface for convenient parameter setting and data recording.

How does a twin-screw extruder work?

1.Material feeding stage

Solid materials (granules, powders, or mixtures) enter the barrel through the main feeding device. Some formulations supplement auxiliary materials (such as glass fiber or fillers) through side feeding ports during the process. Two intermeshing screws generate forced thrust through rotation, conveying the material forward. This process is unaffected by material flowability and offers significantly higher conveying stability than single-screw systems.

2.Conveying and Preheating Stage

The material is pushed forward within the screw grooves of the screw feeding section, while the heating system on the outer wall of the barrel begins to raise the temperature, gradually softening the material. This stage primarily focuses on conveying, with the material’s advancement speed controlled by the gap between the screw and the barrel, preparing for subsequent melting.

3.Melting and Mixing Stage

Upon entering the compression section, the screw groove depth gradually decreases, mechanically compressing and compacting the material. Combined with continuous barrel heating and shear forces generated by screw meshing, solid material gradually melts into a melt. The alternating rotation of the two screws exerts strong kneading action on the melt, uniformly mixing multi-component raw materials (such as resins, additives, and fillers) to prevent local component inconsistencies.

4.Degassing and Plasticization Stage

When the melt reaches the degassing section, the degassing ports in the barrel use negative pressure to remove moisture, volatile components, or air from the material, preventing bubbles or pinholes in the finished product. The melt then enters the metering section, where a stable screw speed and screw groove design ensure more uniform plasticization of the melt and stable pressure.

5.Extrusion molding stage

The uniformly plasticized melt is pushed by the screw into the die head, where it is evenly distributed to the mold channels via the diverter vane, and finally extruded into the desired shape (such as pellets, pipes, profiles, etc.) according to the mold design, completing the entire processing process.

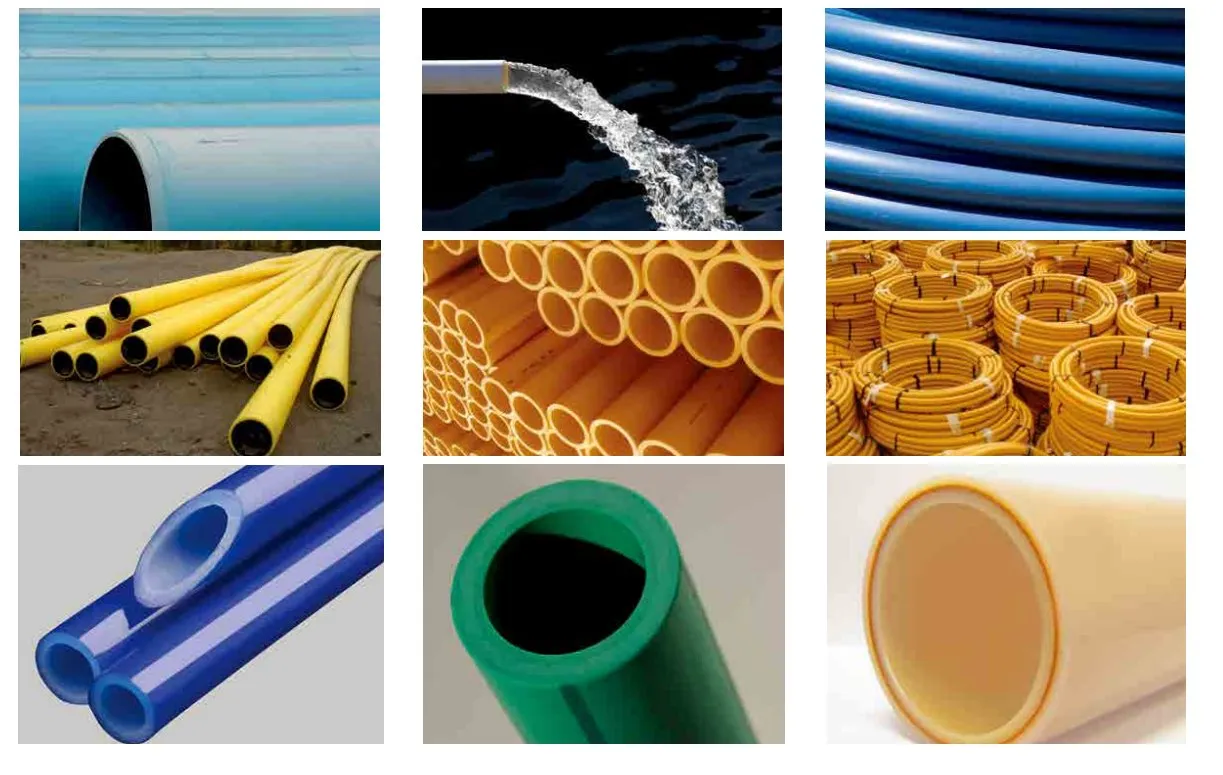

Applications of twin-screw machines

1.Plastic Modification Industry

In the plastic modification industry, twin-screw extruders are used to reinforce, toughen, or flame-retardant modify general-purpose plastics such as polypropylene and nylon. Through the strong shear force generated by the meshing of the screws, reinforcing materials such as glass fiber and carbon fiber, or flame retardants, are uniformly mixed into the resin matrix, thereby altering the mechanical properties or fire resistance rating of the plastic. This process is suitable for mass production of automotive components, electronic enclosures, and other products.

2.Rubber Products Industry

In the rubber products industry, twin-screw extruders are used for the mixing and molding of thermoplastic elastomers (TPE, TPU). They can blend rubber particles, plasticizers, and plastic matrices, precisely controlling temperature to prevent rubber aging, thereby forming composite materials that combine elasticity and plasticity. This is suitable for producing products such as seals and shoe soles.

3.Food Processing Industry

In the food processing sector, twin-screw extruders are used for starch modification and the mixing of functional food base materials. They can blend starch with plant proteins, dietary fibers, and other raw materials at low temperatures between 60-90°C, making them suitable for producing ready-to-eat pastes, meal replacement powders, and other products.

4.Pharmaceutical Excipient Industry

In the pharmaceutical excipient industry, twin-screw extruders are used for the compounding and granulation of pharmaceutical polymer materials. They can mix pharmaceutical excipients such as microcrystalline cellulose and hydroxypropyl methylcellulose with active ingredients, producing uniformly sized particles through gentle shearing, which are convenient for subsequent tableting or capsule filling. The entire process is conducted under inert gas protection to prevent material oxidation, and the bulk density of the particles can be precisely controlled to ensure accurate drug dosing.

5.Environmental recycling industry

In the environmental recycling industry, twin-screw extruders are used for the regeneration of waste plastics (such as PE film and PET bottle flakes). The extruders force-feed the crushed waste plastics into a molten state via the screws, while efficiently removing moisture, oil, and other impurities through the venting ports. This process restores the plastic’s properties, enabling it to be directly used in the production of products like trash bins and pipes, thereby effectively reducing resource waste.

Conclusion

As a key piece of equipment in modern industry, twin-screw extruders demonstrate irreplaceable value in the processing of complex materials thanks to their unique structure and operating mechanism. Their core components include screws, barrels, drive systems, and control systems. Through the meshing rotation of the twin screws, they efficiently handle the entire process from material feeding, preheating, melting, and mixing to degassing, plasticizing, and extrusion molding. Their forced feeding and precise temperature control capabilities far surpass those of single-screw equipment, making them particularly adept at processing multi-component and highly complex raw materials.

In terms of applications, it spans multiple fields including plastic modification, rubber products, food processing, pharmaceutical excipients, and environmental recycling: it can enhance plastic performance for producing automotive components, prepare elastic composite materials for sealing strips, meet the stringent cleanliness and component uniformity requirements of the food and pharmaceutical industries, and facilitate plastic recycling to promote a circular economy. This multifunctionality and efficiency make it a vital link between material innovation and industrial production, continuously providing core momentum for technological upgrades and sustainable development across various industries.

Frequently Asked Questions About Twin-Screw Extruders

Q: What is the difference between a twin-screw extruder and a single-screw extruder?

A: A twin-screw extruder uses two intermeshing screws to forcefully convey material, resulting in stronger mixing performance. It is suitable for processing high-viscosity, multi-component, or poorly flowing materials. A single-screw extruder relies on the friction between the material and the screw for conveyance, with weaker mixing capability, and is more suitable for simple materials. Twin-screw extruders offer clearer advantages in terms of production stability and processing of complex materials.

Q: What materials can a twin-screw extruder process?

A: It is widely used for plastics (e.g., PP, nylon), rubber (thermoplastic elastomers TPE/TPU), food (starch, plant protein), pharmaceutical excipients (microcrystalline cellulose), and recycled plastics (PE, PET), among others. It is particularly adept at processing materials requiring the mixing of multiple components (e.g., adding glass fiber, flame retardants).

Q: What should be noted for the daily maintenance of twin-screw extruders?

A: Regularly clean the screws and barrels to prevent residual material from carbonizing; inspect the wear condition of the screws and barrels and replace wear parts in a timely manner; maintain lubrication of the transmission system (such as the reducer); clean impurities from the exhaust port to ensure smooth flow; and regularly calibrate the temperature sensors and control system to ensure parameter stability.

Q: What is the approximate price range for twin-screw extruders?

A: Prices are significantly influenced by specifications (screw diameter, length-to-diameter ratio), configuration (motor power, control system), and brand. Small laboratory-use equipment costs approximately several ten thousand yuan, medium-sized industrial-grade equipment (screw diameter 30–60 mm) costs approximately several hundred thousand yuan, and large production lines (diameter over 100 mm) can reach over one million yuan or higher.

Q: How is the production capacity of a twin-screw extruder calculated?

A: Production capacity is primarily related to screw diameter, speed, material density, and fill rate. The approximate formula is: Production capacity (kg/h) ≈ Effective screw volume × Speed × Material density × Fill factor. For example, a screw with a diameter of 65 mm operating at 300 rpm has a production capacity of approximately 200–500 kg/h (depending on the material).

Q: What factors should be considered when selecting a twin-screw extruder?

A: Select the screw type (meshing/non-meshing, co-rotating/counter-rotating) based on material properties (viscosity, heat sensitivity); determine screw diameter and length-to-diameter ratio based on production capacity requirements; consider temperature control accuracy (especially for heat-sensitive materials), number of vent ports (for impurity removal), and control system compatibility (e.g., PLC automation level).

Q: What are the common issues with twin-screw extruders? How can they be resolved?

A: Common issues include material blockages (often caused by excessive feed rate or insufficient temperature; reduce feed rate and increase preheating temperature), bubbles in the product (possibly due to poor venting; check vent port negative pressure or clear blockages), and abnormal screw noise (possibly due to bearing wear or hard impurities in the material; shut down the machine for inspection and replace components).

Q: How important is temperature control in twin-screw extruders?

A: Temperature control directly affects material plasticization quality and performance. Too low temperatures may cause uneven plasticization, while too high temperatures may cause material degradation (e.g., yellowing of plastics, spoilage of food). Cylinder temperatures should be set in segments based on material melting points (e.g., low temperatures in the feed section to prevent sticking, high temperatures in the melting section to promote melting), typically controlled precisely via an electric heating + water cooling system.

Q: How is a twin-screw extruder specifically used in plastic recycling?

A: First, waste plastic (such as PE film or PET bottle flakes) is crushed and cleaned, then fed into the extruder via the main feed; the screws forcefully convey and heat the material to melt it, while simultaneously expelling moisture, oil residues, and other impurities through the venting port; the melted material is extruded through a die to form pellets, which can be used to produce products like trash bins or pipes, achieving resource recycling.

Q: What safety precautions should be taken when operating a twin-screw extruder?

A: Before starting the machine, confirm that the emergency stop button is functioning properly and wear protective gear (high-temperature resistant gloves, safety goggles); avoid inserting hands or tools into the feed port or die opening; after shutdown, wait until the screw has completely stopped before disassembling components; when cleaning high-temperature components, allow them to cool first to prevent burns; regularly inspect the electrical circuit and grounding to prevent electrical leakage.